As a seasoned electrical engineer, one should be well-versed in various bus systems. Today, I have compiled relevant materials for everyone!

1. Overview

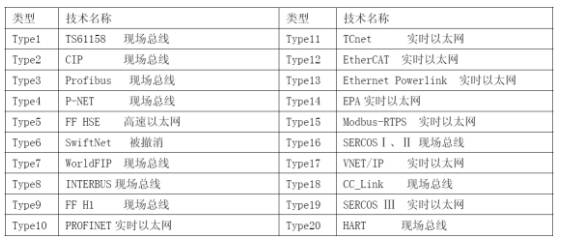

1. Introduction to IEC61158

IEC61158 is the fieldbus standard from the International Electrotechnical Commission (IEC). Currently, the IEC61158 fieldbus standard has developed a series of standards, with the latest version being IEC61158-6-20 (released in 2007), which includes a total of 20 types of fieldbuses as shown in Table 1.1.

The IEC 61158 standard for industrial control systems was jointly developed by the IEC SC65C technical committee on “Digital Data Communication for Measurement and Control” and the ISA SP50 working group of the Instrument Society of America, drafted in 1984 and approved after the final voting round in 1999, taking over 14 years.

Table 1.1: 20 Fieldbuses Included in IEC61158

2. Comparison of Some Fieldbuses

Table 2 compares some fieldbuses (some data are unverifiable or uncollected).

Table 2: Comparison of Some Communication Buses

|

Bus Protocol |

Max Rate |

Max Distance |

Rate at 100m |

Release Year |

Bus Count |

Node Count |

Electrical Characteristics |

|

RS422 |

10Mbps |

1200m/100kbps |

1Mbps |

4 |

10 |

-6V~+6V |

|

|

RS485 |

10Mbps |

1200m/100kbps |

1Mbps |

1983 |

2/4 |

32 |

-6V~+6V |

|

CAN |

1Mbps/40m |

10000m/5kbps |

– |

1986 |

2 |

110 |

0~+5V |

|

Ethernet/IP |

100Mbps |

100m |

– |

||||

|

ControlNet |

5Mbps |

6000m |

– |

1997 |

99 |

||

|

LonWorks |

1.25Mbps |

2700m/78kbps |

– |

127 |

|||

|

EIB |

9.6kbps |

1000m |

1990 |

64 |

|||

|

Interbus |

500kbps |

1200m |

500kbps |

1984 |

|||

|

Profibus |

12Mbps/100m |

1200m/9.6kbps |

12Mbps |

1991 |

32 |

0~+24V |

|

|

FF HSE |

2.5Mbps |

1900m/31.25kbps |

|||||

|

Profinet |

100Mbps |

100m |

|||||

|

P-net |

76.8kbps |

1200m |

76.8kbps |

1983 |

125 |

||

|

CC_Link |

10Mbps |

1200m |

10Mbps |

1996 |

|||

|

DeviceNet |

500kbps/100m |

500m/125kbps |

500kbps |

2. Introduction to Some Fieldbuses

This article mainly introduces several commonly used remote communication buses based on fieldbus. The maximum transmission distance mentioned in the text only indicates the one-time transmission distance without a repeater.

1. RS422

Maximum transmission rate: 10Mbps

Maximum transmission distance: 1200m, transmission rate: 100kbps

RS422 is developed from RS232, improving the shortcomings of RS232’s short communication distance and low speed by adopting differential transmission. Differential operation is the fundamental reason for its long transmission distance under the same rate conditions, which is the fundamental difference from RS232, as RS232 is single-ended input/output.

The RS422 four-wire interface, due to its separate sending and receiving channels, does not require control of data direction. The maximum transmission distance of RS422 is 4000 feet (approximately 1219 meters), with a maximum transmission rate of 10Mb/s. Its balanced twisted pair length is inversely proportional to the transmission rate, and the maximum transmission distance can only be achieved at a rate below 100kbps; the highest rate can only be achieved at very short distances. Generally, the maximum transmission rate on a 100-meter twisted pair is only 1Mb/s. RS422 requires terminating resistors, which should have a resistance approximately equal to the characteristic impedance of the transmission cable. Terminating resistors are not required for short-distance transmission, generally below 300 meters.

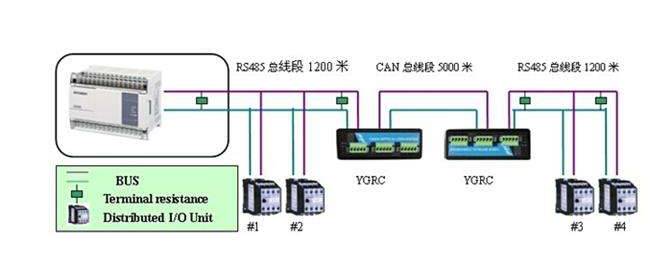

2. RS485

Maximum transmission rate: 10Mbps

Maximum transmission distance: 1200m, transmission rate: 100kbps

Its performance is basically the same as RS422.

Table 4: Comparison of RS232, RS422, and RS485

|

Specification |

RS232 |

RS422 |

RS485 |

|

Working Mode |

Single-ended |

Differential |

Differential |

|

Node Count |

1 send 1 receive |

1 send 10 receive |

1 send 32 receive |

|

Max Cable Length |

15m |

1200m |

1200m |

|

Max Transmission Rate |

20kbps |

10Mbps |

10Mbps |

|

Max Drive Output Voltage |

+/-25V |

-0.25V~+6V |

-7V~+12V |

|

Receiver Input Voltage Range |

+/-15V |

-10V~+10V |

-7V~+12V |

|

Receiver Input Threshold |

+/-3V |

+/-200mV |

+/-200mV |

RS485 has two-wire and four-wire wiring; the four-wire system can only achieve point-to-point communication, which is rarely used now. The two-wire wiring method is commonly used, forming a bus topology, with a maximum of 32 nodes on the same bus. Table 3 compares the parameters of RS232, RS422, and RS485.

3. CAN

Maximum transmission rate: 1Mbps, transmission distance: 40m

Maximum transmission distance: 10000m, transmission rate: 5kbps

The Controller Area Network (CAN) was originally developed by the German company Bosch in 1983 for automotive applications and is a serial communication network that effectively supports distributed and real-time control, falling under the category of fieldbus. In November 1993, the ISO officially issued the international standard for CAN (ISO11898), paving the way for the standardization and promotion of controller area networks. It has now become one of the most widely used open fieldbuses internationally.

Characteristics of the CAN bus: strong real-time capability, long transmission distance, strong electromagnetic interference resistance, low cost, etc.; it uses a dual-line serial communication method, has strong error detection capability, and can operate in high-noise environments; it has priority and arbitration functions, allowing multiple control modules to connect to the CAN bus; it can decide to receive or filter messages based on the message ID; reliable error handling and detection mechanisms; information can be automatically retransmitted after being damaged; nodes can automatically exit the bus under severe error conditions; messages do not contain source or destination addresses, only identifiers to indicate functional and priority information.

4. Ethernet/IP

Maximum transmission rates: 10, 100, 1000Mbps

Maximum transmission distance: 100m

Ethernet/IP is developed by ODVA, with strong support from Rockwell Automation. It uses the Control and Information Protocol (CIP) for application layer protocol, which has been used in ControlNet and DeviceNet.

CIP provides a range of standard services for accessing and controlling data in network devices, both implicitly and explicitly. CIP packets must be encapsulated before being sent over Ethernet and are assigned a message header based on the requested service type. This header indicates the importance of sending data to the response service. CIP packets transmitted over Ethernet have a special Ethernet header, an IP header, a TCP header, and an encapsulation header. The encapsulation header includes control commands, format and status information, synchronization information, etc. This allows CIP packets to be transmitted via TCP or UDP and unpacked by the recipient. Compared to DeviceNet or ControlNet, this encapsulation has the disadvantage of lower protocol efficiency. The Ethernet header may be longer than the data itself, leading to excessive network load. Therefore, Ethernet/IP is more suitable for sending large amounts of data (such as programs), while DeviceNet and ControlNet are better suited for analog or digital I/O data.

Ethernet/IP Technical Parameters

Network Scale: Can form networks of almost unlimited size

Network Length: 10/100 Base-T = 100m

Communication Speed: 10, 100, 1000Mbps

5. ControlNet

Maximum transmission rate: 5Mbps

Maximum transmission distance: 6000m

ControlNet International Ltd. was founded in July 1997 by Rockwell and 22 other companies, as a non-profit independent organization responsible for promoting ControlNet technology worldwide (including testing software).

ControlNet is a real-time, control-layer network used for transmitting time-sensitive I/O data and message data, including uploading and downloading programs and configurations over a single physical medium link. Due to its determinism and repeatability, ControlNet’s high-speed control (5Mbps) and data capabilities significantly enhance I/O and peer communication performance.

ControlNet Technical Indicators

Network Scale: Up to 48 nodes.

Network Length: 1000m (coaxial cable)/5Mbps; 1000m for 2 nodes, 250m for 48 nodes; 3000m (fiber optic)/5Mbps;

6. LonWorks

Maximum transmission rate: 1.25Mbps

Maximum transmission distance: 2700m, transmission rate: 78kbps

LonWorks is a local operating network launched by the American company Echelon in 1992, initially used for building automation but quickly developed into an industrial field network. LonWorks technology provides a complete, open, and commercial solution for designing and implementing interoperable control networks, gaining recognition from an increasing number of manufacturers, users, integrators, and technicians. Its characteristics of peer-to-peer functionality, flatness, openness, and interoperability are increasingly applied in various fields.

LonWorks network truly provides a complete solution for control systems, similar to computer systems. Control systems can essentially ignore applications; networked control systems are more powerful, flexible, and scalable than non-networked systems; over the long term, networked systems can save more costs than non-networked systems.

LonWorks Technical Indicators

Network Scale: 32,000 nodes/domain

Network Length: 2000m, 78kbps

7. EIB

Maximum transmission rate: 9.6kbps

Maximum transmission distance: 1000m

EIB (European Installation Bus) is the most widely used industry specification and product standard in the field of electrical wiring. It officially became China’s national standard GB/Z20965-2007 in 2007. The biggest feature of EIB is that it replaces traditional separate control cables and power cables with a single multi-core cable, ensuring that all switches can transmit control commands, allowing bus cables to be laid in line, tree, or star configurations, facilitating expansion and modification.

In May 1990, over 110 European electrical manufacturers jointly established the European Installation Bus Association, headquartered in Brussels, Belgium, and formulated the European Installation Bus specification. According to statistics, about 30% of commercial buildings and large supermarkets in Germany have installed EIB systems to varying degrees, while this proportion reaches 60% in planned buildings. Due to its excellent performance, this protocol has been absorbed by the Consumer Electronics Manufacturers Association (CEMA) in the United States as the EIA-776 standard for home networks. After more than a decade of development, EIB has become the de facto European standard and was nominated as one of the international standards at the IEC International Fieldbus Standard Conference in 2000.

The basic structure of the EIB system is a branch (Line), where one branch can connect 64 elements. Through a line coupler (Line Coupler), up to 15 branches can be connected to form an area (Area), and through a backbone coupler (Backbone Line Coupler), 15 areas can be connected into the largest system. Therefore, the EIB system can accommodate up to 14,400 elements, with an astonishing number of controllable electrical devices.

8. Interbus

Maximum transmission rate: 500kbps

Maximum transmission distance: 1200m

INTERBUS was launched in 1984, with its main technical developer being the German company Phoenix Contact. InterBus is a sensor/regulator bus system particularly suitable for industrial use, providing consistent network interconnection from control-level devices to lower-level limit switches. As one of the IEC61158 standards, INTERBUS is widely used in manufacturing and machine processing industries to connect the signals from sensors/actuators to computer control stations, being an open serial bus system.

The INTERBUS bus includes remote bus networks and local bus networks, both transmitting the same signals but at different levels. The remote bus network is used for long-distance data transmission, using RS-485 transmission, with the network itself not supplying power. The remote network communicates in full duplex mode at a communication rate of 500k/s. The local bus network connects to the remote network, with the bus terminal (BUS Terminal) on the network responsible for converting remote network data into local network data.

INTERBUS is designed for rapid transmission of process data from sensors/actuators in industrial environments. Due to its transmission method and ring topology, Interbus has many excellent features, such as fast speed, periodic and isochronous transmission of process data. The optimized diagnostic functions minimize maintenance cycles, making it easy to handle and install (plug and play), and it can also use fiber optic technology when necessary.

Interbus Technical Indicators

Network Scale: Up to 512 nodes

Network Length: 400m between two remote bus stations, 13km using RS-485

9. Profibus

Maximum transmission rate: 12Mbps, transmission distance: 100m

Maximum transmission distance: 1200m, transmission rate: 9.6kbps

PROFIBUS was developed in 1987 by the Federal Ministry of Technology of Germany, consolidating the efforts of 13 companies and 5 research institutes, based on the ISO/OSI reference model, with Siemens as its main supporter, and was officially published in DIN19245 in April 1991, becoming a German standard. Initially, only PROFIBUS-DP and PROFIBUS-FMS were available, and in 1994, PROFIBUS-PA was launched, which referenced the physical layer of IEC standards (IEC1158-2, passed in 1993), allowing the connection of intrinsically safe field instruments powered through the bus in explosive environments, thus enhancing PROFIBUS’s completeness. PROFIBUS was approved as the European standard EN50170, Volume 2, on March 15, 1996.

Baud Rate (kbps)

9.6

19.2

93.8

187.5

500

1500

12000

Distance/Segment (m)

1200

1200

1200

1000

400

200

100

Transmission distance and transmission rate:

Profibus Technical Parameters

Network Scale: Up to 126 nodes

Network Length: 100-1200m

10. Profinet

Maximum transmission rate: 100Mbps

Maximum transmission distance: 100m

PROFINET, launched by the PROFIBUS International organization (PI), is the next generation automation bus standard based on industrial Ethernet technology. As a strategic technological innovation, PROFINET provides a complete network solution for the automation communication field, encompassing current hot topics such as real-time Ethernet, motion control, distributed automation, fault tolerance, and network security. Moreover, as a cross-vendor technology, it is fully compatible with industrial Ethernet and existing fieldbus technologies (such as PROFIBUS), protecting existing investments.

PROFINET is a new Ethernet communication system developed by Siemens and the Profibus user association. PROFINET has communication capabilities between multi-manufacturer products, automation, and engineering modes, and is optimized for distributed intelligent automation systems. Its application results can significantly save configuration and debugging costs. The PROFINET system integrates systems based on Profibus, providing protection for existing system investments. It can also integrate other fieldbus systems.

PROFINET Technical Parameters

Network Scale: Can form networks of almost unlimited size

Network Length: 10/100 Base-T = 100m

PROFIBUS is based on RS485, while PROFINET is based on industrial Ethernet; the comparison is as follows

11. FF HSE

Maximum transmission rate: 2.5Mbps

Maximum transmission distance: 1900m, transmission rate: 31.25kbps

The Foundation Fieldbus (FF) is based on the ISO/OSI open systems interconnection model, taking its physical layer, data link layer, and application layer as the corresponding levels of the FF communication model, and adding a user layer at the application level. It is a fully digital, bidirectional transmission, multipoint communication link powered by the bus, used to connect intelligent devices and automation systems. Established in 1994, the Foundation aims to form a dedicated, international, interoperable fieldbus standard to meet the development requirements of the latest automation control technology and provide education, interoperability testing, consistency testing, testing tools, R&D support software, and testing assistance. The Foundation Fieldbus is an international organization with over 120 members, including major process control product suppliers, and the transmitters, DCS systems, actuators, and flow instruments produced by its members account for 90% of the world market.

Since some of the world’s largest instrumentation companies participate in FF, the fieldbus products developed by FF can meet the requirements of process control in terms of variety and performance, and are easy to use, with excellent interoperability and interchangeability. Interoperability means that devices from the same manufacturer can communicate with each other and can function in a multi-vendor environment. Interchangeability means that devices from different manufacturers can be functionally swapped with similar devices.

12. P-net

Fixed transmission rate: 76.8kbps

Maximum transmission distance: 1200m

P-NET originated in Denmark in 1983, researched and developed by Proces-Data A/S. It is a globally applicable open standardized bus. Due to its use of universal hardware and software, its improvements and upgrades are relatively fast.

P-NET is a multi-master, master-slave bus (each segment can accommodate up to 32 master controllers), using shielded twisted pair cable RS485, with a maximum segment length of 1200m. Each segment can connect up to 125 devices, and repeaters are used between bus segments, with data transmitted asynchronously using NRZ encoding at a transmission rate of 76.8kbit/s.

13. CC-Link

Maximum transmission rate: 10Mbps, transmission distance: 100m

Maximum transmission distance: 1200m, transmission rate: 156kbps

CC-Link, short for Control & Communication Link, was launched in November 1996 by Mitsubishi Electric and several other companies, rapidly gaining a significant market share in Asia and currently developing rapidly in Europe and North America. In its system, control and information data can be transmitted simultaneously at high speed (10Mbps) to the field network, with excellent performance, ease of use, wide application, and cost savings. It not only solves the complex wiring issues in industrial fields but also has excellent noise resistance and compatibility. CC-Link is a device-layer-focused network that can also cover higher-level control layers and lower-level sensor layers. In July 2005, CC-Link was approved as a guiding technical document by the National Standardization Administration of China.

CC-Link Technical Parameters

Network Scale: Up to 354 nodes

Network Length: 156kbps/1200m; 625kbps/900m; 2.5Mbps/400m; 5Mbps/160m; 10Mbps/100m

14. DeviceNet

Maximum transmission rate: 500kbps, transmission distance: 100m

Maximum transmission distance: 500m, transmission rate: 125kbps

DeviceNet is an open, globally standard-compliant, low-cost, high-performance communication network based on CAN (Controller Area Network) technology, initially developed by Rockwell Automation in the mid-1990s. It is a digital, multipoint connection network that facilitates communication between controllers and I/O devices. Each device and controller is a node on the network.

DeviceNet systems can be configured to operate in a master-slave mode or a distributed control structure based on peer communication, supporting single-point connections for configuration and control using I/O and explicit messaging, and has a unique feature of supporting network power. This allows low-power devices to draw power directly from the network, reducing wiring points and logistics size.

DeviceNet uses a trunk/branch topology, with two pairs of twisted wires transmitting signals and power. The thick and thin cables are used for the trunk and branches, respectively. The network length varies depending on the rate and cable thickness.

DeviceNet Technical Indicators

Network Scale: Up to 64 nodes

Network Length: 125kbps/500m; 250kbps/250m; 500kbps/100m

3. Conclusion

From the comparison of various fieldbuses above, it can be seen that Ethernet-based bus transmission is fast, but its structure may be relatively complex; some buses are based on RS485, indicating that RS485 (RS422) still has significant advantages; when transmitting distances around 100 meters, the following can be selected based on transmission rates: Ethernet/IP, Profinet, Profibus, CC-Link, ControlNet, RS485/RS422, FF HSE, CAN, etc. From the perspective of widespread application, Ethernet, RS485/RS422, Profibus, FF HSE, and CAN are more commonly used.

We welcome all engineers to leave your wonderful comments in the comment section below!

Link: How to Become an Industrial Robot Application Engineer?

Link: How to Become an Industrial Robot Application Engineer?

Link: How to Become an Industrial Robot Application Engineer?

We are not just carriers of dry goods.

Distance from the Industrial Robot Master is just a follow away.

Guide Car Robot Academy, the cradle of robotic craftsmen.