Currently, technology is advancing rapidly, with precision circuit boards carrying thousands of signal transmissions, acting as the central nervous system of the intelligent world, linking key instructions together. Jingwang Electronics Co., Ltd. (hereinafter referred to as “Jingwang Electronics”), established in 1993 and listed on the Shanghai Stock Exchange in 2017 (stock code: 603228), has been deeply engaged in the printed circuit board (PCB) industry for 32 years, focusing on the research, production, and sales of high-end printed circuit boards and high-end electronic materials. Starting from a small factory, Jingwang Electronics has now become one of the top ten PCB companies globally, continuously climbing the technological peak with a firm step across mountains and seas, laying out a global presence.

Jingwang Electronics Intelligent Workshop

Products Sold Worldwide

In the production workshop of Jingwang Electronics located in the Taohuayuan Science and Technology Park in Xixiang, Bao’an, Shenzhen, various PCB products are being manufactured. Some resemble Lego mini blocks, with 2 to 30 layers of different structures; some are as small as a fingernail; some are hard and stable; others are flexible enough to be folded. These products are being shipped globally from six major production bases in Shenzhen Bao’an, Heyuan Longchuan, Ji’an Jishui, Ganzhou Xinfeng, Zhuhai Jinwan, and Zhuhai Fushan. Jingwang Electronics’ first overseas production base in Prachinburi, Thailand, is also under construction.

Jingwang Electronics Intelligent Workshop

Jingwang Electronics Intelligent Workshop

“Our products cover multilayer boards, carrier boards, high-frequency and high-speed boards, multilayer flexible circuit boards, high-density flexible circuit boards, HDI boards, metal-based circuit boards, and rigid-flex boards. We are one of the few manufacturers in China that cover rigid circuit boards, flexible circuit boards, and metal-based circuit boards,” said Xie Lenkui, the technical director of Jingwang Electronics. The PCB products produced by the company are widely used in AI computing power, intelligent driving, data centers, and smart terminals, making them ubiquitous in human production and life.

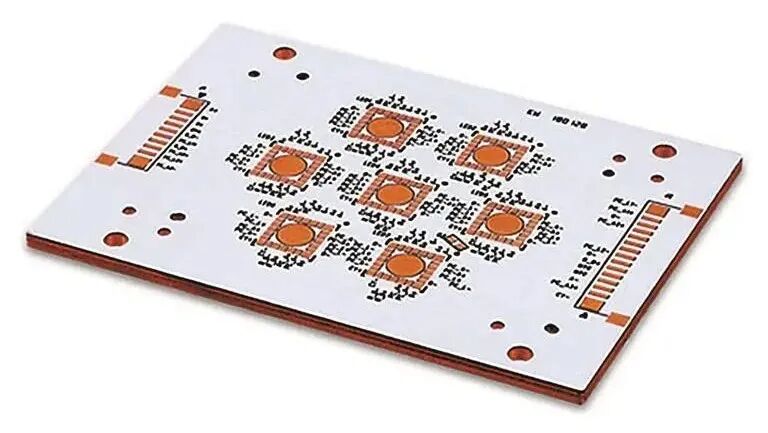

Metal Substrate

Metal Substrate

According to reports, Jingwang Electronics has built a global customer service network based on excellent product quality and technology innovation that closely aligns with customer needs. Currently, the company has established 11 offices both domestically and internationally, hiring local experts to provide localized technical and sales support through FAE (Field Application Engineering) services, as well as multilingual customer service. With over 19,000 employees worldwide, they provide the most efficient, professional, and high-quality service to customers.

AI Empowering Manufacturing

Export Ratio Increased to 42%

In Jingwang Electronics’ intelligent factory, AGV logistics vehicles shuttle orderly between production lines, robotic arms precisely handle loading and unloading, and the MES system monitors the operational status of tens of thousands of devices in real-time… Digital transformation is deeply practiced everywhere here.

- In recent years, Jingwang Electronics has comprehensively improved production efficiency and product quality through digital workshops, leveraging AI to promote deep integration of big data and artificial intelligence, achieving precise quality control and agile delivery.

- Through RPA robots automatically obtaining customer orders and completing orders, MRP automatically calculating material procurement needs, and the SRM system automatically issuing purchase orders and receiving supplier delivery replies, the customer order response cycle has significantly shortened, with the export ratio expected to increase to 42% in 2024.

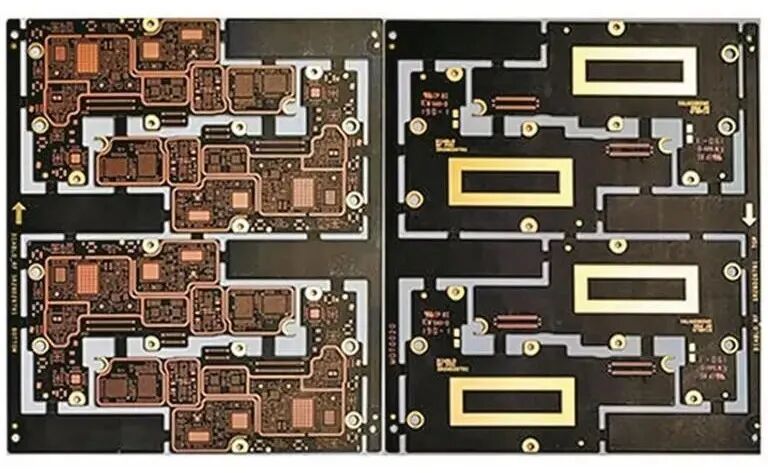

Carrier Board

The increase in production capacity is backed by technological breakthroughs and significant investment in R&D by the company. As of now, Jingwang Electronics has accumulated 314 domestic invention patents, 316 domestic utility model patents, and 2 foreign invention patents, with over a hundred core journal papers published. Among them, seven technologies, including key technologies for micro-power chip power supply embedded magnetic core PCB, have been rated as internationally advanced technologies, and 35 technologies, including key technologies for high-speed PCB for low-orbit satellite communication, have been rated as domestically leading/advanced technologies. Coupled with global market expansion capabilities and a “front store, back factory” collaborative model, Jingwang Electronics has achieved seamless integration from order taking, R&D to delivery, with significant results in overseas market expansion, earning unanimous praise from customers.

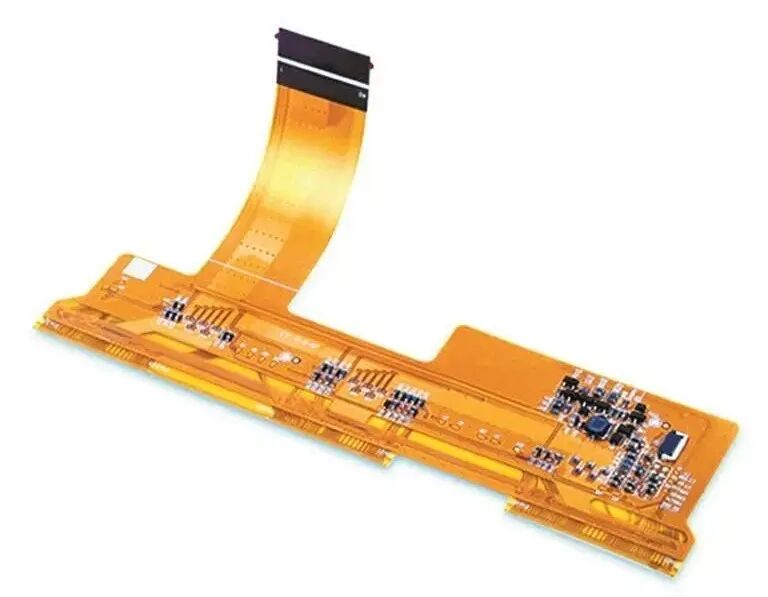

Flexible Circuit Board

“Jingwang Electronics focuses on the present while paying attention to the sustainable development of the future,” said Liu Pingang, the environmental management director of Jingwang Electronics. On the roof of the Jingwang factory in Zhuhai Jinwan, 10MW of photovoltaic panels continuously convert sunlight into clean electric energy. Jingwang Electronics employs advanced wastewater, waste gas, and solid waste treatment technologies, establishing a comprehensive three-waste treatment system, actively engaging in source waste reduction and clean production efforts, and has received titles such as “Green Environmental Protection Demonstration Enterprise,” “Waste-Free Factory,” and “Clean Production Enterprise” for several consecutive years. Jingwang Electronics has also incorporated sustainable development into its strategic planning, aiming to achieve carbon peak by 2025 and promote carbon neutrality in the supply chain by 2050.

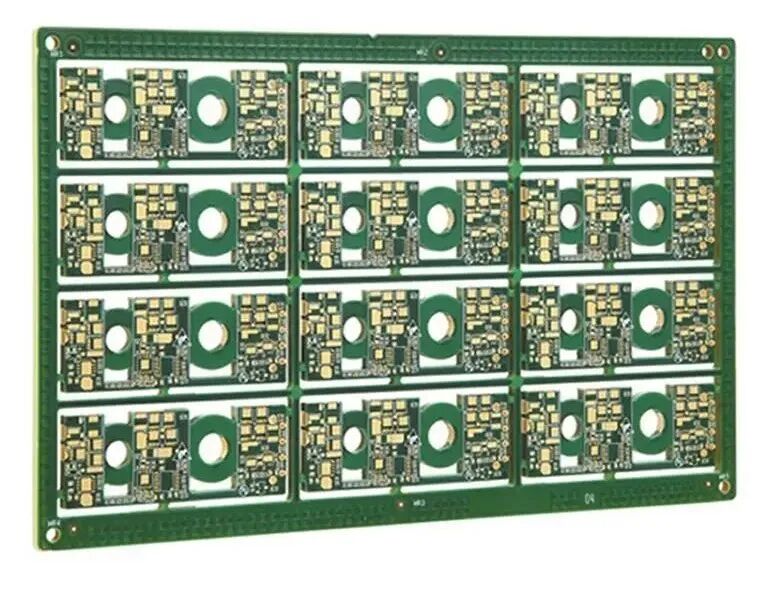

High Multilayer PCB

Standing on the path of technological breakthroughs, Jingwang Electronics is on a mission to “connect the world through circuits and build an interconnected universe,” injecting innovation into every circuit board. From the speed of smart cars to the establishment of 6G base stations, from the stunning foldable screen phones to the networking of satellite internet, the craftsmanship of Jingwang people is quietly connecting everything, allowing the world to hear the strong pulse of Chinese intelligent manufacturing.

Must-Buy Gene PoolHigh Multilayer Printed Circuit Boards, Carrier Boards

High multilayer PCBs and carrier boards with higher layers, smaller line widths and spacings, capable of carrying more functional modules, with the highest product layer count of over 40 layers and an average of more than 12 layers. Carrier boards have arbitrary layer interconnection and mSAP production capabilities, with applications in servers, high-end consumer electronics, AR/VR, communications, and automotive fields.

Flexible Circuit Boards

Due to their lightweight and flexible characteristics, flexible circuit boards have become fundamental components of many electronic products, widely used in smart terminals, wearable electronics, consumer electronics, automotive, medical, and industrial control fields. Jingwang’s flexible circuit boards have a 4-layer stack structure, with a total board thickness of 0.18mm and a conductor layer copper thickness of less than 1/3oz, capable of dynamic bending over 300,000 times.

Source: Bao’an Daily Disclaimer:This article’s copyright belongs to the original author and does not represent the views of the association.The articles promoted by the “Jiangxi Province Electronic Circuit Industry Association” are for sharing purposes only and do not represent the position of this account. If there are any copyright issues, please contact us for removal.