Field of Application

Smart Manufacturing

Pain Points

· Issue 1: Insufficient Bandwidth and Poor Anti-Interference of Traditional Fieldbus Technology

With the intelligent development of the manufacturing industry and the exponential increase in the number of bus nodes, traditional fieldbus technologies (such as CAN, Profibus, etc.) can no longer meet the transmission requirements of massive data. Additionally, traditional fieldbus technologies often use copper wires as the physical medium for information transmission, making it difficult to ensure signal quality in extreme environments or under strong electromagnetic interference.

· Issue 2: Real-Time Issues of Traditional Ethernet Technology

Although Ethernet technology’s high bandwidth characteristics can meet the data transmission needs of smart manufacturing, traditional Ethernet technology uses the Carrier Sense Multiple Access with Collision Detection (CSMA/CD) mechanism to manage access to the communication medium, which introduces significant communication uncertainty, making traditional Ethernet unsuitable for scenarios with high real-time requirements, such as industrial control. Therefore, relevant real-time improvements to traditional Ethernet technology are necessary.

· Issue 3: Real-Time Transmission Issues of High-Bit-Rate Data Such as Video and Audio

The technology that improves the real-time protocols at the link layer, transport layer, and application layer of traditional Ethernet is called Real-Time Ethernet (RTE), which is widely used in the industrial control field, mostly based on the 100Mbps Ethernet physical layer. As emerging technologies like visual recognition, point cloud processing, and noise analysis are applied in industrial control, the 100Mbps RTE struggles to meet the high bitrate data transmission requirements and to ensure the real-time nature of such data transmission.

· Issue 4: Clock Synchronization Problems in Real-Time Ethernet

For Real-Time Ethernet that adopts a multi-node distributed local clock, the hardware crystal oscillators of the slave communication nodes have frequency and phase differences, leading to synchronization errors (local clock errors) among the local clocks of each node. The synchronization error of the local clock directly results in deviations in the multi-axis coordinated control of the manufacturing system.

· Issue 5: Localization of Real-Time Ethernet Technology

Currently, the more mature and standardized 100Mbps real-time Ethernet technologies in the market are still EtherCAT (from Beckhoff, Germany), Profinet (from Siemens, Germany), and Sercos III (from Rexroth, Germany). Although the domestic EPA real-time Ethernet protocol launched by Zhejiang University Zhongkong has become an international standard, its communication real-time capabilities, guaranteed by the transport layer and application layer scheduling mechanisms, are difficult to compare with EtherCAT, which is based on link layer real-time mechanisms.

Solutions

To address the aforementioned pain points, NCUC Real-Time Ethernet Fieldbus Technology employs the following methods:

1) Solution for Insufficient Bandwidth of Traditional Fieldbus Technology

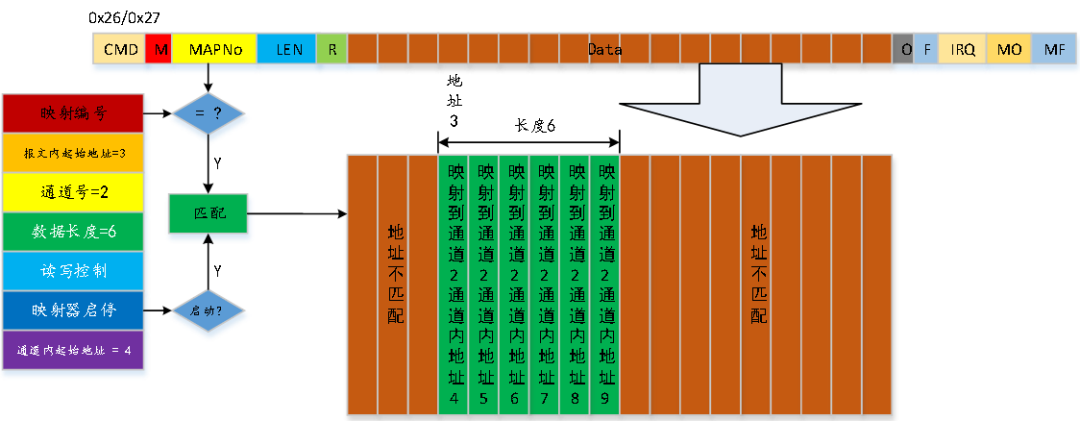

NCUC Real-Time Ethernet Fieldbus Technology supports communication methods based on 100M/1000M standard Ethernet physical layers. Each NCUC data frame can accommodate a maximum of 1500 bytes of data transmission and features a special Mapping access mechanism, allowing a single NCUC message to complete data exchange for multiple slave node memory addresses, significantly improving bandwidth utilization.

Figure 1 Mapping Access Mechanism

2) Solution for Poor Anti-Interference of Traditional Fieldbus Technology

NCUC Real-Time Ethernet Fieldbus Technology can be modified according to the different PHY chips used, allowing NCUC to adopt fiber optic communication to enhance the anti-interference capability of the communication network.

Figure 2 NCUC Slave Using Fiber Optic Communication

3) Solution for Real-Time Issues of Traditional Ethernet Technology

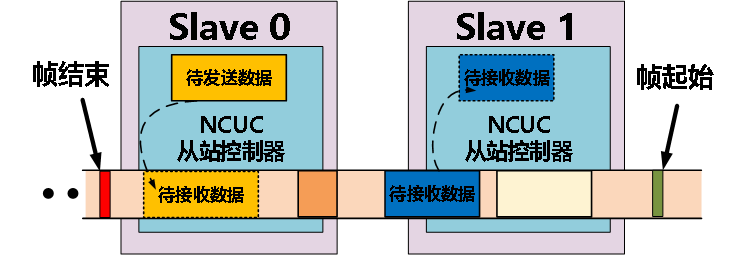

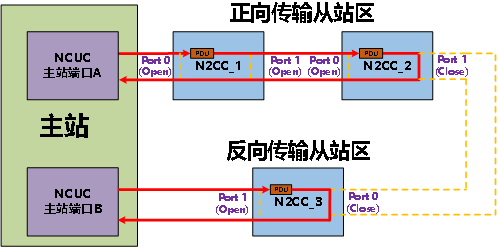

NCUC has modified the real-time protocols at the data link layer to minimize the impact of link layer data buffering on real-time performance and employs a fly-read-fly-write mechanism to maximize communication real-time capabilities.

Figure 3 NCUC Fly-Read-Fly-Write Mechanism

4) Solution for Real-Time Transmission of High-Bit-Rate Data Such as Video and Audio

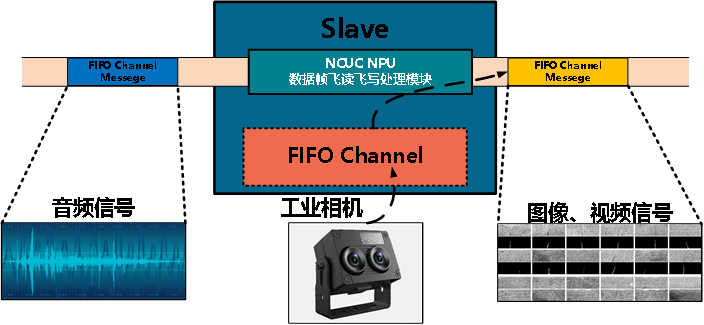

Based on a 1000M bandwidth transmission, NCUC features a unique FIFO data channel that dynamically adjusts the word length to achieve real-time transmission of video, audio, and other data streams.

Figure 4 NCUC FIFO Channel Data Processing

5) Solution for Clock Synchronization Issues in Real-Time Ethernet Technology

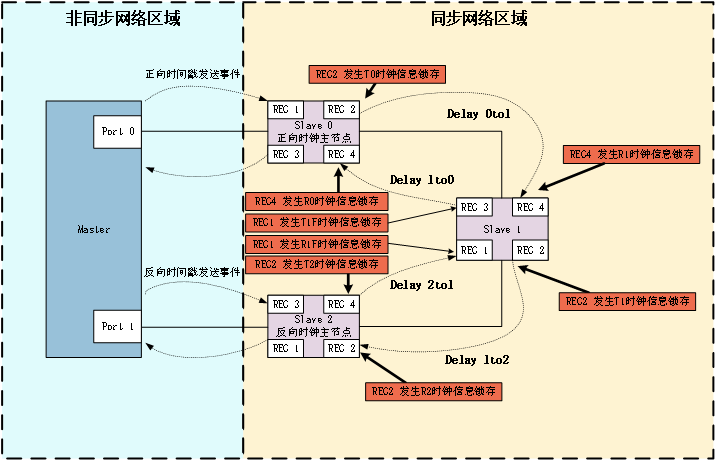

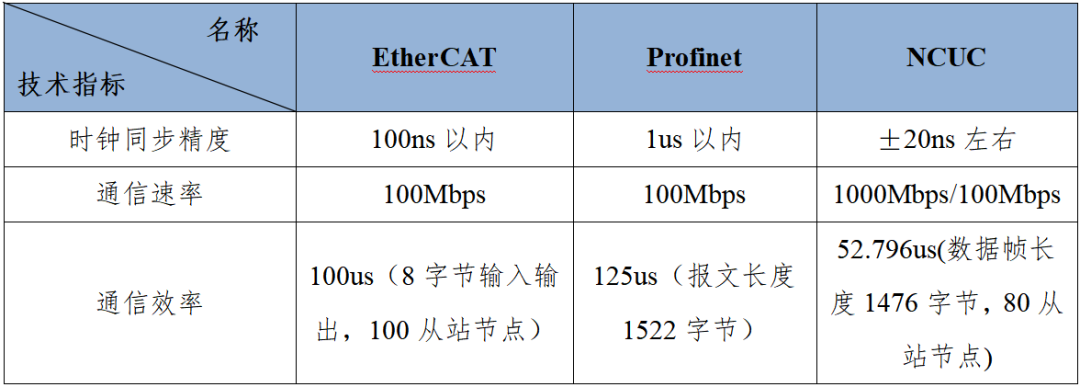

NCUC adopts a distributed clock architecture, using a point-to-point transparent clock mechanism to measure phase deviations and designs a physical transmission delay automatic calculation scheme. Meanwhile, the NCUC IP core is equipped with a clock servo algorithm, and tests show that the Sync signal peak-to-peak jitter between NCUC slave nodes can stabilize around ±20ns, demonstrating excellent clock synchronization performance.

Figure 5 NCUC Physical Delay Calculation Scheme

Technical Advantages

The relevant technical indicators and comparisons are shown in the table below:

Table 1 Technical Indicator Comparison

Competitive Advantages

· Technical Advantages

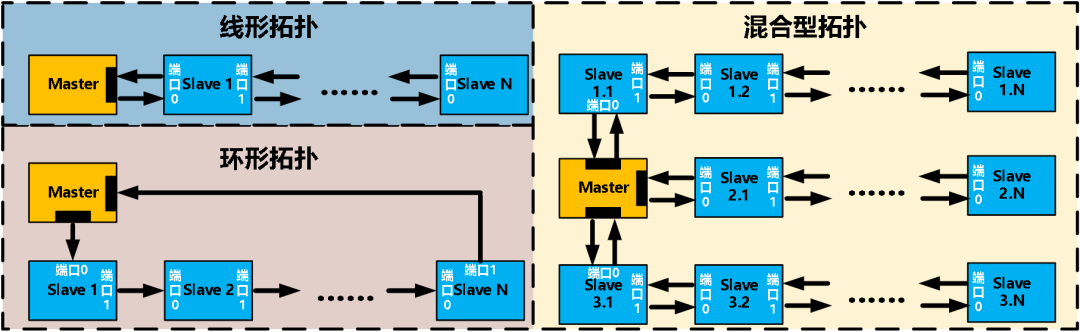

In addition to the aforementioned NCUC clock synchronization accuracy of ±20ns, support for Gigabit Ethernet physical layer, support for various physical layer transmission media, and strong real-time capabilities, NCUC also supports various communication topology structures such as linear topology, ring topology, and hybrid topology.

Figure 6 NCUC Communication Topology Structure

In a ring topology structure, NCUC has a line break detection mechanism and can automatically reconstruct the communication topology structure when a line break occurs.

Figure 7 NCUC Topology Reconstruction Principle

· Market Advantages

① Compared to EtherCAT, Profinet, and other real-time Ethernet technologies, NCUC is more autonomous and controllable. In the current severe international situation, NCUC is safer and more stable compared to similar technical products;

② NCUC technology has now entered the chip physical design and tape-out stage, and NCUC products will ultimately be promoted and applied in the form of ASIC chips. Compared to other real-time Ethernet technologies that provide modular slave nodes and FPGA IP core solutions, NCUC’s ASIC chip application has a lower cost.

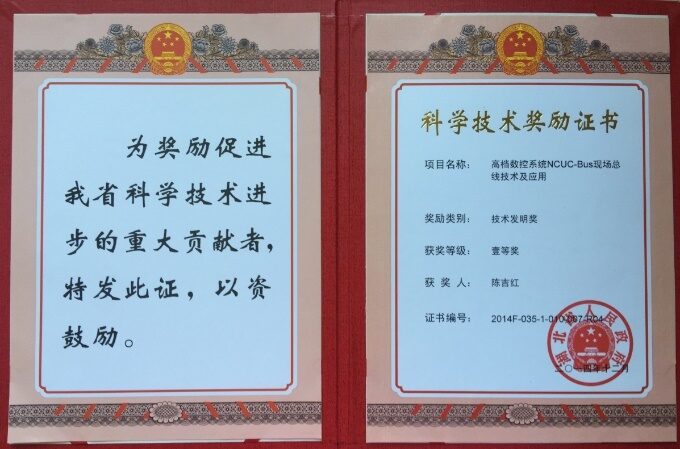

Qualifications and Honors

NCUC Won the First Prize of Hubei Provincial Technology Invention Award

Figure 8 First Prize of Hubei Provincial Technology Invention Award

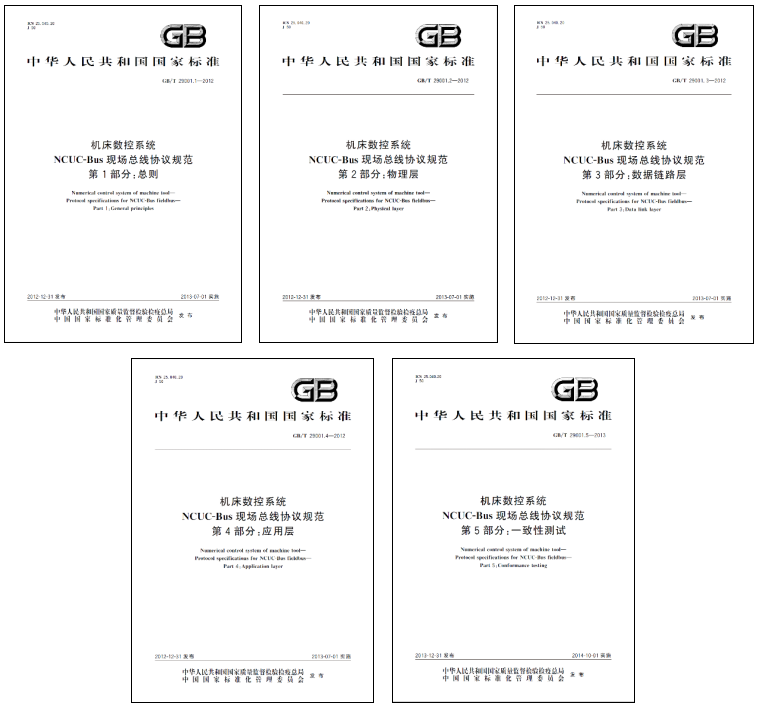

Formation of 5 National Standards for NCUC Bus

Figure 9 5 National Standards of NCUC

Technical Maturity

Can be mass-produced.

Industrial Application

Market Prospects:

1. Smart Manufacturing Field: According to MIR Industrial Statistics, as of 2021, the market size of bus-type motion controllers in China exceeded 6 billion, accounting for more than 70% of the overall motion controller market. Among them, the market size of EtherCAT bus-type motion controllers exceeded 4 billion, accounting for more than 60% of the bus-type motion controller market. Compared to EtherCAT technology, NCUC technology’s high bandwidth advantage provides a better medium for the transmission of large amounts of data in smart manufacturing, while precise clock synchronization technology lays a solid foundation for high-speed and high-precision multi-axis coordinated processing. Although EtherCAT is currently more widely used, with the continuous advancement of technology localization, NCUC has greater application potential than EtherCAT. If we can leverage NCUC’s unique technological innovations to complete the construction of the product ecosystem within four years and successfully achieve domestic substitution, even capturing just 1% of the market could yield an annual revenue of 40 million yuan.

2. Automation Field: In the automation field, some scenarios will involve a large number of slave nodes, but traditional technologies like CAN and Profibus do not have the capacity to handle large loads (generally limited to around 100). NCUC uses a 16-bit wide station address and sequential addressing, theoretically allowing for 65,535 slave nodes, fully meeting the needs of the automation field.

3. In-Vehicle Communication Field: In automotive applications, as the electronic architecture gradually shifts from domain-centric to region-centric, and even to central control; cross-domain collaborative control for intelligent driving; and precise distributed control of wheel motors or hub motors, the demand and reliance on high-speed real-time buses for in-vehicle communication will become increasingly strong. The application of laser radar and visual recognition in vehicles has brought a large number of point cloud data sets and video stream data transmission needs; NCUC technology’s 1000M bandwidth physical transmission characteristics and FIFO channel data exchange functions provide a good solution for the real-time transmission of such data. According to Forward Economic Research and data cited from iResearch and the Ministry of Industry and Information Technology, by 2026, the market size of smart connected vehicles in China is expected to reach 600 billion yuan, with mid-to-high-end models reaching 1 million units. If we can promote NCUC 2.0 for application in 10% of mid-to-high-end models, with an average of 10 bus chips used per vehicle (estimated at 20 yuan per chip), the annual output value is expected to reach 20 million yuan.

Application Cases:

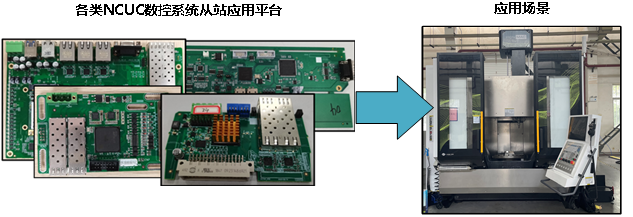

1. CNC System Slave Application Case: NCUC has been comprehensively promoted in the Central China CNC systems, estimating nearly 100,000 sets of NCUC buses based on an annual sales volume of 15,000 CNC systems. Meanwhile, our team continuously iterates and upgrades various NCUC slave application platforms for CNC systems, applying the latest NCUC technology to servo drives, IO devices, panels, and other slave nodes of CNC systems.

Figure 10 Application on CNC Systems

2. In-Vehicle Ethernet Application Case: Using a CAN-NCUC conversion board, NCUC real-time Ethernet technology is deployed into vehicle buses.

Figure 11 NCUC In-Vehicle Application

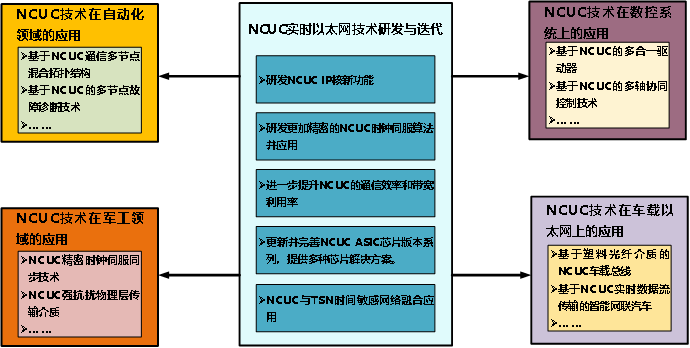

Development Plan:

The application promotion and technical research and development plan for NCUC Real-Time Ethernet Fieldbus Technology is shown in the figure below.

Figure 12 NCUC Real-Time Ethernet Fieldbus Technology Development Plan

Intellectual Property:

This achievement has applied for/authorized multiple Chinese invention patents.

Collaboration Methods:

Patent licensing, patent transfer, equity investment, technical development, and discussions.

Team Introduction

The National Intelligent Design and CNC Technology Innovation Center (referred to as “Guozhi Center”) is built on the foundation of the Ministry of Science and Technology’s “National CNC System Engineering Technology Research Center” and “National Enterprise Information Application Support Software Engineering Technology Research Center (Wuhan)”. It was approved by the Ministry of Science and Technology in January 2022, and is recognized by the Ministry of Science and Technology and the Hubei Provincial People’s Government.

The Guozhi Center focuses on the transformation of science into technology, adhering to the frontiers of global technology, major national needs, the main battlefield of the national economy, and people’s health. It aims to break through key core technologies and solve “bottleneck” issues, focusing on three main directions: industrial software for intelligent system design, high-end CNC systems, and intelligent manufacturing system industrial software. It conducts research on basic industrial software and high-end CNC systems, developing engines, platforms, and systems for intelligent system design and CNC. “With R&D as the mission and technology as the product”, it collaborates with deeply integrated domestic high-tech enterprises to promote the productization of technology, forming core technologies, products, and ecosystems.

The Guozhi Center adheres to the route of “benchmarking, catching up, and innovating beyond”, benchmarking against internationally leading products such as MATLAB, Siemens, and Heidenhain, and independently developed a series of core technology achievements such as scientific computing and engineering modeling design systems, high-end CNC systems, production system modeling and simulation software, PLM software, geometric topology optimization engines, production scheduling optimization engines, geometric constraint engines, and remote operation and maintenance systems, which are widely applied in key industries such as aerospace, aviation, energy, vehicles, ships, communications, and construction machinery. It provides domestic alternatives, independent control, safe and reliable digital factory solutions for digital factories, digital workshops, digital production lines, digital equipment, and intelligent applications.

Left Image: Unified Modeling Industrial Software Across Multiple Domains

Middle Image: Geometric Topology Optimization Industrial Software

Right Image: PLM Industrial Software

Left Image: High-End CNC System

Middle Image: Intelligent CNC System

Right Image: Intelligent Production Scheduling Optimization Industrial Software

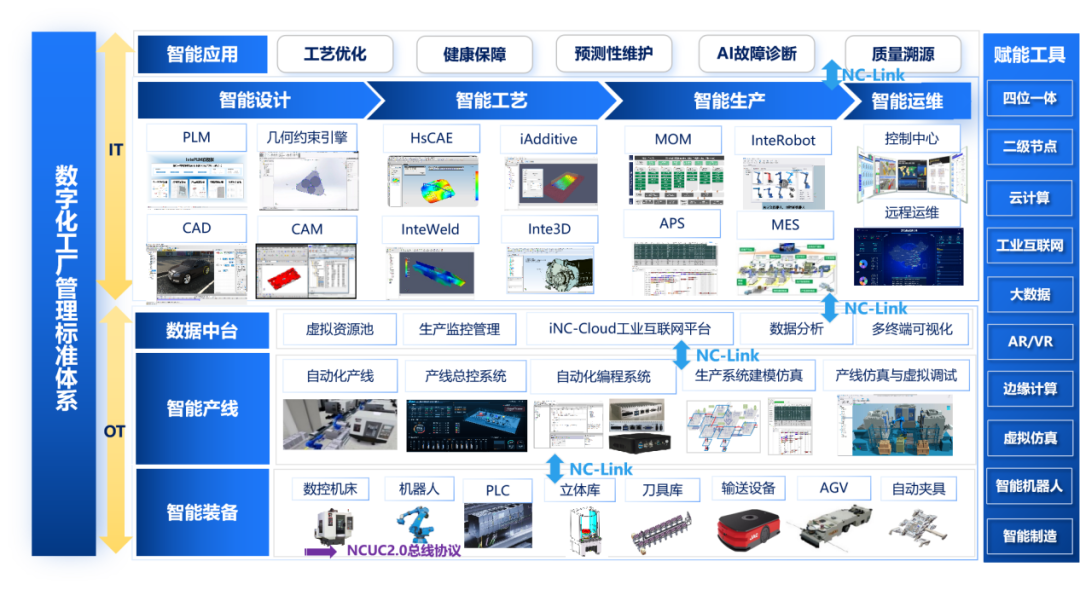

Guozhi Center Digital Factory System Architecture

Contact Information

Editor | Li Mengnan

Review | Li Zhi