Click the blue text to follow us

Scattering the eagle spirits to soar across the land,

With wisdom and courage, calling for the brilliance of China.

01

Introduction

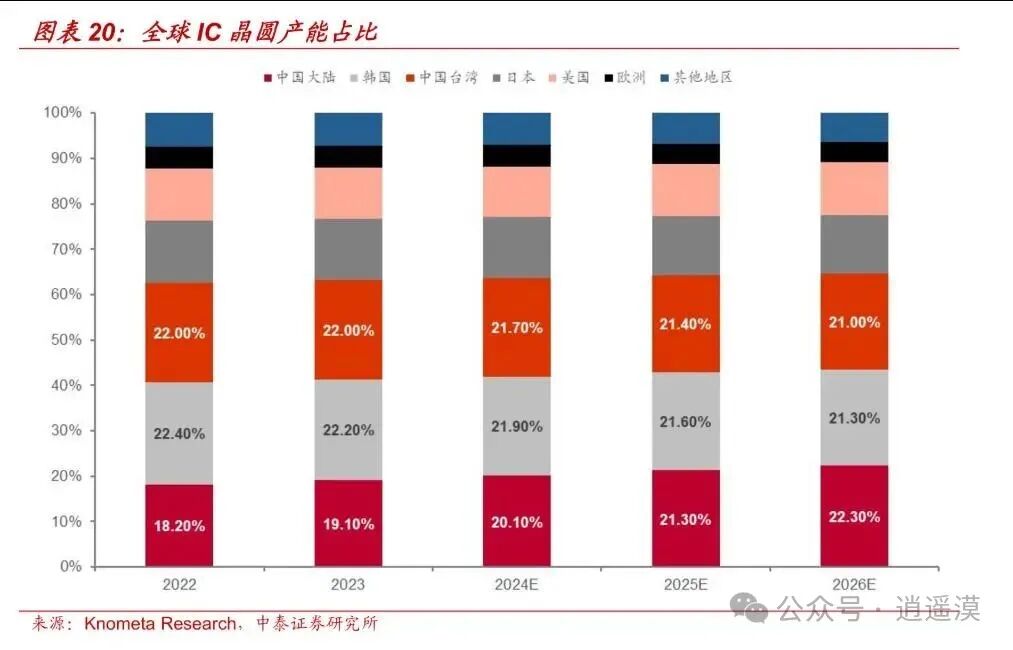

According to a report by the market research and technology consulting firm Yole Group, the current global chip manufacturing landscape shows that Taiwan leads with a 23% production capacity, followed by mainland China with a 21% share, then South Korea at 19%, Japan at 13%, the USA at 10%, and Europe at 8%. #Chip

Driven by market demand, the chip manufacturing industry in mainland China is developing rapidly, approaching the production capacity of Taiwan. Taiwan, relying on TSMC, has been the critical player in the international chip industry for many years, and its importance is undeniable. #TSMC

However, with the increasing emphasis and investment in the chip industry by mainland China, it is expected that by 2030, the chip manufacturing industry in mainland China will surpass that of Taiwan, capturing over 30% of the global production capacity.

02

Capacity Expansion

According to a report released by the Semiconductor Industry Association, in the first quarter of 2025, the total export value of China’s integrated circuit industry exceeded 180 billion yuan, a year-on-year increase of 13%. Chips manufactured by Chinese companies have become one of the important pillars of the international market.

According to news from Boston Consulting Group, the total market size of China’s semiconductor industry has reached one-third of the global market and continues to show a growth trend. The future capacity competition will unfold among Taiwan, mainland China, and South Korea.

Taiwan, relying on TSMC, has secured absolute control over advanced chip manufacturing. South Korea, with companies like Samsung and SK Hynix, has significant advantages in the manufacturing of advanced chips and memory chips.

Although mainland China faces restrictions from the USA, blocking the export of ASML’s EUV lithography machines, mainland companies have a clear advantage in mature chip production capacity. The robust development of China’s new energy vehicle industry has also, to some extent, promoted the large-scale development of domestically produced mature chips. #ASML, #Lithography Machine

In an environment where external advanced technologies are blocked, mainland chip companies are concentrating their resources to rapidly iterate on mature chip technologies. By leveraging trade cooperation in mature chips, they are able to recycle funds, which are then reinvested into the research and development of advanced chips, achieving a positive cycle in the industry chain.

Chinese companies have a unique manufacturing advantage in products such as smartphones, new energy vehicles, and smart home appliances. According to an international industrial planning report, over 65% of mobile phones and home appliances globally are manufactured by Chinese companies.

Although the development of advanced chips is severely hindered, China has already achieved full domestic manufacturing capabilities in the mature chip field of 28nm and above.

Peter Wennink, former CEO of ASML, once told Dutch technology journalist Mark Heijink that the US sanctions against China would inevitably lead Chinese companies to invest heavily in overcoming outdated foreign technologies. As long as they master the technological pathways, Chinese companies will directly engage in the research and development of advanced technologies, thus eliminating imported technological equipment from the domestic market.

03

Industrial Advantages

American economic historian Chris Miller stated in an interview that China’s industrial resources are abundant, and the consumer market in mainland China is the largest and most promising single consumer market in the world, which is also the market that the international chip industry aims to capture, making it the most competitive market among various enterprises.

The unilateral sanctions imposed by the US government on the Chinese market and Chinese companies, even collaborating with international companies to isolate China, will not only greatly affect the economic development of US chip companies but also accelerate the development of an independent industrial chain model by Chinese companies, leading to a market filled with self-controlled chip products that can be prioritized for internal consumption.

In order to break through the blockade and sanctions in the chip industry, Chinese companies began to accumulate technological strength many years ago.

ASML’s Chief Technology Officer Martin visited China in 2018 and 2019 for technical exchanges and found that Chinese companies had already started developing immersion lithography equipment for 28nm chips. Although at that time, Chinese companies faced strong suppression from the US government, they still had the determination and perseverance to develop their own lithography machines.

Before 2024, Chinese companies began to order a large number of unrestricted DUV lithography machines and related consumables from ASML, accumulating sufficient materials and equipment to engage in a protracted technological battle with the US.

Although the US later discovered the intentions of Chinese companies and pressured the Dutch government to prohibit ASML from providing any equipment necessary for chip manufacturing to Chinese companies, Chinese companies had already accumulated a considerable amount of equipment and materials, which would provide technical experience for the Chinese team to develop their own lithography machines.

Classic Review: 200,000+ Reads

Chinese-American says: China’s 7nm is just a numerical game, with a 10-year gap from the US

Former R&D Director of TSMC: China is being choked because the industry is not profitable, and no one is making equipment

Professor from USTC: Making 5nm chips is ten times harder than making an atomic bomb

Classic Review: 400,000+ Reads

Chinese who once contributed to US chips is being strangled by the US for helping China develop technology

He is a Chinese expert in lithography machines, who has never interacted with the mainland

Chinese Academy of Engineering Academician admits: 85% choose to work in the US, talent reserve is severely insufficient

Classic Review: 1,000,000+ Reads

Academician from the Chinese Academy of Sciences criticizes Engineering Academician: No ability, no achievements after leaving Lenovo