Follow me as we analyze 100 Mitsubishi PLC program cases.

In the fascinating world of automation control, the Mitsubishi PLC acts like a precise commander, methodically orchestrating the operation of various devices. Today, let’s discuss an interesting application of the Mitsubishi PLC control system — the start-stop control with dual stop buttons, and see how it cleverly avoids operator misoperation.

1. Requirement Background: Preventing Misoperation with “Small Wisdom”

In many industrial sites or automated equipment, starting operations are relatively simple, but stopping operations require caution. If the stop button is accidentally pressed, it may cause the running equipment to suddenly stop, affecting the production process and even causing minor faults. Therefore, to avoid this awkward and troublesome misoperation, we have implemented a “double insurance” for the stop button — setting up two stop buttons, X1 and X2, which must be pressed simultaneously for the system to stop. It’s like needing two keys to lock an important “big door”; only by using both can it be secured, significantly reducing the probability of misoperation.

2. Program Analysis: The “Logical Password” in PLC

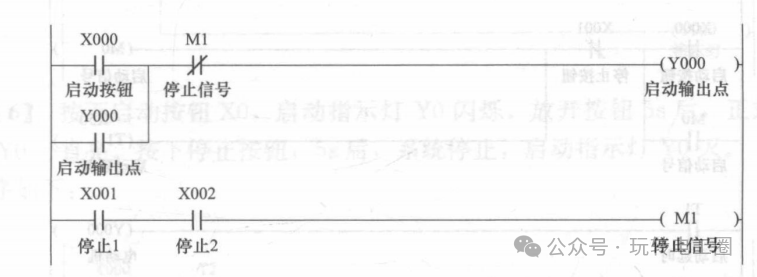

Let’s first look at the general logic of the program. In the start section, when the start button X0 is pressed, Y0 outputs, and Y0 will also self-lock, keeping the device in a running state. The key point is that the stop section controls the stop signal M1 through the two stop buttons X1 and X2 in series. This means that only when both X1 and X2 are pressed simultaneously will M1, the “stop signal messenger,” take action, cutting off the output of Y0 and stopping the system.

From the logical relationship of the PLC program, this utilizes series contacts to achieve “AND” logic. X1 and X2 act like two “guards”; only when both “allow passage” (are pressed and conductive) can the stop command be transmitted. This design is both simple and effective, significantly reducing the possibility of misoperation.

3. Practical Application Value: The “Small Guardian” of Stable Production

In actual factory production, such a design can play a significant role. For example, in some assembly line operations, if equipment stops unexpectedly, subsequent material handling and processing steps will be disrupted, and restarting will require time to adjust the state. With these two stop buttons, a single accidental press by the operator will not affect the equipment operation; only when a stop is genuinely needed will both buttons be pressed simultaneously, ensuring operational accuracy and making the production process more stable and smoother.

Moreover, for situations with strict requirements for stop operations, such as involving precision machining or hazardous operations, this dual stop button design adds a “solid lock” for safety and stability, effectively preventing safety hazards and production losses caused by misoperation.

4. Expanding Thoughts: Flexible and Varied Control Logic

In fact, from the design of this dual stop button, we can expand to more interesting control logics. For instance, applying this “AND” logic to other operations requiring multiple confirmations, such as adding an additional confirmation step for emergency stops; or conversely, using “OR” logic to design multiple start conditions, making control more flexible and diverse. The Mitsubishi PLC is like a “magic box” filled with various logical instructions, waiting for us to explore and combine to create automation control systems that better meet practical needs.

In summary, the application of dual stop buttons in this Mitsubishi PLC control system, while not complex in principle, embodies the concept of “precision and reliability” in automation control. In actual projects, paying attention to these small details can lead to more stable equipment operation and higher production efficiency, as well as inspire us with more ideas and techniques in our learning and practice of automation control.

Have you encountered similar interesting design requirements or small ideas in Mitsubishi PLC programming or automation control practice? Feel free to share in the comments section, and let’s discuss those “wonderful things” in automation control!