Click the above “Mechanical and Electronic Engineering Technology” to follow us

As competition in the mobile screen manufacturing industry intensifies, it is essential to continuously improve processes to enhance yield rates and reduce costs in order to secure a market position. The mainstream process for mobile screen assembly—full lamination technology—requires ongoing improvements. In mobile screen assembly, full lamination technology has become the mainstream technique, significantly improving the display quality of touch screens when combined with technologies such as In-Cell, On-Cell, and OGS. By using only liquid adhesive and a single glass layer for lamination, material costs are saved, production processes are simplified, and products become noticeably thinner and lighter, enhancing light transmittance and significantly improving display quality. Smartphones produced using full lamination technology provide users with a better experience.

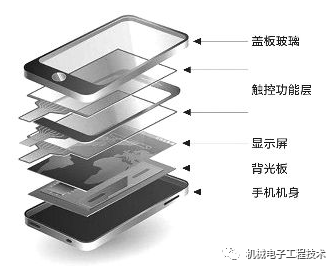

1. Screen Structure

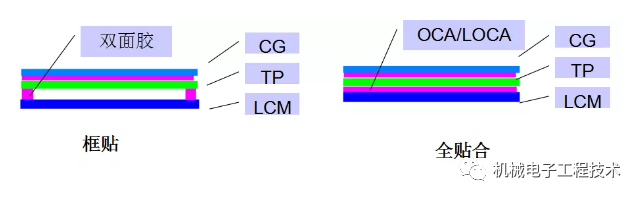

From the structural perspective, a screen can be roughly divided into three parts: the protective glass, the touch screen, and the display screen. These three parts need to be laminated together, which can be categorized into three types based on the lamination method: full lamination, frame lamination, and zero lamination. Frame lamination, also known as the “mouth-shaped adhesive lamination,” simply uses double-sided tape to fix the touch screen to the four edges of the display screen; there is an air layer between the display screen and the touch screen. Full lamination technology involves using water-based or optical adhesives to completely bond the display screen and touch screen without any gaps. Currently, high-end smartphones such as Apple’s iPhone, Samsung’s S series, Xiaomi Mi 2, Nexus 7, Ascend D1 Quad-core, koobee i90, Coolpad 8730, and Huawei Honor 2 all adopt full lamination technology. Zero lamination is a concept that emerged in 2018 and has already been successfully applied by some manufacturers. Its lamination method is between full lamination and frame lamination, primarily filling the gap between the TP and the display screen with a non-adhesive transparent medium that has a refractive index similar to glass. This not only eliminates gaps between the glass and the display screen, reducing diffuse reflection and enhancing display quality, but also simplifies assembly and maintenance due to its non-adhesive nature, resulting in lower overall costs. Currently, the cost of zero lamination on the market is under 500 yuan (taking 86 inches as an example, with low maintenance costs).

2. Full Lamination vs. Frame Lamination

Advantages of Full Lamination Technology Compared to Traditional Frame Lamination:

-

Better display quality. Full lamination technology eliminates the air layer between the screens, significantly reducing light reflection and minimizing light loss, thereby enhancing brightness and improving display quality.

-

Prevents dust and moisture. The air layer in traditional lamination methods is susceptible to contamination from environmental dust and moisture, affecting machine usage; whereas full lamination with OCA adhesive fills the gaps, tightly bonding the display panel and touch screen, preventing dust and moisture from entering and maintaining screen cleanliness.

-

Reduces noise interference. The close bonding of the touch screen and display panel not only enhances strength but also effectively reduces noise interference on touch signals, improving the smoothness of touch operations.

-

Thinner device. Full lamination screens have a thinner profile, with the touch screen and display screen bonded using optical adhesive, adding only 25μm-50μm in thickness; this is 0.1mm-0.7mm thinner than traditional lamination methods.

-

Simplified assembly. Full lamination modules can be directly secured to the device using clips or screws, reducing assembly issues caused by lamination deviations, simplifying the assembly process, and lowering assembly costs. This also facilitates narrow bezel designs, allowing for thinner bezels.

-

Comparison of Full Lamination Technology with Traditional Frame Lamination

Disadvantages of Full Lamination Technology Compared to Traditional Frame Lamination:

-

Complex process, lower yield rates, difficult rework, high costs, and significant investment.

Animation of Screen Lamination Principles3. Full Lamination Technology

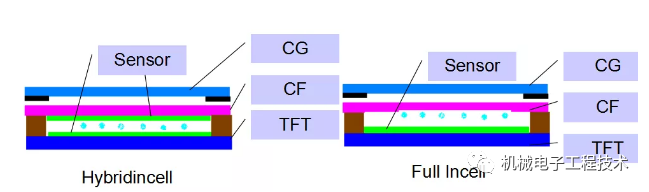

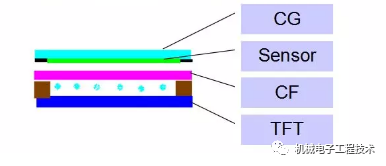

3.1 In-Cell Technology

Refers to the technology that integrates the touch panel function into the liquid crystal pixels, meaning that the touch sensor function is embedded within the display screen, thus transforming the original three layers of protective glass + touch screen + display screen into two layers of protective glass + display screen with touch functionality, making the screen lighter and thinner. This technology is primarily developed by panel manufacturers and has a relatively high barrier to entry for any display panel manufacturer. Currently, In-Cell technology is used in Apple’s iPhone 5/5s and Nokia’s high-end Lumia series smartphones. In-Cell technology screen layers: The In-Cell screen consists of a top layer of glass bonded to the LCD layer (the touch screen is on the LCD layer), totaling 2 layers.

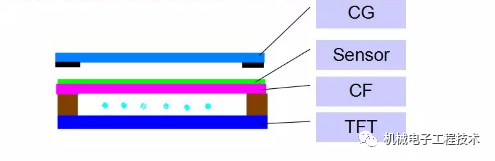

3.2 On-Cell Technology

On-Cell refers to the method of embedding the touch screen between the color filter substrate and polarizer of the display screen, meaning that a touch sensor is paired with the liquid crystal panel. Compared to In-Cell technology, the difficulty is significantly reduced. Currently, On-Cell is widely used in Samsung’s AMOLED panel products, although it has not yet overcome issues related to thinness and color uniformity during touch operations. Manufacturers such as Samsung, Hitachi, and LG have made rapid progress in On-Cell structured touch screens. On-Cell technology screen layers: The On-Cell screen consists of a top layer of glass bonded to the touch screen and the LCD layer, totaling 3 layers.

3.3 OGS/TOL TechnologyOGS technology integrates the touch screen with the protective glass, depositing an ITO conductive layer on the inner side of the protective glass, allowing for coating and photolithography directly on the protective glass. By saving one glass layer and one lamination process, the touch screen can be made thinner and at a lower cost. This technology is currently led and developed by touch screen manufacturers, with domestic smartphone brands such as nubia Z5mini, ZTE GEEK, and Huawei Honor 3C adopting OGS technology. However, OGS still faces challenges regarding strength and processing costs, both of which require secondary reinforcement to increase strength. OGS technology screen layers: The OGS layer is bonded to the LCD layer, totaling 2 layers.

3.4 Traditional Technologies (GG, GG2, GF, G1F, GF2, GFF, etc.)Other traditional full lamination technologies such as GG, GG2, GF, G1F, GF2, GFF, etc., require two lamination processes, resulting in thicker screens and lower yield rates. 4. Full Lamination Process

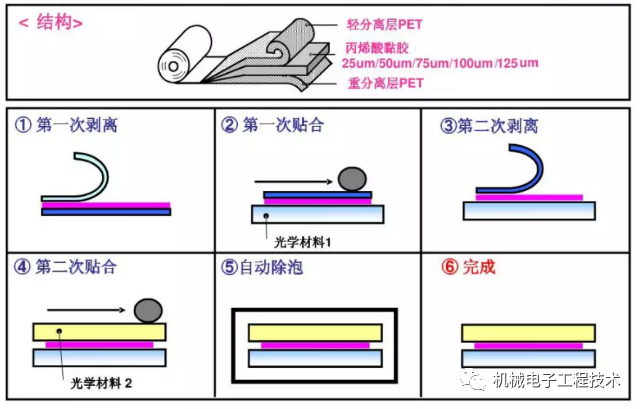

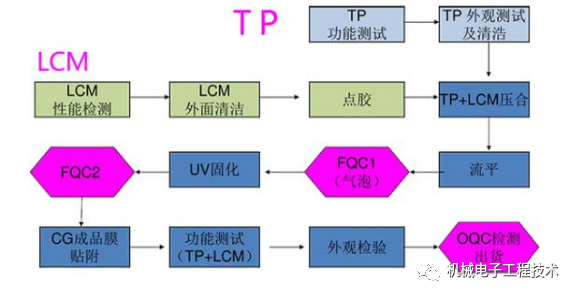

4.1 OCA Lamination

-

OCA (Optically Clear Adhesive) is a special adhesive used for bonding transparent optical components (such as lenses). It must be colorless and transparent, with a light transmittance of over 90%, good bonding strength, and the ability to cure at room temperature or medium temperature, with minimal curing shrinkage.

-

Currently, it is mainly suitable for small-sized product lamination, with each product requiring a mold, making it expensive and resulting in high lamination costs. It contains light initiators, which can easily lead to yellowing, and bubbles can form at the ink segment differences. The typical thickness for small sizes is generally between 100um-200um. For large sizes, the lamination thickness needs to reach 1000um or 1mm, partly due to interference issues with larger sizes and partly to compensate for the unevenness of the glass.

-

Advantages:High production efficiency, uniform thickness, no glue overflow issues, controllable bonding area, no corrosion issues, and simple maintenance.

Common Brands:

-

Japan: Nitto, Hitachi, Mitsubishi, Nichiban, Prince, DIC, Yamazaki, etc. South Korea: LG, TAPEX, ST, YOUL CHON Taiwan: Changxing, Chi Mei, BenQ, etc.

-

Domestic: Liwang, Huazhuo, etc.

-

USA: 3M

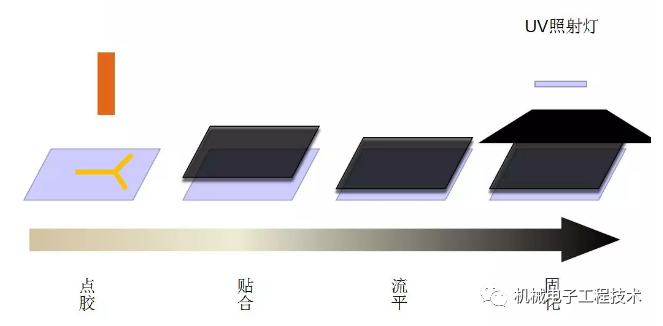

4.2 LOCA Lamination

-

Liquid Optical Clear Adhesive, abbreviated as LOCA, is a special adhesive primarily used for bonding transparent optical components.

-

It is colorless and transparent, with a light transmittance of over 98%, good bonding strength, and can cure at room temperature or medium temperature. It also has a low curing shrinkage rate and is resistant to yellowing.

-

It is mainly suitable for large-size lamination, curved or complex structure lamination, and for bonding surfaces with high ink thickness or unevenness.

-

Advantages: Can bond curved or uneven surface materials, is insensitive to ink thickness, easy to rework, and lower cost compared to OCA.

Currently, screens produced using full lamination technology have excellent visual quality, and the differences between them are often hard to detect without comparison. Therefore, the fact that Apple uses In-Cell does not necessarily mean it has the best visual quality; in fact, extreme thinness is the true advantage of In-Cell. OGS, to some extent, has higher touch sensitivity, but its disadvantage is that the cutting process during manufacturing can affect the strength of the glass panel, making it prone to breakage. Additionally, many manufacturers now use “GFF full lamination” as a promotional point in budget smartphones, but GFF is not strictly a full lamination in the true sense.

Want to learn more?

Scan the code to follow us