Industry Insights

Ceramic materials are widely used in aerospace, energy, and biomedical fields due to their high hardness, high-temperature resistance, and corrosion resistance. However, their inherent brittleness (low fracture toughness and poor impact resistance) limits their reliability. The introduction of a second phase (reinforcing phase) to form Ceramic Matrix Composites (CMMCs) is a core strategy to overcome the brittleness bottleneck. Recently, Professor Zhou Shixiang and Professor Shi Yusheng from Huazhong University of Science and Technology, along with Professor Zhang Feng from Nanjing Normal University, led a team that published a study titled “3D printing of ceramic matrix composites: Strengthening and toughening strategies” in the journal Composites Part B: Engineering. They investigated multifunctional 3D printed ceramic composites, focusing on Carbon Reinforced Ceramic Matrix Composites (CMrCMCs) and Polymer Reinforced Ceramic Matrix Composites (PrCMCs).

Original Link:https://doi.org/10.1016/j.compositesb.2025.112335 If you cannot open it, please copy the URL into your browser to view.

Carbon Reinforced Ceramic Matrix Composites (CMrCMCs)

Technical Applications and Mechanisms

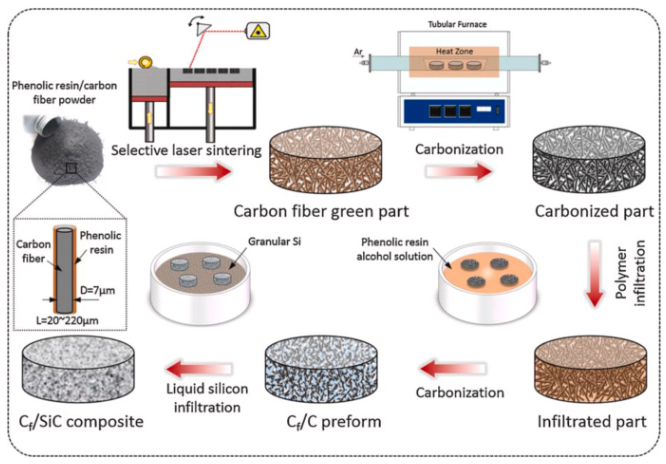

1. SLS Combined with Liquid Silicon Infiltration (LSI) Technology

1. Process Steps

Using Selective Laser Sintering (SLS) technology, phenolic resin-coated carbon fiber powder is used as raw material to print porous preforms; after high-temperature carbonization, a three-dimensional carbon skeleton is formed; the skeleton pores are filled using Liquid Silicon Infiltration (LSI) technology to generate a Silicon Carbide (SiC) matrix.

2. Toughening Mechanism

Carbon fibers disperse stress through crack deflection effects and absorb fracture energy through fiber pullout; ultimately, the fracture toughness reaches 6.5 MPa·m¹/², significantly enhancing the material’s damage resistance.

Figure 1: Schematic of the process for producing Cf/SiC composite material components using SLS technology.

Figure 1: Schematic of the process for producing Cf/SiC composite material components using SLS technology.

2. Material Extrusion (DIW) Coaxial Reinforcement Technology

1. Structural Design

Using coaxial extrusion technology, carbon fiber is used as the core layer (diameter 50 μm), and SiOC pre-ceramic polymer is used as the shell layer to form a “core-shell” structure; after high-temperature sintering, the shell layer transforms into a SiC matrix, while the core layer retains continuous carbon fiber reinforcement.

2. Performance Optimization

When the core-shell diameter ratio is 0.6, the material’s bending strength reaches 320 MPa, an increase of 300% compared to pure SiC; the oriented distribution of continuous fibers effectively suppresses crack propagation, enhancing the material’s load-bearing capacity.

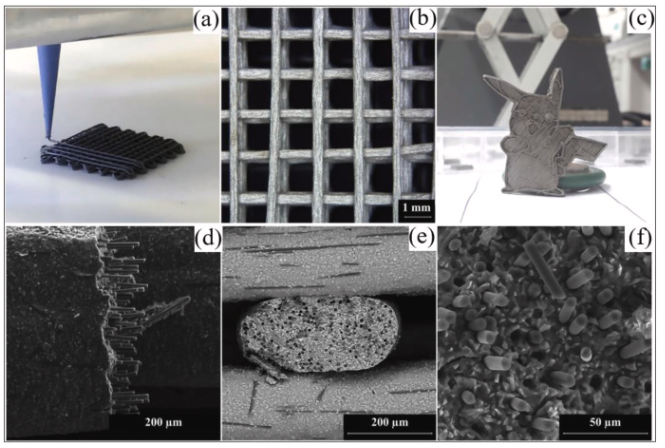

Figure 2: (a) DIW of lattice using the final ink composition and 410 μm nozzle; (b) Top view of the lattice after ceramicization at 1000℃; (c) Printed and ceramicized bulk shapes, demonstrating the versatility of the process; (d) SEM top view of the cross-section of pyrolyzed CMC filaments, showing fiber alignment and pullout; (e) Side view of the cross-section, showing partial deformation of the filaments and fiber alignment along the printing direction in the pillars; (f) Magnified view of the fracture surface of the pillars.

Figure 2: (a) DIW of lattice using the final ink composition and 410 μm nozzle; (b) Top view of the lattice after ceramicization at 1000℃; (c) Printed and ceramicized bulk shapes, demonstrating the versatility of the process; (d) SEM top view of the cross-section of pyrolyzed CMC filaments, showing fiber alignment and pullout; (e) Side view of the cross-section, showing partial deformation of the filaments and fiber alignment along the printing direction in the pillars; (f) Magnified view of the fracture surface of the pillars.

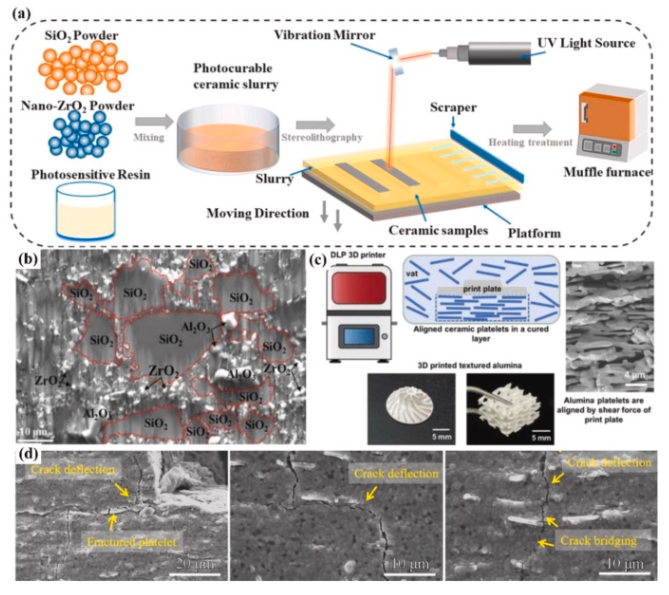

3. Photocuring (VPP) Directional Arrangement Technology

1. Fiber Orientation Control

Short-cut nickel-coated carbon fibers (length 200 μm) are dispersed in photocurable slurry, inducing fiber orientation through shear flow; after UV light curing, a short fiber/SiC composite material is formed through silicon infiltration.

2. Toughening Effect

When the fiber volume fraction is 15%, the material’s fracture work increases to 2.1 kJ/m² (pure SiC is only 0.3 kJ/m²); the synergistic effect of fiber orientation and interfacial bonding significantly improves energy dissipation efficiency.

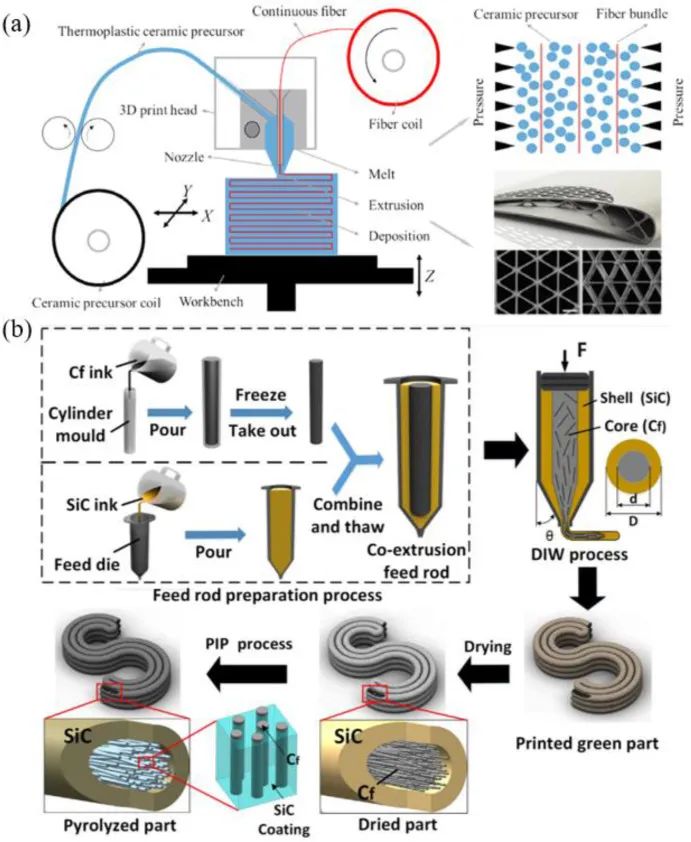

Figure 3: Co-extrusion reinforcement and toughening strategies for 3D printed ceramics.

Key Challenges

1. Graphene Dispersion: Graphene oxide (GO) tends to agglomerate, requiring ball milling or surface modification (e.g., silane coupling agents) to improve dispersion.

2. High-Temperature Stability: The carbon phase is prone to degradation in oxidative environments, necessitating the development of antioxidant coatings (e.g., SiC coating).

Polymer Reinforced Ceramic Matrix Composites (PrCMCs)

Toughening Strategies and Data

1. Phase Transformation Toughening (Zirconia)

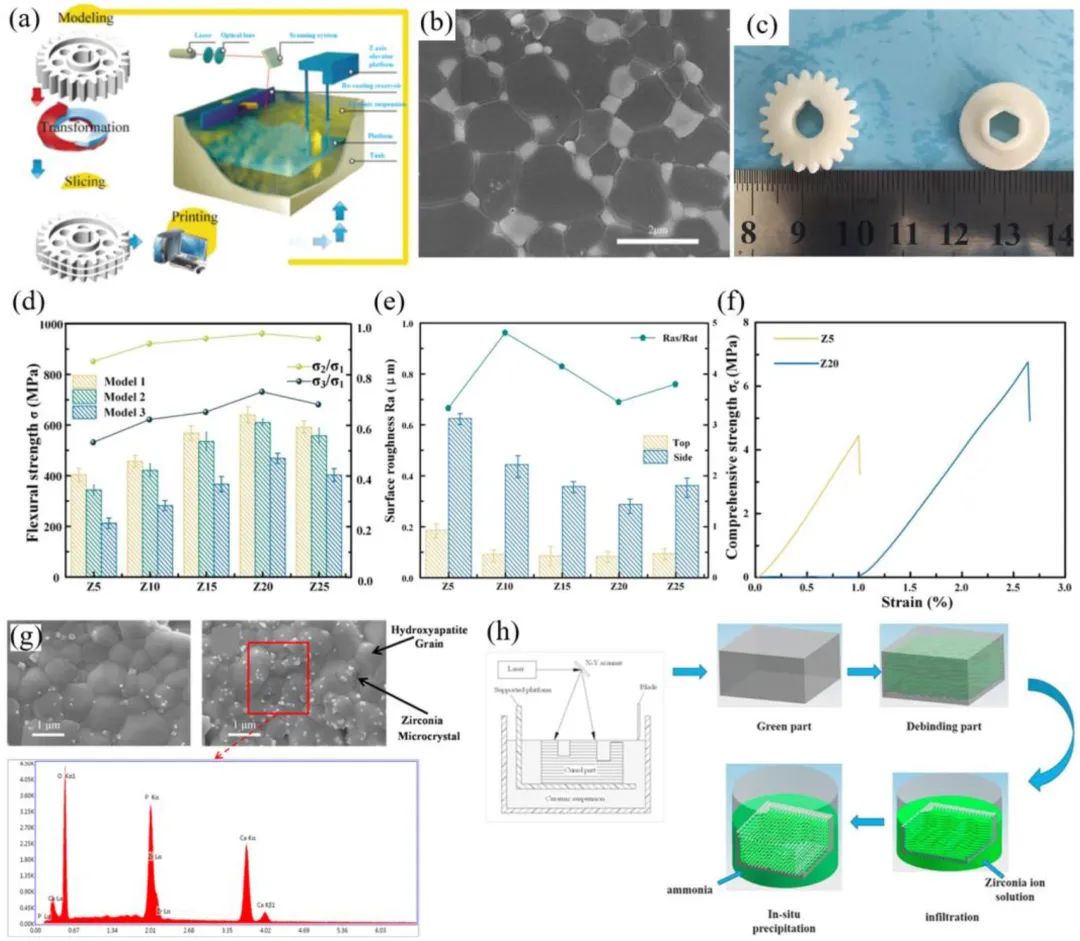

Material System and Process

Using an alumina (Al₂O₃) matrix doped with yttrium-stabilized tetragonal zirconia (Y₂O₃-ZrO₂), ZTA (Zirconia Toughened Alumina) composites are formed; the stress at the crack tip triggers the ZrO₂ phase transformation (tetragonal to monoclinic), releasing compressive stress to suppress crack propagation.

Performance and Mechanism

Bending strength reaches 422.5 MPa, and fracture toughness is 6.8 MPa·m¹/²; the phase transformation driving force ΔGchem must satisfy ΔGchem > γ (surface energy), and the critical crack size determines the phase transformation triggering conditions.

Figure 4: (a) Schematic of VPP 3D printed ZTA ceramic components, (b) Microstructure, (c) Typical application as industrial gears; (d) Bending strength and bending strength ratio in three different printing directions, (e) Surface roughness of sintered ZTA ceramic and the ratio of side surface roughness to top surface roughness, (f) Comprehensive stress-strain curves of sintered Z5 and Z20 all-ceramic crowns; (g) Microstructure and energy dispersive X-ray spectroscopy (EDS) elemental mapping of VPP 3D printed HAP/Zirconia composites, and (h) Schematic of ZTA ceramic manufacturing through VPP and liquid precursor infiltration.

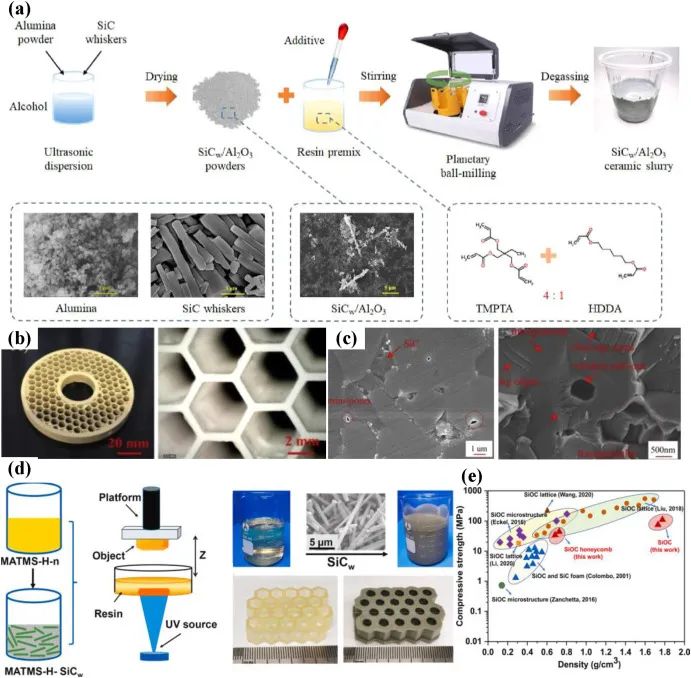

2. Whisker/Fiber Reinforcement

Short fiber reinforcement (SiC whiskers)

Adding 20 vol% SiC whiskers (SiCw) in an Al₂O₃ matrix increases fracture toughness from 3.5 MPa·m¹/² to 8.7 MPa·m¹/²;

Toughening Mechanism: Whisker pullout energy consumption, crack bridging, and interfacial debonding synergistic effects.

Continuous fiber reinforcement (SiO₂ fibers)

Continuous SiO₂ fiber reinforced wave-transparent ceramics are prepared through coaxial extrusion; bending strength increases from 110 MPa to 140 MPa, and the dielectric constant stabilizes at 3.2-3.5 (meeting wave-transparent functional requirements).

Figure 5: (a) Schematic of the preparation of Al₂O₃/SiCw ceramic slurry for VPP 3D printing; (b, c) Images and microstructure of complex-shaped Al₂O₃/SiCw composites printed by VPP 3D printing (notable whisker pullout phenomenon); (d) Schematic of VPP 3D printed SiOC/SiCw composites; (e) Ashby diagram of compressive strength-density of polymer-derived SiOC/SiCw ceramics.

Figure 5: (a) Schematic of the preparation of Al₂O₃/SiCw ceramic slurry for VPP 3D printing; (b, c) Images and microstructure of complex-shaped Al₂O₃/SiCw composites printed by VPP 3D printing (notable whisker pullout phenomenon); (d) Schematic of VPP 3D printed SiOC/SiCw composites; (e) Ashby diagram of compressive strength-density of polymer-derived SiOC/SiCw ceramics.

3. Biomimetic Multiscale Structures

Structural Design

Imitating the layered structure of shells, oriented Al₂O₃ platelets (thickness 1 μm) are combined with nanoscale ZrO₂ particles; platelets deflect cracks, while particles provide phase transformation toughening, creating a multiscale toughening effect.

Performance Improvement

Fracture toughness reaches 16.9 MPa·m¹/², four times that of traditional ceramics; the multiscale synergistic effect (platelet-particle-matrix) significantly enhances energy absorption capacity.

Figure 6: (a) Schematic of VPP 3D printed SiO₂/ZrO₂ ceramic cores for casting high-performance aircraft engine turbine blades; (b) Cross-sectional SEM image of network structure ZrSiO₄ surrounding large particles of molten quartz in VPP 3D printed silica cores; (c) Schematic and microstructure of textured alumina printed by VPP 3D; (d) Multiple toughening mechanisms of VPP 3D printed platelet alumina reinforced zirconia ceramics.

Figure 6: (a) Schematic of VPP 3D printed SiO₂/ZrO₂ ceramic cores for casting high-performance aircraft engine turbine blades; (b) Cross-sectional SEM image of network structure ZrSiO₄ surrounding large particles of molten quartz in VPP 3D printed silica cores; (c) Schematic and microstructure of textured alumina printed by VPP 3D; (d) Multiple toughening mechanisms of VPP 3D printed platelet alumina reinforced zirconia ceramics.

Conclusion

3D printing technology provides a revolutionary solution for the strengthening and toughening of ceramic matrix composites. The multi-phase composites of carbon and ceramics break through the performance limits of single materials, while innovations such as biomimetic multiscale structures achieve a synergy of strength, toughness, and lightweight. In the future, this breakthrough in additive manufacturing that transcends the performance limits of single materials will shine in more fields.

End

End

Source: Composites Part B: Engineering, Qiyu Technology

Editor: FAN | Reviewer: HOHO