A nimble caterpillar firmly grips a circular tube, undulating as it moves forward. In fact, this flexible caterpillar is a soft robot directly “printed” using a new modular flexible drive method developed by Tianjin University.

Soft robots have received continuous and widespread attention in recent years due to their high flexibility and safety for human interaction. The advantage of 3D printing lies in its ability to manufacture complex shapes and structures without the need for subsequent processing, allowing for one-step formation.

The printed assembly-free structure is a typical application of 3D printing technology in the manufacture of soft robots in recent years.

Recently, the research team led by Zuo Siyang and Liu Jianbin at Tianjin University proposed a new modular flexible drive method based on film cylinders. By changing the arrangement and combination according to specific applications and reasonably laying out connection schemes, it has been applied to artificial muscles and pipeline crawling robots.

This method is based on a one-time 3D printing forming technology, eliminating the assembly process in traditional electromechanical equipment manufacturing, significantly reducing the manufacturing cost and cycle of the drive module, while also featuring low air consumption, high dynamic response, high reliability, and strong adaptability to application scenarios.

The results were published online in early January 2021 in the “IEEE Robotics and Automation Letters”.

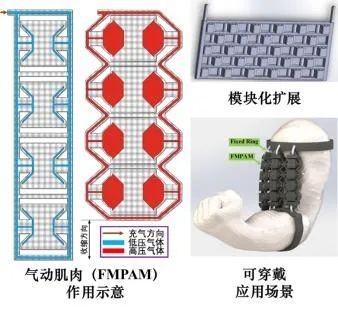

Design concept and application scenarios of the new pneumatic artificial muscle based on film cylinders

Design concept and application scenarios of the new pneumatic artificial muscle based on film cylinders

“Each film cylinder is like a small piece of muscle in the human body or a segment of a reptile, only made of thermoplastic polyurethane material,” Liu Jianbin explained that adopting this new film cylinder structure is the team’s “creative idea”.

If we compare this structure to a basic muscle unit, then according to different application needs, the connection methods of these units can be arranged and combined, just like connecting individual muscle units to form a whole muscle, which can then be applied in different scenarios, with the entire “muscle” being manufactured using 3D printing technology in one step.

Based on this idea, the research team first proposed a new type of pneumatic artificial muscle, which can be used in the drive of flexible exoskeletons and other human-machine interaction equipment. Pneumatic means using compressed air as the power source to drive the mechanism to perform stretching or rotating actions.

Compared to traditional pneumatic artificial muscles, the most prominent feature of this design is that it does not produce expansion in the thickness direction, thus avoiding pressure on the human body.

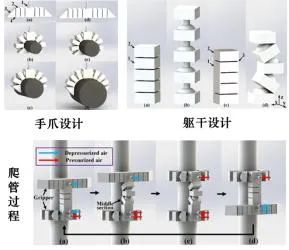

Design concept of the pipeline crawling robot based on film cylinders

In addition, the research team also proposed a new type of pneumatic pipeline crawling robot, which can be used for inspection and real-time monitoring of industrial pipeline facilities. This pipeline crawling robot adopts the bionic caterpillar principle, achieving the robot’s crawling on the inner and outer wall surfaces of the pipeline through the clever arrangement of connections between film cylinder units.

The application of flexible drive methods allows this robot to adapt to a wide range of changes in pipeline diameters and to cope with various application scenarios such as straight pipes, bent pipes, vertical pipes, horizontal pipes, and pipes inclined at various angles, while the robot can bear loads over 80 times its own weight.

Because it uses pneumatic methods for driving, the soft robot can only work while dragging a long air hose. If sensors are integrated into the device, these air hoses can be removed, making the robot more independent and refined. This is also the future direction of scientists’ efforts.

(Guangming Daily All-Media Reporter Liu Qian, Chen Jianqiang, Correspondent Liu Xiaoyan)

Recommended Hot Videos

↓↓↓

Source: Guangming Daily All-Media Reporter Liu Qian, Chen Jianqiang, Correspondent Liu XiaoyanImages: InternetEditor: Zhang YongqunEditor: Xing Yanyan