Hello, electrical friends!

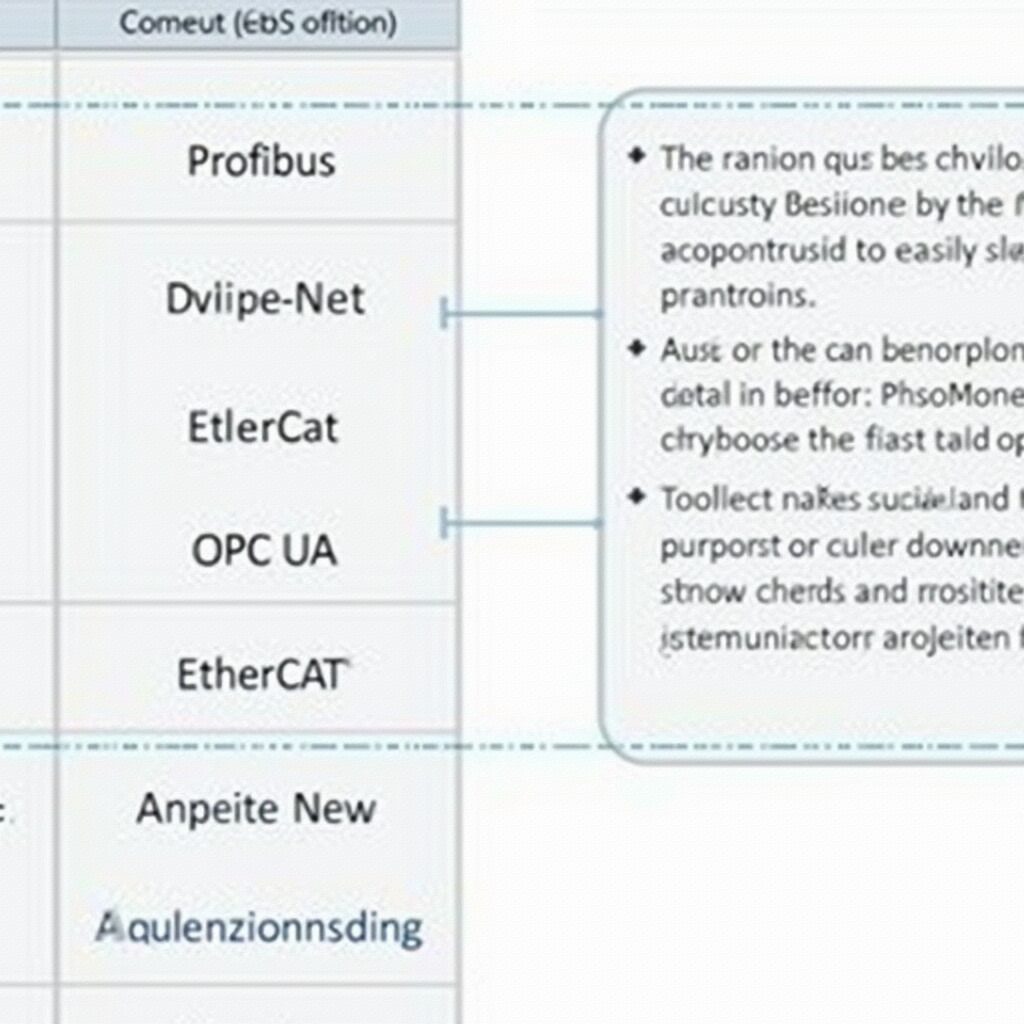

Today, let’s talk about Siemens PLC communication protocols.

As a seasoned automation engineer, I understand the importance of communication protocols in industrial automation systems.

Just like people need a common language to communicate, different automation devices also require a “common language” to “talk” to each other.

So, let’s embark on this exploration journey of communication protocols!

1. Profibus-DP: The “Big Brother” of Industrial Fieldbus

Profibus-DP is a widely used fieldbus protocol, acting like a “postman” in factories, responsible for transmitting information between the master station (like PLC) and slave stations (like sensors and actuators).

Working Principle

Profibus-DP uses a master-slave communication method, where the master polls each slave, and slaves can only respond when queried by the master. It’s like a teacher calling roll in class; students can only respond when they hear their name.

Hardware Connection

Profibus-DP typically uses a purple dedicated cable, with 120Ω terminating resistors required at both ends. Remember not to forget to connect the terminating resistors, as this may lead to unstable communication.

Application Case

In a production line, the PLC acts as the master, controlling multiple frequency converters and remote I/O modules via the Profibus-DP protocol. This greatly reduces wiring work and increases system flexibility.

Common Issues

-

Unstable communication: Check the terminating resistors, whether the cable is damaged, and if the grounding is good. -

Slave disconnection: Check the slave address settings and whether the baud rate is consistent.

2. Profinet: The “Newcomer” of Industrial Ethernet

Profinet is a fieldbus protocol based on industrial Ethernet, which can be understood as an “upgraded version” of Profibus. It acts like a “highway” in factories, capable of transmitting large amounts of data more quickly.

Working Principle

Profinet adopts a provider/consumer model, allowing devices to communicate directly without needing to go through the master station like Profibus. It’s like colleagues communicating directly without always going through the manager.

Hardware Connection

Profinet uses standard Ethernet interfaces and cables, meaning you can use regular network cables to connect devices. However, it’s best to use industrial Ethernet cables with stronger anti-interference capabilities in industrial environments.

Application Case

In a large packaging production line, Profinet connects PLCs, HMIs, smart cameras, and motion controllers. This not only speeds up transmission but also enables direct data exchange between devices, improving system response time.

Common Issues

-

IP address conflict: Ensure that each device in the network has a unique IP address. -

Communication interruption: Check if the network cable is damaged and if the switch is functioning properly.

3. Modbus: The Simple and Universal “Workhorse”

The Modbus protocol is like the “Mandarin” of the automation field; although it’s not the most advanced, its simplicity and ease of use have led to its widespread application in various scenarios.

Working Principle

Modbus also uses a master-slave communication model, where the master sends requests and the slave responds. Its data model is very simple, mainly consisting of coils, discrete inputs, holding registers, and input registers.

Hardware Connection

Modbus RTU uses RS485 interfaces, while Modbus TCP uses Ethernet interfaces. When using RS485, remember to choose the appropriate signal line and set the terminating resistors correctly.

Application Case

In a small water treatment system, the PLC communicates with multiple transmitters and actuators via the Modbus RTU protocol to achieve water quality monitoring and chemical dosing control.

Common Issues

-

Communication timeout: Check if the baud rate, data bits, stop bits, and parity bits are consistent. -

Data errors: Confirm the correctness of function codes and register addresses.

4. OPC UA: The “Universal Translator” for Data Integration

OPC UA (OPC Unified Architecture) is a cross-platform, vendor-independent communication standard, acting like the “United Nations” of the industrial automation world, enabling devices from different “countries” (vendors) to “talk” to each other.

Working Principle

OPC UA uses a client/server architecture and organizes data in an object-oriented manner. It supports multiple communication modes, including read/write, subscribe/publish, etc.

Software Implementation

OPC UA is primarily implemented through software, requiring no special hardware. However, it is important to note that the configuration and security settings of the OPC UA server are critical; incorrect settings may lead to data leakage.

Application Case

In a smart factory project, OPC UA is used to integrate workshop-level PLC data into the enterprise-level MES system, achieving real-time monitoring and analysis of production data.

Common Issues

-

Certificate errors: Ensure that the certificates of the client and server are correctly configured. -

Performance issues: Set the sampling rate and dead zone appropriately to avoid generating too much invalid data.

Considerations

-

Security: When configuring communication protocols, always pay attention to network security. Especially when using Profinet and OPC UA, correctly configure firewalls and access controls.

-

Compatibility: Different vendors’ devices may have different implementations of the same protocol, so compatibility should be thoroughly tested before use.

-

Bandwidth: Assess the data transmission needs of the system and choose the appropriate protocol and network structure.

-

Redundancy: For critical systems, consider using redundant communication to improve reliability.

-

Diagnostics: Utilize the diagnostic features provided by the protocol to quickly locate and resolve issues.

Communication protocols are the “veins” of industrial automation; selecting the appropriate protocol is crucial for the performance and reliability of the system.

As an automation engineer, I once spent a lot of time debugging on-site due to my insufficient understanding of the Profibus protocol.

Later, I realized how important it is to thoroughly understand the principles and characteristics of communication protocols for designing and maintaining automation systems.

Practical Suggestions:

-

Build a small communication testing platform that includes PLCs, HMIs, and some I/O modules. -

Try connecting these devices using different communication protocols and observe the speed and stability of data transmission. -

Simulate some common fault scenarios, such as disconnections and address conflicts, to practice fault diagnosis and troubleshooting. -

Use packet capture tools to analyze communication data and gain a deeper understanding of the protocol’s working principles.

Remember, while theoretical knowledge is important, hands-on practice can deepen understanding. I hope this article opens the door to industrial communication for you and inspires your interest in exploring more automation technologies!

Like and Share

LetMoney and Love Flow to You