“PLC Temperature and Humidity Monitoring: Accurate Collection of Environmental Data Reduces Equipment Failure Rate by 90%!”

Hello everyone! Today we are going to address a problem that keeps factory owners awake at night—equipment frequently acting up. Do you think employees are slacking off? In fact, it could be the temperature and humidity causing the trouble! It’s like installing an “environmental alarm” on the production line, preventing equipment from “overheating” or “catching a cold”. How effective is this method? Keep reading!

Blood and Tears Case: Don’t Let Temperature and Humidity Steal Your Profits

Last month, a pharmaceutical factory experienced uncontrolled temperature and humidity for 3 hours, resulting in the complete loss of a batch of vaccines, costing them 5 million! Even more heartbreaking, they initially planned to use a 200 yuan sensor for monitoring, but ended up losing a lot more by trying to save a little. Another food factory faced a shutdown of their packaging machine due to excessive humidity, halting production for 3 days and causing all customer orders to be lost… These tragedies boil down to not taking environmental data seriously!

Is your PLC only monitoring machine speed? Wake up! Temperature and humidity are the “invisible bodyguards” of your equipment. When they fail, you’ll quickly understand what it means for “machines to lie flat and bosses to feel cold”.

Three-Tier Defense System: Let Data Speak

Sensing Layer: Equip the Workshop with “Electronic Skin”

Stop using outdated single sensors! Distributed temperature and humidity networks are now in vogue, like spreading “electronic tentacles” throughout the workshop. For example, a chip factory installed laser temperature and humidity meters at 18 critical points, achieving data collection accuracy of 0.5%!

Analysis Layer: PLC Becomes a “Data Detective”

Do you think PLCs can only open and close valves? Upgraded PLCs can now perform trend predictions. For instance, if humidity fluctuates more than 3% for 2 consecutive hours, it immediately activates the dehumidification plan, more reliable than the experience of a seasoned worker!

Execution Layer: Automatic Adjustment Without Pause

Have you seen the automatic mode of smart air conditioners? The industrial version is even more powerful! In a chemical factory, the PLC interacts with the fresh air system, automatically intervening to adjust when temperature and humidity exceed 0.1%, responding 20 times faster than an employee running to the site!

Avoid Pitfalls: Steer Clear of These Traps!

❗ Is installing sensors on the ceiling enough?

A certain auto parts factory installed 8 sensors on the roof, but the ground humidity exceeded the limit without any alarms! Remember: Focus on monitoring the “microenvironment” within 30cm around the equipment!

❗ Is communication delay not a concern?

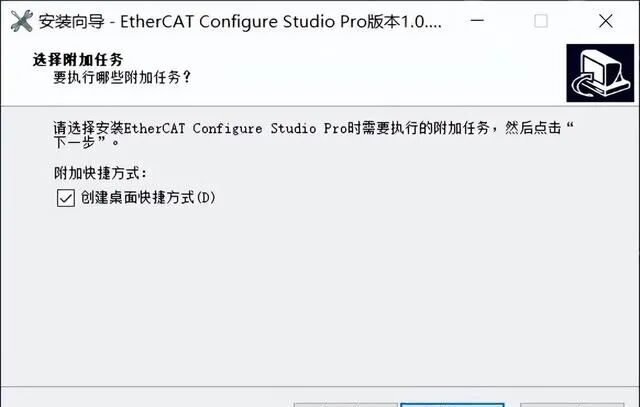

A certain paper factory used an old gateway with an 8-second data delay, and by the time the PLC reacted, the roller was already jammed. Current mainstream solutions need to control this within 2ms; choosing smart gateways that support EtherCAT and Profinet is the way to go!

❗ Is the alarm threshold set too wide?

Don’t follow the example of that careless food factory, which set a temperature fluctuation range of 10℃, resulting in the production line becoming a breeding ground for bacteria! Precision workshops recommend a dynamic adjustment of 1℃, like giving equipment a smart watch.

Cost-Benefit Ratio: Savings Are Pure Profit

A certain electronics factory reported even more exaggerated data: before installing the system, they experienced 15 downtimes per month; now they only have one minor fault every three months, cutting maintenance costs by 70%!

Step-by-Step Implementation Route

Risk Scanning: Use a thermal imaging camera to conduct a “full body check” of the workshop

Solution Comparison: Wireless sensor networks vs. wired deployment; don’t be fooled by sales! High-risk areas must use industrial-grade wired equipment

Pilot Testing: Start with one production line as a “guinea pig”; run it for 200 hours before scaling up

Comprehensive Training: Teach staff to understand warning signals; don’t wait for the PLC to alarm while still sipping tea!

Three Soul-Searching Questions

👉 Has your equipment recently been “coughing and running a fever”?

👉 Is there always someone complaining that “winter feels like a sauna” in the workshop?

👉 Is every instance of temperature and humidity control failure resolved by relying on the experience of senior workers?

Leave your industry in the comments, and the top 3 likes will receive the “PLC Pitfall Avoidance Manual”! Join us tonight at 8 PM for a live breakdown of the complete plan for the pharmaceutical factory’s 5 million loss; bring your questions, we specialize in all kinds of disputes!

In conclusion, let’s be honest: the cost of preventive monitoring is much cheaper than accident compensation! Your equipment deserves a “24-hour personal doctor”, doesn’t it?