PLC Intelligent Control: Adaptive Algorithms Reduce Equipment Failure Rate by 70%!

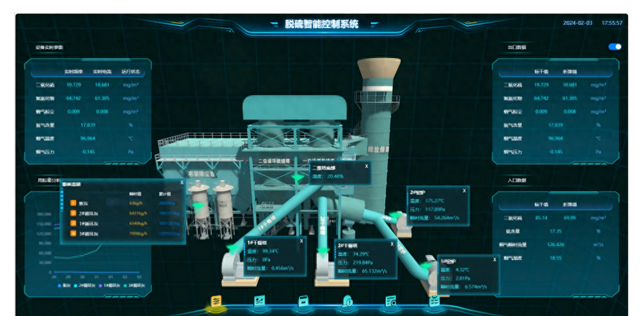

Hello everyone! Today we are going to tackle a problem that has left countless engineers scratching their heads — when there are sudden changes in the production environment, the PLC control parameters remain as unresponsive as a “wooden man”! For example, last week a chemical plant suffered a direct temperature spike of 200°C due to a sudden increase in the viscosity of raw materials, resulting in a loss of 3 million in half an hour! Wouldn’t it be great if the PLC could automatically adjust parameters like a chameleon?

1. Parameter Self-Tuning Pyramid

2. Siemens S7-1200 Practical Code

ladder

4. Pitfall Guide: 5 Common Misconceptions That Could Cost You Millions!

6. Implementation Roadmap: 4 Steps to Evolve Your PLC

Risk Assessment: List the 3 most likely changing parameters (such as temperature, pressure, flow rate).

Solution Selection: Choose Siemens S7-1200 or Mitsubishi Q series based on the scenario.

Pilot Testing: Deploy on one production line first, observe for 2 weeks.

Full Promotion: Cover the entire plant within 3 months!

7. Interactive Time: 3 Questions That Hit Home

Has your factory ever experienced accidents due to delayed parameters?

Would you like to cut the equipment failure rate in half with adaptive control?

If likes exceed 100, we will send an electronic version of the “Industrial Protocol Secrets”!

(This article was compiled by an industrial veteran burning the midnight oil, please indicate the source when reprinting!)