Introduction

The smart textile market is gradually becoming a new engine for global economic growth. Market research company ReportLinker predicts that the global smart textile market is expected to grow from $2.52 billion in 2021 to $9.3 billion by 2026, with a compound annual growth rate of 28.7%. In the next decade, during the Internet of Things era, smart textiles are likely to change human life alongside artificial intelligence, human-computer interfaces, and cloud technology. This publication has set up a special column on recent advances in smart textiles, aiming to provide readers with a deeper understanding of smart textiles through comprehensive introductions.

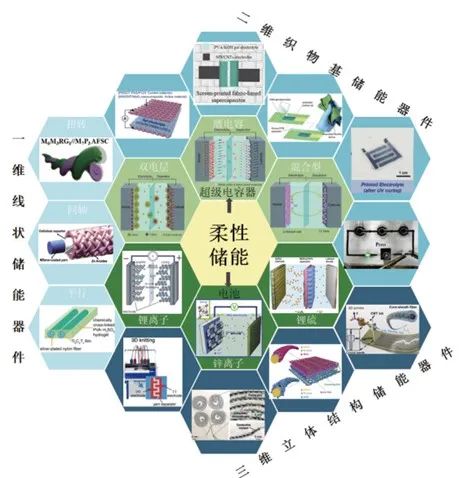

Energy Storage Textile Devices

(1) Selecting suitable packaging materials and processes to maximize the flexibility and electrochemical performance of electrode materials, ensuring the durability of flexible energy storage devices;

(2) Researching issues related to the interface between electrode materials and textile substrates, as well as the flow of liquid electrolytes, to further improve electrochemical stability and eliminate safety hazards during the use of flexible energy storage devices;

(3) Evaluating and comparing the flexibility and wearable-related performance of flexible energy storage devices to lay a foundation for commercialization and standardization.

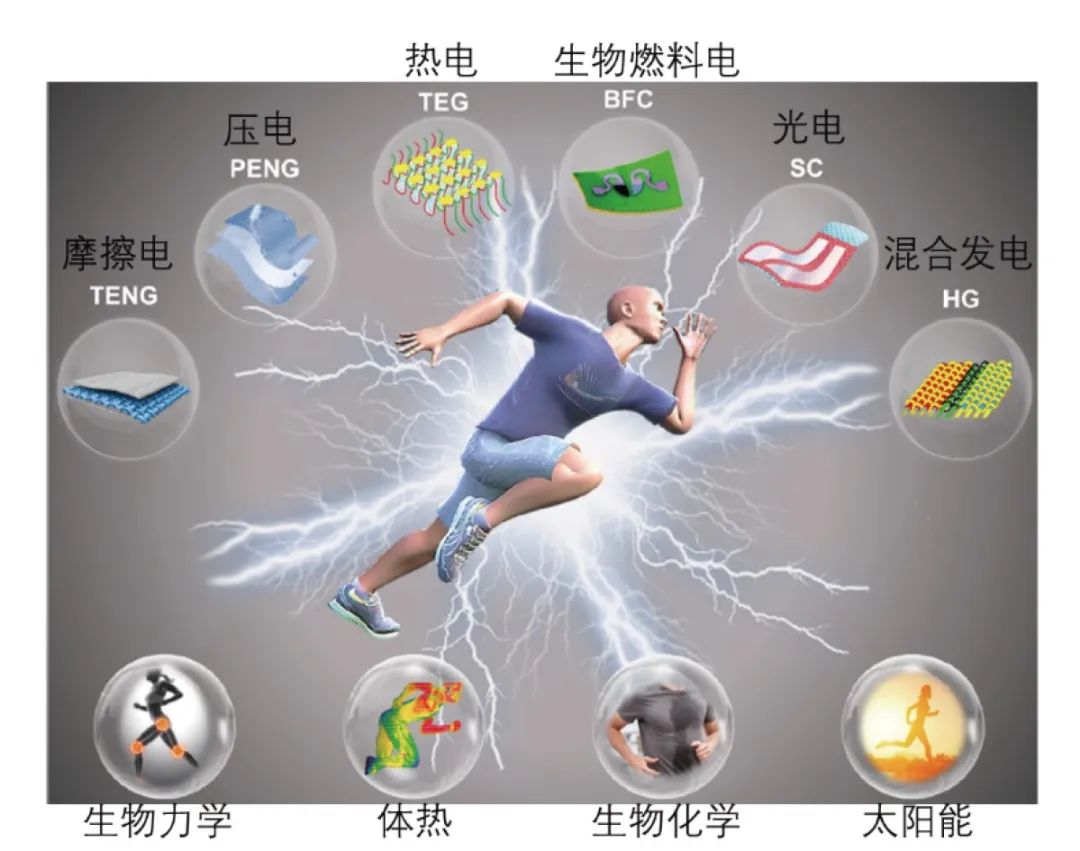

Energy Harvesting Textile Devices

Textile-based Triboelectric Nano-generator

Textile-based Piezoelectric Nano-generator

Textile-based Thermoelectric Nano-generator

Textile-based Photovoltaic Nano-generator