Authors: Xing Weijie, Pan Yadong, Jin Bo, Li Shangmin*, Fan Jianhua, Jiang Yixiu, Zhao Huaxuan, Dou Xinhong

Affiliation: Jiangsu Provincial Poultry Science Research Institute, Key Laboratory of Poultry Genetics and Breeding, Jiangsu Province

Introduction: Xing Weijie, from Wuxi, Jiangsu, assistant researcher, master’s degree, engaged in research on poultry breeding equipment technology. *Corresponding author, associate researcher, engaged in research on poultry farming environmental control.

Funding Projects: Jiangsu Provincial Key R&D Program (Modern Agriculture) Project (BE2019347); Yangzhou Soft Science Research Project (YZ2019201); Jiangsu Provincial Innovation Capability Construction Plan (Technology Facility) Project (BM2018026); Key Laboratory of Poultry Genetics and Breeding, Jiangsu Province Funded Project (JQLAB-ZZ-202004).

Source: “Anhui Agricultural Sciences” 2020 Issue 17

Press and hold to identify

OSID Open Science Program

Press and hold to identify the exclusive QR code for the paper, listen to the author talk about the writing background, and communicate insights with peers.

Poultry farming has a long history in China and is a fundamental industry. Since the reform and opening up, it has developed rapidly, with poultry numbers and egg production maintaining the world’s highest for many consecutive years, and poultry meat production ranking second in the world, effectively ensuring the dietary consumption of Chinese residents. However, the development of modern poultry farming is undergoing a strategic shift from quantity to quality, with sustainable development and smart farming being the main directions for future development. At the same time, with the rapid development of information technology, the third wave of the information industry represented by IoT technology is thriving, which will play an important role in the transformation and upgrading of traditional industries.

The Internet of Things (IoT) is an extension of the Internet, a network that connects objects. It uses communication technology to connect sensors, controllers, objects, machines, and people in new ways, forming an intelligent network that connects things to things and people to things. Compared to the Internet, IoT provides deeper, more personalized, and broader content and services.

Poultry Coding Standards and Identification

Individual coding and identification are important foundations for the development of IoT technology in the poultry industry, which can not only solve problems related to breeding, reproduction, precise feeding, and management but also achieve full-process tracking and traceability of production. Therefore, establishing poultry coding and identification standards is a prerequisite for the development of IoT technology in the poultry industry. In 2006, China began implementing a pilot project for “Animal Identification and Disease Traceability System Construction,” and the Ministry of Agriculture issued the “Livestock and Poultry Identification and Breeding File Management Measures,” which detailed the coding and identification of livestock and poultry, requiring that the identification code consist of 15 digits made up of the species code, county-level administrative region code, and identification sequence number, with the species codes for pigs, cattle, and sheep being 1, 2, and 3 respectively, but no species codes were specified for poultry. Identified products include electronic ear tags, implantable electronic chips, electronic leg bands, etc.

Currently, some companies in China have independently developed RFID chips and tags, significantly reducing production costs, and these have been widely used in livestock production, with some provinces also formulating corresponding technical specifications. The poultry industry mainly uses electronic leg bands, which are suitable for identifying poultry, tracing poultry, breeding, feeding, and disease prevention and control.

Application of IoT Technology in Modern Poultry Farming

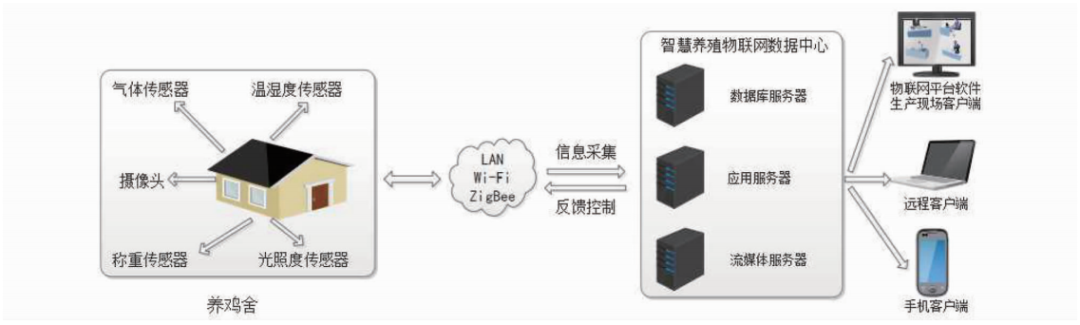

Currently, the poultry farming industry is developing towards scale and intensification, and refined management is an important means to improve economic efficiency while ensuring the quality and safety of poultry products. The indoor environment monitoring system for poultry farming generally includes gas sensors, temperature and humidity sensors, illumination sensors, weighing sensors, cameras, network nodes (sensor gateways), intermediate servers, system monitoring software, and remote monitoring clients, etc. (Figure 1).

Figure 1 Poultry Smart Farming Indoor Environment Monitoring System

Li Nianyou and others developed an Arduino-based poultry farm monitoring system using the Arduino Mega 2560 microcontroller, DHT11 temperature and humidity sensor, light sensor, buzzer, relay, motor, WiFi communication module, and display, which can automatically monitor the environment (temperature, humidity, light) of the farm; Gao Rui and others designed and developed an environmental information monitoring system based on ARM and WSN technology. This system collects environmental data such as temperature, humidity, and NH3 concentration in poultry houses and uses wireless sensor network technology to transmit the data to a data monitoring platform for subsequent management, viewing, and analysis.

Zhou Peng and others designed an intelligent livestock monitoring system that combines ZigBee and Ethernet communication methods, deploying various environmental monitoring sensors within the house, with sensor nodes forming a monitoring network to achieve real-time monitoring and control of the livestock environment.

Zhu Fengwu and others integrated ZigBee and GPRS technology to design and develop a harmful gas monitoring system for chicken coops, using short-range wireless sensor networks to monitor environmental parameters in the chicken coop, and then transmitting the data to the upper computer port through long-distance GPRS wireless transmission network, using the upper computer to issue feedback control commands to the node relay to achieve the expected control of the environment within the chicken coop.

In modern farming, accurately monitoring daily information about poultry production is crucial, as it can effectively assess the production level and reflect the standard of the poultry raising process, providing technical guidance for production management.

Chen Yangyang and others designed a poultry production process management system based on IoT technology, which adopts a browser/server (B/S) model, records production process information of poultry and real-time environmental parameters transmitted by smart sensors, weighing of perches, water and electricity usage, audio and video data, effectively extracting massive and diverse data, achieving effective visual expression of data, and constructing statistical analysis reports on environmental data, production material consumption data, and profit and loss curves tailored to enterprise user production needs, providing basic data for enterprises to optimize the production process. This management system can also be accessed, browsed, operated, and controlled via mobile phones and computers, realizing remote management of the farming process and fully utilizing IoT technology in the poultry industry. Yu Qun and others designed a breeding hen production management system based on a three-level IoT architecture and C/S development model, achieving production management functions such as introduction of breeding flocks, daily management, hatching, and immunization, as well as environmental monitoring and traceability tracking, realizing intuitive quantification of indicators at various production stages, providing data reference for breeding and variety improvement.

Hefei Wanhe Company invented an IoT-based layer chicken breeding system, including chicken coops, feeding trays, watering trays, egg collection trays, manure collection trays, routers, and data statistics servers, using weight sensors, water quantity sensors, and pressure sensors to transmit data via WiFi signals, automatically monitoring the individual and group feeding amounts, drinking amounts, excretion amounts, egg-laying times, egg weights, and the number of eggs laid under natural conditions, providing references for scientific breeding.

In recent years, incidents of livestock product quality and safety have occurred frequently, and food safety issues have attracted widespread attention from society. How to ensure the quality and safety of livestock products has become a hot topic. Animal identification and traceability systems can effectively trace and track livestock product production, processing, and sales at different stages, promptly addressing any issues that arise.

Chen Changxi and others developed an IoT-based broiler farming environment monitoring and early warning system, integrating it into a broiler traceability and supervision platform, which is developed using a combination of B/S and C/S architecture, enabling full traceability and supervision of broiler feed, medication, vaccines, slaughter processing, storage and transportation, and sales, while government management departments can also conduct inspection, product quarantine, random sampling, and statistical inquiries, achieving early warning for broiler epidemics and quality safety.

Xu Xiaohua and others used Microsoft C# as the development language, SQL Server as the database management system, and RFID tags as the information transmission carrier, adopting a .NET three-tier architecture design, developing a full-process quality traceability platform for broilers, which can realize full traceability from chick, broiler production, slaughter, processing, sales to consumer evaluation.

Zhan Xiaolin and others built a system for egg traceability based on smartphones using QR codes, allowing consumers to conveniently and quickly query information about the origin, rearing environment, and feed of eggs.

Shen Yangguang and others used Java EE (enterprise edition) technology architecture, with Spring Side3 as the development framework, combined with MySQL database management system and Tomcat server, to design a quality control and traceability system for broiler products, enabling quality control and traceability of broilers from production, slaughter, storage, transportation, and sales, ensuring the quality and safety of broiler products at all stages of production management.

Diseases are important factors affecting poultry production. IoT technology can provide technical support for poultry disease monitoring and diagnosis by equipping sensors that perceive life information, combined with indoor cameras to monitor individual poultry in real-time, timely understanding individual physiological status. The sensors transmit the physiological data of the poultry (such as weight, temperature, step count, etc.) over the network to a database and compare it with the latest data in the database, achieving real-time monitoring of diseases.

Luan Hongliang adopted a B/S structure model for design, using Visual Basic.NET, Asp.NET development languages, and SQL Server 2005 database to develop a poultry disease auxiliary diagnosis and management information system, utilizing the poultry disease knowledge database equipped with the backend database for diagnosis, and automatically generating disease diagnosis results based on user descriptions of suspected diseases or actual symptoms, providing reasonable treatment plans. This system can meet the needs of clinical diagnosis of chicken diseases and farm management, providing references for users.

Henan University of Science and Technology developed an IoT-based livestock disease prevention and control system, including temperature and humidity sensors, pulse sensors, data relay stations, intelligent control terminals, and monitoring devices, achieving remote real-time monitoring of livestock disease diagnosis and production.

Currently, the application of IoT technology in poultry disease monitoring and diagnosis is still in the exploratory stage, mainly due to a lack of specialized and sensitive sensors.

Main Challenges Faced

The coding in the “Livestock and Poultry Identification and Breeding File Management Measures” issued by the Ministry of Agriculture has not aligned with international standards, and no species codes have been specified for poultry, so it needs to be revised as soon as possible.

A complete IoT system primarily requires various core sensors, which have vastly different market prices, and also requires matching auxiliary facilities and equipment, resulting in high construction costs for the system.

Currently, although relevant units have developed some IoT application systems and platforms, there is still a lack of mature technological application models, with significant gaps compared to developed countries.

Poultry farming is primarily based on smallholder farming, with most practitioners having low educational backgrounds, and beyond basic breeding knowledge, there is a severe lack of professional knowledge in IoT.

In recent years, although the government has increasingly emphasized the importance of intelligent equipment and information technology in the poultry industry, believing that “information technology is the high ground of modern agriculture,” relevant government policies often focus on breed improvement, biosecurity, and waste resource utilization, with little involvement in poultry IoT technology.

Although some enterprises and institutions have established enterprise-level or cross-enterprise IoT data platforms, such as the internal data integration platform of Wens Foodstuff Group, “China Feed Network Database,” and “China Domestic Animal Genetic Resources Network Database,” these are still not true big data platforms.

Outlook

Scale, standardization, and intelligence are the development trends of China’s poultry farming industry. With the continuous advancement of communication technology, especially the latest 5G technology, IoT technology is bound to develop towards low-cost, adaptive, high-reliability, and low-power consumption, building IoT systems and developing modern intelligent equipment to achieve full coverage of the entire farming process and product flow, thereby safeguarding the poultry farming industry and achieving sustainable and healthy development of the poultry industry.

Paper|Exploration and Application of GIS-Based Biological Migration Corridor Construction Methods

♔ Edited by: Xia Meng ♔ Typeset by: Xiao Tong