Skip to content

With the continuous growth of societal demand for high-performance electronics and communication technologies, coupled with the ongoing reduction in the size of electronic components, the power density of these components has been steadily increasing. This has raised higher requirements for the thermal management strategies of electronic components. Passive thermal management technologies have attracted increasing interest due to their zero energy consumption, higher compactness, and lower maintenance costs. Phase change materials (PCMs) are the most commonly used materials in existing passive thermal management strategies for electronic components. Despite extensive efforts by scholars both domestically and internationally to improve the performance of PCMs, low phase change enthalpy (typically below 200 J/gPCM) remains a fundamental limitation. The liquid-vapor phase change of water (i.e., desorption cooling) offers a new avenue for passive thermal management due to its extremely high phase change enthalpy (about 2400 J/g), inspired by the natural process of mammals regulating their body temperature through sweating. Currently, the utilization of this technology is mainly based on hydrogel and MOFs materials. Specifically, hygroscopic adsorbents (hydrogels or MOFs) provide a highly porous structure that can capture moisture from the atmosphere. The water stored in the adsorbent can evaporate during peak operation periods of electronic devices, extracting a large amount of heat to prevent overheating (i.e., desorption cooling). During non-peak periods, hygroscopic adsorbents can spontaneously absorb moisture from the surrounding atmosphere to restore their cooling capacity (i.e., self-regeneration). However, hydrogels (~10-12-10-11) and MOFs (~10-13-10-11) have lower mass diffusion coefficients, leading to very slow regeneration rates. Generally, passive thermal management strategies based on hydrogels rely on actively replenishing water to maintain high cooling capacity, while the high cost of MOFs (over 10000 USD/kg) limits their large-scale application. In contrast, hygroscopic inorganic salts, such as lithium chloride and lithium bromide, show promise in addressing these issues due to their extremely high hygroscopic capacity and low cost.

Recently, Associate Professor Wei Wu from City University of Hong Kong collaborated with Professor Ronggui Yang from Huazhong University of Science and Technology to propose a passive thermal management technology based on the evaporation process of moisture in hygroscopic salt solutions to suppress the temperature rise of electronic components. In this study, the moisture desorption process in low-cost hygroscopic salt solutions was utilized to extract the heat generated during the operation of electronic components to prevent overheating; importantly, this passive technology can automatically restore its cooling capacity during non-operational periods (or non-peak periods) of electronic components. Experimental results show that this technology can provide approximately 400 minutes of effective cooling capacity (ΔTmax = 11.5 °C), with measured heat fluxes reaching up to 75 kW/m2. Applying this technology to actual computing devices can enhance performance by 32.65%. Compared to existing passive thermal management technologies, this technology boasts a record high cost-effectiveness. Notably, this technology demonstrates high scalability and can be applied to other scenarios requiring intermittent thermal regulation, such as batteries, LEDs, photovoltaics, and the construction field (the team is conducting related research). The research findings were published in the sister journal of Cell, Device, under the title “Membrane-encapsulated, Moisture-desorptive Passive Cooling for High-performance, Ultralow-cost, and Long-duration Electronics Thermal Management.” PhD student Zengguang Sui from City University of Hong Kong is the first author, and Associate Professor Wei Wu from City University of Hong Kong and Professor Ronggui Yang from Huazhong University of Science and Technology are the corresponding authors.

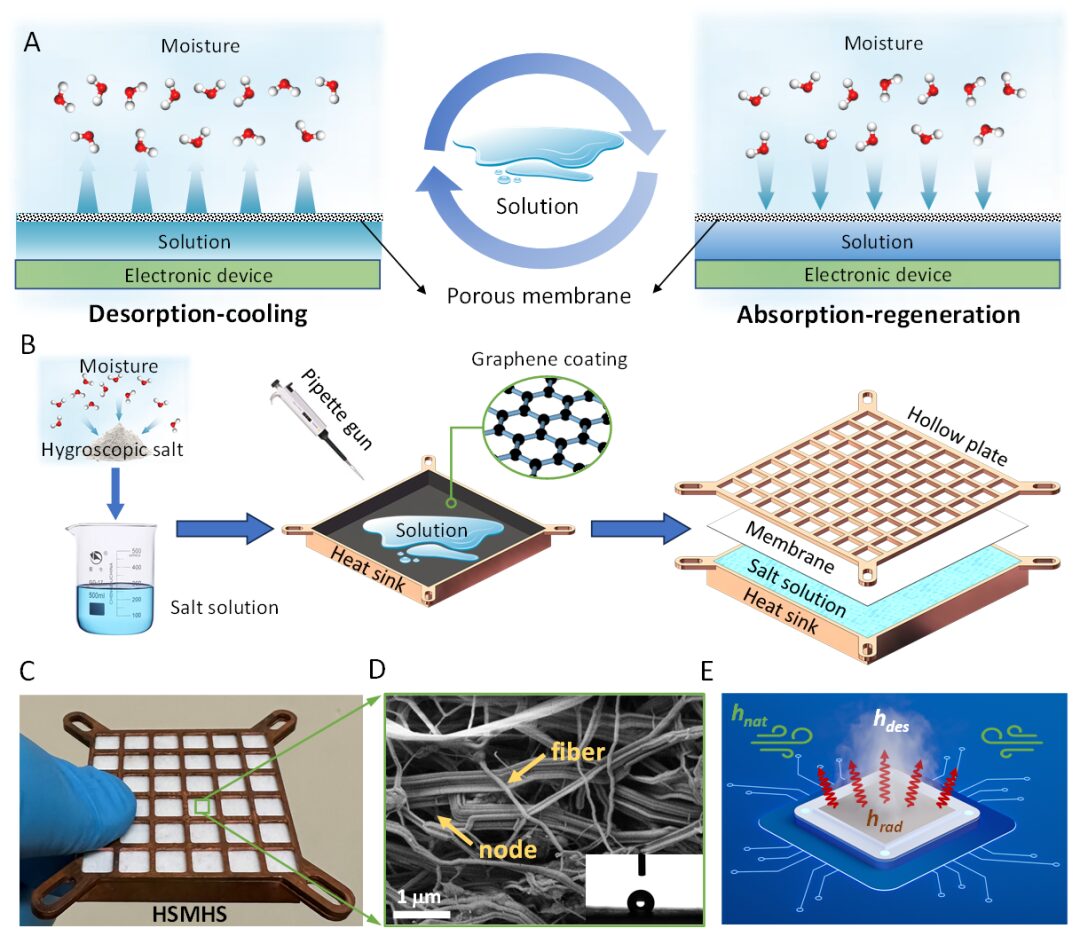

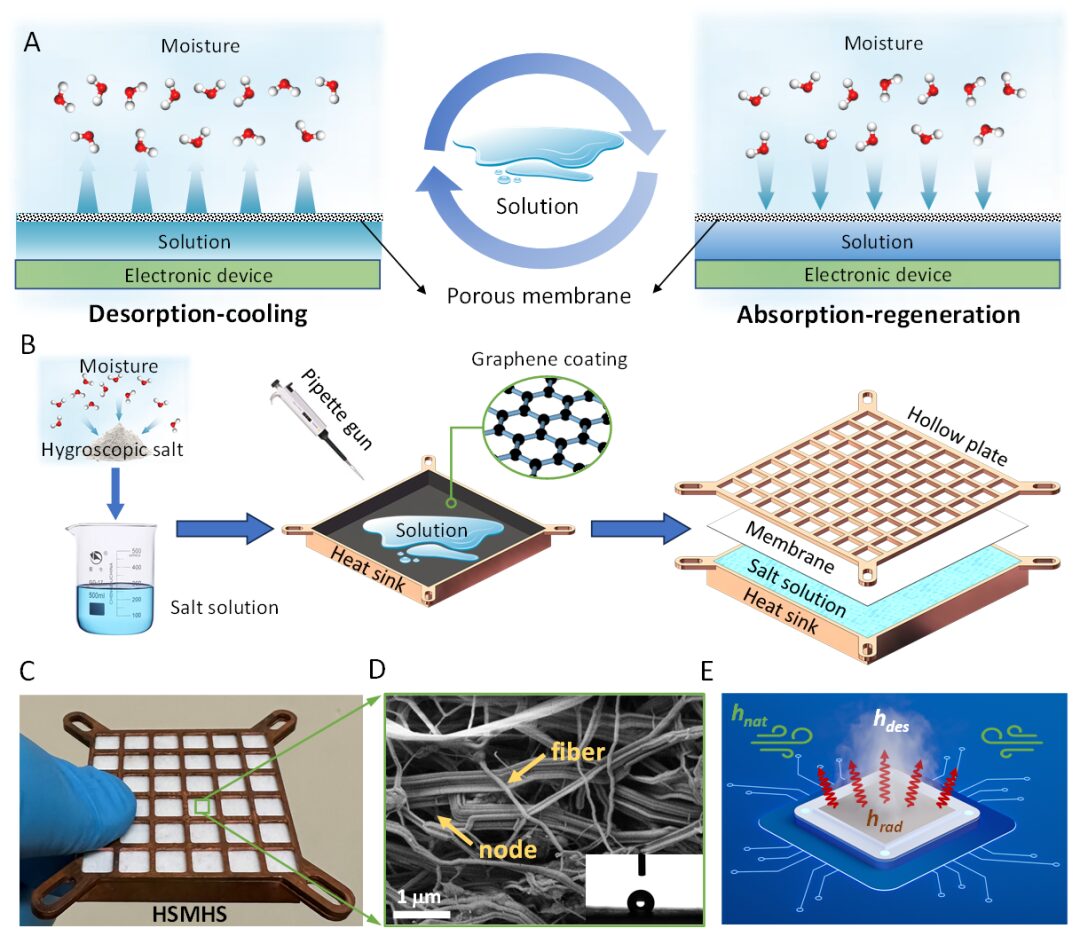

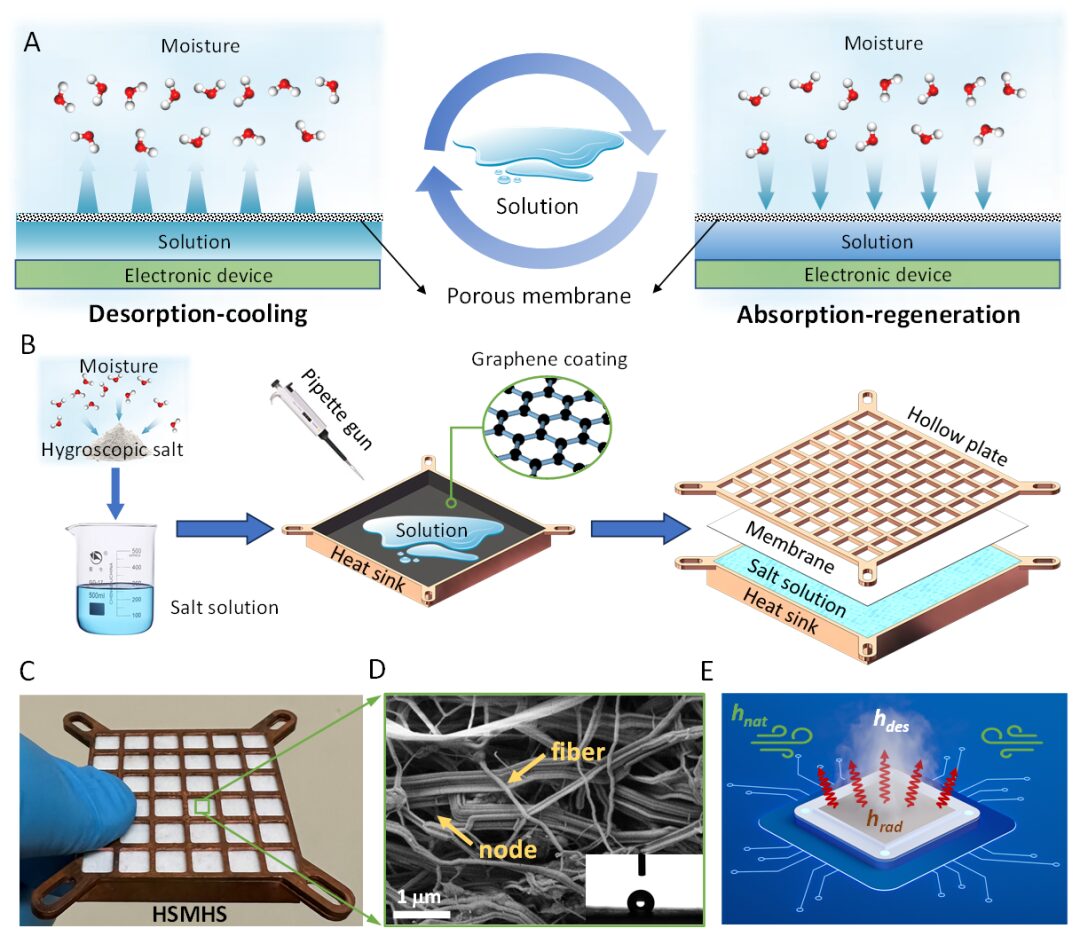

The inspiration for this technology comes from the natural phenomenon of mammals sweating to regulate their body temperature, with its working principle and manufacturing process illustrated in Figure 1. During the desorption cooling process, moisture evaporates from the salt solution to carry away the heat generated by electronic components, similar to how mammals sweat to lower their body temperature. In the absorption regeneration process, the colder concentrated salt solution spontaneously absorbs moisture from the surrounding atmosphere, autonomously restoring its cooling capacity, akin to how mammals drink water to replenish their internal moisture. The porous membrane prevents solution leakage and equipment corrosion while allowing water vapor to pass through, similar to mammalian skin. The device mainly consists of an aluminum heat sink, anti-corrosion coating, salt solution, porous membrane, and support plate, featuring a simple structure and low cost.

Figure 1 HSMHS Working Principle: (A) Schematic of Desorption and Absorption Processes; (B) Schematic of HSMHS Manufacturing Process; (C) HSMHS Prototype; (D) High-Magnification SEM Image of PTFE Membrane with a Pore Size of 0.45 μm; (E) Schematic of HSMHS Heat Dissipation Process.

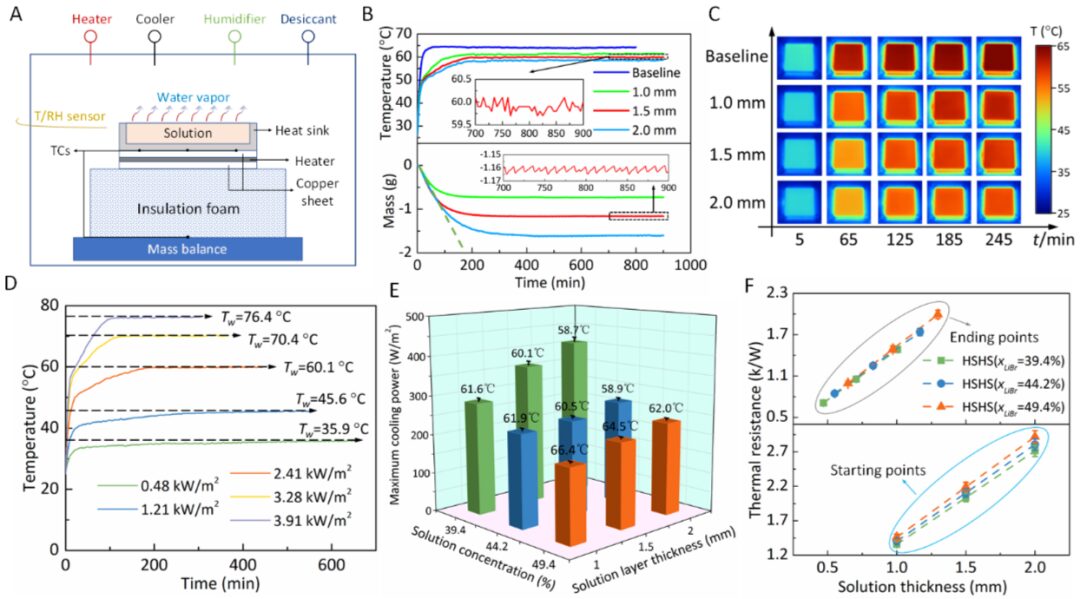

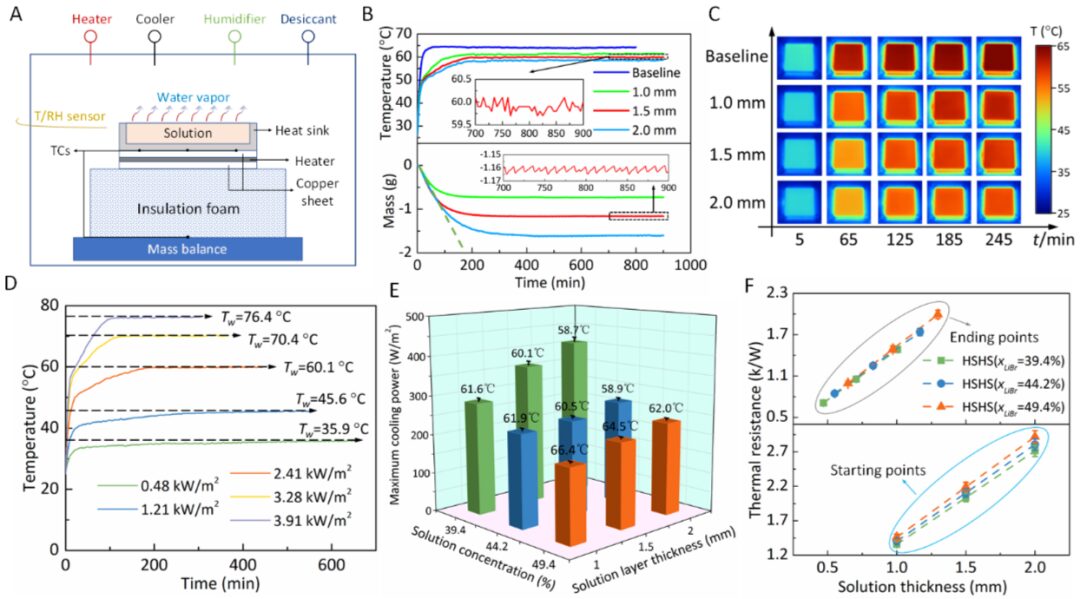

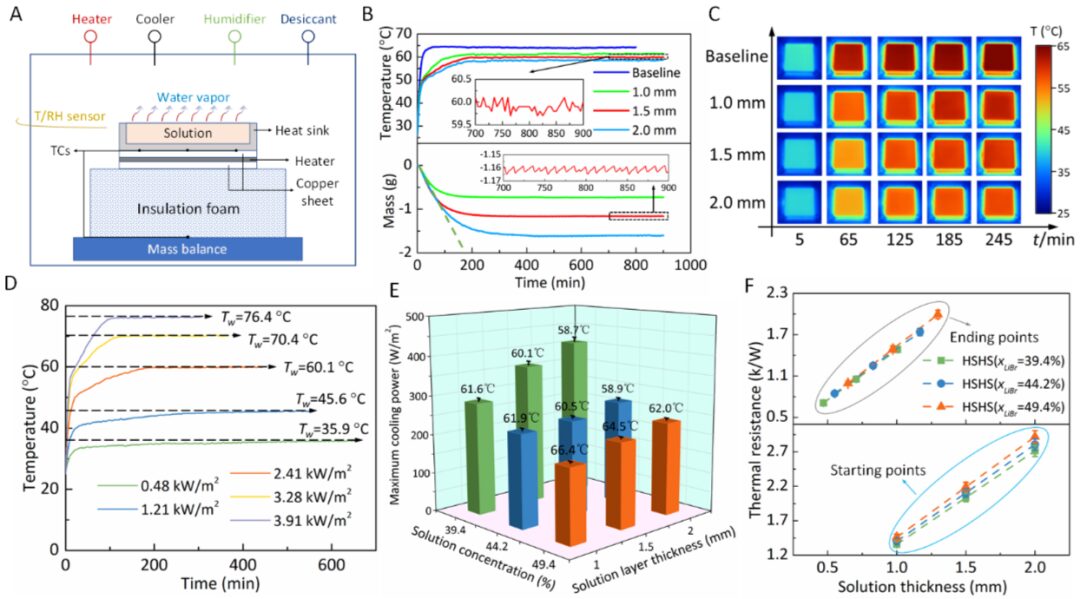

In preliminary experiments, researchers first removed the porous membrane to observe the changes in the solution. A PI heating film was used to simulate the chip, multiple thermocouples were used to record temperature changes, and a high-precision scale was employed to monitor mass changes, with the entire setup placed in a constant temperature and humidity chamber for testing. Experimental data is shown in Figure 2, where researchers measured the effects of different solution thicknesses and concentrations on cooling performance.

Figure 1 HSMHS Working Principle: (A) Schematic of Desorption and Absorption Processes; (B) Schematic of HSMHS Manufacturing Process; (C) HSMHS Prototype; (D) High-Magnification SEM Image of PTFE Membrane with a Pore Size of 0.45 μm; (E) Schematic of HSMHS Heat Dissipation Process.

In preliminary experiments, researchers first removed the porous membrane to observe the changes in the solution. A PI heating film was used to simulate the chip, multiple thermocouples were used to record temperature changes, and a high-precision scale was employed to monitor mass changes, with the entire setup placed in a constant temperature and humidity chamber for testing. Experimental data is shown in Figure 2, where researchers measured the effects of different solution thicknesses and concentrations on cooling performance.

Figure 2 Desorption/Absorption Experiments Under Typical Environmental Conditions (RH 60% and 25℃): (A) Schematic of HSHS Experiment in Constant Temperature and Humidity Chamber; (B) Temperature and Mass Changes of HSHS with Different Solution Layer Thicknesses; (C) Infrared Images of HSHS at Different Solution Layer Thicknesses; (D) Temperature Changes Under Different Heat Flux Conditions; (E) Comparison of Maximum Transient Cooling Power and Temperature; (F) Thermal Resistance Induced by Salt Solution During Desorption.

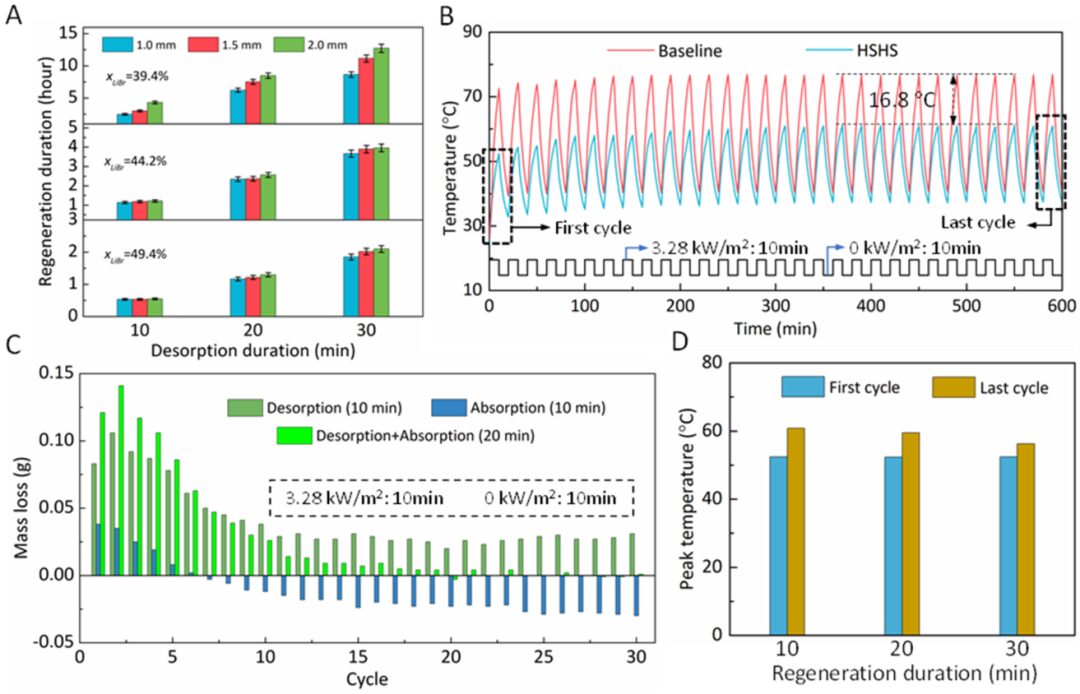

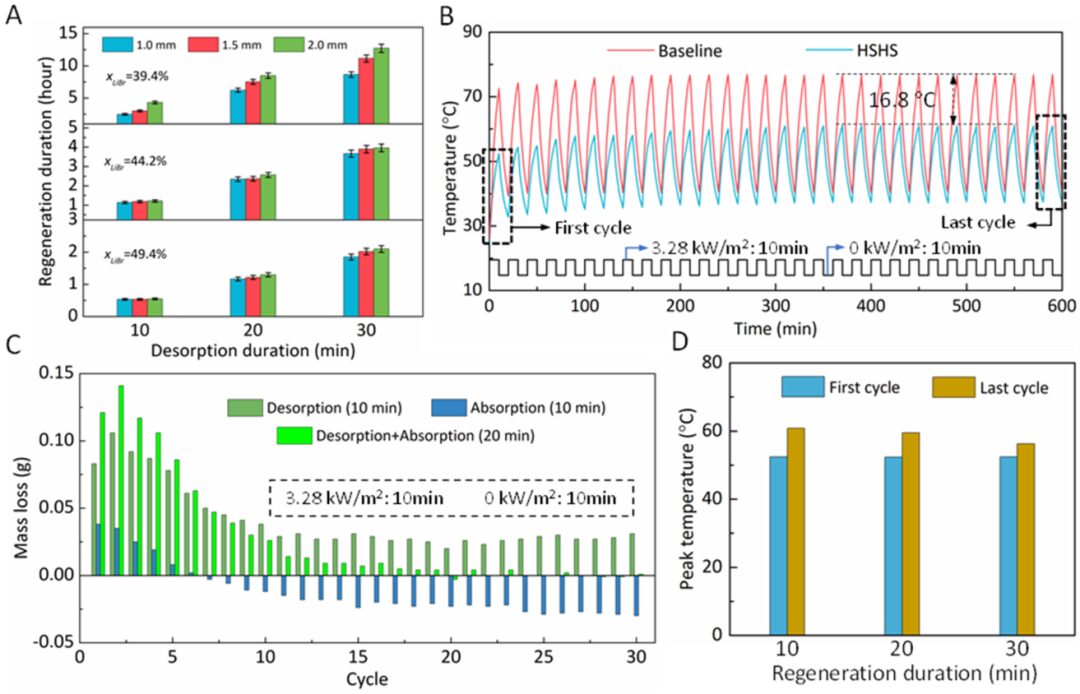

Simultaneously, researchers also measured the cycling performance of the device. As shown in Figure 3, this work discusses in detail the impact of regeneration time on the cooling performance of this device. Experimental results demonstrate that this device can provide stable and long-lasting thermal management for equipment requiring intermittent thermal regulation.

Figure 3 HSHS Cycling Experiments Under Typical Environmental Conditions (Relative Humidity 60% and 25℃): (A) Relationship Between Desorption Time and Regeneration Time; (B) Cycle Stability Testing; (C) Mass Changes During Desorption and Absorption Processes in Each Cycle; (D) Impact of Regeneration Time on Cooling Performance.

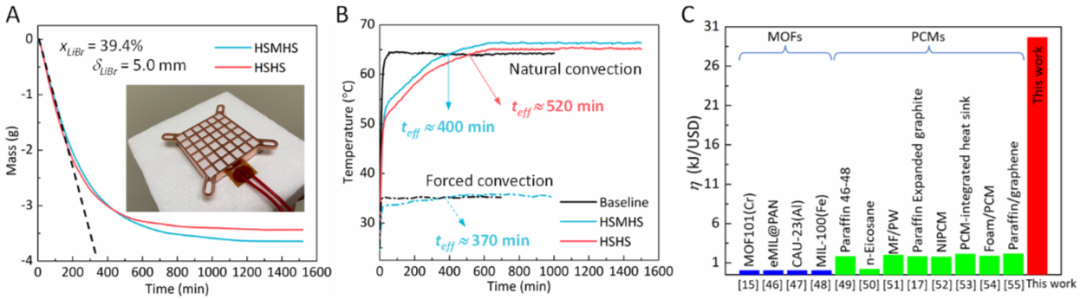

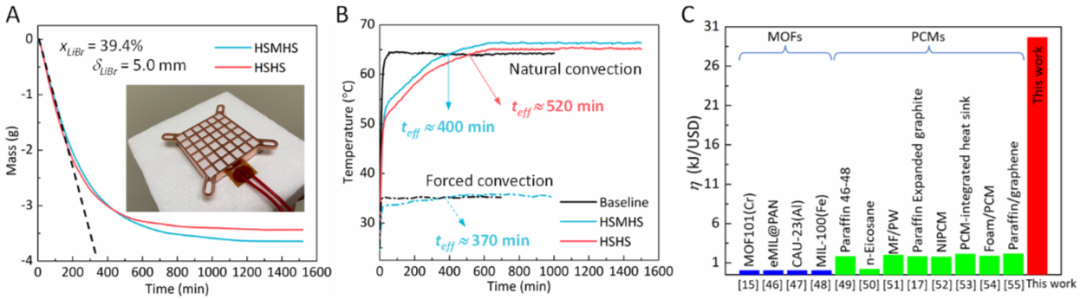

Based on the above experimental studies, this work tested the effect of the membrane on the cooling performance of the device, as shown in Figure 4. This work discusses the impact of the membrane on the effective cooling time of the device. Meanwhile, researchers defined a cost-effectiveness index to compare existing passive thermal management technologies. The results indicate that the thermal management technology proposed in this work possesses record-high cost-effectiveness.

Figure 4 HSMHS Cooling Performance Testing: (A) Effect of Membrane on Mass Changes of Testing Device; (B) Effect of Membrane on Temperature Changes of Testing Device; (C) Cost-Effectiveness Comparison.

Finally, this work also tested the thermal management capability of the device under high heat flux conditions. Actual test results indicate that the applicable heat flux of this device can reach up to 75 kW/m2. To evaluate the performance of this technology in real scenarios, the device was assembled onto an ODROID-XU4 single-board computer. The results showed that this device could significantly reduce the chip temperature (11 °C). Thanks to the excellent thermal management capability of this device, the performance of the ODROID-XU4 can be improved by 32.65%.

Figure 2 Desorption/Absorption Experiments Under Typical Environmental Conditions (RH 60% and 25℃): (A) Schematic of HSHS Experiment in Constant Temperature and Humidity Chamber; (B) Temperature and Mass Changes of HSHS with Different Solution Layer Thicknesses; (C) Infrared Images of HSHS at Different Solution Layer Thicknesses; (D) Temperature Changes Under Different Heat Flux Conditions; (E) Comparison of Maximum Transient Cooling Power and Temperature; (F) Thermal Resistance Induced by Salt Solution During Desorption.

Simultaneously, researchers also measured the cycling performance of the device. As shown in Figure 3, this work discusses in detail the impact of regeneration time on the cooling performance of this device. Experimental results demonstrate that this device can provide stable and long-lasting thermal management for equipment requiring intermittent thermal regulation.

Figure 3 HSHS Cycling Experiments Under Typical Environmental Conditions (Relative Humidity 60% and 25℃): (A) Relationship Between Desorption Time and Regeneration Time; (B) Cycle Stability Testing; (C) Mass Changes During Desorption and Absorption Processes in Each Cycle; (D) Impact of Regeneration Time on Cooling Performance.

Based on the above experimental studies, this work tested the effect of the membrane on the cooling performance of the device, as shown in Figure 4. This work discusses the impact of the membrane on the effective cooling time of the device. Meanwhile, researchers defined a cost-effectiveness index to compare existing passive thermal management technologies. The results indicate that the thermal management technology proposed in this work possesses record-high cost-effectiveness.

Figure 4 HSMHS Cooling Performance Testing: (A) Effect of Membrane on Mass Changes of Testing Device; (B) Effect of Membrane on Temperature Changes of Testing Device; (C) Cost-Effectiveness Comparison.

Finally, this work also tested the thermal management capability of the device under high heat flux conditions. Actual test results indicate that the applicable heat flux of this device can reach up to 75 kW/m2. To evaluate the performance of this technology in real scenarios, the device was assembled onto an ODROID-XU4 single-board computer. The results showed that this device could significantly reduce the chip temperature (11 °C). Thanks to the excellent thermal management capability of this device, the performance of the ODROID-XU4 can be improved by 32.65%.

Figure 5 Practical Application of the Proposed Thermal Management Strategy: (A) Impact of Different Solution Thicknesses on Regeneration Time; (B) Cycling Experiments of HSMNHS; (C) Temperature Comparison of HSMNHS and FHS Under High Heat Flux Conditions; (D) Physical Images of ODROID-XU4 with HSMNHS and Original Heat Sink; (E) Temperature Changes Under Two Thermal Management Strategies; (F) Changes in Transient Input Power Under Two Thermal Management Strategies.

This work proposes a novel passive thermal management technology utilizing low-cost hygroscopic salt solutions. This technology achieves efficient thermal management of electronic components through the introduction of a porous PTFE membrane and salt solution, with no risk of solution leakage or corrosion. Thanks to the high hygroscopic properties of hygroscopic salts, this device exhibits excellent self-regeneration capability. Compared to existing passive thermal management strategies, the proposed thermal management strategy demonstrates record-high cost-effectiveness and shows great commercialization potential. Furthermore, researchers have developed an experimentally validated CFD heat transfer and mass transfer model to guide further optimization of this technology. The thermal management strategy proposed in this work is both economical and highly scalable. This technology provides a novel thermal management approach for devices requiring intermittent thermal regulation, applicable to electronic components, batteries, photovoltaic panels, and construction, with virtually no technical barriers.

Zengguang Sui, Yunren Sui, Zhixiong Ding, Haosheng Lin, Fuxiang Li, Ronggui Yang, Wei Wu, Membrane-encapsulated, moisture-desorptive passive cooling for high-performance, ultra-low-cost, and long-duration electronics thermal management, Device, 2023, 100121.

Figure 5 Practical Application of the Proposed Thermal Management Strategy: (A) Impact of Different Solution Thicknesses on Regeneration Time; (B) Cycling Experiments of HSMNHS; (C) Temperature Comparison of HSMNHS and FHS Under High Heat Flux Conditions; (D) Physical Images of ODROID-XU4 with HSMNHS and Original Heat Sink; (E) Temperature Changes Under Two Thermal Management Strategies; (F) Changes in Transient Input Power Under Two Thermal Management Strategies.

This work proposes a novel passive thermal management technology utilizing low-cost hygroscopic salt solutions. This technology achieves efficient thermal management of electronic components through the introduction of a porous PTFE membrane and salt solution, with no risk of solution leakage or corrosion. Thanks to the high hygroscopic properties of hygroscopic salts, this device exhibits excellent self-regeneration capability. Compared to existing passive thermal management strategies, the proposed thermal management strategy demonstrates record-high cost-effectiveness and shows great commercialization potential. Furthermore, researchers have developed an experimentally validated CFD heat transfer and mass transfer model to guide further optimization of this technology. The thermal management strategy proposed in this work is both economical and highly scalable. This technology provides a novel thermal management approach for devices requiring intermittent thermal regulation, applicable to electronic components, batteries, photovoltaic panels, and construction, with virtually no technical barriers.

Zengguang Sui, Yunren Sui, Zhixiong Ding, Haosheng Lin, Fuxiang Li, Ronggui Yang, Wei Wu, Membrane-encapsulated, moisture-desorptive passive cooling for high-performance, ultra-low-cost, and long-duration electronics thermal management, Device, 2023, 100121.

Dr. Wei Wu, Associate Professor at City University of Hong Kong, Master’s Program Director, National Outstanding Youth (Hong Kong and Macao). He obtained his Bachelor’s degree in Building Environment and Energy Application from Huazhong University of Science and Technology in 2010 and his Ph.D. from Tsinghua University in Architectural Technology Science in 2016. He served as a visiting scholar at the Center for Environmental Energy Engineering, University of Maryland in 2013, and as a guest researcher at the Energy and Environment Department of the National Institute of Standards and Technology in the USA in 2016. Since 2018, he has been an Assistant Professor and then Associate Professor at City University of Hong Kong (awarded tenure a year early). His research interests include efficient heat pumps, high-density energy storage, advanced thermal management, renewable thermal energy utilization, and zero-energy buildings. He has published over 150 academic papers, including more than 110 SCI papers; he holds 15 authorized patents in China and the USA and has 8 patents pending; he has published one English monograph with Springer Nature. He has received numerous awards, including the Willis H. Carrier Young Researcher Award from the International Institute of Refrigeration, the Outstanding Researcher Award from NIST, recognition as a Top 2% Global Scientist by Stanford (for three consecutive years; annual influence and lifetime influence), the Excellent Young Scholar Award from the Global Energy and Artificial Environment, the Outstanding Young Scholar Award from the National HVAC Society, the Special Scholarship from Tsinghua University, and the Academic New Star Award from Tsinghua University; he has won two gold medals at the Geneva International Inventions Exhibition and four gold medals at the Asia International Inventions Exhibition; he has received multiple excellent paper awards from the Chinese Society of Refrigeration, the Beijing Society of Refrigeration, and the Hong Kong Institution of Engineers; he is an expert for the IEA SHC and HPT; and serves on the editorial board of several SCI journals.

Personal Information Homepage:

https://scholars.cityu.edu.hk/en/persons/wei-wu(74d189ea-20bf-4bab-bd8a-7fed3ba1aea2).html

Dr. Wei Wu, Associate Professor at City University of Hong Kong, Master’s Program Director, National Outstanding Youth (Hong Kong and Macao). He obtained his Bachelor’s degree in Building Environment and Energy Application from Huazhong University of Science and Technology in 2010 and his Ph.D. from Tsinghua University in Architectural Technology Science in 2016. He served as a visiting scholar at the Center for Environmental Energy Engineering, University of Maryland in 2013, and as a guest researcher at the Energy and Environment Department of the National Institute of Standards and Technology in the USA in 2016. Since 2018, he has been an Assistant Professor and then Associate Professor at City University of Hong Kong (awarded tenure a year early). His research interests include efficient heat pumps, high-density energy storage, advanced thermal management, renewable thermal energy utilization, and zero-energy buildings. He has published over 150 academic papers, including more than 110 SCI papers; he holds 15 authorized patents in China and the USA and has 8 patents pending; he has published one English monograph with Springer Nature. He has received numerous awards, including the Willis H. Carrier Young Researcher Award from the International Institute of Refrigeration, the Outstanding Researcher Award from NIST, recognition as a Top 2% Global Scientist by Stanford (for three consecutive years; annual influence and lifetime influence), the Excellent Young Scholar Award from the Global Energy and Artificial Environment, the Outstanding Young Scholar Award from the National HVAC Society, the Special Scholarship from Tsinghua University, and the Academic New Star Award from Tsinghua University; he has won two gold medals at the Geneva International Inventions Exhibition and four gold medals at the Asia International Inventions Exhibition; he has received multiple excellent paper awards from the Chinese Society of Refrigeration, the Beijing Society of Refrigeration, and the Hong Kong Institution of Engineers; he is an expert for the IEA SHC and HPT; and serves on the editorial board of several SCI journals.

Personal Information Homepage:

https://scholars.cityu.edu.hk/en/persons/wei-wu(74d189ea-20bf-4bab-bd8a-7fed3ba1aea2).html

Dr. Ronggui Yang, Professor at the School of Energy and Power Engineering, Huazhong University of Science and Technology. Dr. Yang obtained his Bachelor’s degree in Thermal Engineering from Xi’an Jiaotong University in 1996, his Master’s degree in Engineering Thermophysics from Tsinghua University in 1999, his Master’s degree in Microelectromechanical Systems Engineering from UCLA in 2001, and his Ph.D. in Mechanical Engineering from MIT in 2006, under the guidance of Academicians Gang Chen and Mildred S. Dresselhaus. Since January 2006, Dr. Yang has worked at the University of Colorado Boulder for 13 years, serving as Assistant Professor, Associate Professor (tenured two years early), and Full Professor (named professor). Dr. Yang has published approximately 240 journal papers, including 4 in Science, 4 in Nature Materials, 3 in Science Advances, 4 in Joule, and 1 in Review of Modern Physics. Since 2021, he has been recognized as one of the top 2% scientists globally, a Clarivate

Dr. Ronggui Yang, Professor at the School of Energy and Power Engineering, Huazhong University of Science and Technology. Dr. Yang obtained his Bachelor’s degree in Thermal Engineering from Xi’an Jiaotong University in 1996, his Master’s degree in Engineering Thermophysics from Tsinghua University in 1999, his Master’s degree in Microelectromechanical Systems Engineering from UCLA in 2001, and his Ph.D. in Mechanical Engineering from MIT in 2006, under the guidance of Academicians Gang Chen and Mildred S. Dresselhaus. Since January 2006, Dr. Yang has worked at the University of Colorado Boulder for 13 years, serving as Assistant Professor, Associate Professor (tenured two years early), and Full Professor (named professor). Dr. Yang has published approximately 240 journal papers, including 4 in Science, 4 in Nature Materials, 3 in Science Advances, 4 in Joule, and 1 in Review of Modern Physics. Since 2021, he has been recognized as one of the top 2% scientists globally, a Clarivate