“The trend is to move forward together, envisioning the future.” In recent years, taking advantage of the boom in the Chinese automotive market and the turning point of the automotive “new four modernizations” trend, it has become a trend for large enterprises to flock to car manufacturing. Many internet technology companies have entered the automotive sector, largely seeing the demand for internet and smart technology driven by the automotive “new four modernizations” trend, which are their areas of expertise. There are also real estate companies like Evergrande and Baoneng, leveraging their strong capital to establish their foothold in the automotive circle. In a short time, a large number of “new forces in car manufacturing” have surged into the automotive sector, reminiscent of the rise of smart phones back in the day.Amidst this high-profile car manufacturing army, Midea, as a cross-industry player, has chosen a completely different path.Founded in the 1970s by He Hengjian, who established the Beijiao Commune Auto Parts Factory in Shunde County, Midea chose to turn away from the crowd of car manufacturers and instead invested in the research and production of automotive motors.Unlike the competitive landscape of foreign brands in the car manufacturing sector, the Chinese automotive parts market is still dominated by foreign enterprises operating in China. According to data from the China Association of Automobile Manufacturers, not only do most American, German, and Japanese joint venture brands use foreign brands, but even domestic independent brands choose foreign brands for over 50% of their parts procurement. This has resulted in domestic independent parts manufacturers holding only a 20% market share in the domestic automotive first-tier supply market.At the same time, the automotive parts industry is influenced by the overall vehicle market. While domestic parts manufacturers are struggling to capture more market share from foreign enterprises, foreign enterprises are also contemplating how to seize opportunities in the upcoming automotive industry transformation through industrial transformation. Thus, in some core component areas of the automotive industry, domestic and foreign companies are gradually being brought to the same starting line. This has allowed many domestic manufacturers to vaguely see the opportunity for “overtaking on a curve.” Midea is one of them.Industrial transformation is about “change,” but the most essential aspect during this process is “stability.”Compared to the various small and large parts manufacturers in the industry, Midea has the unique advantage of a large group’s financial and talent reserves, and as a multi-field cross-industry player, Midea possesses strong adaptability and resource integration capabilities across multiple tracks. Midea’s “stability” allows us to see more possibilities for surpassing.

In recent years, taking advantage of the boom in the Chinese automotive market and the turning point of the automotive “new four modernizations” trend, it has become a trend for large enterprises to flock to car manufacturing. Many internet technology companies have entered the automotive sector, largely seeing the demand for internet and smart technology driven by the automotive “new four modernizations” trend, which are their areas of expertise. There are also real estate companies like Evergrande and Baoneng, leveraging their strong capital to establish their foothold in the automotive circle. In a short time, a large number of “new forces in car manufacturing” have surged into the automotive sector, reminiscent of the rise of smart phones back in the day.Amidst this high-profile car manufacturing army, Midea, as a cross-industry player, has chosen a completely different path.Founded in the 1970s by He Hengjian, who established the Beijiao Commune Auto Parts Factory in Shunde County, Midea chose to turn away from the crowd of car manufacturers and instead invested in the research and production of automotive motors.Unlike the competitive landscape of foreign brands in the car manufacturing sector, the Chinese automotive parts market is still dominated by foreign enterprises operating in China. According to data from the China Association of Automobile Manufacturers, not only do most American, German, and Japanese joint venture brands use foreign brands, but even domestic independent brands choose foreign brands for over 50% of their parts procurement. This has resulted in domestic independent parts manufacturers holding only a 20% market share in the domestic automotive first-tier supply market.At the same time, the automotive parts industry is influenced by the overall vehicle market. While domestic parts manufacturers are struggling to capture more market share from foreign enterprises, foreign enterprises are also contemplating how to seize opportunities in the upcoming automotive industry transformation through industrial transformation. Thus, in some core component areas of the automotive industry, domestic and foreign companies are gradually being brought to the same starting line. This has allowed many domestic manufacturers to vaguely see the opportunity for “overtaking on a curve.” Midea is one of them.Industrial transformation is about “change,” but the most essential aspect during this process is “stability.”Compared to the various small and large parts manufacturers in the industry, Midea has the unique advantage of a large group’s financial and talent reserves, and as a multi-field cross-industry player, Midea possesses strong adaptability and resource integration capabilities across multiple tracks. Midea’s “stability” allows us to see more possibilities for surpassing. Ten Years of Planning, Breaking Through One by OneThe upgrade path for most domestic independent parts manufacturers is through overseas acquisitions or establishing joint ventures with foreign enterprises. Companies like CATL have deeply cultivated a specific segment for many years and have now grown into industry leaders with considerable strength. Midea, on the other hand, adopts a strategy of “multiple points of connection, breaking through one by one.”In 2011, after experiencing a rapid growth phase in the Chinese passenger car market, Midea foresaw the future market demand for power economy and formed a team for automotive motor research and established the Weiling R&D Center, focusing on steering and hybrid technology. In 2015, Midea collaborated with automotive companies to research key technologies for energy-saving automotive core components.By 2018, as China’s independent electric vehicle brands began to rise, Midea’s electromechanical business had also developed and grown, becoming an indispensable part of the group, leading to the establishment of Weiling Automotive Components Company. In the following two years, Weiling Automotive Components Company set up manufacturing bases in Shunde, Guangdong, and Hefei, Anhui, and achieved mass production of electronic water pumps and drive motors.During Midea’s decade-long exploration of the electromechanical business, China has leapfrogged to become the world’s largest market for new energy vehicles. At this point, Midea’s electromechanical product layout has expanded from core components of home appliances to four major fields: home appliance components, automotive components, industrial control, and 3C.

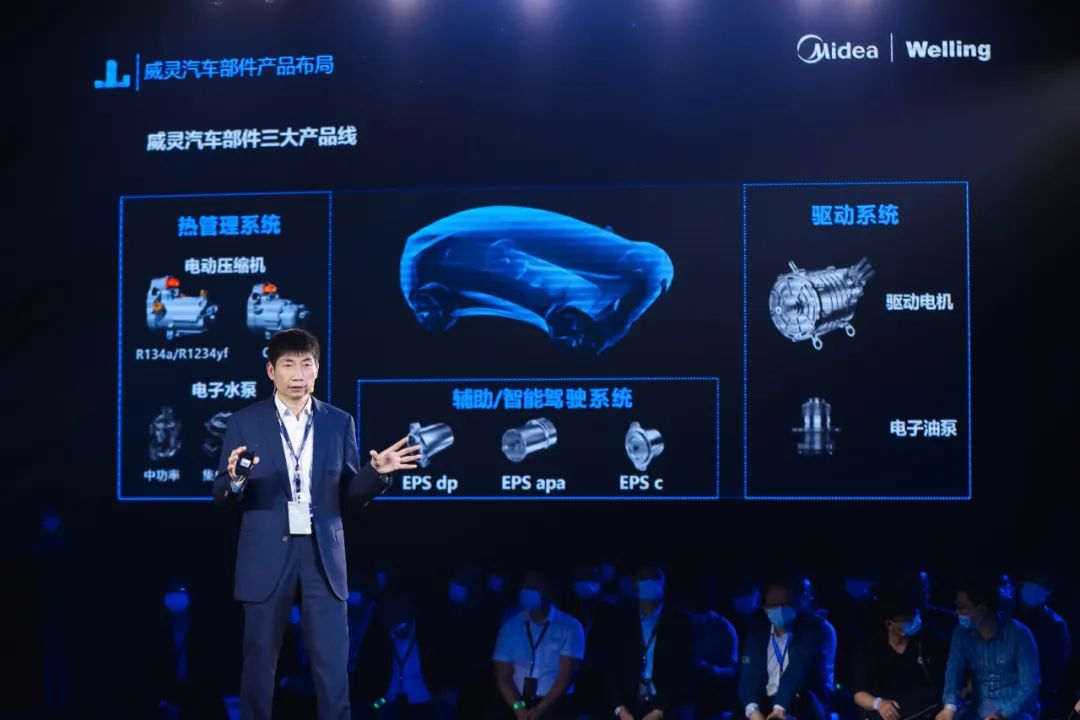

Ten Years of Planning, Breaking Through One by OneThe upgrade path for most domestic independent parts manufacturers is through overseas acquisitions or establishing joint ventures with foreign enterprises. Companies like CATL have deeply cultivated a specific segment for many years and have now grown into industry leaders with considerable strength. Midea, on the other hand, adopts a strategy of “multiple points of connection, breaking through one by one.”In 2011, after experiencing a rapid growth phase in the Chinese passenger car market, Midea foresaw the future market demand for power economy and formed a team for automotive motor research and established the Weiling R&D Center, focusing on steering and hybrid technology. In 2015, Midea collaborated with automotive companies to research key technologies for energy-saving automotive core components.By 2018, as China’s independent electric vehicle brands began to rise, Midea’s electromechanical business had also developed and grown, becoming an indispensable part of the group, leading to the establishment of Weiling Automotive Components Company. In the following two years, Weiling Automotive Components Company set up manufacturing bases in Shunde, Guangdong, and Hefei, Anhui, and achieved mass production of electronic water pumps and drive motors.During Midea’s decade-long exploration of the electromechanical business, China has leapfrogged to become the world’s largest market for new energy vehicles. At this point, Midea’s electromechanical product layout has expanded from core components of home appliances to four major fields: home appliance components, automotive components, industrial control, and 3C. Midea Weiling Automotive Components’ three major product lines officially launchedAt the “2021 Midea Weiling Automotive Components Three Major Product Lines Launch and Product Release Conference” held on May 18, Midea officially announced the full launch of its three major product lines: drive systems, thermal management systems, and auxiliary/automated driving systems, and officially released five automotive component products, including drive motors, electronic water pumps, electronic oil pumps, electric compressors, and EPS motors, presenting a new achievement to the industry.

Midea Weiling Automotive Components’ three major product lines officially launchedAt the “2021 Midea Weiling Automotive Components Three Major Product Lines Launch and Product Release Conference” held on May 18, Midea officially announced the full launch of its three major product lines: drive systems, thermal management systems, and auxiliary/automated driving systems, and officially released five automotive component products, including drive motors, electronic water pumps, electronic oil pumps, electric compressors, and EPS motors, presenting a new achievement to the industry. Mr. Chen Jintao, General Manager of Midea Weiling Automotive Components, explains the five representative productsIt is worth mentioning that the new products launched by Midea focus on energy efficiency, comfort, and safety. For instance, the electric compressor, weighing only 5.8 kg, boasts a COP > 2.45 ultra-high efficiency, achieving a super high speed of 12000 rpm with a quiet effect of only 78 dB, and can continuously operate under a high pressure of 2.8 MPa, providing a reliable, efficient, and quiet driving experience for vehicles.

Mr. Chen Jintao, General Manager of Midea Weiling Automotive Components, explains the five representative productsIt is worth mentioning that the new products launched by Midea focus on energy efficiency, comfort, and safety. For instance, the electric compressor, weighing only 5.8 kg, boasts a COP > 2.45 ultra-high efficiency, achieving a super high speed of 12000 rpm with a quiet effect of only 78 dB, and can continuously operate under a high pressure of 2.8 MPa, providing a reliable, efficient, and quiet driving experience for vehicles. Electric CompressorAs Midea’s first rotor-type electric compressor, it uses natural refrigerant CO2, solving the problem of rapid range degradation in extremely cold conditions, and can operate normally in extreme low-temperature environments of -35°C, improving the range by 20% compared to traditional heat pumps. The CO2 refrigerant used in this electric compressor is mainly derived from the purification of industrial waste gas, aligning with the national strategy of “carbon neutrality,” and has gained favor in markets such as Europe. According to official information, the production line for Weiling Automotive’s electric compressors can achieve an annual production capacity of 660,000 units. Such product performance and capacity are sufficient for Weiling Automotive Components Company to secure a place in the compressor segment.

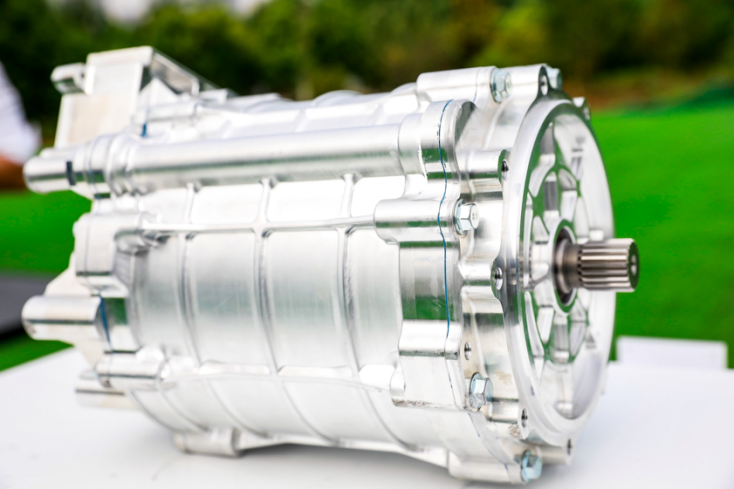

Electric CompressorAs Midea’s first rotor-type electric compressor, it uses natural refrigerant CO2, solving the problem of rapid range degradation in extremely cold conditions, and can operate normally in extreme low-temperature environments of -35°C, improving the range by 20% compared to traditional heat pumps. The CO2 refrigerant used in this electric compressor is mainly derived from the purification of industrial waste gas, aligning with the national strategy of “carbon neutrality,” and has gained favor in markets such as Europe. According to official information, the production line for Weiling Automotive’s electric compressors can achieve an annual production capacity of 660,000 units. Such product performance and capacity are sufficient for Weiling Automotive Components Company to secure a place in the compressor segment.  Drive MotorThe released Weiling main drive motor, as well as the electronic water pump and electronic oil pump, also achieve small size, high efficiency, and low noise. Among them, the main drive motor’s torque density is improved by 4% compared to high-end vehicles in the industry; the efficient range (efficiency > 85%) exceeds the industry level by 2%; and the torque ripple across the entire speed range (a key technical indicator affecting motor noise) is below the industry level by 3%+. It is reported that five technical platforms and multiple power segments for the drive motor’s electromagnetic, cooling, and structural design technology verification and prototype testing have been completed, with some products having passed vehicle measurement verification and mass production, covering the current passenger vehicle market demand comprehensively.

Drive MotorThe released Weiling main drive motor, as well as the electronic water pump and electronic oil pump, also achieve small size, high efficiency, and low noise. Among them, the main drive motor’s torque density is improved by 4% compared to high-end vehicles in the industry; the efficient range (efficiency > 85%) exceeds the industry level by 2%; and the torque ripple across the entire speed range (a key technical indicator affecting motor noise) is below the industry level by 3%+. It is reported that five technical platforms and multiple power segments for the drive motor’s electromagnetic, cooling, and structural design technology verification and prototype testing have been completed, with some products having passed vehicle measurement verification and mass production, covering the current passenger vehicle market demand comprehensively.

EPS Motor

There is also the key component for intelligent driving—the EPS motor (electric power steering motor). During the product development process, challenges such as jerkiness, noise, vibration, and low-speed torque output issues were encountered. Through in-depth basic research on underlying technologies by Midea’s electromechanical business group, the key issues were identified and successfully resolved, breaking the foreign technology monopoly and achieving the localization of key components. This is precisely Midea’s intention to make a mark in the future automotive intelligence field. It is reported that the production lines for Weiling Automotive’s electronic water pumps and electric power steering motors are fully automated, requiring only three staff members to complete the production and management of various types and models.In addition to continuously improving product processes and production management, Weiling Automotive Components also emphasizes product quality control, possessing certifications such as IATF16949, CNAS recognition, and ISO14001 quality systems. Accumulation Over TimeYou will find that Midea understands its advantages better than anyone else, and it also knows that only by providing customers with efficient and reliable products and services can it win the market. As Midea Group Chairman and President Fang Hongbo said: “After the internet, the boundaries of enterprises will expand infinitely. In the future, the underlying technological capabilities and the ability to reach customers will define the boundaries of enterprises.”

Accumulation Over TimeYou will find that Midea understands its advantages better than anyone else, and it also knows that only by providing customers with efficient and reliable products and services can it win the market. As Midea Group Chairman and President Fang Hongbo said: “After the internet, the boundaries of enterprises will expand infinitely. In the future, the underlying technological capabilities and the ability to reach customers will define the boundaries of enterprises.”

President of Midea’s Electromechanical Business Group, Fu Yongjun, shares the electromechanical strategic layoutTo maintain the uniqueness and foresight of products and keep them competitive, Midea has invested heavily in R&D. Currently, Midea’s electromechanical business group holds 6,731 basic and common patents and 328 automotive component patents. This is thanks to Midea’s five R&D centers located in China, the UK, and Japan, a basic technology R&D team of 280 people, a 150-person automotive component R&D team, and a doctoral R&D team led by Academician Zhu Ziqiang and Dr. Chen Jintao.As a manufacturer of motors and compressors, Midea has a vast supply chain management system, with the supply chain in the home appliance sector ensuring the supply of components for 10 million new energy vehicle drive motors, thus providing customers with stable, safe, and cost-effective component products.On this basis, Midea also adopts digitalization and robotics to create production workshops, and in conjunction with Rhein IATF16949 process guidance, has established an intelligent production system with full visual information management, featuring high efficiency, high quality, high stability, and short delivery times to respond to various market demand changes.Behind the solid R&D and production strength, we should also recognize Midea’s forward-looking layout over the past decade.Domestic enterprises still need long-term efforts to surpass joint ventures. Ten years ago, it foresaw the automotive market’s demand for energy-saving, efficient, and safe technologies, and chose the right timing to enter the most needed improvement areas based on its advantages. Now, riding the wave of the automotive “new four modernizations,” Midea Weiling Automotive Components Company, as a latecomer among domestic automotive parts manufacturers, has quickly entered the public eye and is catching up, which is a process that requires long-term accumulation to yield returns.As the theme of Midea’s recent press conference states—”The trend is to move forward together, envisioning the future”, all of this is just the beginning for Midea. It is foreseeable that as new energy vehicles gradually become an important platform for people’s travel and life, Midea, a giant holding key areas such as smart home, robotics and automation, digital innovation, and electromechanical business, will reveal a broader blueprint in its future endeavors.