1. Omron PLC Programming Software

The Omron PLC programming software integrates CX-Programmer V9.5, providing comprehensive software support for Omron PLC programming, fully compatible with 32/64-bit WIN8 systems, and available in multiple languages, including Simplified Chinese.

It can be used for configuring networks, programmable terminals, servo systems, electronic temperature control, and more. It is suitable for those responsible for installing FA systems, designing FA systems, and managing and maintaining FA systems, who already possess knowledge of electrical systems (electrical engineers or equivalent).

2. Mitsubishi PLC Programming Software

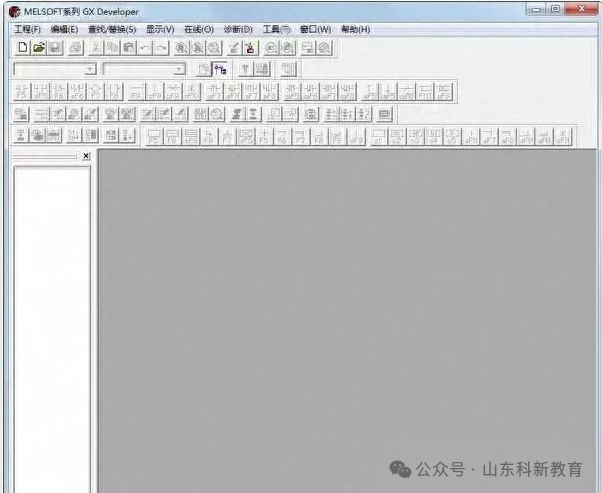

The Mitsubishi PLC programming software is suitable for the entire series of programmable controllers including Q, QnU, QS, QnA, AnS, AnA, FX, etc.

The Mitsubishi PLC programming software GX Developer is positioned as a comprehensive development platform for programmable controllers, supporting ladder diagrams, instruction lists, SFC, ST, FB, and Label programming languages, network parameter settings, online program modifications, monitoring, and debugging, with remote read/write PLC program capabilities.

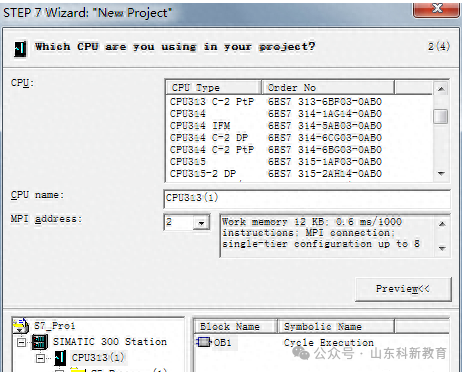

3. Siemens STEP 7

STEP 7 is Siemens’ most classic programming software, corresponding to the Siemens S7-300/400 series, representing the older models of Siemens PLCs.

STEP 7 has the following functions: hardware configuration and parameter settings, communication configuration, programming, testing, commissioning, maintenance, file archiving, operational and diagnostic functionalities, etc. All functions of STEP 7 come with extensive online help; by clicking on an object with the mouse and pressing F1, related help for that object can be obtained.

In STEP 7, a project is used to manage the hardware and software of an automation system. The SIMATIC Manager centrally manages the project, allowing easy browsing of data for SIMATIC S7, M7, C7, and WinAC. All SIMATIC software tools necessary for implementing STEP 7 functions are integrated within STEP 7.

4. Siemens TIA Portal

TIA Portal, short for Totally Integrated Automation Portal, is a new all-in-one automation software released by Siemens Industrial Automation Group.

It is the first automation software in the industry to adopt a unified engineering configuration and software project environment, applicable to almost all automation tasks. With this new engineering software platform, users can quickly and intuitively develop and debug automation systems.

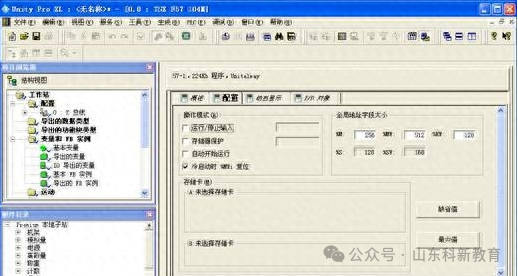

5. Schneider Programming Software

Unity Pro XL is Schneider Electric’s core product for automation, representing a new generation of hardware and software automation platforms. Its innovative design reduces development time, while the flexibility of the processor achieves higher performance.

Based on openness and collaborative use of tools, Unity has reached a higher level in software development and control system operation, prioritizing improved productivity.

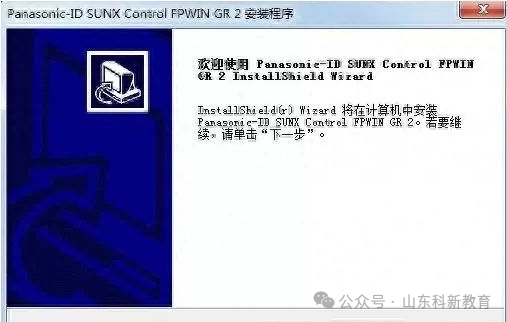

6. Panasonic PLC Programming Software

The Panasonic FP series PLC programming software FPWIN GR is a powerful and user-friendly system programming software. The downloaded compressed package contains a serial number, which has been tested and is functional.

The installation includes software needed for MEWNET-H link systems, software for setting various intelligent modules, programming manuals, and this document is a PDF format file explaining PLC instructions.

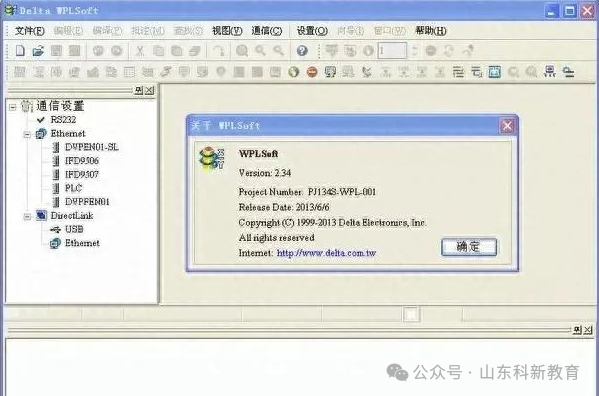

7. Delta WPLSoft PLC Programming Software

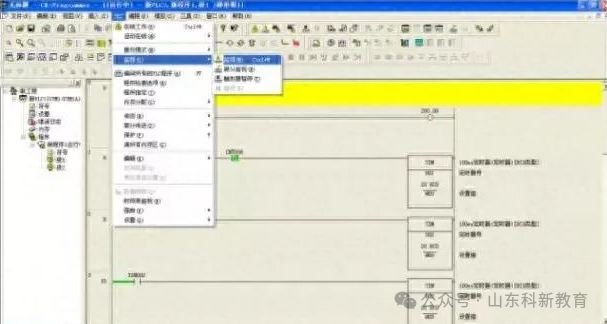

The latest version of Delta PLC programming software WPLSoft allows simulating the execution of PLC programs on a computer without a real PLC. First, click simulation, then click on the ladder diagram monitoring. You can right-click to control the status of some quantities. This achieves simulation. Note that it needs to be connected to the PLC.

After starting the simulator, monitoring, uploading, and downloading programs, and other communication functions can be performed without selecting a communication interface, operating in the same way as if connected to a real PLC.

The simulator supports timers and counters, but the running time of the timers and counters may vary depending on the performance of the user’s computer. The timer processing method is the same as that of the DVP-ES/SA series PLC actions.

Source: This article is reprinted from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact us to delete it in time. Thank you!

Scan to Follow

WeChat ID|13615417996

Follow the left QR code to get free access to

[Siemens Data Collection]