(Advertisement Break)

[PCB Information Network]

Copper-clad laminate is an essential raw material for circuit boards. This material saw a price increase of approximately 60 yuan over a span of just three months from October to December last year, with seven price hikes occurring during that period.

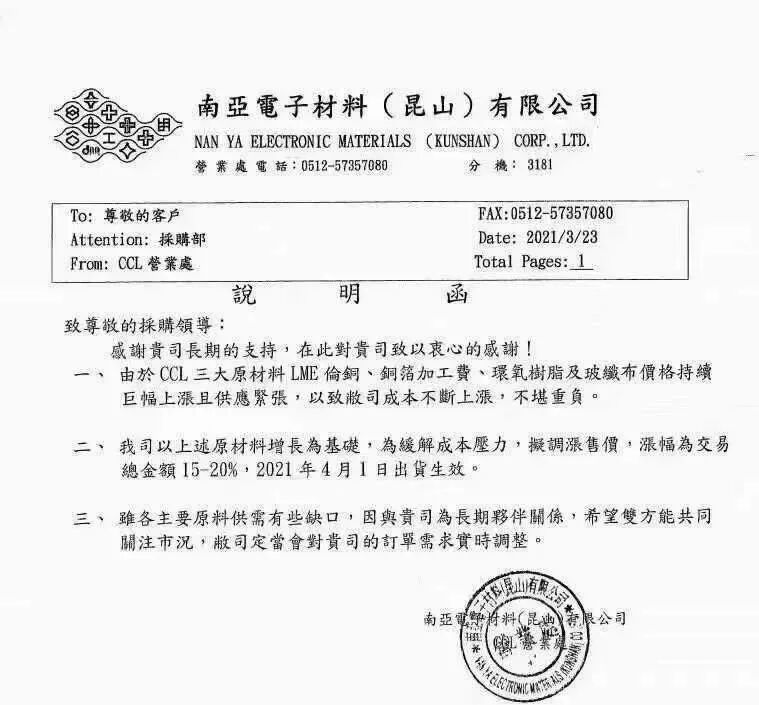

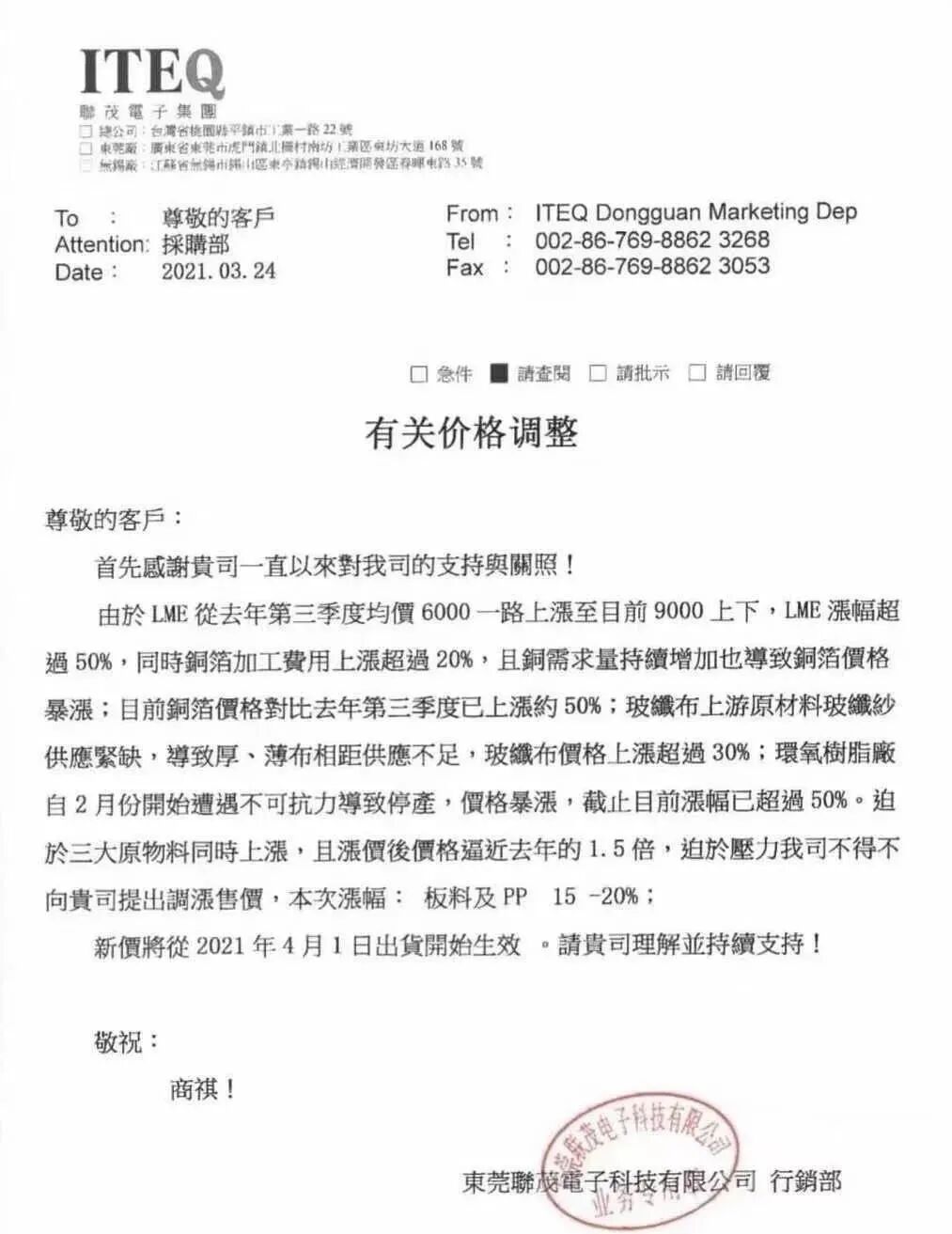

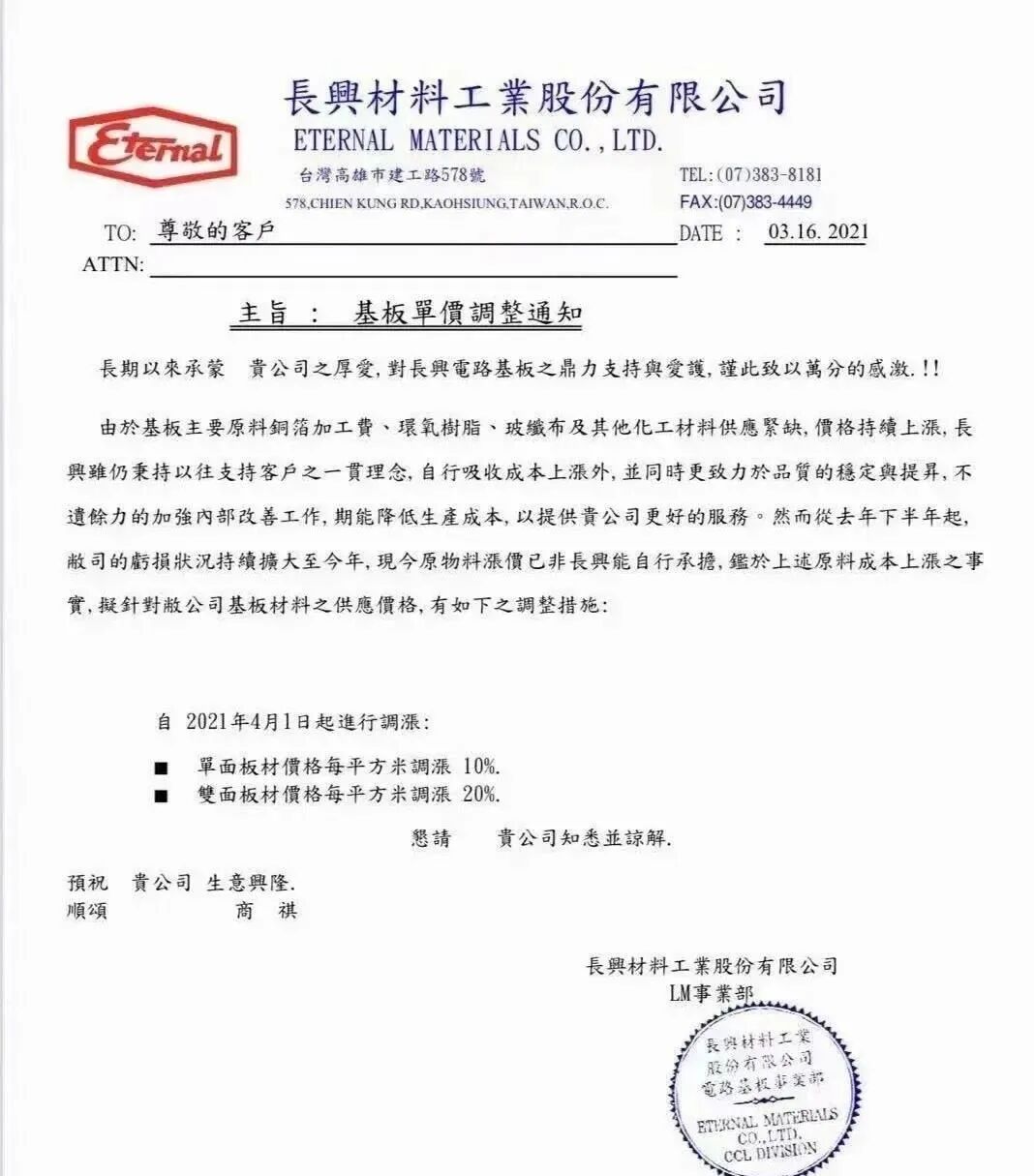

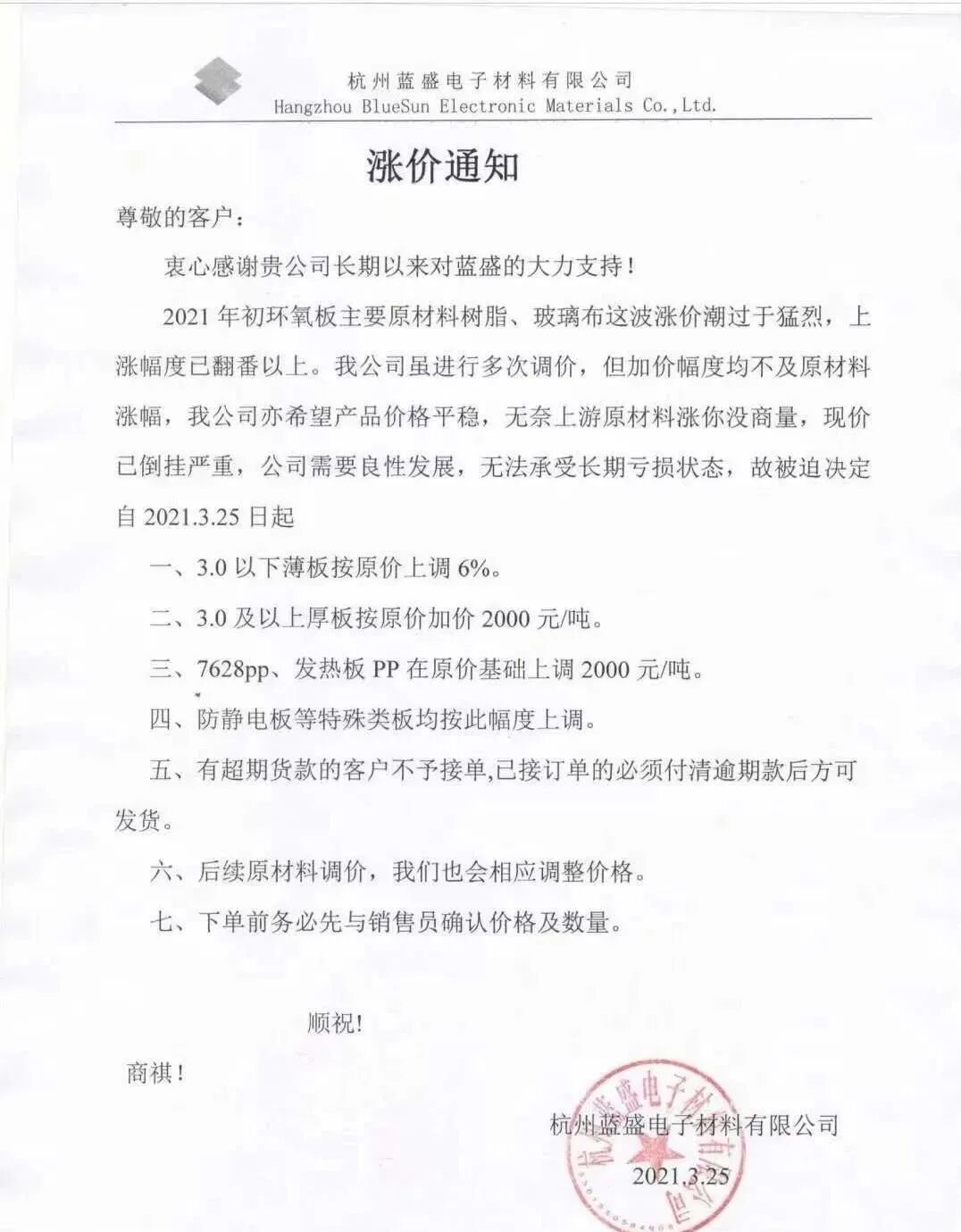

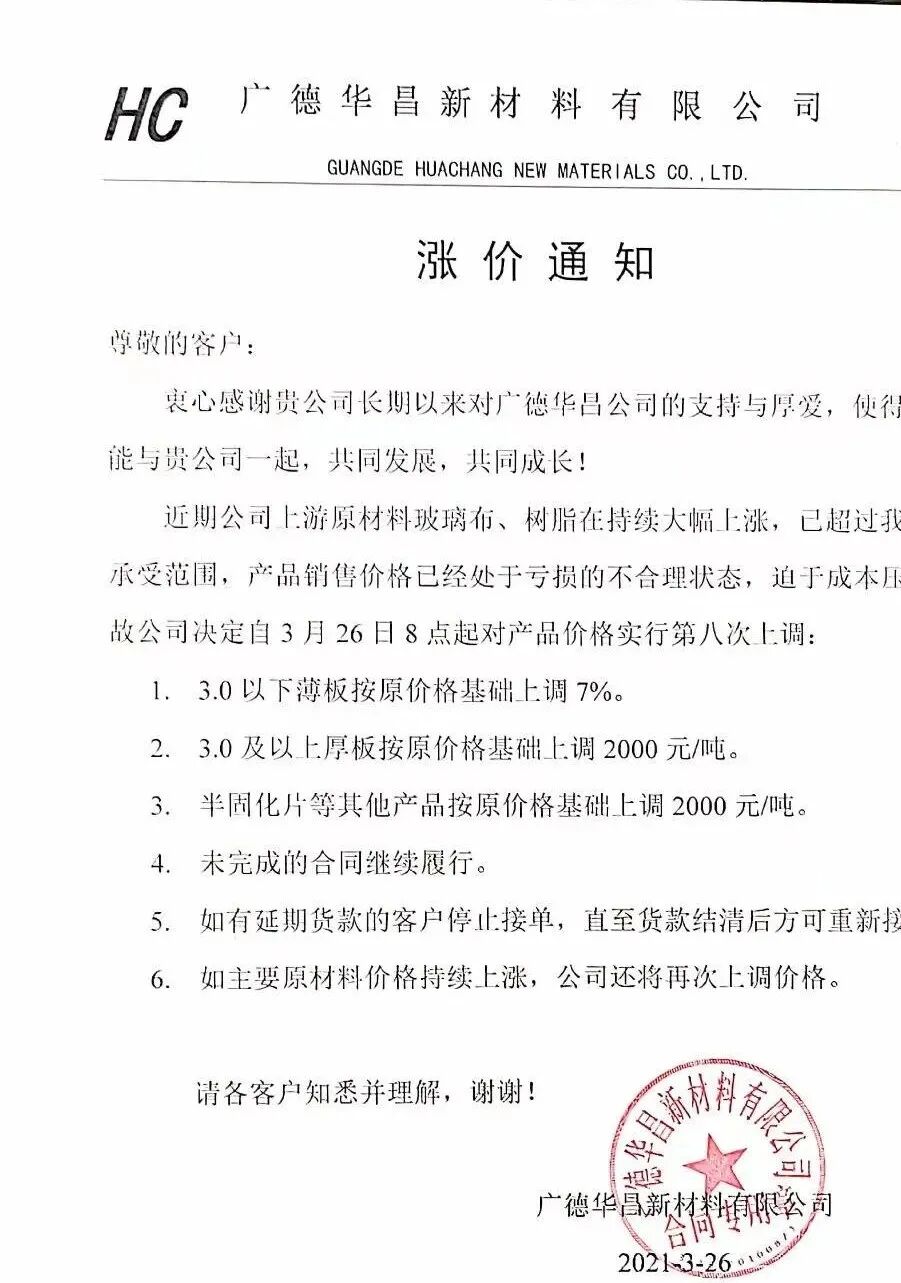

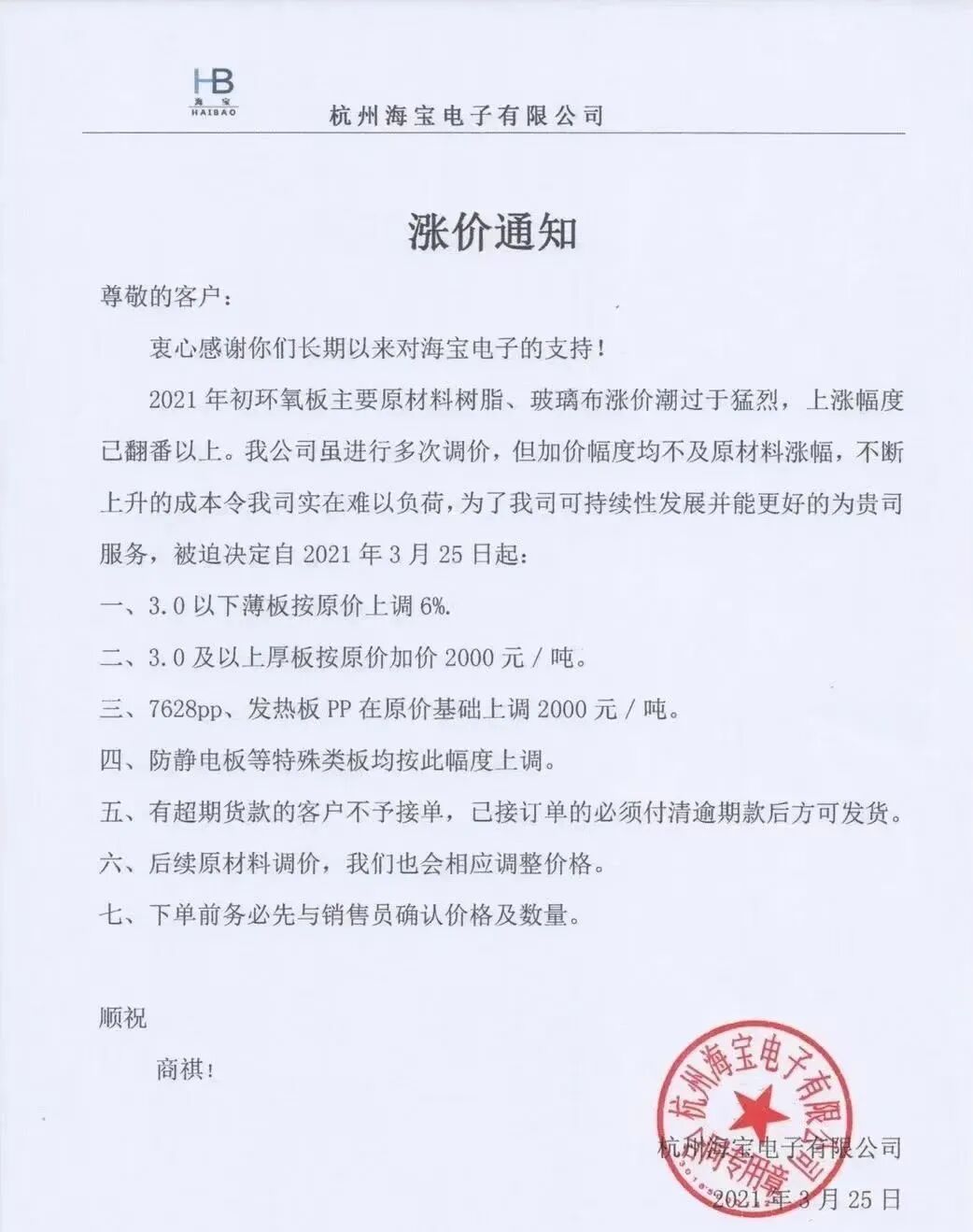

As we enter 2021, the price increases have not eased. With the continuous and significant rise in prices of raw materials such as LME copper, copper foil processing fees, epoxy resin, and fiberglass cloth, along with tight supply, the prices of copper-clad laminates have also surged. Recently, several PCB manufacturers, including Nanya Technology, Unimicron Technology, Changxing Materials, Lansen Electronics, Huachang New Materials, and Haibao Electronics, have consecutively issued price increase notices, with substantial hikes.

Industry insiders predict that the copper-clad laminate industry will remain in a high prosperity phase at least until the second quarter of this year, and price increases may continue.

The upstream of the PCB industry chain includes copper foil, copper balls, copper-clad laminates, prepregs, gold salts, and inks, with the overall material cost accounting for nearly 60%. Among the upstream materials, copper-clad laminates are primarily responsible for the three main functions of conductivity, insulation, and support for PCBs. Their performance directly determines the performance of PCBs and is a key foundational material for PCB production, accounting for 20%-40% of direct material costs.

The recent price increase of copper-clad laminates, coupled with tight supply requiring cash transactions, has severely impacted the cash flow of some small and micro PCB enterprises. Even some major circuit board manufacturers have admitted that the significant rise in raw material prices will affect their profitability.

Some major PCB companies have stated that although their raw material supply channels are smooth and supply is relatively sufficient, they cannot completely rule out the possibility of supply tightness or fluctuations in price and quality due to changes in the supply-demand structure of related raw materials, which could adversely affect product quality, costs, and profitability.

In the face of this crisis, one cannot sit idly by. So how are these well-performing major circuit board companies responding to this massive and prolonged price increase? The PCB Information Network reporter has summarized the responses from several major circuit board manufacturers on this issue, highlighting the following points:

1. Actively negotiate with customers to pass on costs to downstream clients.

Some companies have stated that new orders are quoted at new prices, while some customers’ original supply agreements have been canceled this year, effectively resulting in a price increase.

2. Further strengthen cooperation and collaboration among major manufacturers within the industry chain, actively communicate and coordinate with suppliers and customers based on specific market conditions to jointly respond to changes in the external environment and mitigate the impact of rising raw material prices on all parties.

Recently, Zhuhai Zhongjing Electronics signed a strategic procurement cooperation agreement with Zhongshan Taiguang; ChaoHua Technology reached a strategic cooperation with Jingwang Electronics; and ChaoHua Technology also established a strategic partnership with Shenghong Technology. They are leveraging deep alliances along the PCB industry chain to support each other and achieve win-win cooperation.

3. Strengthen enterprise management to reduce costs and increase efficiency. Actively promote “improving efficiency, enhancing quality, and reducing costs” to improve enterprise process capabilities, increase per capita output value and benefits, and lower unit product costs.

4. Accelerate technological innovation, speed up the development of new products and new materials, enhance product added value, and strengthen the core competitiveness of enterprises.

5. Procure from multiple suppliers to reduce dependence on major suppliers and enhance procurement bargaining power to transfer the pressure of significant cost increases.

Special report from PCB Information Network, please indicate the source when reprinting.

Click to see the adorable viewers are always 18 years old

Click to see the adorable viewers are always 18 years old