Introduction

In recent years, the popularity of battery-powered electronic products has made power consumption an increasingly important issue for analog circuit designers. This article will introduce how to use low-power operational amplifiers for system design, also covering low-power operational amplifiers with low supply voltage capabilities and their applications, discussing how to correctly understand the specifications in operational amplifier datasheets, and comprehensively considering energy-saving technologies in circuit design to achieve more efficient component selection.

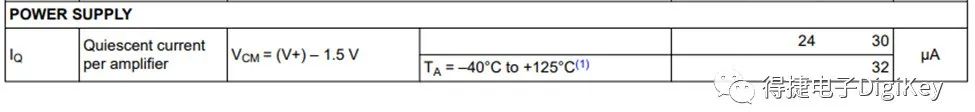

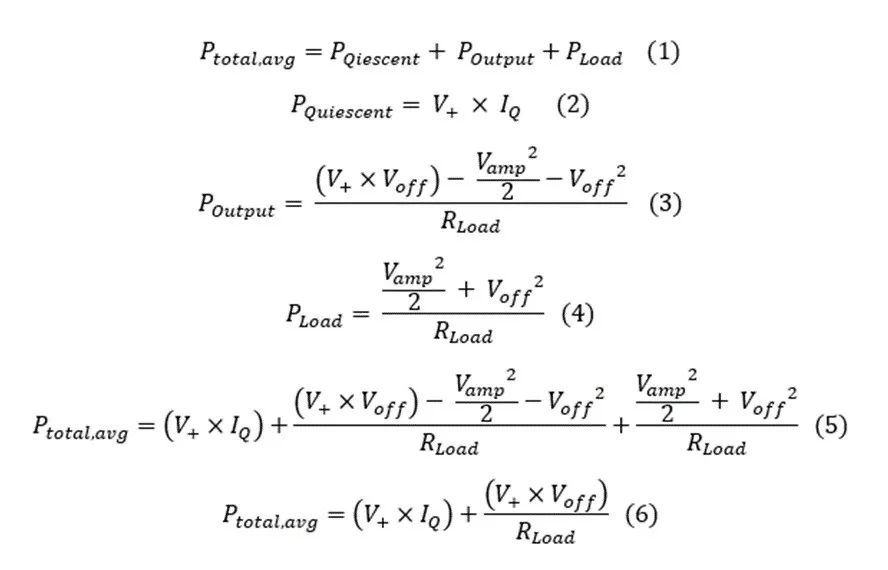

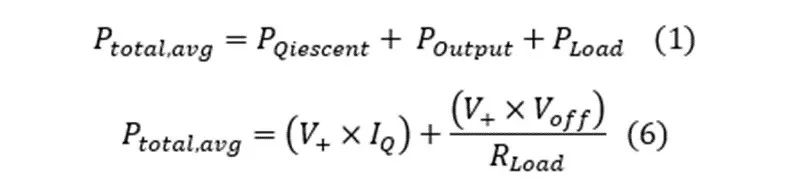

Understanding Power Consumption in Operational Amplifier Circuits

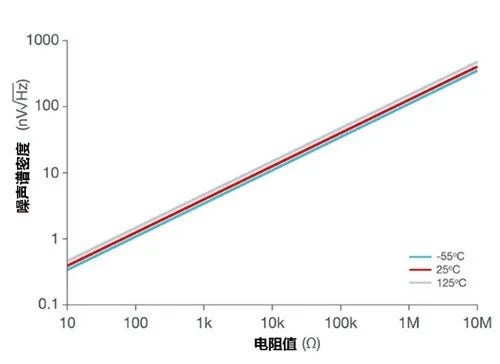

Figure 3: Quiescent Current of TI OPA391 (Image Source: Texas Instruments)

Figure 3: Quiescent Current of TI OPA391 (Image Source: Texas Instruments)

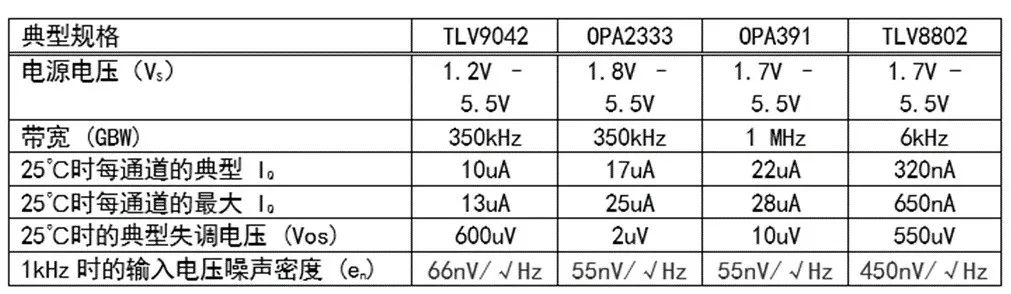

Selecting Components with SuitableIQ Values

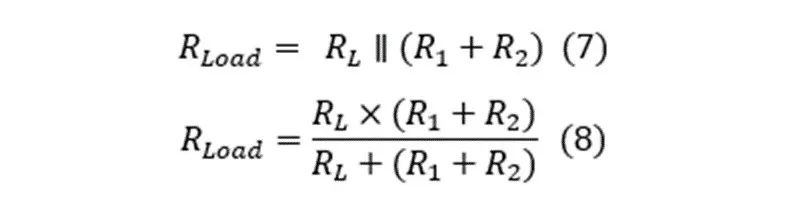

Reducing the Resistance Value of Load Networks

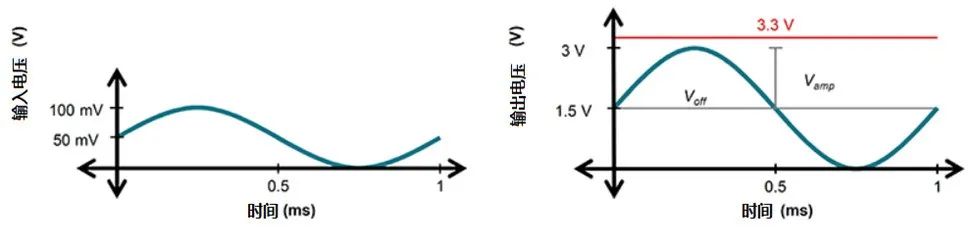

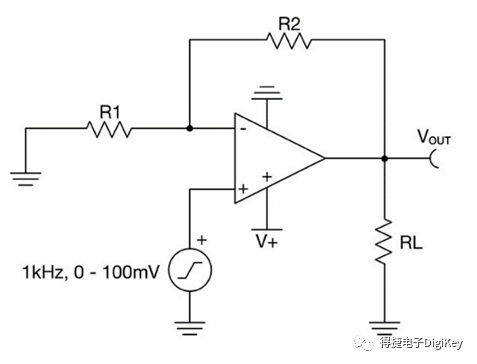

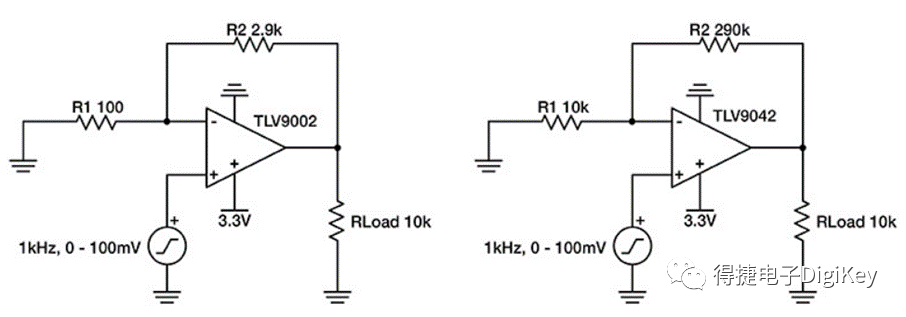

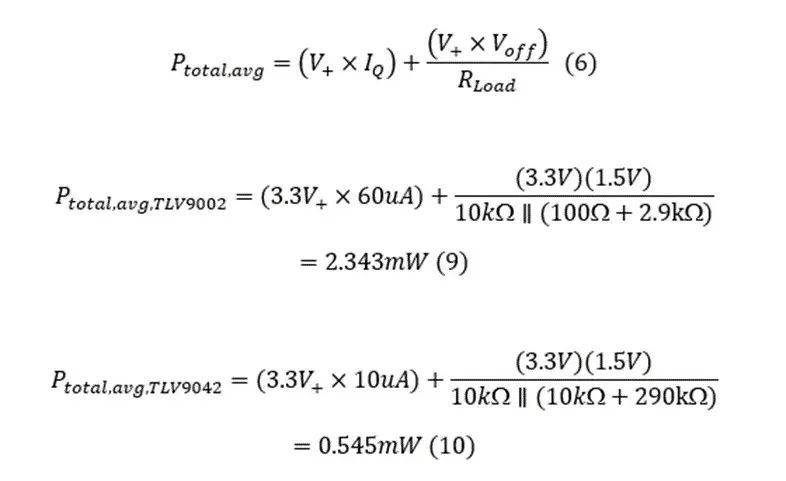

Real-World Examples

Saving Power with Low Voltage Rails

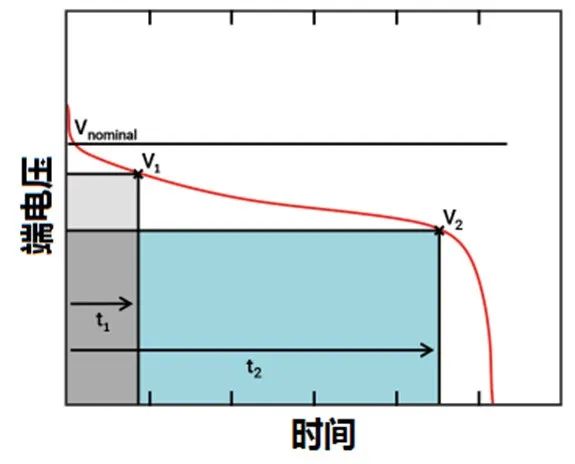

Battery-Powered Applications

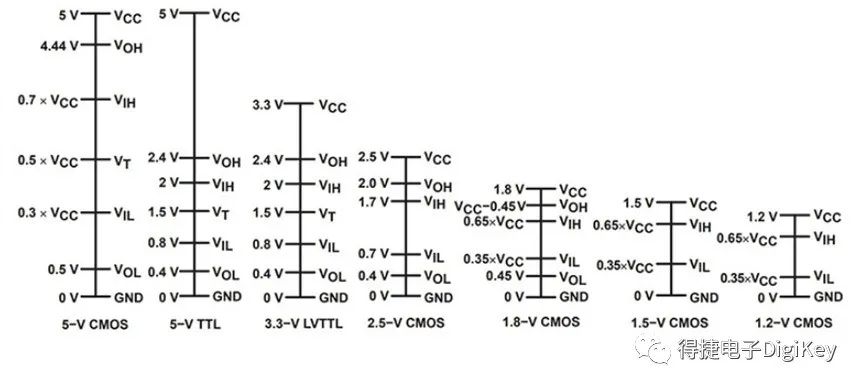

Low Voltage Digital Logic Levels