Before understanding the PLC control cabinet, we need to grasp a few requirements.

01

Wiring according to the diagram is the highest principle. First, before wiring, you must carefully read the drawings and fully understand the designer’s intentions, rather than relying on personal so-called rich experience. If there are unclear or contradictory points, you should contact the designer immediately for confirmation. Only after everything is correct should you proceed with the wiring construction.

02

The wiring order must be clear and simple, with checkability. This is rarely achieved in practice; usually, wires are connected, and the box is closed without further checks.

03

Learn wiring techniques and be adept at using professional tools.

For example:

Q: When making a PLC cabinet, there are many wiring boards and terminals. If not handled properly, there can be looseness or burrs. Should we strip the wire and press it directly? Or use a pin? Or solder?

A: Single-core wires should be stripped and pressed directly; multi-core wires should use cold-pressed terminals, and soldering is not recommended.

Q: When there are many expansion modules for PLC, how are the common and power terminals wired? Should they be directly paralleled to the next module through the terminals on each PLC module, or should they be connected to the terminal block and shorted on the terminal block?

A: When maintaining equipment on site, we prefer to distribute the power supply at the terminals and short it to the user points (indicated with wire number tubes or marked at the terminals), making it intuitive and minimizing mutual interference. We do not want to connect two or more wires to one point. For power terminal blocks, we prefer terminals with fuses or those that can disconnect connections between terminals, as it is very convenient for troubleshooting short circuits.

1. PLC Internal and External Circuits

1. External Circuit Wiring

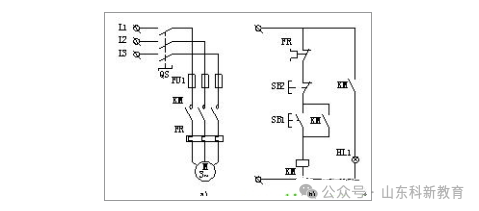

Figure 1 shows the electrical control circuit for direct-on-line starting of a motor. The control logic is implemented by connecting the AC contactor KM coil, indicator lights HL1, HL2, normally closed contacts of thermal relays FR, stop button SB2, start button SB1, and normally open auxiliary contacts of the contactor KM through wires.

After closing QS and pressing the start button SB1, the coil KM is energized and self-locks, connecting the branch circuit of the indicator light HL1 through the auxiliary contact KM and the main contact in the main circuit, causing HL1 to light up and the motor M to start; pressing the stop button SB2 de-energizes the coil KM, turning off HL1 and stopping M.

▲Figure 1 Electrical control circuit for direct-on-line starting of a motor

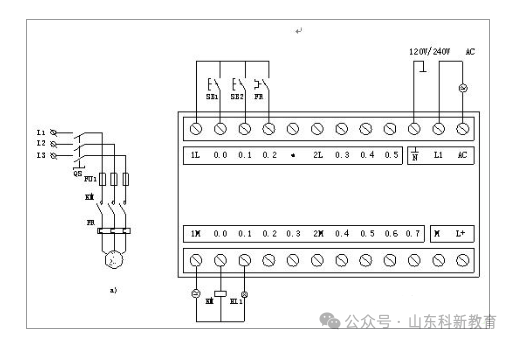

Figure 2 is the external wiring diagram for the direct-on-line starting control of the motor using a SIEMENS S7 series PLC. The main circuit remains unchanged, while the normally closed contacts of thermal relays FR, stop button SB2, start button SB1, etc., are connected to the PLC’s input interface as input devices, and the AC contactor KM coil, indicator lights HL1, HL2, etc. are connected to the PLC’s output interface as output devices. The user program is written and stored in the program memory according to the logic for the direct-on-line control of the motor.

▲Figure 2 PLC control wiring diagram for direct-on-line starting of a motor a) Main circuit b) I/O actual wiring diagram

2. Establishing Internal I/O Image Area

Within the PLC memory, an I/O image memory area is established to store the status of I/O signals, referred to as input image registers and output image registers. Additionally, other programming elements of the PLC also have corresponding image memory, referred to as element image registers.

The size of the I/O image area is determined by the PLC’s system program. For each input point in the system, there is always a corresponding bit in the input image area, and for each output point, there is also a corresponding bit in the output image area. The addressing number of the system’s input and output points corresponds to the address number of the I/O image area.

When the PLC is in operation, the collected input signal status is stored in the corresponding bit of the input image area, and the calculation results are stored in the corresponding bit of the output image area. The data required to describe the equivalent contacts of the input relays or the equivalent coil states of the output relays during the execution of the user program is taken from the I/O image area, without direct interaction with external devices.

The establishment of the I/O image area allows the PLC to only interact with the status data stored in the address units of memory during operation, and the system output only sets a status data for a specific address unit in memory. This not only speeds up program execution but also isolates the control system from the outside, enhancing the system’s anti-interference capability.

3. Internal Equivalent Circuits

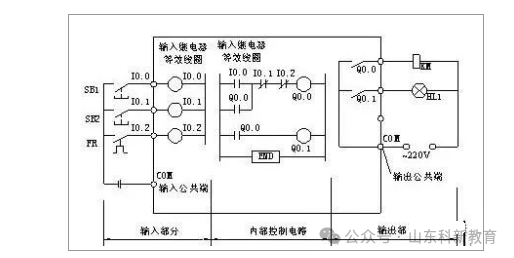

Figure 3 shows the internal equivalent circuit of the PLC. Taking the start button SB1 as an example, its input interface I0.0 is connected to a trigger I0.0 in the input image area. When SB1 is pressed, the trigger I0.0 is triggered to a “1” state, and this “1” state can be directly referenced by the user program as the state of the I0.0 contact. At this time, the I0.0 contact state is the same as the on/off state of SB1; thus, when SB1 is pressed, the I0.0 contact state is “1”. Conversely, if SB1 is released, the I0.0 contact state is “0”. Since the function of the I0.0 trigger is equivalent to that of a relay coil and does not require hard wiring, the I0.0 trigger is equivalent to a soft relay coil inside the PLC. The I0.0 contact, which directly references the state of the I0.0 coil, is equivalent to a normally open contact controlled by the I0.0 coil (also known as a dynamic make contact).

▲Figure 3 PLC internal equivalent circuit

Similarly, the stop button SB2 is connected to a soft relay coil I0.1 inside the PLC. When SB2 is closed, the state of the I0.1 coil is “1”, and conversely “0”. The state of the relay coil I0.1 is inverted by the user program and referenced as the state of the I0.1 contact; thus, I0.1 is equivalent to a normally closed contact controlled by the I0.1 coil (also known as a dynamic break contact). The output contacts Q0.0 and Q0.1 are physical normally open contacts of the PLC’s internal relays. Once closed, the corresponding KM coil and indicator light HL1 will be energized. The PLC output terminal has a common interface COM for the output power.

2. PLC Control System

The PLC is used to implement the electrical control system for direct-on-line starting of a motor, where the main circuit remains essentially unchanged, but the PLC replaces the electrical control circuit.

1. Composition of PLC Control System

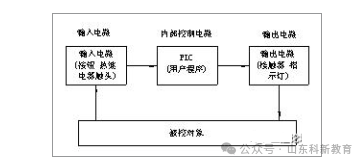

Figure 4 is a basic composition diagram of the PLC control system for direct-on-line starting of a motor, which can be divided into three parts: input circuit, internal control circuit, and output circuit.

Input Circuit

The role of the input circuit is to send input control signals to the PLC. The input devices include buttons SB1, SB2, and normally closed contacts of FR. The external input control signals are sent to a corresponding input relay in the PLC, which can provide any number of normally open and normally closed contacts for programming in the PLC internal control circuit.

Output Circuit

The role of the output circuit is to convert the PLC’s output control signals into signals capable of driving the KM coil and indicator light HL1. The PLC’s internal control circuit has many output relays, each of which, in addition to providing normally open and normally closed contacts for programming in the PLC internal control circuit, also provides a normally open contact connected to the output port. This contact is called an internal hard contact and is a physical normally open contact. This contact drives external loads such as the KM coil and indicator light HL1, while the KM coil controls the starting and stopping of the motor M through the main contact in the main circuit. The power supply for the driven load is provided by an external power source, and the PLC’s output port also has a common terminal COM for the output power.

Internal Control Circuit

The internal control circuit is formed by the user program written according to the actual control requirements of the motor. Its function is to calculate, process, and judge the status of input and output signals according to the logical relationships specified in the user program, and then generate corresponding output control signals to drive output devices: motor M, indicator light HL1, etc.

The user program is input into the PLC’s user program memory through communication with a personal computer or a programmer. Modifications to the user program only require changing certain statements in the memory through programming devices, without altering the internal wiring of the controller, achieving flexibility in control.

2. PLC Control Ladder Diagram

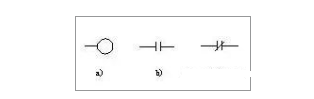

The ladder diagram is a representation that equivalently transforms the PLC into a control circuit composed of many internal relay coils, normally open contacts, normally closed contacts, or functional program blocks. Figure 5 shows the commonly used equivalent control element symbols in the PLC ladder diagram.

▲Figure 5 Commonly used equivalent control element symbols in ladder diagrams a) Coil b) Normally open contact c) Normally closed contact

Figure 6 is the PLC control ladder diagram for direct-on-line starting of the motor, composed of normally closed contacts FR, normally closed button SB2, normally open auxiliary contact KM, and normally open button SB1 in a parallel unit, along with the KM coil. The ladder diagram for direct-on-line starting control of the motor resembles the electrical control circuit diagram but also has many differences from it.

The physical structure of relay elements in ladder diagrams differs from that of electrical elements

The coils and contacts in the PLC ladder diagram are functionally equivalent to the coils and contacts of electrical elements. However, in physical terms, the coils and contacts in the ladder diagram are merely storage bits in the input and output memory, differing from the physical structure of electrical elements.

The on/off states of relay elements in ladder diagrams differ from those of electrical elements

The on/off states of relay elements in ladder diagrams are related to the data stored in the corresponding storage bits. If the data in that storage bit is “1”, the element is in the “on” state; if the data is “0”, it indicates an “off” state. This differs from the actual on/off states of electrical elements.

The state switching process of relay elements in ladder diagrams differs from that of electrical elements

The state switching of relay elements in ladder diagrams is simply an operation on the state data of the storage bits. If the PLC assigns the storage bit data equivalent to a normally open contact to “1”, the make operation is completed. Similarly, if the data equivalent to a normally closed contact is assigned “0”, the break operation is completed. The switching operation process has no time delay. In contrast, the switching of electrical element coils and contacts inevitably involves time delays and generally requires a process of first opening and then closing.

The number of contacts belonging to relay elements in ladder diagrams differs from that of electrical elements

If the PLC retrieves the bit data “0” from the input relay I0.0 and stores it in another memory bit, the stored bit becomes a normally open contact controlled by the I0.0 relay, with the stored data being “0”. If, after retrieving the bit data “0”, an inversion operation is performed before storing it in a memory bit, the stored data becomes “1”, and that memory bit becomes a normally closed contact controlled by the I0.0 relay.

As long as the PLC’s internal memory is sufficient, this bit data transfer operation can be performed infinitely. Each operation generates a relay contact in the ladder diagram, indicating that relay contacts in ladder diagrams can theoretically be reused infinitely.

However, the coils inside the PLC can generally only be referenced once. If the same address number coil needs to be reused, it should be handled with caution. Unlike the PLC, the number of contacts in electrical elements is limited.

The drawing rules for each line in the ladder diagram start from the left bus, passing through contacts and coils (or functional blocks), and terminating at the right bus. Generally, parallel units are drawn on the left side of each line, while output coils are drawn on the right side, with other series components drawn in the middle.

Scan to Follow

WeChat ID|13615417996

Follow the QR code on the left to get free access to

[Siemens Resource Collection]