↑ Click on the above

“Smart Manufacturing Home”

Follow us

Source: Linfei Information Technology Port

Foreword

Previously, we reviewed domestic and international IoT platforms:

Predix, Mindsphere, Thingworx….. A comprehensive review of IoT PaaS platforms

We also shared many related technical examples:

When WinCC OA meets Mindsphere, the digital journey of automation engineers

When Schneider PLC meets Amazon AWS IoT, the digital journey of automation engineers

When Raspberry Pi + S7-1500 meets Alibaba Cloud – the digital journey of automation engineers

Today’s main content:

01 Industrial IoT Architecture

02 Key Technologies of Industrial IoT

03 Comparison between Industrial IoT and IoT

04 Applications of Industrial IoT

01 Industrial IoT Architecture

We explain the architecture of Industrial IoT from different perspectives to gain a deeper understanding of its connotation.

1.1 Description of IIoT Architecture Based on System Concept

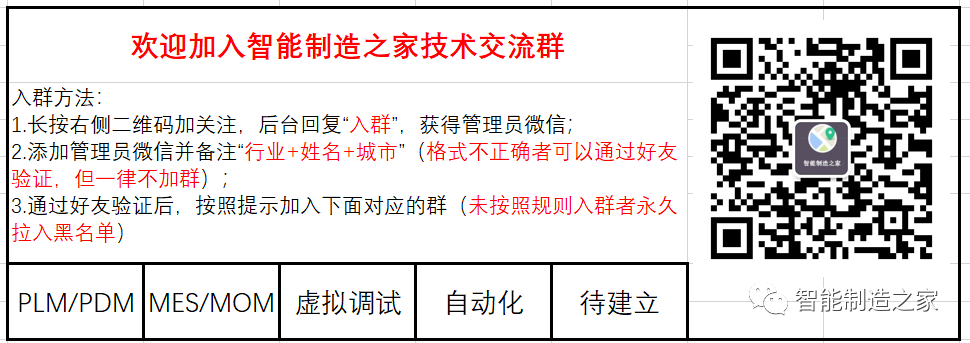

From the perspective of industrial systems, literature [4] provides a concise structure of the IIoT system, divided into three layers: physical layer, communication layer, and application layer.

Figure1 Industrial IoT System Structure[4]

Physical Layer

Composed of widely deployed physical devices, such as sensors, actuators, manufacturing equipment, facility utilities, and other industrial manufacturing and automation-related objects.

Communication Layer

Composed of numerous integrated communication networks, such as Wireless Sensor and Actuator Networks (WSANs), 5G, M2M, SDN, etc. In smart industrial applications, various network technologies will inevitably support a considerable number of sensors and actuators interconnection.

Application Layer

Composed of various industrial applications, including smart factories, smart supply chains, etc. These smart industrial applications utilize numerous sensors and actuators to achieve real-time monitoring, precise control, and effective management.

The above structure is simple and clear, facilitating the understanding of the basic concepts of IIoT.

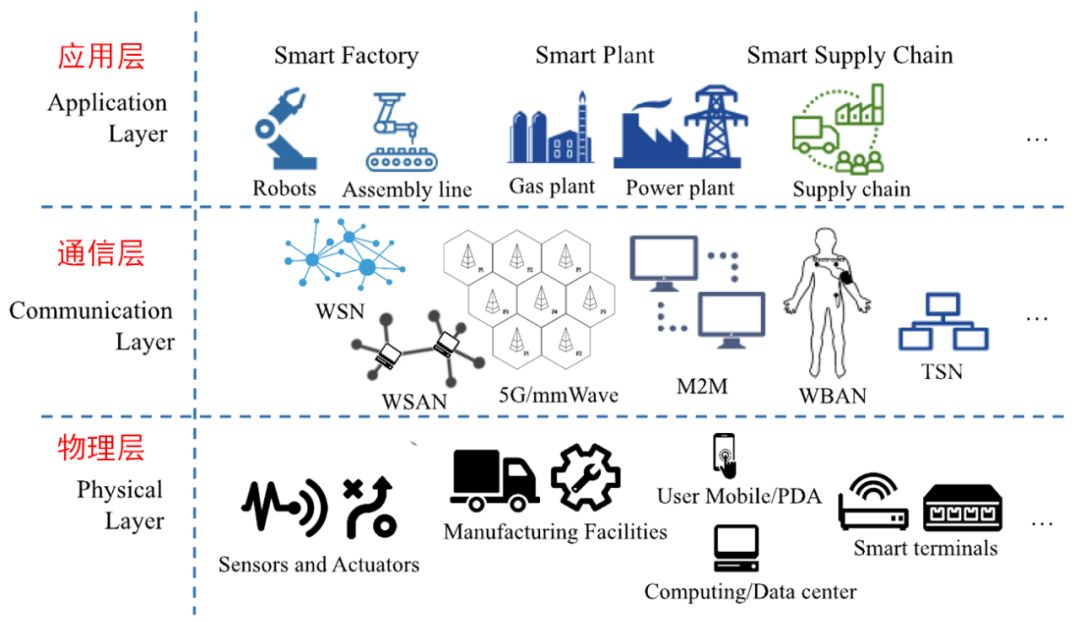

1.2 Description of Service-oriented IoT Architecture

Figure2 Service-oriented IoT Architecture[2]

The sensing layer is a fundamental characteristic of IoT, consisting of sensing (e.g., RFID and smart sensors) and corresponding data perception/acquisition protocols.

IoT can be seen as a network capable of remote connection and control globally. The basic requirement for remote connection and control of objects is sensing (perception). In the sensing layer, wireless intelligent systems with tags or sensors can automatically sense and exchange information between different devices. These technologies significantly enhance the ability of IoT to perceive and recognize objects or environments. In some industries, it is necessary to assign a universally unique identifier (UUID) to each possible service or device, allowing devices with UUIDs to be easily identified and retrieved.

Network Layer

The network layer can obtain and aggregate information from existing IT infrastructures (such as business systems, transportation systems, power grids, medical systems, ICT systems, etc.). In IIoT, service-providing devices are usually deployed in heterogeneous networks, and all relevant devices are introduced into the service network. This process may involve QoS management and meeting the demands of user applications. On the other hand, for dynamically changing networks, automatic network discovery is crucial. Devices need to automatically assign roles for deployment, management, and scheduling, and switch to any other role as needed. These features enable devices to cooperate in completing tasks. To design the network layer of IIoT, designers need to address issues such as network management techniques for heterogeneous networks, energy efficiency, QoS requirements, service discovery and retrieval, data and signal processing, security, and privacy, etc.

Service Layer

Interface Layer

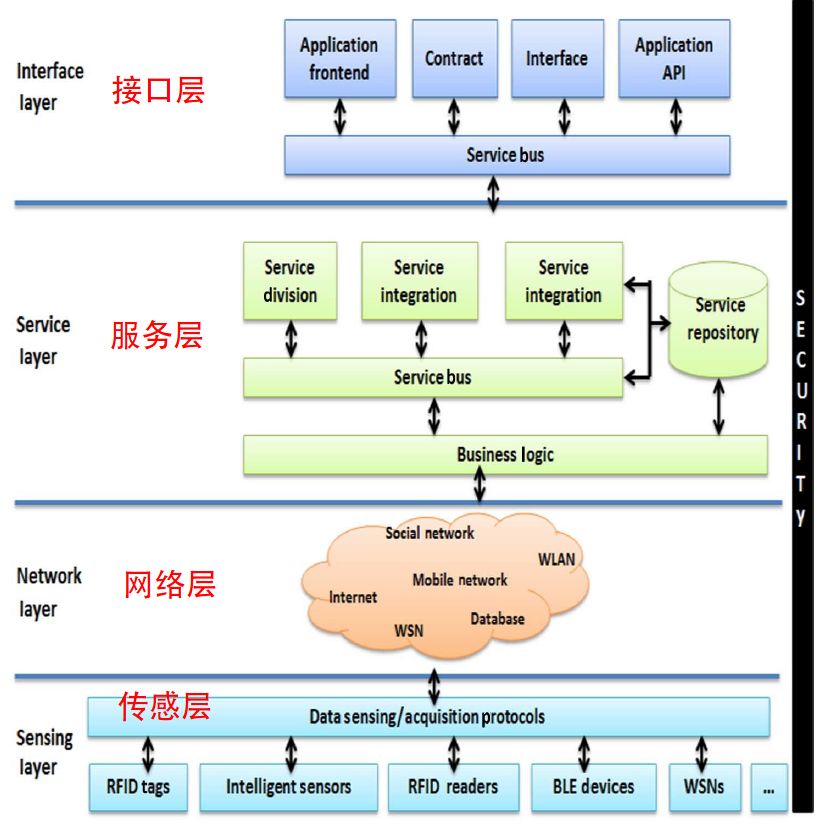

1.3 Description of Cloud-based IIoT Infrastructure

Figure 3 Cloud-based Industrial IoT Architecture [5]

Device Layer

Most IoT devices have limited resources, including memory size, computing power, and communication bandwidth. Furthermore, these devices and their adopted network technologies exhibit high heterogeneity, posing significant challenges for interconnection of IIoT devices. Due to heterogeneity, interoperability among devices should be prioritized, allowing heterogeneous devices to be transformed in a user-acceptable form both syntactically and semantically.

Gateway Layer

Cloud Service Layer

02 Key Technologies of Industrial IoT

2.1 Identification and Tracking Technologies

Identification and tracking technologies involved in Industrial IoT include RFID systems, barcodes, and smart sensors. A simple RFID system consists of an RFID reader and an RFID tag. RFID systems have the capability to identify, track, and trace devices, and are increasingly applied in logistics, supply chain management, and healthcare service monitoring. RFID systems can also provide real-time information about the involved devices, reduce labor costs, simplify business processes, improve the accuracy of inventory information, and enhance business efficiency. There is still great potential for applications based on RFID.

To further promote the development of RFID technology, RFID can be combined with wireless sensor networks to better track objects in real time. Especially the emerging wireless intelligent sensor technologies, such as electromagnetic sensors, biosensors, external sensors, sensor tags, standalone tags, and sensor devices, further facilitate the realization of industrial services. Integrating the data obtained from smart sensors with RFID data can create IoT applications more suitable for industrial environments.

2.2 Communication Technologies

IIoT involves various heterogeneous networks, such as wireless sensor networks, wireless mesh networks, and wireless local area networks. These networks facilitate the exchange of information in the industrial IoT. Gateways can facilitate communication between various devices on the network, and can also be used to handle complex nodes involved in communication on the network. Different devices may have different QoS requirements, such as performance, energy efficiency, and security. Many devices require batteries, so reducing energy consumption of these devices is a primary concern. Industrial IoT also involves the use of existing internet protocols, primarily communication protocols and standards such as: RFID, NFC, IEEE802.11 (WLAN), IEEE 802.15.4 (ZigBee), IEEE 802.15.1 (Bluetooth), multi-hop wireless sensor networks, machine-to-machine (M2M), and traditional IP technologies such as IP, IPv6, etc.

2.3 Network Technologies

2.4 Service Management

03 Comparison between Industrial IoT and IoT

Overall, IIoT can be seen as a subset of IoT.

(1)Different Service Types

Generally, the IoT remains human-centric, where “things” interact and connect among smart electronic devices to enhance human perception and response to the surrounding environment. Typically, IoT communication can be divided into machine-to-user communication and client-server interaction.

Communication in IIoT is machine-oriented and can span various markets and applications. IIoT scenarios include: i) monitoring applications, such as monitoring factory production processes, and ii) creating applications for self-organizing systems, such as automated industrial factories.

(2)Different Connected Devices

IoT focuses more on designing new standards to connect new devices to the internet ecosystem in a flexible and user-friendly manner. In contrast, current IIoT designs emphasize integrating and connecting factories and machines to provide more efficient production and new services. For this reason, IIoT can be seen more as an evolution rather than a revolution compared to IoT.

(3)Different Network Requirements

IoT is more flexible, allowing temporary and mobile network structures, with lower timing and reliability requirements (except for medical applications). On the other hand, IIoT typically uses fixed network structures, with fixed nodes and centralized network management. IIoT communication is machine-to-machine connection that must meet strict real-time and reliability requirements.

(4)Different Data Volumes

The data generated by IoT comes from applications, so the amount of data transmitted is moderate or large. In contrast, IIoT currently involves more big data analysis, such as predictive industrial maintenance, resulting in a very large volume of data transmitted in IIoT.

04 Applications of Industrial IoT

4.1 Overview of IIoT Applications

Industrial IoT is an important branch of IoT, with broad applications, especially in energy, transportation (railways, stations, airports, ports), and manufacturing (mining, oil and gas, supply chain, production), where it will play a significant role.

When discussing the applications of Industrial IoT, two points are noteworthy:

First, industrial applications similar to the IoT concept have a long history. For example, process control and automation systems, industrial Ethernet and wireless local area networks (WALN), programmable logic controllers (PLC), wireless sensors, and RFID technology tags, etc. However, these applications are primarily based on “automation” considerations and do not connect with external enterprises.

Second, the concept and technology of Industrial IoT can extend applications to some “non-industrial sectors,” such as health, security, transportation, etc.

In the “Industrial IoT White Paper” (2017 edition, China Electronics Technology Standard Research Institute) [5], four application projects of Industrial IoT are described, including: leasing applications based on machine tool IoT, new insurance models based on Industrial IoT, full-process automatic control of roller transfer between grinding rollers, and logistics automation based on Industrial IoT. However, this white paper does not provide a more comprehensive description of IIoT applications.

4.2 Classification of IIoT Applications

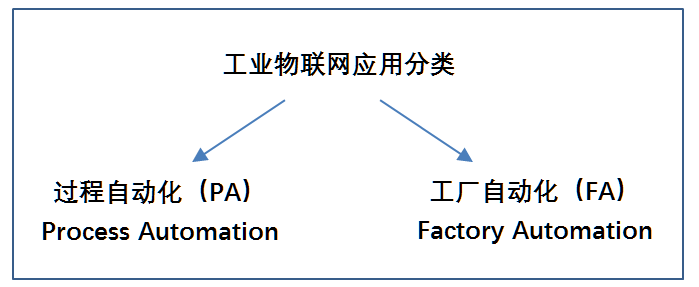

Applications of Industrial IoT (IIoT) can be divided into Process Automation (PA) applications and Factory Automation (FA) applications [4].

4.2.1 Process Automation

Process automation is characterized by an industrial process, such as the “autonomous” processes in chemical, oil, and power plants, achieving control and management with little or no human intervention. Process automation systems typically integrate sensors, controllers, and actuators to achieve information collection, interaction, and process driving.

Power system automation (PSA) is an example of process automation, aimed at automatically controlling, monitoring, and protecting power generation, distribution, and consumer systems through various instruments and control devices. PSA includes three key components: data acquisition, remote monitoring, and control. Data acquisition is used to collect data from various sensing and control devices, which can be processed locally or at data centers; remote monitoring is used to monitor the status of the power system, alerting the operation center of anomalies to prevent power outages; PSA control functions to operate the power system from the operation center to control substations.

4.2.2 Factory Automation

Factory automation, or the automation of manufacturing processes, utilizes robotic systems and assembly line machinery to enhance production capacity and efficiency. For example, the appearance and driving force of robotic arms are often similar to those of humans, and they can perform functions as human operators do but with greater robustness, productivity, precision, and efficiency. In achieving the same goals, assembly lines typically break complex tasks into smaller sub-tasks and perform step-by-step operations according to the designed workflow.

4.2.3 Basic Performance Characteristics of IIoT

The performance requirements of Industrial IoT significantly differ from consumer-oriented IoT, especially in terms of timing, scale, and reliability. These three basic performance characteristics can be described using cycle time, number of nodes, and reliability.

Cycle time: The time required to receive commands from the control center and send sensor data back to the control center. Cycle time depends on different applications. For instance, the cycle time for general process automation is about several hundred milliseconds.

Number of nodes: The number of nodes covered by a controller in a workspace, representing the size of the system.

Reliability: Characterized by the quality of information transmission, which can be measured using Packet Error Rate (PER). Clearly, IIoT has high reliability requirements; for some industrial environments, the requirement is PER ≤ 10-9..

4.3 Industry Applications of IIoT

In addition to the obvious applications in factory automation, this section briefly introduces the applications of Industrial IoT in several industries.

4.3.1 Smart Grid

The power grid includes three basic functions: generation (power generation), transmission, and distribution. For traditional power grids, due to many factors, such as inefficient appliances among consumers, lack of smart technologies, inefficient power delivery routing and distribution, unreliable communication and monitoring, especially the lack of energy storage mechanisms, there is a huge waste of energy in the grid. In addition, the grid faces other challenges, including growing energy demand, reliability, security, emerging renewable energy, and aging infrastructure issues. To address these issues, the smart grid, based on information processing and communication technologies, has emerged, and Industrial IoT will play an important role in the smart grid. IIoT will greatly improve the efficiency and safety of smart grids by providing smart devices or IoT devices (such as sensors, actuators, and smart meters) for monitoring, tracking, analyzing, and controlling.

4.3.2 Transportation

Industrial IoT will play an increasingly important role in the transportation and logistics sectors. As more objects are equipped with barcodes, RFID tags, or sensors, transportation and logistics companies can achieve real-time monitoring of mobile transport from the point of origin throughout the supply chain. Furthermore, IIoT is expected to provide promising solutions for the transformation of traffic systems and the automotive manufacturing industry. Industrial internet technologies can track the current location of transportation vehicles, monitor their movements, and predict their future locations. Other applications include using unmanned marine vehicles to monitor seabed conditions and collect data across oceans, etc.

4.3.3 Mining Safety Production

Due to the working conditions in underground mines, safety issues in mining are receiving increasing attention. To prevent and reduce the occurrence of mining accidents, IIoT is needed to perceive disaster signals in mines for disaster prediction and early warning, thereby improving safety levels in underground production. By using RFID and wireless communication technologies on the surface and underground, the positions of underground miners can be tracked, and key data collected from sensors can be analyzed to strengthen safety measures. Additionally, chemical and biological sensors can be used for early disease detection and diagnosis of underground miners. These chemical and biological sensors can extract biological information from the human body and organs, detecting harmful dust, harmful gases, and other environmental hazards that could cause accidents.

4.3.4 Food Supply Chain

Due to the large geographic and temporal scale and complex operational processes of the Food Supply Chain (FSC), it exhibits characteristics of decentralization and complexity. This complexity brings many issues to food quality management, operational efficiency, and public food safety. IIoT can accurately track the entire process of food production, processing, storage, distribution, and consumption. Future FSC systems will be safer, more efficient, and sustainable. A typical industrial IoT solution for FSC includes three parts: on-site devices, such as WSN nodes, RFID readers/tags, user interface terminals, etc.; a backbone system connected by distributed computer networks, including databases, servers, various small computing devices, etc.; and communication infrastructure, such as wireless local area networks, cellular networks, satellites, power line communication, Ethernet, etc. Since the industrial internet system provides ubiquitous networking capabilities, all these elements can be distributed throughout the FSC. Furthermore, IIoT also provides effective sensing capabilities to track and monitor the food production process.

4.3.5 Health Services

Based on the ubiquitous identification, sensing, and communication capabilities in Industrial IoT, all objects in the healthcare system (people, devices, medications, etc.) can be tracked and continuously monitored. Through global connectivity, all healthcare-related information, including logistics, diagnosis, treatment, rehabilitation, medications, management, finance, and even daily activities, can be effectively collected, managed, and shared. For example, a patient’s heart rate can be collected by sensors and then sent to a doctor’s office. Using personal terminals and mobile internet access, healthcare services based on Industrial IoT can be more mobile and personalized.

References

[1] Xia Zhijie, Architecture and Key Technologies of Industrial Internet, China Mechanical Engineering, 2018,29(10):1248-1259

[2] Li Da Xu, WuHe, Shancang Li, Internet of Things in Industries: A Survey, IEEE Transactions on Industrial Informatics, volume.10, No.4, November 2014

[3] Emiliano Sisini, Abusayeed Saifullah, et. al., Industrial Internet of Things: Challenges, Opportunities, and Directions, IEEE Transactions on Industrial Informatics, volume.14, April 2018

[4] Hansong Xu, We Yu, et. al., A Survey on Industrial Internet of Things: A Cyber-Physical Systems Perspective, IEEE Access, Volume 6, 2018

[5] Gang Wang, Zhijie Jerry, et. al., Shi_ChainSplitter: Towards Blockchain-based Industrial IoT Architecture for Supporting Hierarchical Storage, 2019 IEEE International Conference on Blockchain (Blockchain).

[6]“Industrial Internet White Paper” (2017 edition), China Electronics Technology Standard Research Institute, 2017.09

[7] Yasir Saleem, Noel Crespi, et. al., Internet of Things-Aided Smart Grid: Technologies, Architectures, Applications, Prototypes, and Future Research Directions, IEEE Access, Volume 7, 2019

Disclaimer: The articles published in this public account are original or edited based on online searches, and the copyright of the articles belongs to the original author. Due to numerous reprints, it is impossible to find the actual source. If the source is incorrectly marked, or if there are infringements regarding the images, materials, download links, etc. used in the article, please contact us for consultation or deletion, thank you.

We are a group of enthusiasts in smart manufacturing technology, we enjoy sharing, we are positive and upward, we may be a bit reclusive, but we are full of love, and we look forward to your joining us

— Smart Manufacturing Home

Multiple Benefits

1. If you have a demand for smart manufacturing-related materials, you can leave a message in the comment area~

2. Enter the knowledge star planet Smart Manufacturing Home, enhance self-awareness, meet more friends, master more resources, and more skills~