3D Printing Technology Revolutionizes Building Templates: voxeljet Supports DFAB House in Achieving Lightweight and Functional Integration

voxeljetprints the “smart” concrete ceiling template for DFAB (NEST project), which is highly complex.

voxeljet used 3D printing technology to create highly complex templates for the DFAB House (Digital Fabrication House) project— this project is part of the NEST project (Next Evolution of Sustainable Building Technologies) by EMPA (Swiss Federal Laboratories for Materials Science and Technology). The project utilized a 78 square meter lightweight concrete slab as a ceiling panel for structural optimization and functional integration, designed with complex performance characteristics. In such a project, the value of the powder binder-jetting 3D printing process has been reaffirmed.

At the NEST exhibition in Zurich, voxeljet once again demonstrated how useful 3D printing is for creating highly complex template projects.The DFAB House project (Digital Fabrication House) is a research project by ETH Zurich as part of the Swiss National Centre of Competence in Research (NCCR DFAB), which produced 136 template components using the powder binder jetting process.The process used is voxeljet’s furan resin process.This is a 3D printing technology that combines layers of silica sand with an organic binder (furan resin) through polymerization.

3DPrinting Saves Time, Material, and Money

The smart slab is one of the core elements of the DFAB House, designed, planned, and constructed by the Digital Building Technology (DBT) research group at ETH Zurich under the guidance of Professor Benjamin Dillenburger, within EMPA’s NEST. The template system for this large project was designed by the DBT team. The goal of the project is to demonstrate how improved CAD data combined with 3D printing technology can save resources on construction sites. Compared to columns, the amount of concrete required for slabs is significantly higher, with slabs alone accounting for 80% of the total weight of the building. Accordingly, the potential for savings is enormous, and this goal has been achieved. In the DFAB House, the weight of the slabs only meets the static requirements at each point. More than 60% of concrete was saved compared to traditional construction methods. The 3D printing using the powder binder jetting process is the ideal solution for these highly complex and three-dimensional curved template components. The purpose of the “Smart Slab” is to help the construction industry build more compact and material-efficient structures in the future, with other functions such as light fixtures, drilling, or sprinkler system openings being integrated into the 3D printing.

Flexible and Economical Template Method for Complex Shapes

For such demanding projects, many factors support the 3D printing of individual template components.

Project manager Dr. Mania Aghaei Meibodi introduced the main advantages of this method:“With parametric models, adjustments can be made at any time without additional costs.If the shape needs to be modified, the 3D data and 3D printing can be easily adjusted.This allows us to accurately adjust the slab shape based on the three-dimensional scan results of the load-bearing walls.Additionally, very complex geometries can now be created, which were previously impossible.“

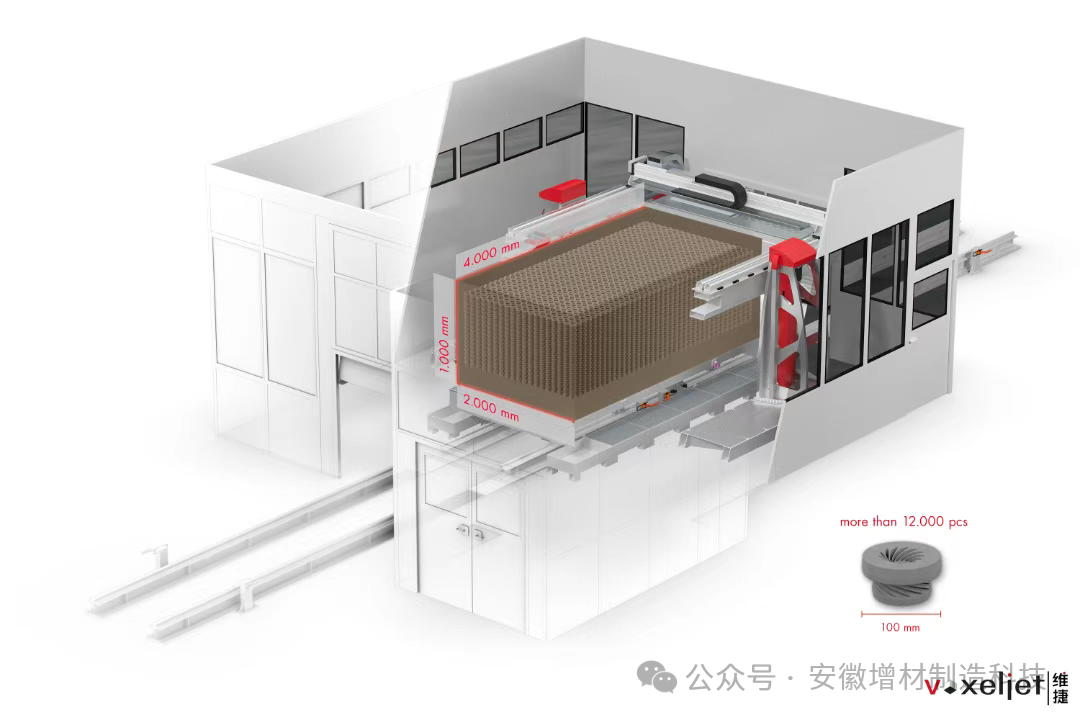

Using voxeljet’s VX4000—the world’s largest sand mold 3D printing system—template components measuring 4.00 x 2.00 x 1.00m can be printed. The corresponding post-processing allows each component to withstand a concrete pouring pressure of 100kN/m². The 136 components printed by voxeljet for the DFAB House have a total volume of over 6,000 liters. The largest component has a volume of about 70 liters. The 3D printed components are prefabricated by voxeljet and impregnated with polyester resin by ETH Zurich.

Glass fiber reinforced concrete is continuously sprayed onto the 3D printed templates.

Subsequently, these components are assembled into 7-meter-long slab template components and coated with a release agent. Before concrete pouring, a thin layer of fiber-reinforced shotcrete is applied. Finally, laser-cut wooden templates are used for formwork and concrete pouring. Therefore, after demolding, the finished components can be directly transported to the construction site for assembly.

In summary: Utilizing powder binder jetting 3D printing can save time, materials, and funds. In the long run, the use of 3D printed templates will bring revolutionary changes to the widespread application of concrete construction (templates, template layers, exterior walls, etc.) and provide companies with a decisive market advantage with unprecedented novel designs.

What is Powder Binder Jetting 3D Printing Technology?

Powder binder jetting 3D printing technology is a rapid prototyping manufacturing process that uses particulate materials such as sand or plastic. The voxeljet 3D printing system lays down thin layers (150-300µm) of powder material on the printing platform. Subsequently, high-performance print heads apply the binder to the parts that need to be created. Selectively, the material is bonded together to form cross-sections of the parts. The printing platform is then lowered by one layer thickness, and another layer of powder and binder is applied. This process is repeated until the desired part is completed. A key prerequisite for 3D printing is that there must be printable 3D data. Afterward, the 3D printed templates can be used just like traditional concrete templates.

Post-processing of 3D printed template parts. Uncured sand particles are being removed from the print bed.

3DPrinting Technology Applications in the Construction Field

voxeljet provides various 3D printing applications for the construction industry. These applications include printing detailed, highly realistic architectural models that provide perfect and accurate impressions for the future construction industry. Additionally, 3D printed replicas can serve as precise models for sculpting or preserving historical artifacts. One of the most innovative applications is the 3D printing of 21mm thick template layers that can be combined with traditional wooden templates for concrete pouring. voxeljet is one of the global leaders in providing this process.

Smart slabblocks are placedone by one onthe 12cmwidemesh form wall.

Digital Building Technology/DFAB HOUSE

The Digital Building Technology research group at ETH Zurich investigates the interaction between digital design and digital manufacturing, as demonstrated in the Smart Slab project within the DFAB HOUSE. DFAB HOUSE is a collaborative demonstration of the Swiss National Centre of Competence in Research (NCCR) digital manufacturing project at the NEST building of Empa and Eawag. As part of a fully functional building project, researchers from ETH Zurich, along with industry experts and planning specialists, explore and test in unique ways how digital manufacturing can change our design and construction methods.

About voxeljet

voxeljet is one of the world’s leading manufacturers of large-scale rapid 3D printing systems, with service centers in Germany, India, China, the UK, and the USA, producing molds and models economically on demand for industrial customers according to German quality standards. The main applications include sand molds and cores for sand casting, plastic models for additive manufacturing, as well as display models, functional prototypes, and end-use consumer parts. The company’s clients include renowned automotive manufacturers, the aerospace industry, as well as sectors such as mechanical engineering, consumer goods, film and entertainment, art, and architecture.