Click the blue text above to follow us~Related to SIL Functional Safety1. Introduction

Click the blue text above to follow us~Related to SIL Functional Safety1. Introduction

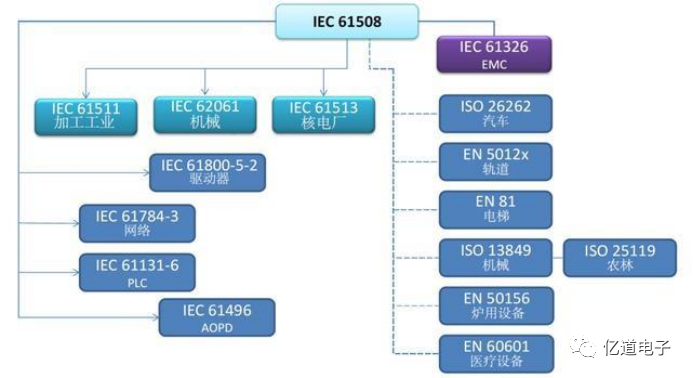

The Safety Integrity Level (SIL) certification is a third-party assessment, verification, and certification process based on standards such as IEC61508, IEC61511, IEC61513, IEC13849-1, IEC62061, and IEC61800-5-2, which evaluates and confirms the safety integrity level (SIL) or performance level (PL) of safety devices. Determining the safety integrity level requires a risk analysis of the safety system, which serves as the goal and foundation for system development and is the basis for assessing whether the system can ensure safety. This mainly involves documentation management (FSM) assessments for the safety device development process, hardware reliability calculations and assessments, software evaluations, environmental testing, and EMC (electromagnetic compatibility) testing.

SIL certification is divided into SIL1, SIL2, SIL3, and SIL4, with SIL1 being the lowest product functional safety level and SIL4 being the highest level.

2. Origin of Functional Safety Standardization

The movement for functional safety standardization originated in the 1990s. Starting in the 1970s, with the increasing use of various modern technologies and the automation of industrial production processes, modern control systems characterized by the extensive application of electrical, electronic, and programmable electronic products began to permeate various fields, participating in various control processes. However, industrial civilization has brought both benefits and disasters. Accidents, personal injuries, and environmental pollution caused by unreasonable system design, component failures, or software system faults have increasingly threatened our safety and the environment we depend on. People began to realize that measures must be taken to regulate the use of safety-related systems in the field through standards and regulations, allowing technology to develop within a safe framework, enabling humanity to enjoy the safety and comfort brought by new technologies while also managing risks. Thus, research into functional safety standards began.

In May 2000, the International Electrotechnical Commission officially released the IEC61508 standard, titled “Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems.” This was the first international standard in the field of functional safety, and subsequent functional safety standards applicable to different application areas are all based on the safety concepts derived from the IEC61508 standard.

3. SIL Certification Bodies

3. SIL Certification Bodies

There are many certification bodies for SIL, including TÜV in Germany, Exida in the USA, and Bureau Veritas (BV) in France; in China, the main certification bodies are the Beijing Institute of Measurement and Testing Technology (ITEI) and the Shanghai Institute of Automation (SITIIAS), among others. The TÜV certification is widely accepted in the software domain in China.

4. SIL Certification Process

The general process for SIL certification projects is as follows:

Phase 1: Concept Assessment

1. Review and evaluate product requirement specifications and safety design concepts;

2. Check and assess the planned fault avoidance measures at various stages of the product lifecycle, especially during development (quality management);

3. Evaluate the measures needed to detect and control faults (diagnostics) through FMEDA (Failure Modes Effects and Diagnostic Analysis) to determine if the safety integrity level can meet the intended purpose;

4. Audit the documentation system (design and quality management);

5. Define electromagnetic compatibility and environmental testing requirements;

6. Prepare a project plan for the main inspection phase;

7. Issue a report based on the results of the concept assessment;

Phase 2: Main Inspection

1. Test all safety-related functions and conduct worst-case analysis (hardware and software);

2. Validate fault control measures (fault insertion testing) and execute FMEDA validation;

3. Review software validation testing (module, integration testing, system testing);

4. Review product documentation created during the development process (design documents, testing, validation, audit records);

5. Define and calculate safety-related reliability data;

6. Conduct environmental testing (including EMC);

7. Check user documentation (installation, operation manuals, safety manuals);

8. Provide a test report;

Phase 3: Certification

Based on the test report, if all requirements are met, the certification body will issue a certificate.

ARM Functional Safety Related1. Introduction

1. General Overview

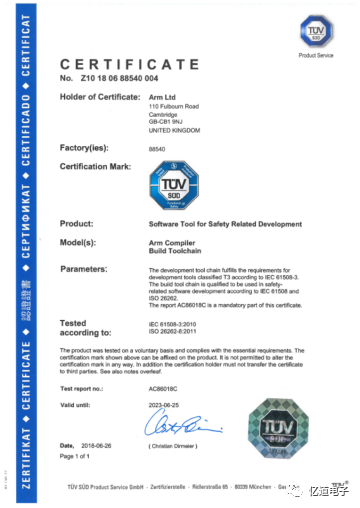

The certification requirements for safety terminal products require that the compiler toolchain used in development complies with the relevant functional safety standards. The process of certifying these tools is known as “tool qualification” or “tool validation,” which can be time-consuming and costly. Moreover, it does not provide any differentiation for the final product. While end users must take responsibility for the entire tool certification process, development tool suppliers can simplify this process by providing tools that comply with appropriate safety standards.

The Arm Compiler for Embedded FuSa is a qualified C/C++ toolchain that has been assessed by the safety certification body TÜV SÜD. The qualified toolchain is suitable for developing embedded software for safety markets such as automotive, industrial, medical, railway, and aerospace. With the TÜV certificate and a comprehensive certification suite, the Arm Compiler for Embedded FuSa greatly simplifies the entire “tool certification” process, allowing end users to focus on their final product development.

The Arm Compiler for Embedded FuSa is qualified to develop software that meets the highest safety integrity levels for the following standards:

-

IEC 61508 (Industrial) – SIL 3

-

ISO 26262 (Automotive) – ASIL D

-

EN 50128 (Railway) – SIL 4

-

IEC 62304 (Medical) – Class C

For other safety standards, many of which are derived from IEC 61508, the certification suite provides key information needed for end users to perform “tool validation.”

Note:

-

ISO 26262 is the safety standard for the automotive industry. This standard uses Automotive Safety Integrity Levels (ASIL A–D) to measure risk, with A being the lowest and D being the highest.

-

IEC 62304 is the safety standard used in the medical device industry. This standard uses software safety classifications (Class A-C) to set risk-based requirements, with A being the lowest and C being the highest.

2. Qualification Kit

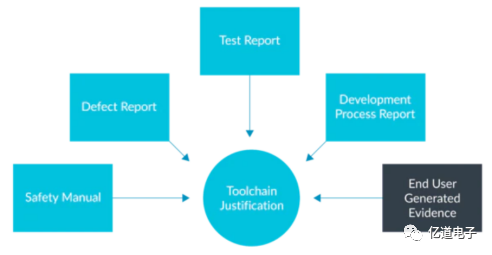

The Qualification Kit provides important safety information regarding toolchain operation, recommended usage, and diagnostic capabilities.

This includes:

-

Safety Manual – Defines the safety boundaries of the toolchain.

-

Defect Report – Describes known safety-critical defects.

-

Development Process – Documents the processes used to develop the safety toolchain.

-

Test Report – Records the results of language consistency tests used in the qualification.

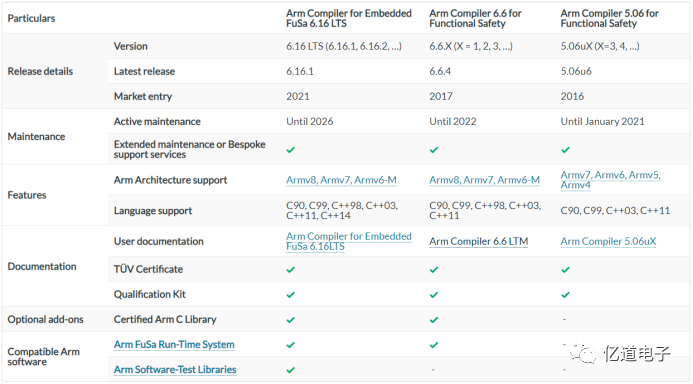

3. Safety Tools Provided by the Arm Compiler Toolchain are Shown Below

2. Introduction to Arm Compiler for Embedded FuSa 6.16LTS

2. Introduction to Arm Compiler for Embedded FuSa 6.16LTS

The Arm Compiler for Embedded FuSa 6.16LTS is the latest functional safety embedded C/C++ compiler toolchain from Arm, and all new users of the functional safety toolchain will purchase this version. It is used for developing bare-metal software, firmware, and real-time operating system (RTOS) applications with functional safety or long-term support requirements. With powerful optimization techniques and optimized libraries, the Arm Compiler for Embedded FuSa enables embedded system developers to meet challenging performance targets and memory constraints.

The Arm Compiler for Embedded FuSa is used by leading companies across various industries, including automotive (ISO 26262), consumer electronics, industrial (IEC 61508), medical (IEC 62304), networking, railway (EN 50128), storage, and telecommunications.

It is also used to develop the following Arm functional safety products:

Qualified Libraries: https://developer.arm.com/tools-and-software/embedded/arm-compiler/safety

Arm FuSa RTS: https://developer.arm.com/tools-and-software/embedded/fusa-run-time-system

Software Testing Libraries: https://www.arm.com/products/development-tools/embedded-and-software/software-test-libraries

The main features of Arm Compiler for Embedded FuSa 6.16LTS include:

-

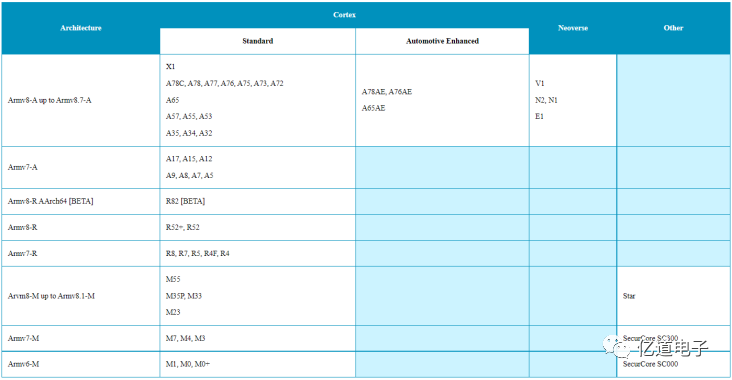

Support for Cortex and Neoverse processors

-

Support for dynamic linking for A-profile and R-profile targets

-

Support for Thread Local Storage (TLS)

-

Support for C++14 source language mode

-

Compatibility with Arm FuSa C library version 6.6.A

The Arm Compiler for Embedded FuSa 6.16LTS includes:

-

Qualified Toolchain Components:

-

armclang: A compiler and integrated assembler based on LLVM and Clang technology

-

armar: An archiver that collects ELF object files

-

armlink: A linker that combines objects and libraries to generate executable files

-

fromelf: An image conversion utility and disassembler

-

Non-Safety Toolchain Components:

-

Arm C Library: Runtime support library for embedded systems

-

Arm C++ Library: Library based on the LLVM libc++ project

-

armasm: An older assembler for armasm-syntax assembly code, applicable only to older Arm architectures. armclang uses the integrated assembler for all new assembly files.

-

Qualification Kit:

-

Safety Manual: Describes the certification scope and how to use the toolchain for safety-related development

-

Defect Report: Provides information on known safety-related defects

-

Test Report: Contains results of language consistency tests

-

Development Process: Provides an overview of the processes used to develop the toolchain

-

Release History: Identification information for all versions of the Arm Compiler for Embedded FuSa 6.16LTS series to date

-

User Documentation:

-

User Guide: Provides examples and guidelines to help you use the toolchain

-

Reference Guide: Provides information to help you configure the toolchain

-

Arm C and C++ Libraries and Floating Point Support User Guide: Provides information about non-restricted Arm libraries and floating point support

-

Error and Warning Reference Guide: Lists errors and warnings that tools in Arm Compiler for Embedded FuSa 6.16LTS can report

-

Migration and Compatibility Guide: Provides information to help you migrate from Arm Compiler 5 to Arm Compiler for Embedded FuSa 6.16LTS

-

Release Notes

-

The toolchain is available for:

-

Integration into Arm Development Studio Gold or Platinum Edition toolkits

-

Integration into Keil MDK-Professional toolkits (requires Windows 64-bit host platform with Windows 32-bit toolchain)

-

Standalone installation

What does Arm Compiler for Embedded FuSa 6.16LTS support?

According to the licensing terms, Arm Compiler for Embedded FuSa 6.16LTS can be used to build for the following Arm architectures and processors:

Note:

The Arm Compiler for Embedded FuSa 6.16LTS is expected not to work on host operating system platforms earlier than those listed above.

Using a Keil MDK license, the Arm Compiler for Embedded FuSa 6.16LTS is only supported on Windows host platforms. Windows 32-bit x86 host platforms are not supported.

If you are using a floating license, your license server must run version 11.14.1.0 or higher of armlmd and lmgrd.

You must choose the appropriate installation location based on how you intend to use Arm Compiler for Embedded FuSa 6.16LTS:

-

Integrated into Arm Development Studio Gold Edition 2021.2 or higher, or Platinum Edition 2021.c or higher

-

Integrated into Keil MDK-Professional 5.36 or higher

-

As a standalone installation

END

We welcome your inquiries!

You can call the consultation hotline at 400-821-3806 or email us at [email protected]. Thank you very much for your attention and valuable feedback!

EMDOORELEC

EMDOORELEC Technology Co., Ltd. is a well-established provider of R&D tool software in China, founded in 2002. We provide various software development tools used in the R&D, design, and management processes for a wide range of manufacturing clients in China, aiming to help customers improve R&D management efficiency, shorten product design cycles, and enhance product reliability. Over the past 20 years, we have established strategic partnerships with many globally renowned companies such as Altium, ARM, Ansys, QT, Adobe, Visu-IT, Minitab, Parasoft, Testplant, IncrediBuild, EPLAN, HighTec, GreenHills, PLS, Ashling, MSC Software, Autodesk, Source Insight, TeamEDA, and have served thousands of local Chinese customers as their main distribution partner, providing tools ranging from chip-level development tools, EDA design tools, software compilation and testing tools, structural design tools, simulation tools, electrical design tools, to embedded GUI tools. With years of experience, EMDOORELEC has truly helped customers achieve the goal of making R&D simpler, more reliable, and more efficient.