Click the Blue Text to Follow Us

SUBSCRIBE to US

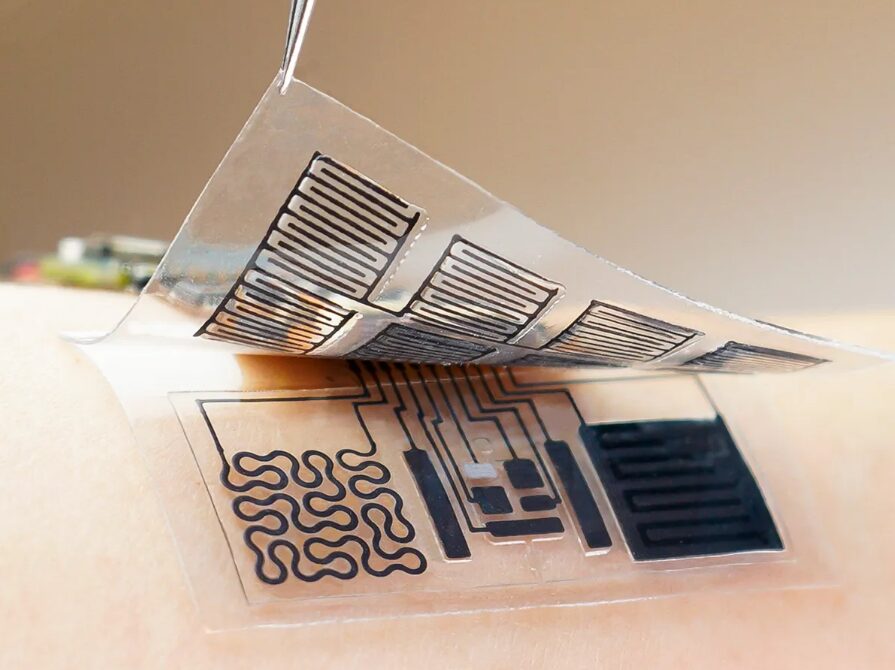

WEI GAO/CALTECH

Wearable devices, like almost all other technologies, require energy. Fortunately, energy is actually ubiquitous under the moderate power budget of wearable devices. It exists in sunlight and radio waves, sweat and body heat from the skin, and the movements and footsteps of a person. Nowadays, technology is maturing to harvest a significant amount of energy gifts, freeing wearable devices from the need for batteries. This seems appealing to a range of companies and researchers.

“Energy is something we take for granted, feeling as omnipresent as air. But we do need a long-term output of this energy,” said Alper Bozkurt, who co-leads the Advanced Self-Powered Systems of Integrated Sensors and Technologies (ASSIST) at North Carolina State University with Veena Misra.

The most well-known wearable energy harvesting technology today is undoubtedly solar energy, which extracts electrons from sunlight or ambient light. But solar energy is just the beginning. Researchers have found multiple options to obtain sufficient microwatt energy to replace the batteries of wearable devices. These include piezoelectric generators and triboelectric generators, which generate electricity by utilizing mechanical strain and the electrostatic properties of materials. At the same time, the well-known phenomenon of electromagnetic induction produces bumps, jumps, and strides, generating small but still useful currents.

While wearable devices typically do not require much power, they must be easy to wear. A backpack with a huge solar panel may be technically feasible, but it is not practical in reality.

The demand and diversity of energy are evident in a recent series of energy harvesting studies, including some that integrate multiple modes of operation.

“

The Power of Sweat

Wei Gao from Caltech has developed a self-powered “electronic skin.” He said that electronic skin is a sensor embedded device that is directly applied to the skin to read and transmit health metrics such as heart rate, body temperature, blood glucose, and metabolic byproducts.

Gao said, “Personalized medicine can revolutionize traditional medical practices. But to combine many different types of sensors, we need different material designs and tools. Among them, energy storage (and generation) is the most important.”

Gao’s first electronic skin was produced in April 2020, made from soft and flexible rubber, utilizing the patient’s sweat to power the device. The device uses an embedded fuel cell that absorbs lactic acid from sweat and combines it with oxygen from the atmosphere to generate water and pyruvate. Through this process, the biofuel generates enough power to keep the sensors and data transmission of the electronic skin powered, continuously charging the capacitor from 1.5 volts to 3.8 volts for about 60 hours. (For capacitors, voltage translates to stored electrons — the voltage drop across the capacitor is proportional to its total charge.)

Months later, Gao and his team developed an electronic skin model that generates electricity from kinetic energy produced by motion, specifically from the relative movement of materials with different electrostatic properties. This second-generation electronic skin incorporates PTFE, copper, and polyimide films, sliding with the movement of a person to produce a maximum power of 0.94 milliwatts.

The team will next turn to 3D printing. In a study published in September in Science Advances (https://www.science.org/doi/10.1126/sciadv.adi6492), they 3D printed the fundamental components of a multimodal health tracking system called e3 skin (electro-fluidic elastic electronic skin) — physical sensors, chemical sensors, microfluidics, and supercapacitors.

This platform utilizes a sensor array, hydrogel-coated electrodes, and micro-supercapacitors powered by solar cells. Gao said the precision of 3D printing allows researchers to create customized components for early warning and diagnosis of health conditions.

“

Wearable Technology and Animals?

Much of the discussion around wearable technology has focused on health or other human needs. However, due to current technological limitations, biologists are also researching energy harvesting for tracking animals. The energy from batteries is always less than that of animals — solar energy does not work for nocturnal animals or organisms in low-light environments. A small device that harvests energy from a runner’s evening jog is clearly not suitable for a large bison that weighs a ton.

These challenges have inspired research teams from the University of Copenhagen, the Danish Technical University, and the Max Planck Institute for Animal Behavior to build a better wearable-sized generator for their purposes: ideally, to track the lives of wild animals. Currently, using batteries and solar-powered devices is not feasible for most mammals to achieve this goal.

In a study published in May in PLoS One (https://journals.plos.org/plosone/article?id=10.1371/journal.pone.0285930 – sec010), they detailed Kinefox, a GPS tracker that charges simply by the movement of wild animals. The team tested their device on three animals: four domestic dogs, a Exmoor pony, and a European bison.

The team was inspired by the automatic winding watch that has existed since the late 18th century, which converts wrist movement into energy. Consequently, the researchers purchased a commercial micro-generator designed for wearable and IoT devices, called Kinetron MSG32. They combined it with lithium-ion capacitors and a custom GPS tracker that transmits data via the Sigfox low-power wireless network.

Troels Gregersen, a guest scientist at the Max Planck Institute for Animal Behavior, said, “We wanted to adjust what has already been created to make it suitable for animal tracking, even though it was not originally designed for that purpose.”

The researchers’ first version installed Kinefox on existing collars and harnesses of the animals for observation and learning.

However, Gregersen said, “The first collar we put on the bison was immediately destroyed. They are 900-kilogram animals that run. This is not a use case for human wearable devices.”

Based on the results of the first version, the team ultimately created a custom tracker and collar. They glued the pendulum automatic watch mechanism of the micro-generator onto a ferromagnetic ring, placing the combination around a coil of copper wire. As the pendulum swings back and forth with the animal’s movement, it generates alternating current in the coil, which the voltage doubling circuit converts to direct current.

Gregersen said, “It is valuable to place a tracker once when the animal is born. If something can transmit new types of data, or if it can last longer, then its application is valuable.”

Kinefox is open-source, with files published on GitHub. Moreover, researchers at the Max Planck Institute stated that traditional wildlife trackers cost between 3500 to 4000 euros, while the materials for Kinefox cost about 270 euros. Gregersen said the team is in talks with Kinetron, based in Tilburg, Netherlands, to produce micro-generators specifically designed for animals.

“

Challenges: Sustainability and Industry Collaboration

Looking to the future, some researchers are focusing on combining unique materials and creating energy harvesting systems with more sustainable materials. A team, including researchers from Tohoku University in Japan (https://www.sciencedirect.com/science/article/pii/S1359835X2300163X?via%3Dihub), recently developed a durable and efficient energy harvester that combines piezoelectric composites with carbon fiber reinforced polymer (CFRP).

The group made their device using CFRP, potassium sodium niobate (KNN) nanoparticles, and epoxy resin. Yu Yaonan, a graduate student at Tohoku University and a co-author of the study, said that even after 100,000 cycles, the device can still store the power it generates.

Yu said that this combination of strength and energy generation can be used for several types of wearable devices and IoT applications, including infrastructure systems for reinforced bridges and highways that can sense when cracks, potholes, or other damages occur.

Additionally, Bozkurt from the ASSIST center stated that the optimal application area would be data analytics, as well as matching energy harvesting capabilities to collect and transmit data that users truly need.

Source | IEEE Electrical and Electronics Engineers

Editor | Lu Sidi

Proofreader | Wang Gang

-End-

Click the link below to view historical articles