Click the arrow and the “blue text” to follow us!

In industrial control, communication plays a very important role. Any control is based on correct, reliable, and efficient communication. Let’s learn about Siemens’ Profibus DP communication.

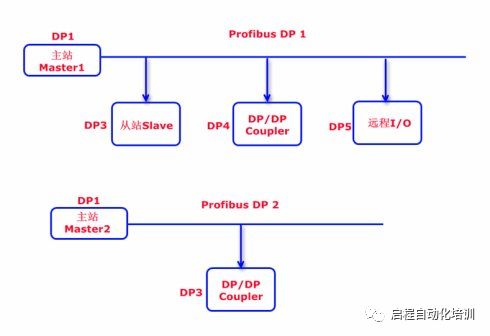

The Profibus DP communication of Siemens is mainly divided into the following three forms.

1. Communication between the master station and remote I/O.

2. Communication between the master station CPU and the slave station CPU.

3. Communication between master station CPUs.

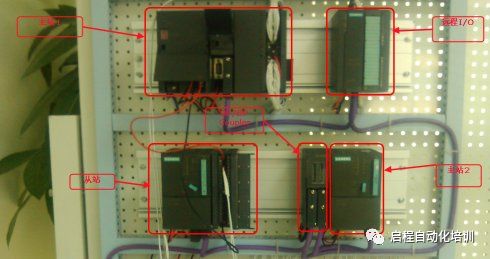

Next, we will explain the specific configuration method of the Profibus DP network through the following examples.

The topology diagram of the network is shown below.

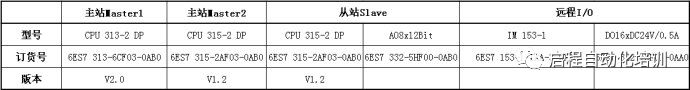

The hardware configuration of the network is shown in the table below.

Next, we will proceed with the specific configuration.

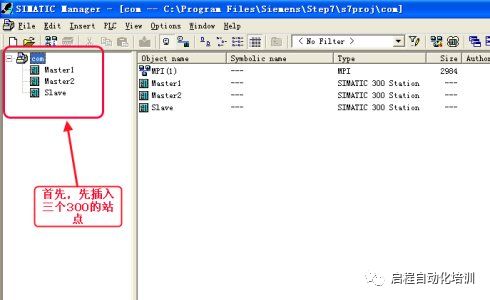

1. Insert three 300 stations and name them as follows:

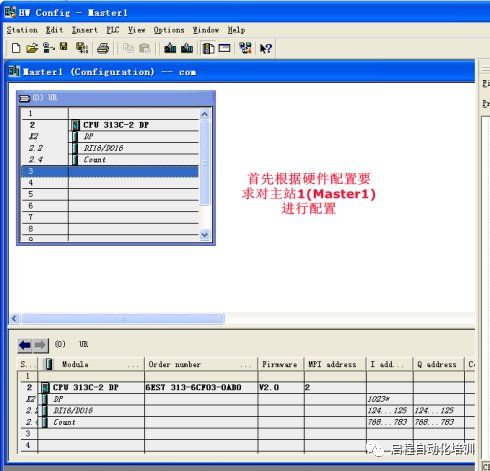

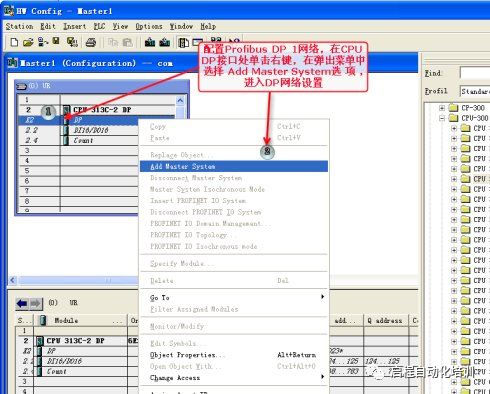

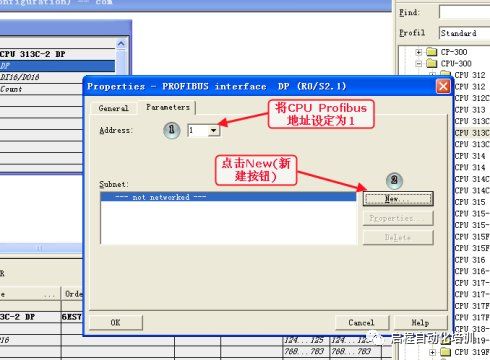

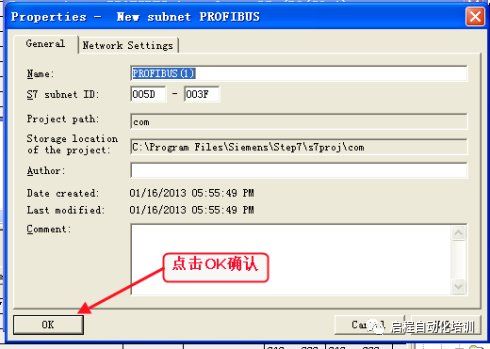

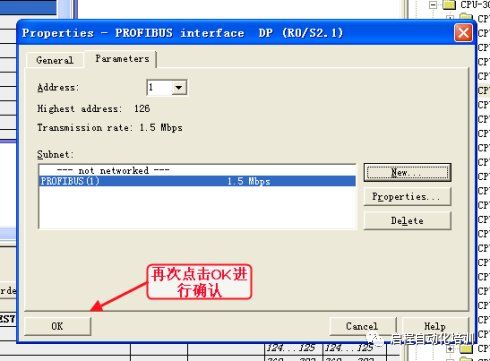

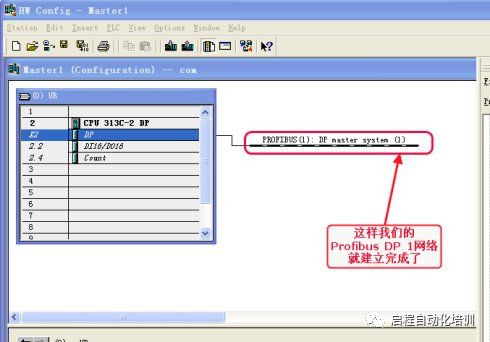

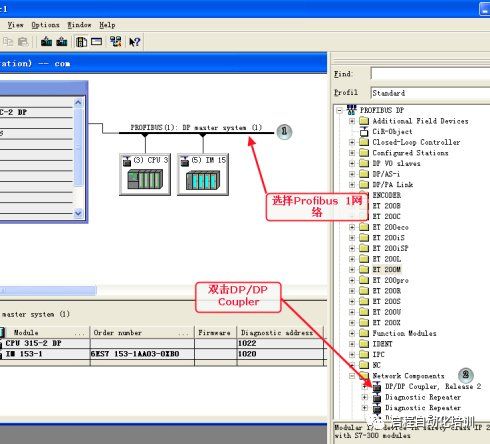

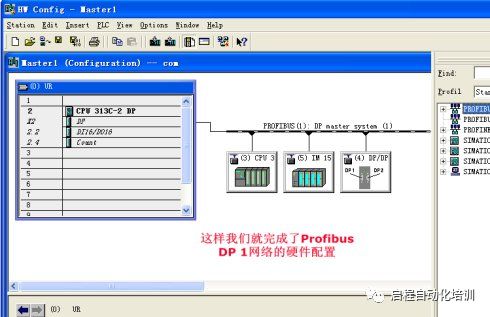

2. Configure Profibus DP 1 network according to the above topology diagram.

2. Configure Profibus DP 1 network according to the above topology diagram.

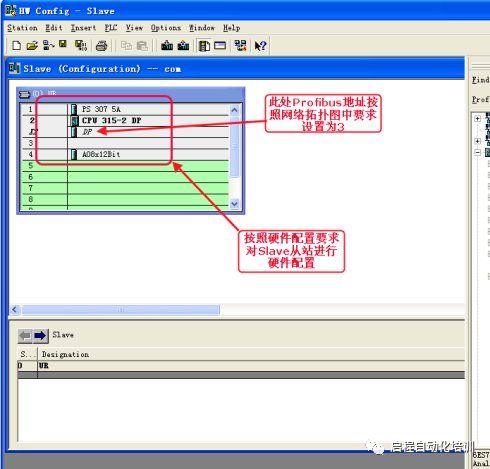

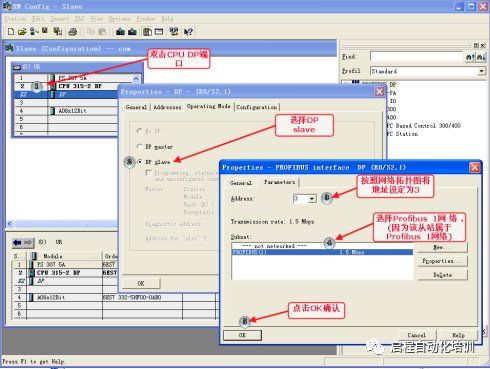

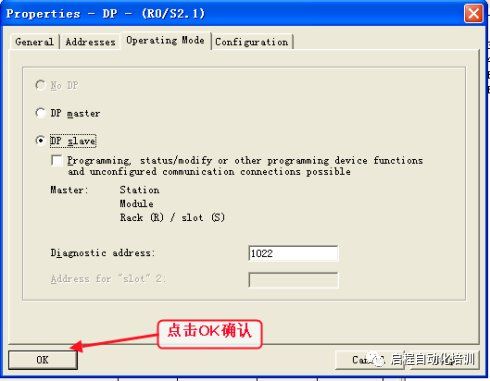

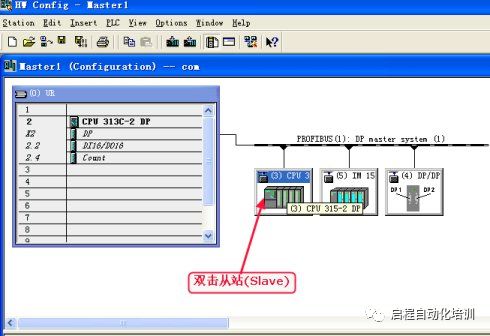

Next, we will configure the slave station (Slave) according to the hardware requirements.

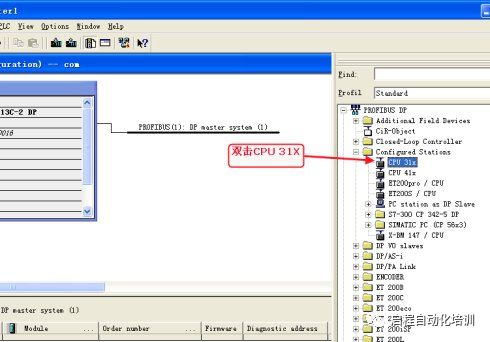

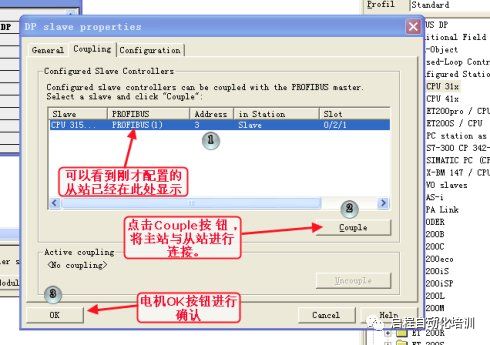

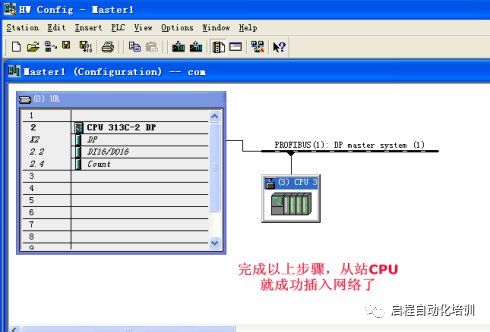

After saving the slave (Slave), insert the slave into the master station.

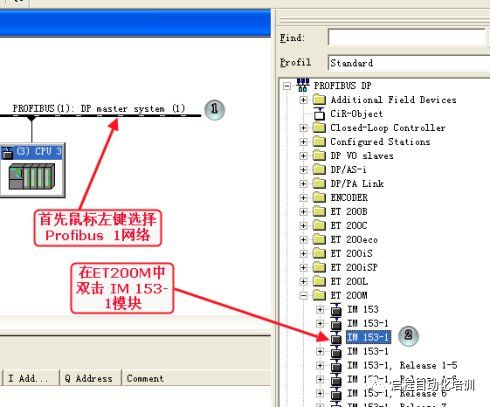

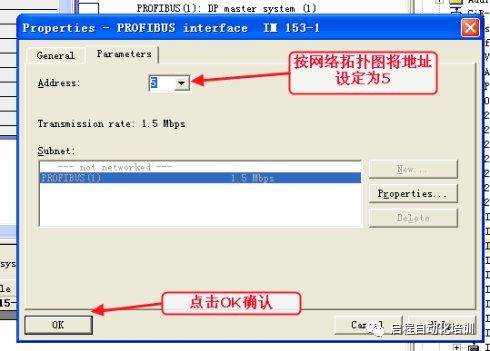

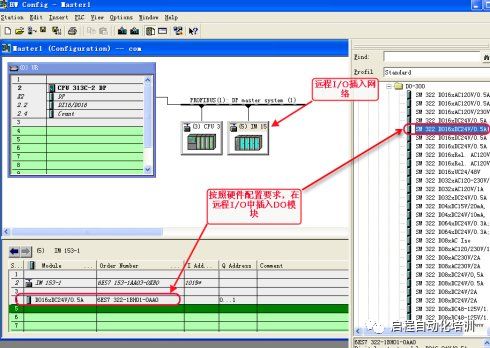

After completing the insertion of the slave CPU into the network, we continue to configure the remote I/O.

After completing the insertion of the slave CPU into the network, we continue to configure the remote I/O.

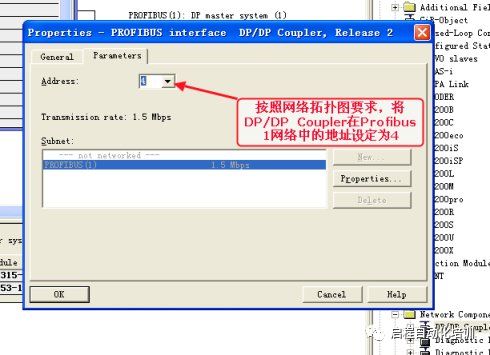

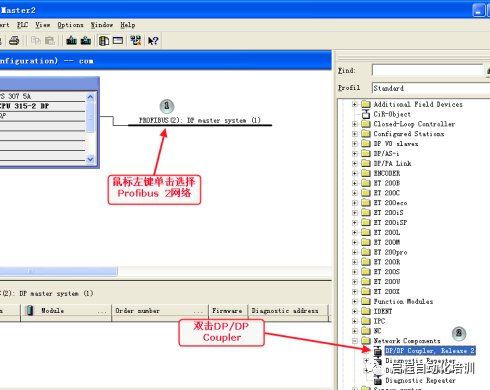

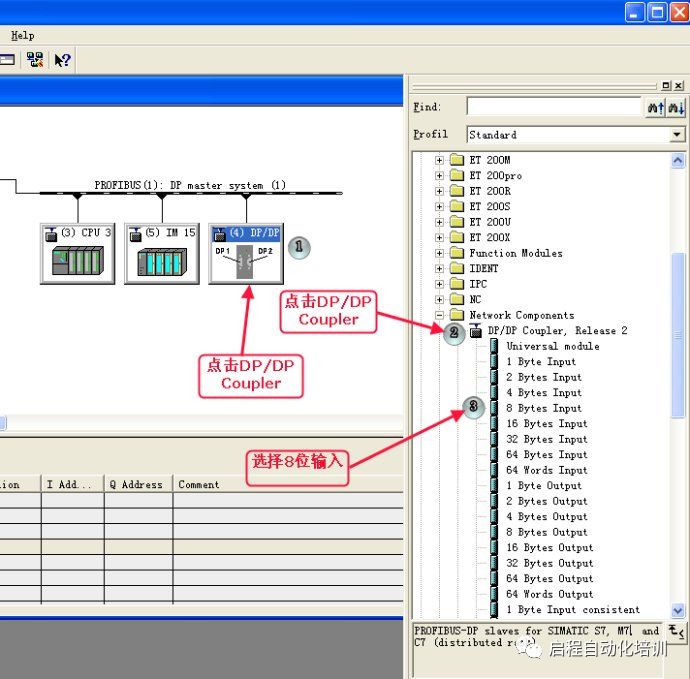

After completing the remote I/O configuration, configure the DP/DP Coupler, which is the interface between the Profibus DP1 network and Profibus DP2 network.

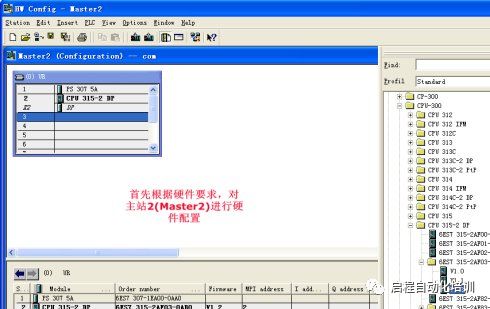

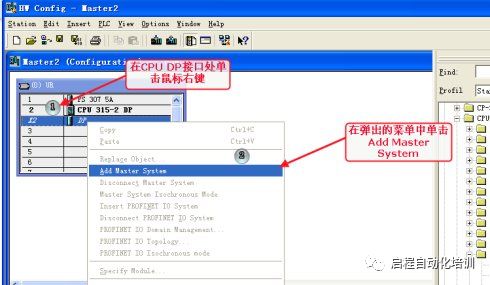

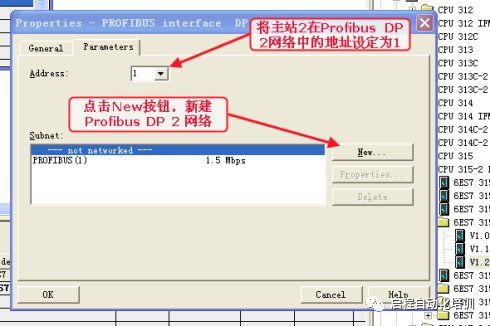

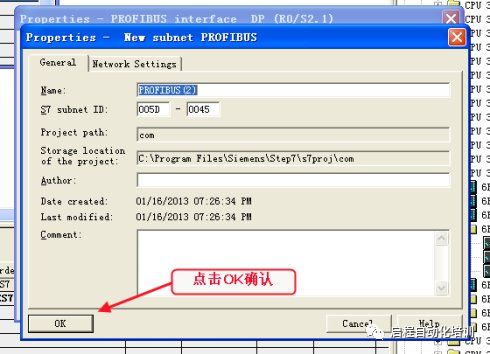

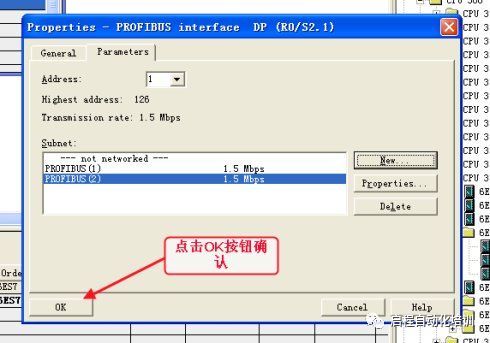

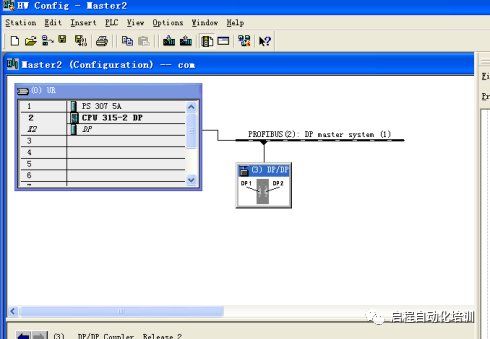

3. Configure the Profibus DP2 network according to the topology diagram.

3. Configure the Profibus DP2 network according to the topology diagram.

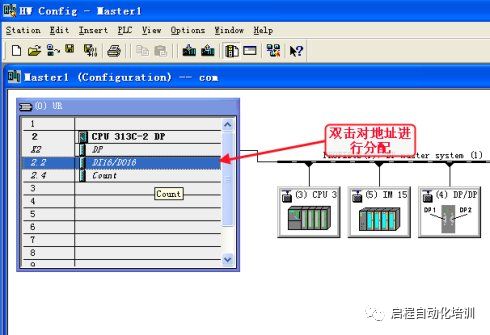

4. Next, we will configure the I/O addresses in the network.

4. Next, we will configure the I/O addresses in the network.

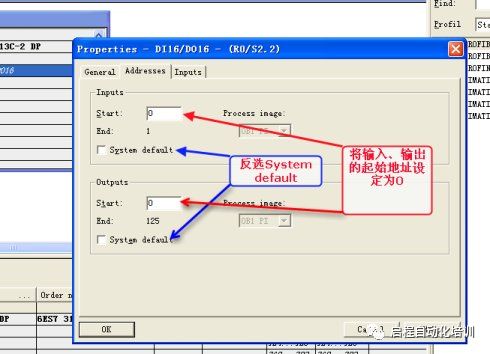

First, allocate the I/O point address of the master station CPU in the Profibus 1 network.

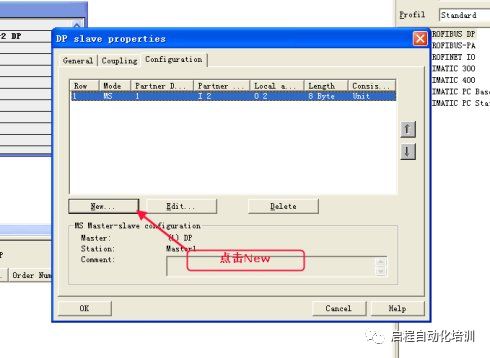

After configuring the I/O point address of the master station CPU, configure the mapping address between the slave and master stations and the address of the slave’s DO module.

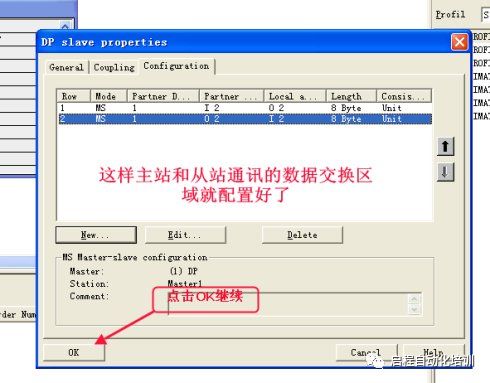

In the above figure, we have configured the input mapping area of the master station and the output mapping area of the slave station. Next, we will configure the output mapping area of the master station and the input mapping area of the slave station.

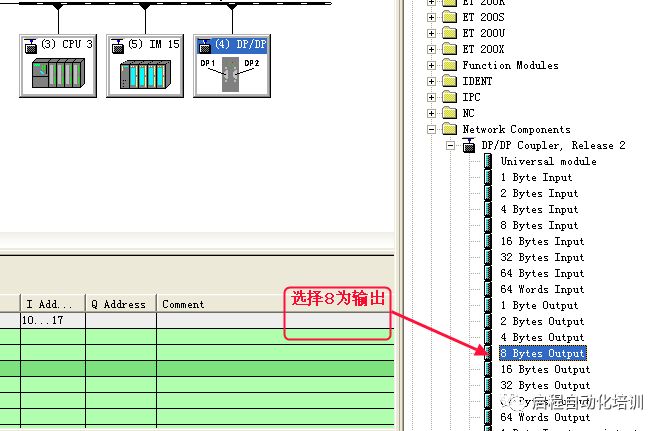

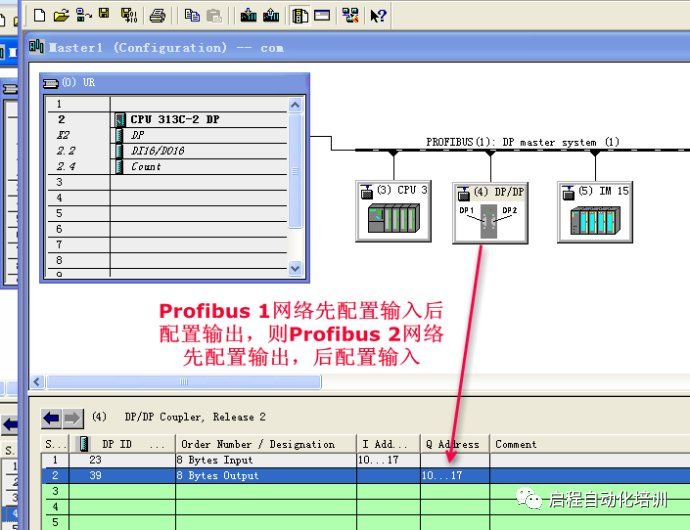

Next, we will configure the DP/DP Coupler. The DP/DP Coupler is the interface connecting two Profibus DP networks and serves as a bridge for communication between the two networks. The process of configuring the DP/DP Coupler is actually the mutual mapping of the data exchange areas of the two networks. In one network, configure the input first and then the output; in the other network, configure the output first and then the input, and vice versa. Moreover, the addresses must correspond one-to-one.

Finally, check if there are any conflicts between the addresses of the slave’s AO and the already set addresses. Open the slave hardware configuration screen, and thus the Profibus 1 network is set up. Next, we will configure the mapping addresses of the DP/DP Coupler that connects the Profibus 2 network with the Profibus 1 network.

Thus, all configurations for communication are completed.

About Us: Qicheng Automation Training, China’s leading industrial robot training service provider.

Contact Number: 13809869603

Training Programs:Robot + PLC System Integration + Motion Control + Robot + Machine Vision

Special Services: 3000 square meters training center + job recommendation + industry-leading curriculum system

Address: Shajing Chuangzhi Park, Baoan District, Shenzhen

Official Website: www.qichengplc.com

Add Teacher WeChat to learn about class details

Tap to look before you go