In the current wave of Industry 4.0 sweeping the globe, sensors, as the “sensory organs” of modern electronic systems, have become the bridge connecting the physical world with the digital world, playing a crucial role. From micron-level precision control in precision manufacturing to force feedback adjustments in humanoid robot dexterous fingers; from millisecond-level early warnings of thermal runaway in new energy vehicle batteries to autonomous obstacle avoidance navigation for drones in the low-altitude economy—the performance boundaries of sensors are defining new heights of intelligence.

At the Shenzhen International Sensor and Application Technology Exhibition (SensorShenzhen 2025), Analog Devices, Inc. (ADI) showcased a series of cutting-edge sensor solutions, demonstrating its technical strength and innovative spirit in the field of sensor technology, injecting new momentum into industrial automation, robotics, and new energy sectors.

“Sensor technology is redefining the ‘touch’ and ‘vision’ of manufacturing,” said Eric Cai, Director of Industrial Markets for ADI China, in an interview with media outlets such as Electronic Engineering Magazine. “ADI not only provides individual devices but also offers system-level solutions based on customer application scenarios, helping customers achieve product realization faster and more efficiently.”

Eric Cai, Director of Industrial Markets for ADI China, introduces product solutions to the media.

Innovative Products Driving Industry Upgrades

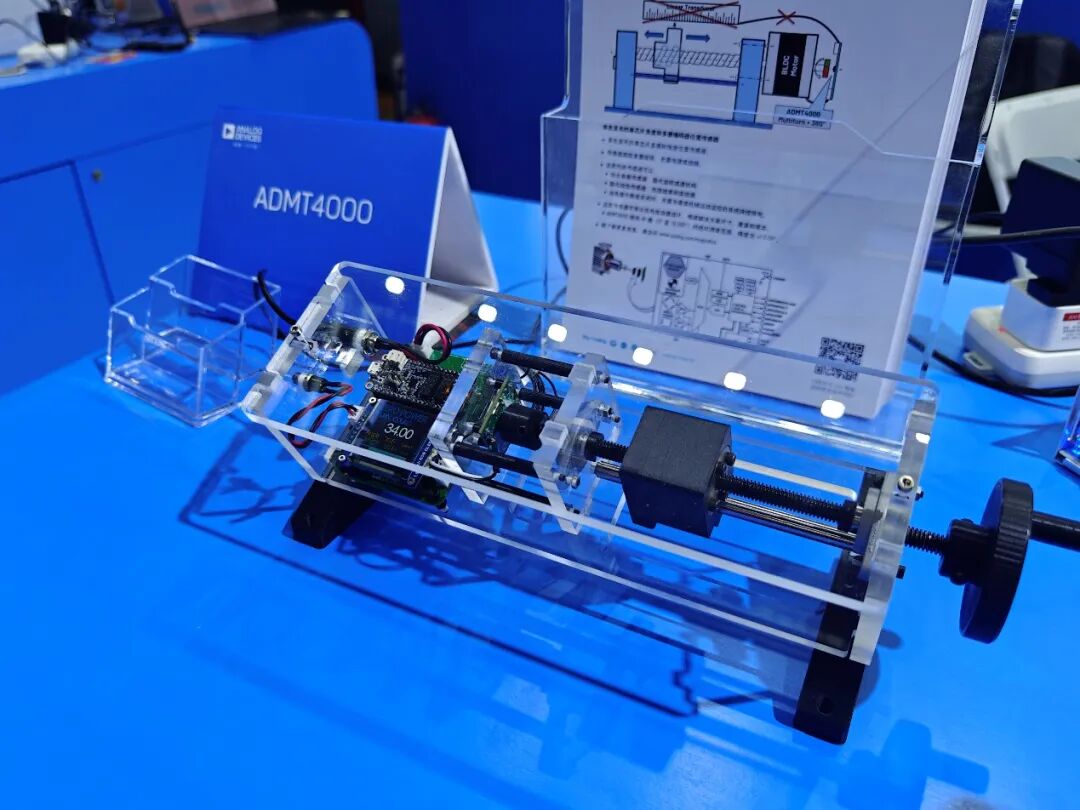

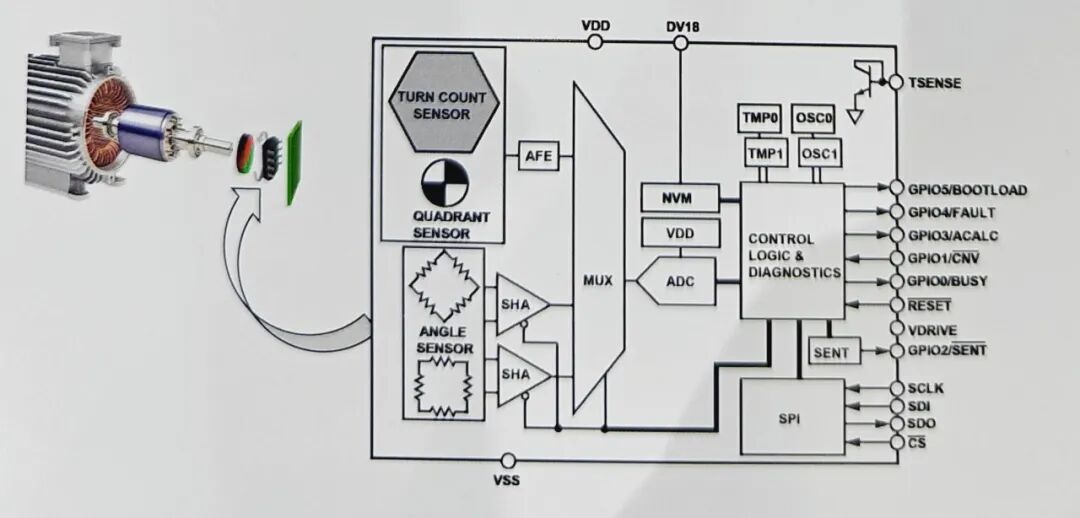

Single-chip and Multi-turn Encoder Position Sensor ADMT4000

As global manufacturing accelerates towards intelligent and flexible production, industrial robots have become a key force in enhancing production efficiency and product quality. Achieving more complex and precise operations in robots relies on accurate perception of the surrounding environment and their own status, as well as efficient and reliable interconnection between systems.

“In the field of industrial robots, precise tracking of motor positions has always been a challenge. Traditional solutions rely on gears or linear sensors, which are not only bulky and costly but also require recalibration after power loss, greatly affecting production efficiency,” said Eric Cai.

ADMT4000 is a revolutionary product launched by ADI for the industrial robotics and automation sector. It achieves position memory during power loss through a dual magnetic sensor architecture that includes a turn count sensor and an angle sensor, supporting passive multi-turn memory that can record 46 turns (0° to 16,560°) of rotation; eliminating the traditional ADC conversion step, with an accuracy of ±0.25°, it can replace traditional gears or linear sensors.

Compared to traditional solutions, ADMT4000 does not require batteries or additional components, significantly reducing the system’s size, weight, and cost.

Eric Cai stated, “The uniqueness of ADMT4000 lies in its power-off position hold technology, which can accurately record motor positions even during power loss, allowing for direct reset upon power restoration without the need for recalibration. This technology has attracted the attention of several humanoid and traditional robot manufacturers, and we will also launch extended multi-turn models in the future to meet the needs of heavy-duty robots.”

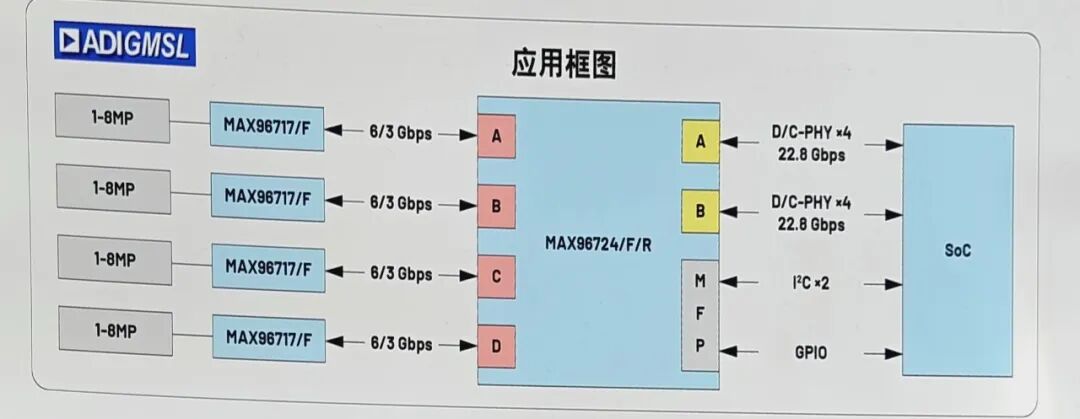

Highly Configurable Interconnect Solution GMSL

GMSL (Gigabit Multimedia Serial Link) is a high-speed interconnect solution based on SerDes technology, supporting full-duplex transmission of video, audio, control signals, and power through a single coaxial cable or twisted pair, significantly reducing wiring complexity.

The MAX96717 serializer supports 3G/6Gbps forward rates and features 4-channel MIPI CSI-2 input; the MAX96724 deserializer supports GMSL1/GMSL2 link rates, can aggregate or replicate data, and convert its signals to D-PHY or C-PHY for SoC processing. The system features low latency, strong anti-interference (better than Ethernet/USB solutions), and is ASIL-B functional safety certified. Its 8mm×8mm small package design optimizes space layout, suitable for high-resolution data transmission between multi-camera sensors and displays, widely used in automotive and industrial fields.

Initially, GMSL was mainly applied in the automotive sector, replacing traditional 100M Ethernet as the preferred solution for in-vehicle multi-screen interconnection, and has now been widely adopted in the industrial sector as well. For example, humanoid robots can quickly transmit high-definition data from multiple cameras to AI model platforms via GMSL, achieving comprehensive perception of the surrounding environment.

“GMSL’s 6Gbps transmission rate (second generation) and 12Gbps (third generation) are higher than in-vehicle Ethernet, meeting the high-definition data flood requirements of up to four 8MP cameras and four displays. Meanwhile, traditional Ethernet requires six wires to loop around the vehicle, while GMSL only needs a single coaxial cable to connect the camera to the master control, reducing the weight and cost of the entire vehicle or equipment,” Eric Cai stated, noting that the multi-camera layout of humanoid robots is similar to that of autonomous vehicles. GMSL technology allows industrial AGVs, AMRs, and service robots to achieve efficient interconnection with “one wire” just like smart cars.

Currently, GMSL has been widely used in automotive 360-degree surround view systems, humanoid robots, and industrial high-speed imaging fields, and has also performed excellently in full HD endoscopes and other areas.

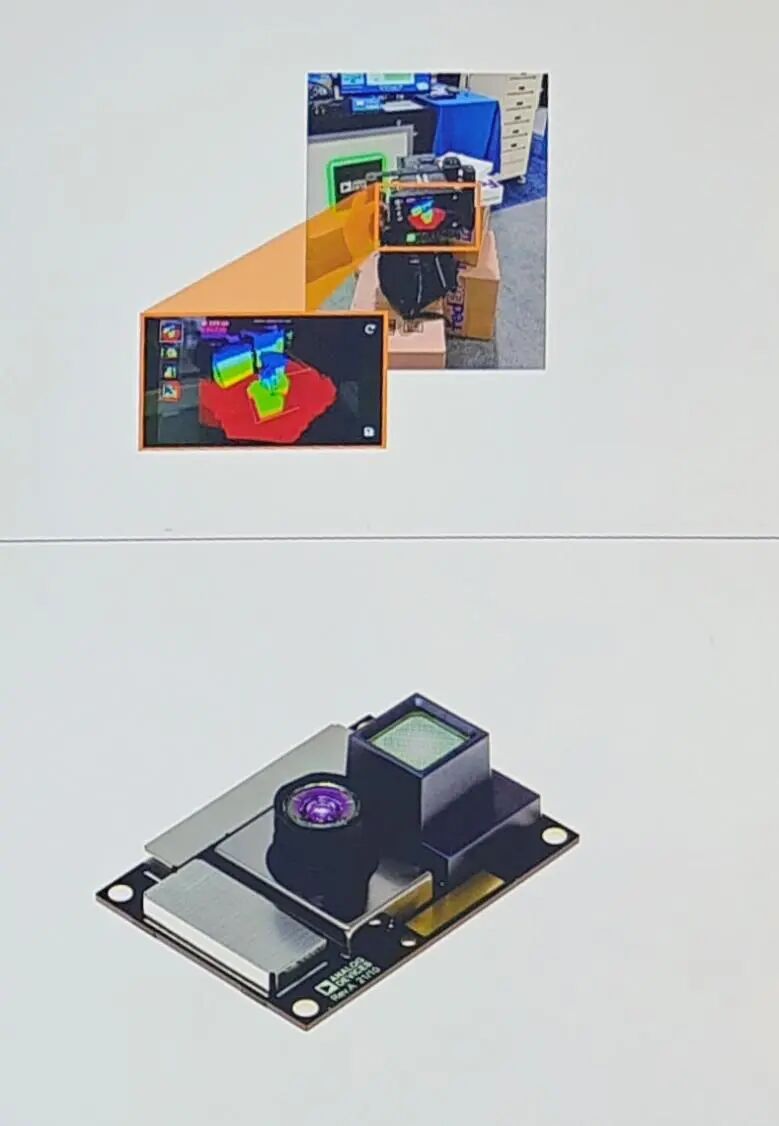

Time-of-Flight (ToF) 3D Object Measurement Solutions

ADI’s ToF (Time-of-Flight) solution employs high-resolution 3D ToF technology based on Microsoft CMOS imaging and depth computing technology. This system uses nanosecond-level high-power light pulses to capture relevant depth information from the target illuminated scene. Combined with precise image stitching algorithms, it can accurately measure the dimensions of large irregular objects through mobile systems, thereby improving operational efficiency and reducing errors. The detection distance of this solution can reach 7 meters, with an error of about 3 millimeters within a range of 5 meters.

Eric Cai stated, “ToF technology has broad application prospects in logistics and robotic vision fields. In logistics, it can help accurately measure the dimensions of items, optimize packaging box selection, and reduce waste; in robotic vision, it can achieve precise object recognition and grasping without relying on ambient light, functioning normally even in dark factories.”

In the field of robotic visual recognition technology, there are currently two main technologies: one is binocular vision, which requires a light source and uses two cameras to capture images, simulating human eyes to outline the approximate external shape of objects; the second is ADI’s solution, which uses only one camera based on ToF technology, without needing a light source, emitting signals from the front, and the signals are affected by the surface morphology of the object upon return, allowing the entire shape of the object to be calculated through time, known as iToF.

The advantage of iToF is its ability to simulate the product’s shape. During the recognition process, the robot can not only identify the object and make preliminary judgments but also perform precise operations. For example, during grasping, the system can be programmed to decide from which angle to grip the target object and instruct the computer to execute the corresponding task.

It is reported that ADI has developed its 3D-TOF solution into a module, with the light source at the bottom and the receiver on top. The module directly transmits distance signals to the central processor via USB, allowing for corresponding calculations and application development, featuring low noise, high resolution, and high system efficiency.

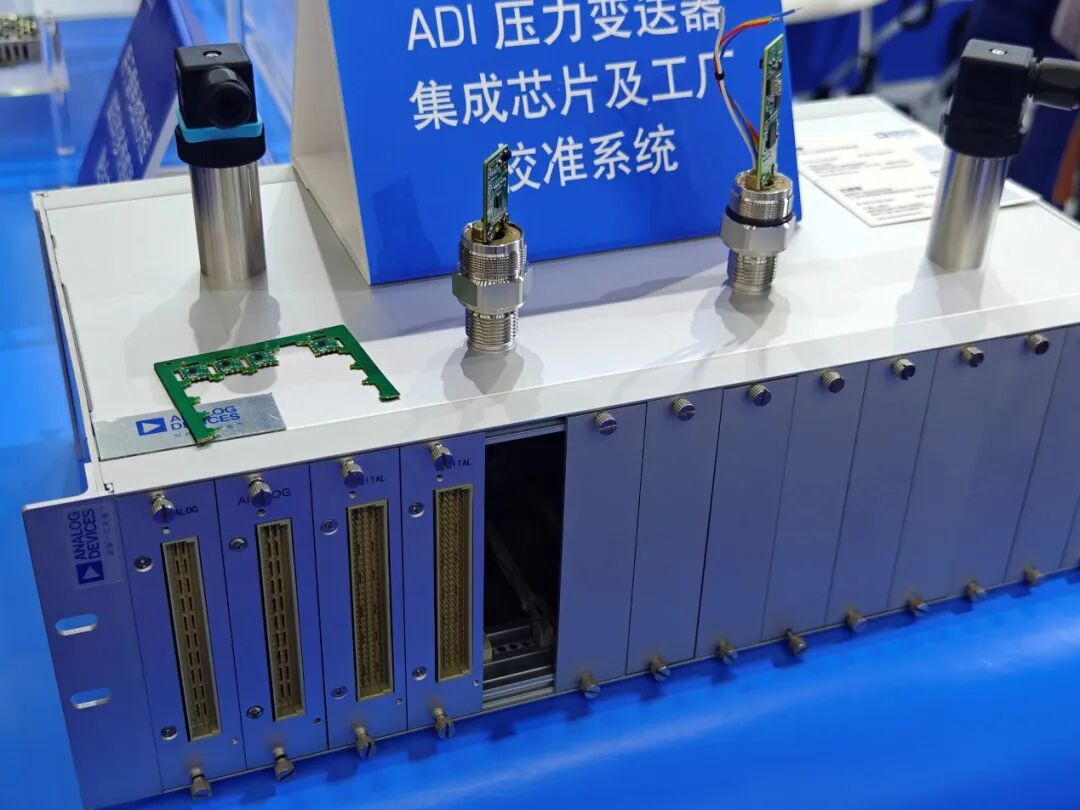

ADI Pressure Transmitter Integrated Chip and Factory Calibration System

Building an efficient and intelligent industrial Internet of Things (IIoT) has become a core strategy for enterprises to achieve digital transformation. By deploying a wide range of sensor networks to collect key data such as equipment operating status and environmental parameters in real-time, enterprises can achieve more refined management and more efficient operations to support industrial digital transformation.

Currently, all pressure sensors require calibration before leaving the factory due to pressure deviations caused by the structure of polycrystalline or monocrystalline silicon. ADI’s pressure transmitter integrated chip and factory calibration system is a testing suite used for calibrating pressure transmitter production lines, developed and supported by ADI’s full-stack technology, providing strong support for the development of the industrial Internet of Things.

Among them, the MAX40109 integrates an AFE, featuring high integration and small packaging advantages, capable of directly outputting digital signals that can be connected to RS-485 interfaces or transmitted directly through other means, requiring only a blank board to connect the wiring harness for pressure signal transmission and reading; the MAX32675C is a SOC integrated with a HART modem, consisting of two chips, with the first chip responsible for collecting signals from the pressure sensor, but its output is analog, which is usually difficult to use directly. At this point, the analog signal can be transmitted to a microcontroller (MCU), where it is converted to a digital signal using ADI’s 24-bit ADC, and after reading, it is transmitted via the HART communication protocol.

It is worth mentioning that ADI’s MCU is the industry’s first product integrated with HART functionality, which is widely used in various factory equipment.

From the on-site demonstration, it can be seen that this calibration system is provided in the form of an industrial standard chassis, used in conjunction with PC calibration programs, collecting the corresponding spectrum, and determining the vibration operating status based on different motors. The analog interface supports 4-20mA current loops and proportional voltage outputs, while the digital interface supports I2C interfaces. Each calibration chassis supports 12 board slots, with selectable analog calibration boards or digital calibration boards; each calibration board, whether analog or digital, supports 32 channels of devices under test, allowing one chassis to support calibration of 384 channels of devices.

Eric Cai pointed out, “Our calibration system can calibrate 12 circuit boards simultaneously, compatible with RS-485 interfaces and HART protocols, compressing the traditional manual adjustment calibration cycle that takes weeks into just a few hours through an automated system, significantly shortening the development cycle. This is the value-added service we provide to help customers bring products to market faster.”

At the same time, ADI also provides a complete calibration system to help customers quickly complete sensor calibration work, improving production efficiency. Currently, this solution has been applied in fields such as stress monitoring of energy storage station battery packs and mass testing of industrial pressure sensors.

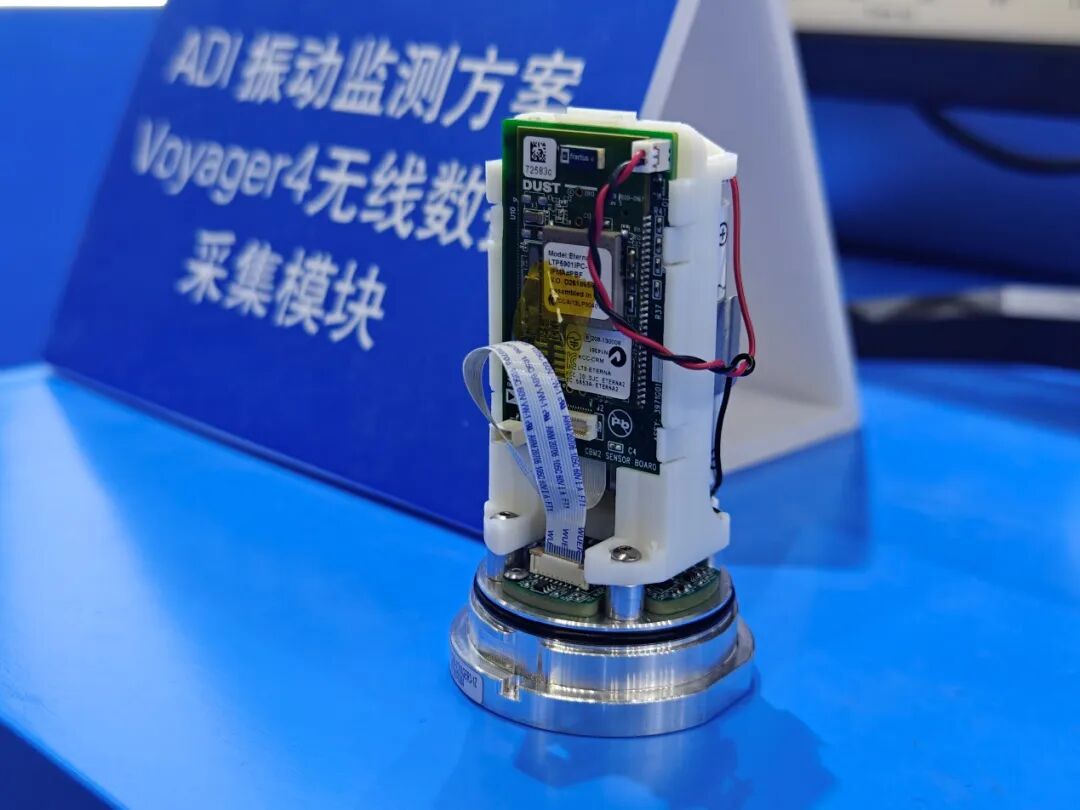

ADI Vibration Monitoring Solution — Voyager4 Wireless Data Acquisition Module

The Voyager4 wireless data acquisition module is a solution launched by ADI for monitoring the status of industrial equipment. It integrates two vibration sensors, ADXL382 and ADXL367, capable of real-time collection of vibration data and transmitting it to a host computer for analysis via Bluetooth SOC MAX32666.

The main vibration sensor ADXL382 captures high-frequency vibrations in the range of 4KHz-8KHz and vibration bandwidths of 4 to 60G (such as bearing faults), while the auxiliary vibration sensor ADXL367 has lower power consumption and is responsible for collecting data between initial and slightly larger amplitude vibrations. This solution also features a flexible power management scheme, allowing real-time switching between the two sensors, and supports Python algorithms to extract vibration feature values in real-time, avoiding massive data uploads to the cloud.

It is noteworthy that this module has pioneered a new model of “local AI + edge computing.” Its AI Edge SOC MAX78000 supports edge-side AI data collection algorithms, with an integrated hardware CNN accelerator enabling localized vibration status monitoring and preliminary processing of vibration data to determine the operating status of the equipment, reducing reliance on the cloud.

Eric Cai stated, “The advantage of Voyager4 lies in its dynamic power management and BLE5 wireless transmission capabilities, with a battery standby time of up to two years. It is mainly used for vibration monitoring of large equipment such as water pumps, coal mines, and cement plants, helping customers detect equipment failures in a timely manner and avoid losses from unplanned downtime.”

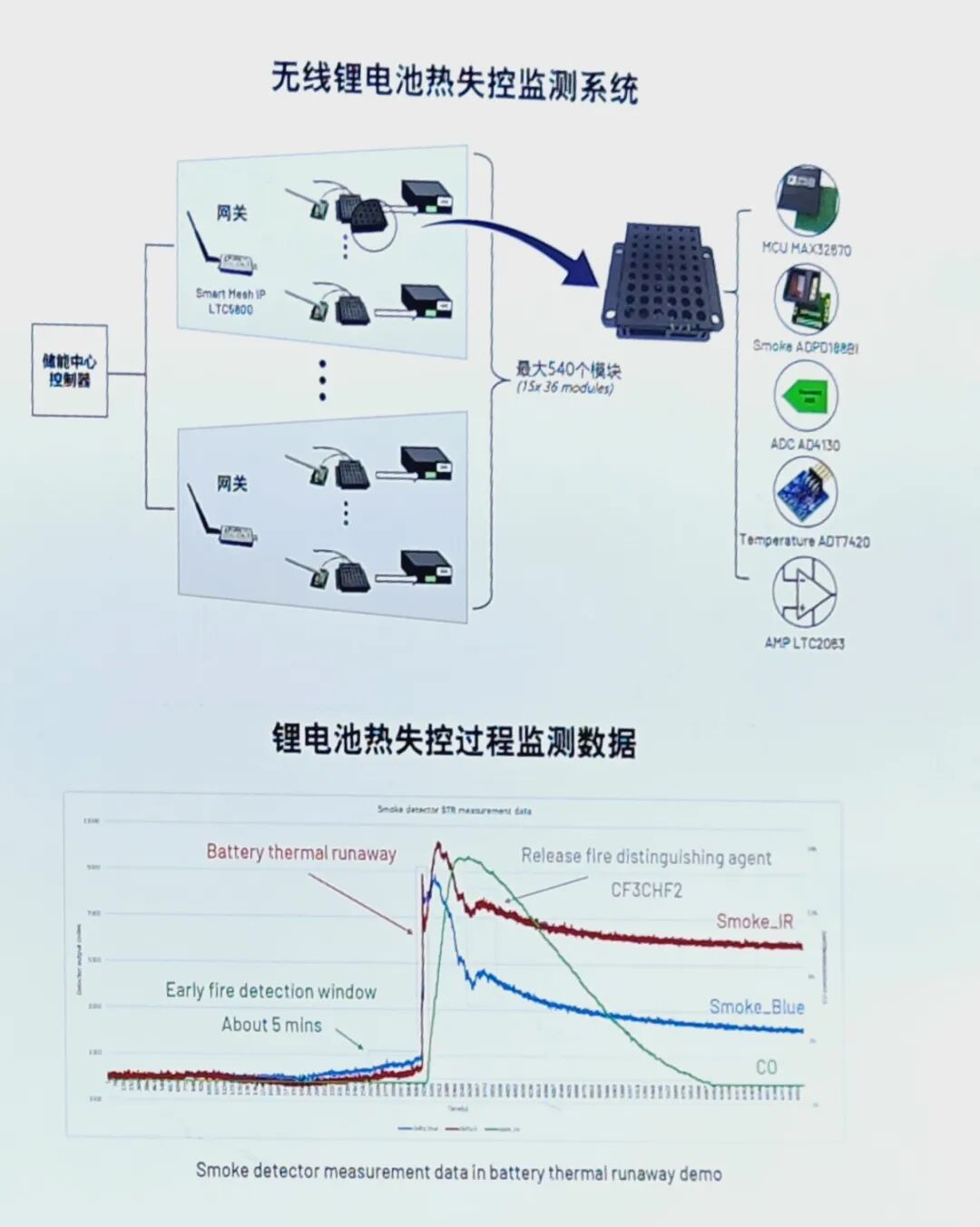

Multi-Sensor Fusion Solution for Lithium Battery Thermal Runaway Monitoring

The safety issues surrounding lithium batteries have always been a focal point of industry concern. Especially in manned vehicles powered by lithium batteries, once thermal runaway occurs, it poses serious safety hazards, necessitating early warnings and evacuation of passengers several minutes in advance.

To address the safety issues of lithium batteries, ADI has launched a multi-sensor fusion solution. This solution is used for real-time monitoring of the thermal runaway process of lithium batteries, primarily applied in energy storage stations and electric vehicle battery packs. By detecting parameters such as smoke, CO, H2, pressure, and temperature, it can effectively monitor changes in parameters before and after lithium battery thermal runaway, and using SmartMesh wireless networks, transmit data to the host for analysis, issuing fire alarms/lithium battery thermal runaway signals accurately and early.

It is reported that ADI provides a complete solution including smoke sensor ADPD188BI, gas, pressure, temperature sensor signal conditioning circuits, and SmartMesh wireless chips. This solution not only supports wireless transmission but is also compatible with fire extinguishing devices, linking with the battery management system (BMS) to trigger emergency mechanisms. For example, if smoke is detected inside a bus, the system will activate the fire extinguishing mechanism to prevent explosions or other safety hazards. Major application scenarios include fire warning, lithium battery thermal runaway monitoring in commercial/home energy storage stations, and electric vehicle lithium battery thermal runaway monitoring.

Initially, ADI only placed a small sensor inside the battery. However, after communicating with customers, it was found that merely detecting smoke was insufficient; batteries may first release hydrogen, carbon monoxide, and carbon dioxide before burning, and batteries may bulge, necessitating stress detection. Based on this application scenario, ADI enhanced the original solution by adding gas sensors, pressure sensors, and temperature sensors alongside the smoke detector, making the entire solution more comprehensive.

“If customers have related needs, they only need to adapt our solution for quick market entry, shortening the time to market. Moreover, with the increasing popularity of electric vehicles, the demand in this field is also continuously rising,” Eric Cai explained. “Our solution is compact and can be non-contact installed in square/cylindrical battery packs, capable of detecting signs of thermal runaway in advance, buying precious escape time for drivers and passengers.”

Currently, thermal runaway monitoring has become a necessity for new energy vehicle companies, and ADI’s solution has been applied in commercial vehicles. This solution has been implemented in buses and energy storage stations, and will further expand into energy storage stations, low-altitude aircraft, and other application fields in the future.

Insights into Industry Trends: Robotics, Aerial Vehicles, AI

The industry generally views 2025 as the year of humanoid robots, with the public gaining a certain understanding of humanoid robots. In the interview, Eric Cai also discussed the technical challenges facing the development of the robotics industry. He stated that currently, humanoid robots are mainly in industrial experimental scenarios, with battery endurance, motor power consumption, and intelligence levels being the three key issues in current robot technology development.

For example, in the recent robot marathon to be held in Beijing, robots need to carry batteries to operate continuously for nearly an hour, which places extremely high demands on battery energy density, while current robot endurance generally falls short of 30 minutes.

Secondly, the issue of motor power consumption cannot be ignored, requiring optimization of servo drive systems to achieve “all-day operation on a single charge,” which not only helps extend battery endurance but also enhances the overall performance of robots.

Thirdly, the intelligence level of robots needs to be improved. Especially for the currently popular humanoid robots, in addition to needing voice recognition capabilities to understand and execute voice commands, the force feedback control of dexterous hands also relies on preset programs, making it difficult to cope with complex operational scenarios, requiring higher adaptive capabilities.

Previously, industrial robots used fixed actions, fixed forces, and fixed torque, and the technology has matured, but the most challenging aspect of humanoid robots is adapting to multi-scenario applications. For instance, when grasping objects, robots need to adjust their grip strength based on the shape and material of the object, distinguishing between picking up a pill and lifting a heavy object, which poses higher demands on force sensor technology and AI algorithms.

Regarding the development of the low-altitude economy, Eric Cai believes its core lies in “industry-level” demand—such as power grid inspections and forest fire prevention, rather than merely pursuing manned technology. ADI’s MEMS technology has significant advantages in these scenarios, and he stated, “Unmanned robots in the low-altitude economy have broad application prospects in disaster relief, forest firefighting, and logistics transportation. ADI’s MEMS sensors have been validated in logistics drones, especially in disaster relief scenarios, where drones equipped with 5G base stations can transmit high-definition video in real-time and restore communication within a certain range.”

With the rapid development of AI technology, the integration of AI and sensors has become a hot topic in the industry, but the choice between edge computing and cloud computing needs to be determined based on the scenario.

Eric Cai believes that edge processing can reduce data transmission volume, while the cloud is suitable for complex calculations. ADI’s strategy is to provide flexible solutions to meet different customer needs. “We have launched edge processing-based vibration sensor applications that can perform preliminary data processing at the edge, reducing the computational pressure on the cloud.” In the future, ADI will continue to increase R&D investment in the integration of AI and sensors, providing customers with smarter solutions.”

Conclusion: From Chips to Systems, ADI Empowers Customer Innovation

From the products showcased at this exhibition, it is evident that ADI is transforming from a single chip supplier to a system-level solution provider, providing complete hardware, software, and algorithm support to convert fragmented sensor data into actionable decision-making, helping customers achieve full-stack capabilities of “hardware-software-service.”

“Having been deeply involved in the industry for decades, ADI understands where the pain points are and how to better meet customer needs. Customers only need to focus on creating core value, while ADI takes care of solving complex technical challenges.” Eric Cai vividly likened ADI’s solutions to “pre-prepared meals”: “The solutions we provide to customers are like pre-prepared meals; customers only need to make simple developments and adjustments to quickly bring products to market. This not only reduces customers’ R&D costs but also shortens the time to market for products.”

In addition, ADI is accelerating localized development, launching customized products for the Chinese market. Eric Cai stated, “We have observed the demand for rapid iteration in the Chinese market, such as the quarterly product release cycles of Siemens and ABB. ADI will also help customers shorten time to market through R&D that is closer to the market.”

In future development, ADI will continue to uphold the philosophy of “In China, for China,” deeply understanding customer needs, continuously launching innovative solutions, and working hand in hand with customers to promote the intelligent upgrade of the electronics industry. (Editor: Luffy)

Hot Articles

2025 China Fabless100 3+10 Category Top 10 Rankings

2025-03-27

2025 China Fabless 100 Listed Company Rankings (Beta Version) Released!

2025-03-25

How is the China Fabless 100 Ranking Calculated?

2025-03-25

Under Trump’s “Reciprocal Tariffs,” Auto Manufacturers Accelerate Shipping Core Components to the U.S.

2025-03-26

$390 Million Smuggling Case! The U.S. Pressures Singapore and Malaysia to Strictly Investigate AI Chip Flow Issues

2025-03-25