Abstract

Recently, Professor Guo Hengyu’s team from the School of Mechanical and Vehicle Engineering at Chongqing University published an article titled “A flexible, channel-minimized and large-scale touch position sensor combining contact electrification effect and screen-printed staggered electrode patterns” in the journal InfoMat, proposing a self-powered and scalable touch positioning strategy that combines contact electrification with screen printing technology. In simple terms, high-impedance electrodes with staggered patterns are screen-printed onto various substrates before being covered with a dielectric layer. The positioning mechanism arises from the charge diversion effect generated by contact in the electrodes. The parameters affecting positioning accuracy in screen printing are discussed in detail. Utilizing this strategy, a customizable large-scale triboelectric touch position sensor (LTPS) has been realized, featuring flexibility, self-powering capability, and minimal signal channels, making it suitable for various practical scenarios.

Recently, Professor Guo Hengyu’s team from the School of Mechanical and Vehicle Engineering at Chongqing University published an article titled “A flexible, channel-minimized and large-scale touch position sensor combining contact electrification effect and screen-printed staggered electrode patterns” in the journal InfoMat, proposing a self-powered and scalable touch positioning strategy that combines contact electrification with screen printing technology. In simple terms, high-impedance electrodes with staggered patterns are screen-printed onto various substrates before being covered with a dielectric layer. The positioning mechanism arises from the charge diversion effect generated by contact in the electrodes. The parameters affecting positioning accuracy in screen printing are discussed in detail. Utilizing this strategy, a customizable large-scale triboelectric touch position sensor (LTPS) has been realized, featuring flexibility, self-powering capability, and minimal signal channels, making it suitable for various practical scenarios.

01. Reference Information

Document Title:A flexible, channel-minimized and large-scale touch position sensor combining contact electrification effect and screen-printed stagger electrode patternsDOI: 10.1002/inf2.70014Original Link:https://doi.org/10.1002/inf2.70014(Download link at the end of the article, click to download)

02. Main Content

01 Research Background

In the era of the Internet of Things, the widespread deployment of position sensors with tracking capabilities has facilitated the realization of smart cities and smart homes, thereby improving the quality of life for individuals (References 1~5). Currently popular position sensing technologies include resistive (References 10~12), capacitive (References 13~15), piezoelectric (References 16~18), and triboelectric (References 19~21). Among these, resistive and capacitive sensors require an external power supply, while piezoelectric sensors require specific materials. In contrast, triboelectric sensors are characterized by their self-powered operation, material diversity, and high signal-to-noise ratio, making their application prospects very broad in the IoT era. (References 22, 23) However, their resolution is proportional to the number of channels. This dependency poses challenges in terms of electrode arrangement, wiring complexity, data acquisition, and signal crosstalk. (References 24~25)

This paper proposes a triboelectric touch position sensor that utilizes contact electrification of uniform high-impedance electrodes to address the challenges associated with channel number dependency and limited adaptability. Using low-cost screen printing technology, various electrode shapes can be produced on different materials, which has been widely applied in large-scale device manufacturing.

02 Production and Working Principle of LTPS

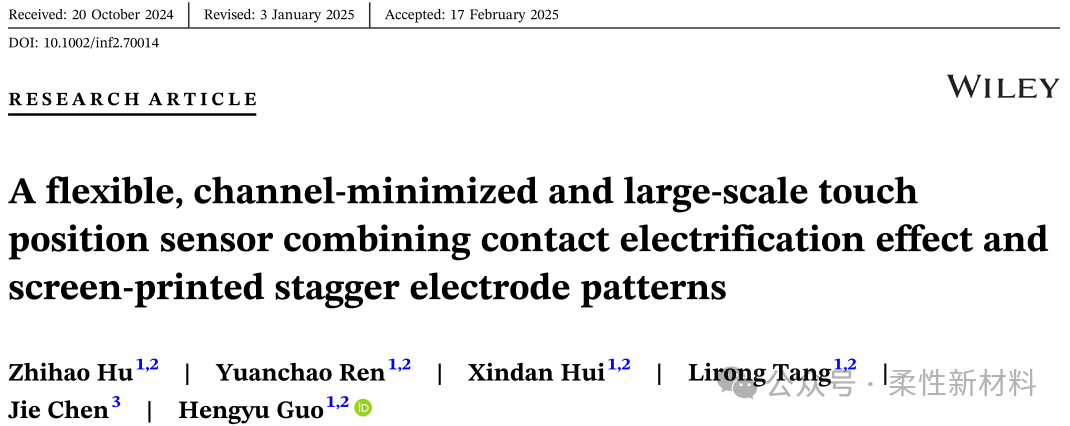

The simplicity of screen printing makes it a universal, economical, and user-friendly technology that only requires ink for printing, a mesh for design, and a rubber squeegee for up-and-down motion.

First, the substrate and a template with staggered electrode patterns are placed on the screen printing platform. Then, an appropriate amount of conductive ink is poured onto the template. The ink is transferred to the substrate using a squeegee. Due to the varying adhesion of the ink on different materials, multiple passes may be required. The substrate is removed and dried for a day to cure the ink and form high-impedance electrodes. The printed electrodes have been successfully applied to various materials, including paper, polyethylene terephthalate (PET), fabric, nylon, polyvinyl chloride (PVC), and Kapton film, without affecting the flexibility of these materials.

Figure 1:Preparation and Working Mechanism of LTPS

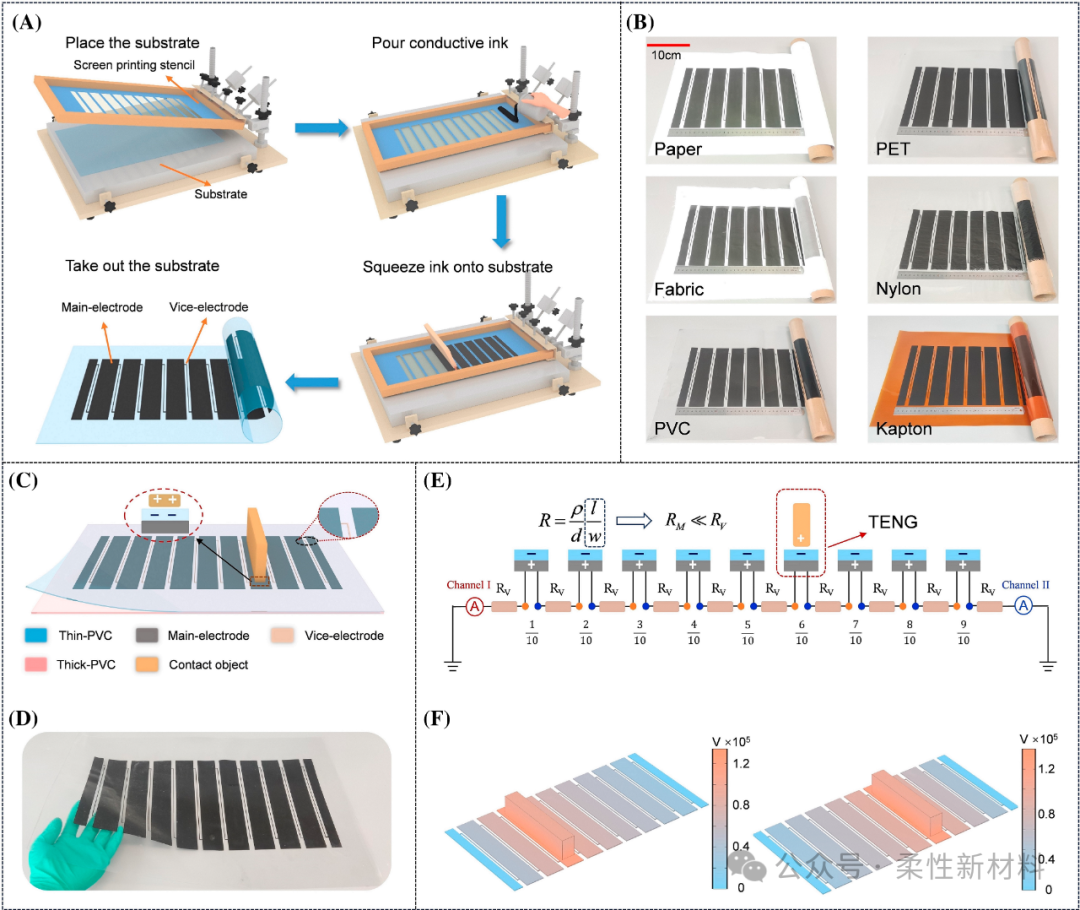

03 Feasibility Verification of LTPS

According to the working mechanism of LTPS, the resistance of the screen-printed electrodes must meet the high-impedance requirements. The impedance of electrodes with widths ranging from 1mm to 5mm on PVC film was characterized using a multimeter. All electrodes were produced in the same batch to ensure accuracy.Additionally, the number of squeegee passes determines the thickness of the printed ink, thereby affecting the sheet resistance of the electrodes. As the number of passes increases, the ink thickness increases, leading to a continuous decrease in the sheet resistance of the electrodes until stabilization. However, even after stabilization, slight fluctuations in ink thickness may occur due to variations in the angle of the squeegee and the force applied during the printing process.Different materials exhibit varying adsorption capabilities for conductive ink, which can be observed in single-pass printing on PVC, paper, nylon, Kapton, PET, and fiber cloth. Due to the many voids on the fiber cloth, the ink cannot fully cover the fiber cloth. The ink thicknesses on these materials were 11.85, 40.03, 11.26, 13.98, and 23.82 μm, respectively. This variation indicates that different materials require different numbers of squeegee passes to achieve the desired electrode. Figure 2:Feasibility Verification of LTPS

Figure 2:Feasibility Verification of LTPS

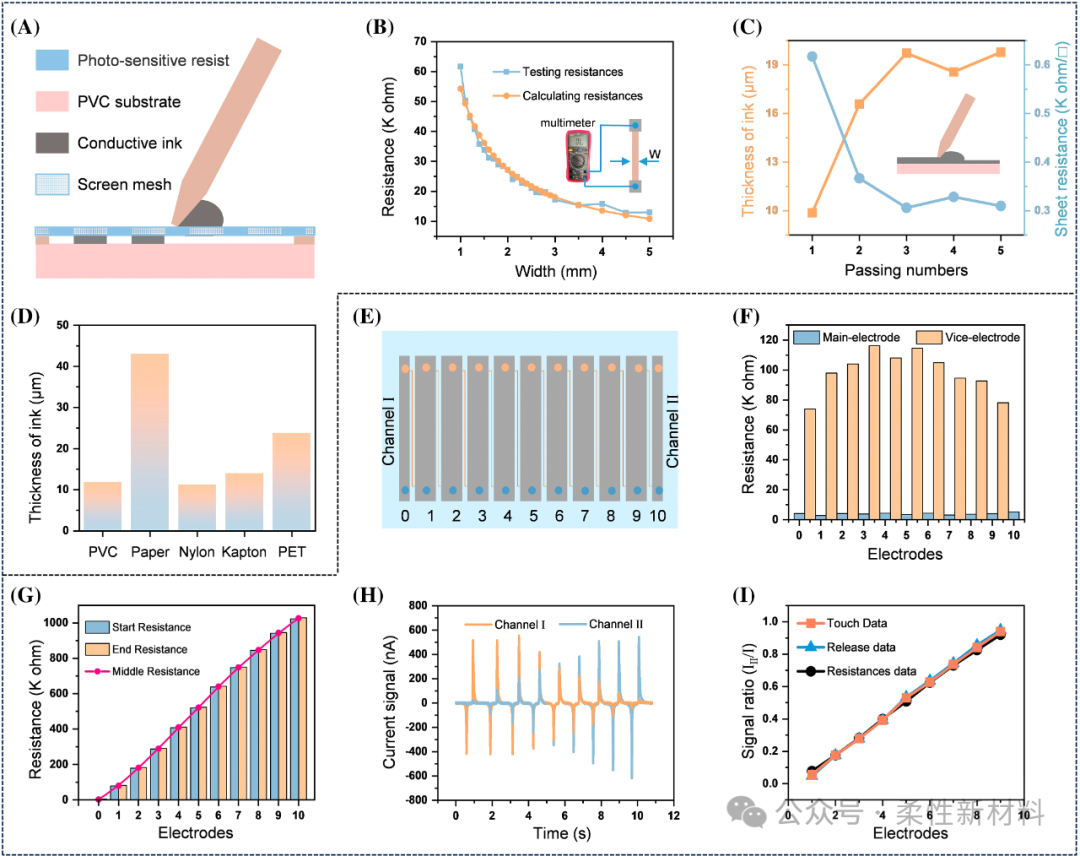

04 Demonstration of Smart Bookshelf

Bookshelves are ubiquitous in daily life, serving as essential places for storing books, documents, or exhibits. In smart homes, endowing bookshelves with intelligence, such as the ability to record the location of items, can enhance the quality and convenience of life. By utilizing the output characteristics of TENG, the contact and separation of objects with the sensor surface generate two opposite signals, allowing the smart bookshelf mat equipped with LTPS to effortlessly detect the placement and removal of books. This functionality can effectively track borrowing frequency.

Figure 3:Application of LTPS in Smart Bookshelf Mat

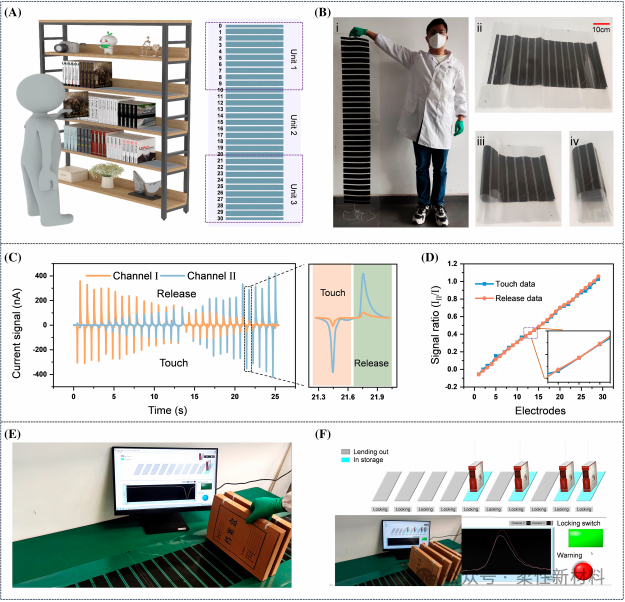

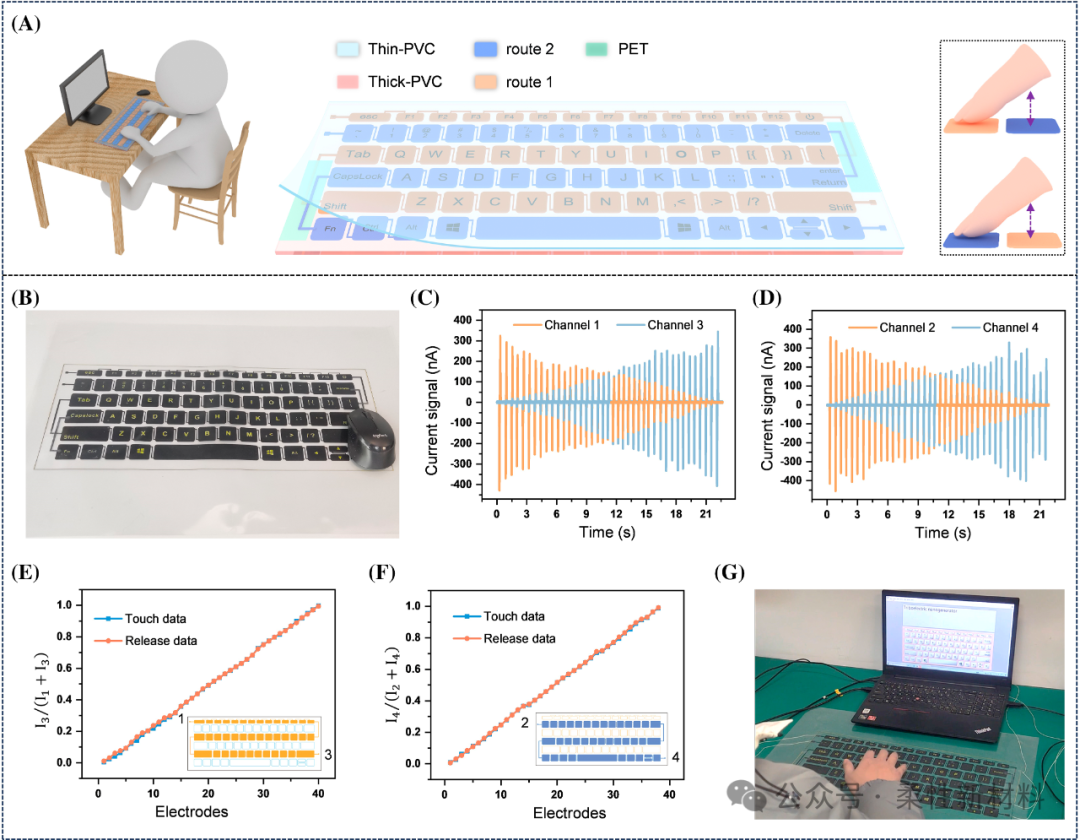

05 Demonstration of Film Keyboard

Keyboards are common position sensors in daily life, widely used as input devices in computer calculations and human-computer interaction. However, mainstream mechanical keyboards require an external power supply and lack portability, limiting their convenience. In this work, a self-powered, portable (rollable and foldable) film keyboard was developed using LTPS technology. During the use of the keyboard, fingers strike the keys at a certain angle rather than vertically. The working mechanism of TENG allows output even without complete contact between the finger and the key. This may lead to weak output current signals from adjacent keys, potentially interfering with the accurate detection of the pressed key. When the keyboard operates, the currents from two paths are first compared to eliminate interference signals. After that, the ratio of the peak output currents detected at both ends of the paths is used to accurately determine the pressed key. The manufacturing process of the keyboard first prints the electrodes of path 1 on a 300 μm PVC film substrate. It is dried for a day to ensure the conductive ink is fully cured. Then, a 50 μm PET film is applied on both sides of the electrodes, creating physical separation between path 1 and path 2. The electrodes of path 2 are printed and similarly dried for a day to allow the conductive ink to solidify. Once cured, the keyboard symbols are printed on the electrodes using standard yellow ink. After the ink dries, a 100 μm PVC film is used as the friction layer.

Figure 4:Application of LTPS in Film Keyboard

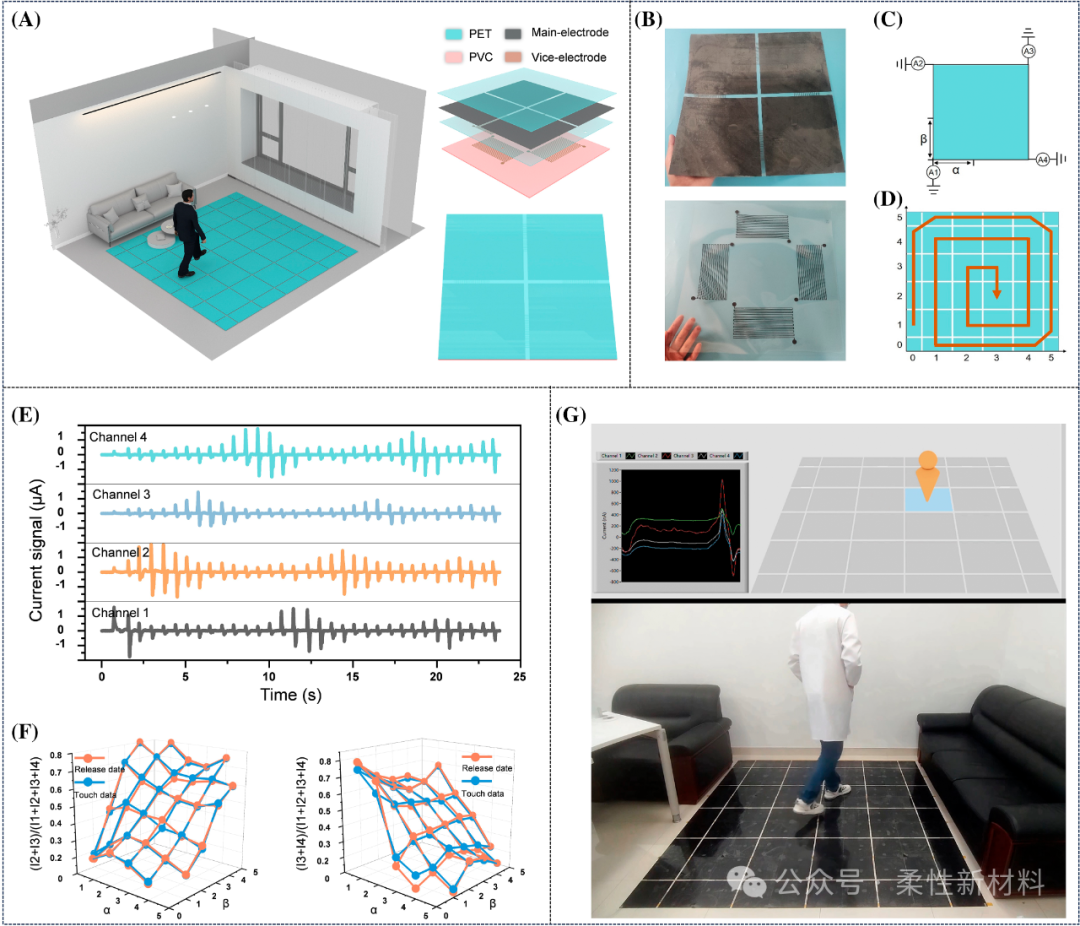

06 Demonstration of Walking Tracking Carpet

Walking tracking carpets help monitor the movement and stationary positions of individuals in real-time, making them an important component of smart homes. For this carpet to function effectively, it must cover a wide area, spanning dozens or hundreds of square meters, while ensuring accurate position detection. Considering manufacturing, installation, and data processing costs, this requires high-resolution and low-cost position sensors.LTPS meets these needs well with its simple structure, cost-effectiveness, and good scalability.

Figure 5:Application of LTPS in Walking Tracking Carpet

03. Analysis and Outlook

In summary, a self-powered and scalable LTPS has been proposed, combining contact electrification and screen printing technology. By utilizing the charge diversion effect when triboelectric charges contact high-impedance electrodes, touch position detection is achieved through comparative analysis of output current ratios. This method reduces the number of channels required for position sensors, optimizes the structural configuration of the sensors, and simplifies signal acquisition and processing. Furthermore, the universality of contact electrification, combined with the cost-effectiveness and versatility of the screen printing process, endows LTPS with advantages such as flexibility, low cost, and ease of mass production, highlighting its tremendous potential for widespread application.

Download link (click to download):A flexible, channel-minimized and large-scale touch position sensor combining contact electrification effect and screen-printed staggered electrode patterns.pdf

Download link (click to download):A flexible, channel-minimized and large-scale touch position sensor combining contact electrification effect and screen-printed staggered electrode patterns.pdf