On May 29, local time in Japan, Nikkei Asia exclusively reported that Renesas Electronics, a leading semiconductor company in Japan, has officially abandoned its plans to use silicon carbide (SiC) for the production of power semiconductors. The mass production plan, which was scheduled to start in early 2025 at the Takasaki plant in Gunma Prefecture, Japan, has been canceled, and the dedicated R&D and production team has been disbanded.

It is noteworthy that Wolfspeed, a leading American silicon carbide supplier and formerly known as Cree, has recently been reported to be facing a financial crisis. Due to excessive expansion leading to cash flow issues, Wolfspeed plans to file for bankruptcy reorganization, and its 8-inch silicon carbide wafer factory in New York has suspended operations.

In 2023, to secure production capacity, Renesas paid Wolfspeed a $2 billion advance and signed a 10-year supply agreement to ensure the supply of 150mm silicon carbide bare wafers and epitaxial wafers. Once the John Palmour Manufacturing Center for Silicon Carbide in North Carolina becomes fully operational, it will also supply Renesas with 200mm silicon carbide wafers and epitaxial wafers.

However, the current situation is that if Wolfspeed goes bankrupt, Renesas may face the risk of not being able to recover this funding.

Two Main Reasons: Reduction of European Subsidies and Impact of the Chinese Supply Chain

Market analysis indicates that while the demand for silicon carbide is expected to grow in the long term, its short-term performance has been disappointing. According to data from Tokyo-based Fuji Keizai, the silicon carbide market is expected to grow only 18% in 2024, reaching 391 billion yen (approximately $2.69 billion), far below the 27% growth forecast to 491.5 billion yen made in February 2024.

Market analysis points out that Renesas’s exit from the silicon carbide sector is primarily driven by two factors:

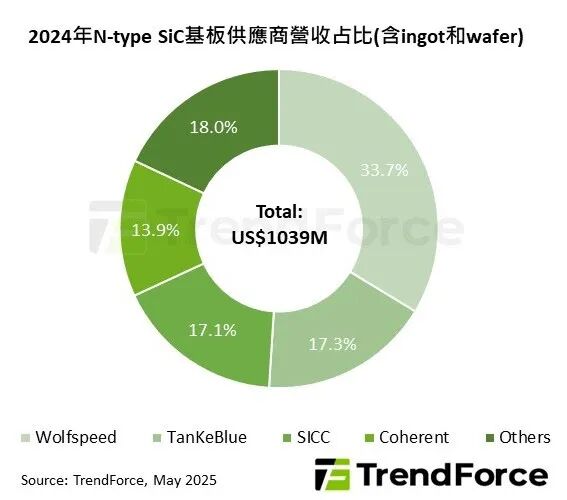

First, the reduction of electric vehicle subsidies in Europe has triggered a chain reaction in demand. The European Union will significantly cut purchase subsidies for pure electric vehicles starting in 2025, with demand expectations in major markets like Germany and France declining by over 30%. Renesas originally targeted European automakers (such as Volkswagen and BMW) as core customers for silicon carbide devices, but the reduction in subsidies has led automakers to shift to lower-cost silicon-based IGBT solutions, directly undermining its business model. TrendForce data shows that the global shipment growth rate of silicon carbide substrates is slowing due to weak automotive and industrial demand, with revenue from N-type SiC substrates expected to decline by 9% year-on-year to $1.04 billion in 2024.

Second, the localization advantages of Chinese silicon carbide companies have created a crushing effect. Chinese manufacturers represented by BYD Semiconductor, Tianyue Advanced, and Starpower have captured 35% of the global market share (2024 Yole data) by leveraging a complete domestic silicon carbide wafer supply chain (such as Tianyue Advanced’s mass production of 8-inch silicon carbide substrates) and cost advantages (with prices for equivalent devices being 40%-50% lower than those in Europe and the U.S.). Renesas originally planned to achieve mass production of 12-inch silicon carbide wafers at its Takasaki plant, but the technological advancements of Chinese companies (such as BYD’s SiC module yield improving to 98%) and price war strategies have drastically reduced its competitiveness.

The silicon carbide sector has entered a “China-dominated period,” and Renesas is now focusing on consolidating its core business.

Renesas’s exit is seen as a landmark event in the reshaping of the global silicon carbide industry landscape, and it is not the only company facing difficulties in the silicon carbide chip market. Rohm reported a net loss for the first time in 12 years in fiscal 2024 due to increased investments in silicon carbide semiconductors. STMicroelectronics, which has silicon carbide products for customers including Tesla, has seen its stock price plummet by over 50% since 2024.

According to TrendForce data, in 2024, Chinese companies are expected to see a year-on-year shipment growth of 120% in the silicon carbide power device sector, while the average growth rate for European and American companies is only 35%. Industry insiders point out that the core cost of silicon carbide devices lies in wafer preparation (accounting for 70% of total costs), and Chinese companies have built a full industry chain advantage from substrate, epitaxy to modules through independent research and development of substrate technology (such as Tianyue Advanced’s semi-insulating substrates) and government subsidies (such as special support policies in Shandong and Hunan).

In response to strategic adjustments, Renesas, as a leading company with over 30% market share in automotive MCUs, may refocus its resources on traditional automotive-grade MCUs and silicon-based power semiconductor businesses to meet the intelligent chip demands of automakers like Tesla and BYD.