With the advancement of Programmable Logic Controller (PLC) technology, there has been a leap from wiring logic to storage logic since its inception; its functions have progressed from weak to strong, achieving improvements from logic control to digital control; its application fields have expanded from small to large, crossing over from simple control of individual devices to handling various tasks such as motion control, process control, and distributed control. Today’s PLC has significantly improved its capabilities in handling analog quantities, digital operations, human-machine interfaces, and networking, becoming an important player in the family of industrial control devices.

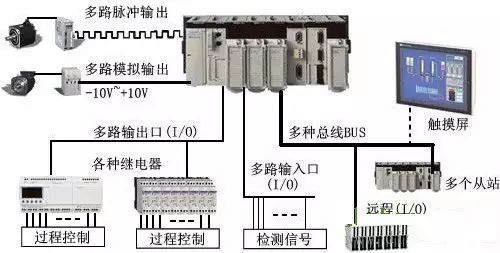

This is a typical block diagram of a PLC control system

Currently, PLC controllers are widely used in various industries such as steel, petroleum, chemical, electric power, building materials, machinery manufacturing, automotive, light textile, transportation, environmental protection, and cultural entertainment. The main application areas can be summarized into the following six aspects:

Used for Switch Quantity Control

The PLC has a strong capability for controlling switch quantities. The number of controlled input and output points can range from a few dozen to hundreds, thousands, or even tens of thousands. Since it can be networked, the number of points is virtually unlimited, and it can control various logical problems: combinations, sequences, immediate, delayed, non-counting, counting, fixed order, random operation, and so on.

The hardware structure of the PLC is variable, and the software program is programmable, making it very flexible for control. If necessary, multiple sets or groups of programs can be written and called as needed. It is well-suited for the needs of industrial sites with multiple working conditions and state changes.

There are numerous examples of using PLCs for switch quantity control in metallurgy, machinery, light industry, chemicals, textiles, and almost all industrial sectors. Currently, the primary advantage of PLCs, which other controllers cannot match, is their convenience and reliability in switch quantity control.

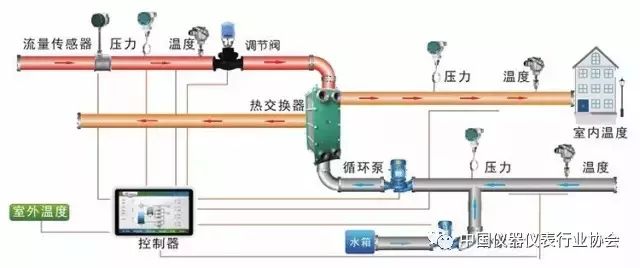

Used for Analog Quantity Control

Analog quantities, such as current, voltage, temperature, pressure, etc., change continuously. In industrial production, especially in continuous production processes, these physical quantities often need to be controlled.

As an industrial control electronic device, if a PLC cannot control these quantities, it is a significant shortcoming. Therefore, various PLC manufacturers are conducting extensive development in this area. Currently, not only large and medium-sized machines can perform analog quantity control, but even small machines can achieve such control. For PLCs to perform analog quantity control, they must be equipped with A/D and D/A units for converting between analog and digital quantities. These are also I/O units, but special I/O units.

The A/D unit converts external circuit analog quantities into digital quantities, which are then sent to the PLC; the D/A unit converts the PLC’s digital quantities back into analog quantities for the external circuit. As a special I/O unit, it still possesses characteristics such as anti-interference for I/O circuits, isolation between internal and external circuits, and exchanging information with input/output relays (or internal relays, which are also a writable area of PLC working memory).

Here, the A in A/D mostly refers to current or voltage, and sometimes temperature (resistance). The A in D/A mostly refers to voltage or current. The voltage and current ranges are typically 0-5V, 0-10V, 4-20mA, and some can even handle positive and negative values. The D in small machines is mostly 8-bit binary numbers, while medium and large machines are mostly 12-bit binary numbers. A/D and D/A can be single-channel or multi-channel, with multi-channel using more input/output relays. With A/D and D/A units, the remaining processing is all digital quantities, which is not difficult for a PLC with information processing capabilities. Medium and large PLCs have stronger processing capabilities, allowing them to perform addition, subtraction, multiplication, division, square roots, interpolation, and even floating-point operations. Some also have PID instructions to perform proportional, derivative, and integral calculations on deviations, generating corresponding outputs; it can almost perform all calculations that a computer can.

Thus, achieving analog quantity control with PLCs is entirely possible.

PLC can also perform analog quantity control with A/D and D/A units combined, and can use PID or fuzzy control algorithms to achieve high control quality. The benefit of using PLC for analog quantity control is that while performing this control, switch quantities can also be controlled. This advantage is not found in other controllers, or the implementation of control is not as convenient as with PLCs. Of course, if the system is purely for analog quantities, using PLCs may not be as cost-effective as using dedicated regulators.

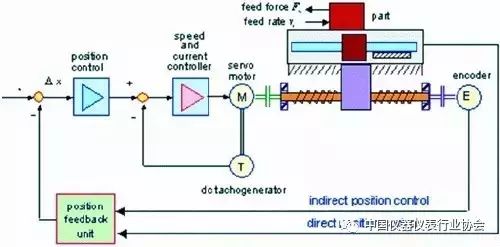

Used for Motion Control

In addition to switch quantities and analog quantities, there is also motion control.Motion control primarily refers to the control of the position, speed, and acceleration of the working object. It can be single-coordinate, meaning the controlled object moves in a straight line; or multi-coordinate, meaning the controlled object moves in a plane, three-dimensional space, or even changes angles. Sometimes, multiple objects can be controlled, and their movements may need to be coordinated.For instance, the displacement of machine tool components is often represented as digital quantities.

A practical method for motion control is NC, or numerical control technology. This technology, which originated in the United States in the 1950s, is based on computer control technology. It is now widely used and well-developed. Currently, in advanced countries, the ratio of numerical control in metal cutting machine tools has exceeded 40%-80%, with some even higher.

PLC technology is also based on computers and is continually improving. PLCs can receive counting pulses with frequencies ranging from several kHz to tens of kHz, and they can receive these pulses in various ways, including multiple channels. Some PLCs also have pulse output functions, with pulse frequencies reaching tens of kHz. With these two functions, combined with the data processing and calculation capabilities of PLCs, and equipped with appropriate sensors (such as rotary encoders) or pulse servo devices, various controls can be fully realized based on the principles of NC.

High-end and mid-range PLCs have also developed NC units or motion units that can achieve point control. Motion units can also implement curve interpolation and control curve movements. Therefore, if a PLC is equipped with such units, it can fully use NC methods for digital quantity control. Newly developed motion units have even introduced programming languages for NC technology, facilitating better digital control using PLCs.

Used for Data Acquisition

With the development of PLC technology, its data storage area has become increasingly large. For example, the PLC from Devenson Company can have a data storage area (DM area) of up to 9999 words. Such a vast data storage area can store a large amount of data. Data acquisition can utilize counters to cumulatively record collected pulse counts and periodically transfer them to the DM area. Data acquisition can also be performed using A/D units, where analog quantities are converted into digital quantities and then periodically transferred to the DM area. PLCs can also be configured with small printers to periodically print out the data from the DM area.

PLCs can also communicate with computers, allowing the computer to read data from the DM area and process it further. In this case, the PLC acts as a data terminal for the computer.

Used for Signal Monitoring

PLCs have numerous self-check signals and internal components, most users have not fully utilized their capabilities. In fact, it is entirely possible to use them to monitor the PLC’s own operation or the controlled objects. For a complex control system, especially an automatic control system, monitoring and further self-diagnosis are very necessary; it can reduce system failures, make troubleshooting easier, improve the cumulative average fault-free running time, reduce fault repair time, and enhance system reliability.

Used for Networking and Communication

PLCs have strong networking and communication capabilities, with new networking structures constantly being introduced.

PLCs can connect to personal computers for communication, allowing computers to participate in programming and managing PLC control, making PLC use more convenient.

To fully leverage the power of computers, a single computer can control and manage multiple PLCs, with the number reaching up to 32. A PLC can also communicate with two or more computers to exchange information for monitoring the PLC control system. PLCs can communicate with each other, either one-on-one or with several PLCs, and can connect dozens or even hundreds of PLCs.

PLCs can also connect to intelligent instruments and smart actuators (such as frequency converters) for networking and data exchange, enabling remote control systems that can cover a range of up to 10 kilometers or more. They can form local networks, where not only PLCs but also high-end computers and various intelligent devices can be interconnected. Networking can utilize bus networks or ring networks; networks can be nested, and networks can bridge with each other. Networking can organize thousands of PLCs, computers, and intelligent devices into a single network, where nodes can communicate and exchange information directly or indirectly.

Networking and communication are perfectly suited to today’s needs for Computer Integrated Manufacturing Systems (CIMS) and intelligent factories. It allows industrial control to progress from point to line to surface, integrating device-level control, production line control, and factory management into a cohesive whole, thereby creating greater benefits. This infinitely promising prospect is becoming increasingly clear to our generation.

1. High Reliability and Strong Anti-Interference Capability

High reliability is a key performance characteristic of electrical control devices. PLCs utilize modern large-scale integrated circuit technology and strict manufacturing processes, employing advanced anti-interference technologies in their internal circuits, resulting in high reliability. When using PLCs to construct control systems, the electrical wiring and switch contacts have been reduced to hundreds or even thousands of times less than equivalent relay contactor systems, thereby significantly reducing failures. Additionally, PLCs come with hardware fault self-detection functions, which can promptly issue alarm information in case of faults. In application software, users can also incorporate fault self-diagnosis programs for peripheral devices, providing fault self-diagnosis protection for circuits and equipment outside of the PLC. Thus, the entire system achieves extremely high reliability.

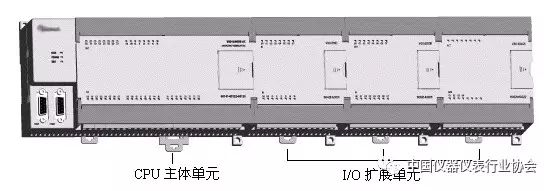

2. Comprehensive Support, Complete Functions, and Strong Applicability

PLCs have developed into a series of products of various scales, suitable for various industrial control scenarios. In addition to logical processing functions, most PLCs have comprehensive data calculation capabilities and can be used in various digital control fields. A wide variety of functional units have emerged, allowing PLCs to penetrate various industrial controls such as position control, temperature control, and CNC. Coupled with enhanced PLC communication capabilities and the development of human-machine interface technology, it has become very easy to use PLCs to form various control systems.

3. Easy to Learn and Use, Well-Received by Engineering Technicians

PLCs are industrial control devices aimed at enterprises. They have easy interfaces, and the programming language is readily accepted by engineering technicians. The graphical symbols and expressions of ladder diagram language are quite similar to relay circuit diagrams, opening the door for those unfamiliar with electronic circuits or computer principles and assembly language to engage in industrial control.

4. Reduced Design Workload, Convenient Maintenance, and Easy Modification

PLCs replace wiring logic with storage logic, greatly reducing the external wiring of control devices, significantly shortening the design and construction cycle of control systems, making daily maintenance easier, and importantly, allowing the same device to change production processes through program modifications. This is particularly suitable for production scenarios with multiple varieties and small batches.

Source: PLC Electrician Forum