For many years, Programmable Logic Controllers (PLC) have made a leap from wiring logic to storage logic; their functionality has progressed from weak to strong, achieving advancements from logic control to digital control; their application fields have expanded from small to large, transitioning from simple control of individual devices to competent motion control, process control, and distributed control tasks. Today’s PLCs have significantly improved their capabilities in handling analog signals, digital calculations, human-machine interfaces, and networking, becoming the mainstream control devices in the industrial control field, playing an increasingly larger role across various industries.

2. Application Fields of PLC

Currently, PLCs are widely used in various industries both domestically and internationally, including steel, petroleum, chemical, electric power, building materials, machinery manufacturing, automotive, light textile, transportation, environmental protection, and cultural entertainment. The usage can be categorized into the following types:

1. Discrete Logic Control

Replacing traditional relay circuits, PLCs implement logic control and sequential control, which can be used for controlling individual devices as well as multi-machine group control and automated assembly lines. Examples include injection molding machines, printing machines, stapling machines, CNC machines, grinding machines, packaging production lines, and electroplating lines.

2. Industrial Process Control

In industrial production processes, there are continuous variables such as temperature, pressure, flow, liquid level, and speed (i.e., analog quantities). PLCs use corresponding A/D and D/A conversion modules and various control algorithm programs to handle these analog quantities and achieve closed-loop control. PID regulation is a commonly used adjustment method in general closed-loop control systems. Process control has extensive applications in metallurgy, chemical engineering, heat treatment, and boiler control.

3. Motion Control

PLCs can be used for controlling circular or linear movements. Typically, dedicated motion control modules are employed, such as single-axis or multi-axis position control modules that can drive stepper motors or servo motors, widely used in various machinery, machine tools, robots, and elevators.

4. Data Processing

PLCs have functions for mathematical operations (including matrix operations, function operations, and logical operations), data transmission, data conversion, sorting, table lookups, and bit manipulation, allowing them to complete data collection, analysis, and processing. Data processing is generally used in large control systems in industries such as papermaking, metallurgy, and food processing.

5. Communication and Networking

PLC communication includes communication between PLCs and communication between PLCs and other intelligent devices. With the development of factory automation networks, modern PLCs come equipped with communication interfaces, making communication very convenient.

3. Application Characteristics of PLC

1. High Reliability and Strong Anti-Interference Capability

High reliability is a key performance characteristic of electrical control devices. PLCs, due to the adoption of modern large-scale integrated circuit technology and strict manufacturing processes, have advanced anti-interference technology in their internal circuits, resulting in very high reliability. Using PLCs to form control systems significantly reduces electrical wiring and switch contacts to hundreds or even thousands of times less compared to equivalent relay contactor systems, thus greatly reducing failures. Additionally, PLCs are equipped with hardware fault self-detection functions, which can promptly issue alarm messages when failures occur. In the application software, users can also incorporate fault self-diagnosis programs for peripheral devices, providing fault self-diagnosis protection for circuits and devices other than the PLC. This ensures the entire system has extremely high reliability.

2. Comprehensive Support, Complete Functions, Strong Applicability

PLCs have developed into a series of standardized products of various scales, suitable for various industrial control scenarios. In addition to logical processing functions, most PLCs also have complete data processing capabilities and can be used in various digital control fields. A wide variety of functional units have emerged, allowing PLCs to penetrate into position control, temperature control, CNC, and various industrial controls. Coupled with enhanced PLC communication capabilities and advancements in human-machine interface technology, it has become very easy to use PLCs to form various control systems.

3. Easy to Learn and Use, Popular Among Engineering Technicians

PLCs are control devices oriented towards industrial enterprises. They have easy interfaces and programming languages that are readily accepted by engineering technicians. The graphical symbols and expression methods of ladder diagram language are quite similar to relay circuit diagrams, making it easier for those unfamiliar with electronic circuits or computer principles to engage in industrial control.

4. System Design Requires Less Work, Easy Maintenance, and Easy Modification

PLCs replace wiring logic with storage logic, significantly reducing external wiring of control devices, greatly shortening the design and construction cycle of control systems, while also making daily maintenance easier. More importantly, it allows for changing production processes by modifying programs on the same equipment, which is particularly suitable for production scenarios with multiple varieties and small batches.

4. Issues to Note in PLC Applications

PLCs are devices used for automated control in industrial production and generally do not require special measures for direct use in industrial environments. However, despite the aforementioned high reliability and strong anti-interference capabilities, if the production environment is excessively harsh, with particularly strong electromagnetic interference or improper installation and usage, it can lead to program errors or calculation errors, resulting in incorrect inputs and outputs, which can cause equipment loss of control and misoperation, thus failing to ensure the normal operation of the PLC. To enhance the reliability of PLC control systems, on one hand, it requires PLC manufacturers to improve the anti-interference capabilities of their devices; on the other hand, it demands high attention during design, installation, and maintenance, requiring multiple parties to cooperate to effectively solve problems and enhance the system’s anti-interference performance. Therefore, attention should be paid to the following issues during use:

1. Working Environment

(1) Temperature

PLCs require an ambient temperature between 0~55°C and should not be placed under components that generate significant heat; the surrounding space for ventilation and heat dissipation should be sufficiently large.

(2) Humidity

To ensure the insulation performance of PLCs, the relative humidity of the air should be less than 85% (no condensation).

(3) Vibration

PLCs should be kept away from strong vibration sources to prevent frequent or continuous vibrations with frequencies between 10~55Hz. If unavoidable vibrations are present, damping measures must be taken, such as using damping rubber.

(4) Air

Avoid corrosive and flammable gases, such as hydrogen chloride and hydrogen sulfide. For environments with significant dust or corrosive gases, PLCs can be installed in well-sealed control rooms or cabinets.

(5) Power Supply

PLCs have certain resistance to interference from power lines. In environments with high reliability requirements or particularly severe power supply interference, an isolation transformer with a shielding layer can be installed to reduce interference between the equipment and the ground. Generally, PLCs have a DC 24V output for the input terminals, and when using an external DC power supply, a DC regulated power supply should be used. Ordinary rectified and filtered power supplies are susceptible to ripple effects, which can easily cause PLCs to receive erroneous information.

2. Interference and Its Sources in Control Systems

Electromagnetic interference in the field is one of the most common and easily impactful factors affecting the reliability of PLC control systems. To address the issue effectively, it is essential to identify the source of interference.

(1) Sources of Interference and General Classification

The sources of interference affecting PLC control systems are mostly generated in areas with significant current or voltage fluctuations, as the change in current produces magnetic fields that create electromagnetic radiation. Changes in magnetic fields generate currents, and electromagnetic high speeds generate electromagnetic waves. Generally, electromagnetic interference is classified into common-mode interference and differential-mode interference based on different interference modes. Common-mode interference is the potential difference of the signal to ground, primarily caused by the insertion of the power grid, ground potential differences, and common-mode (same direction) voltage superimposed on the signal line due to spatial electromagnetic radiation. Common-mode voltage can be converted into differential-mode voltage through asymmetric circuits, directly affecting measurement and control signals, causing damage to components (which is a major reason for high failure rates in some system I/O modules); this common-mode interference can be either DC or AC. Differential-mode interference refers to the interference voltage acting between the two poles of the signal, mainly formed by the coupling of spatial electromagnetic fields on the signal and by the conversion of common-mode interference due to unbalanced circuits, which superimposes interference on the signal, directly affecting measurement and control accuracy.

(2) Main Sources and Pathways of Interference in PLC Systems

Strong Electrical Interference

The normal power supply for PLC systems is provided by the power grid. Due to the wide coverage of the power grid, it is susceptible to all spatial electromagnetic interference, inducing voltage on the lines. Especially changes within the power grid, such as switching operations, large electrical equipment startup and shutdown, harmonics caused by AC and DC drive devices, and transient impacts from power grid short circuits, all transmit through power lines to the power supply’s primary side.

Cabinet Interference

High-voltage devices within control cabinets, large inductive loads, and chaotic wiring can all cause a certain degree of interference to PLCs.

Interference Introduced by Signal Lines

Various signal transmission lines connected to PLC control systems not only transmit effective information but also inevitably allow external interference signals to intrude. This interference mainly has two pathways: one is through the power supply of transmitters or power supply shared with signal instruments, which is often overlooked; the other is the interference induced on signal lines due to spatial electromagnetic radiation, which is quite serious. Interference from signal introduction can lead to abnormal I/O signal operation and significantly reduce measurement accuracy, and in severe cases, it can cause damage to components.

Interference from Chaotic Grounding Systems

Grounding is one of the effective means to improve the electromagnetic compatibility (EMC) of electronic devices. Proper grounding can suppress the influence of electromagnetic interference and hinder devices from emitting interference; however, incorrect grounding can introduce severe interference signals, causing PLC systems to fail to operate normally.

Interference from Within PLC Systems

This is mainly caused by mutual electromagnetic radiation between internal components and circuits, such as the mutual radiation of logic circuits and their influence on analog circuits, the mutual effects of analog ground and logic ground, and the improper use of components.

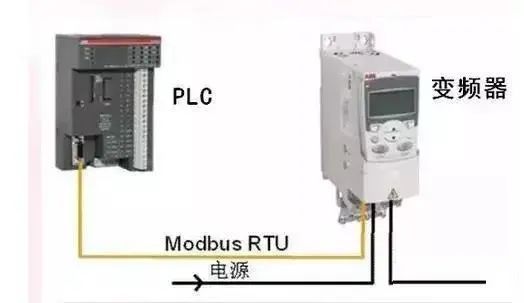

Interference from Frequency Converters

Firstly, harmonics generated during the startup and operation of frequency converters create conducted interference to the power grid, leading to distortion of grid voltage and affecting power supply quality; secondly, the output of frequency converters generates strong electromagnetic radiation interference, impacting the normal operation of surrounding devices.

3. Main Anti-Interference Measures

(1) Reasonable Power Supply Handling to Suppress Power Grid Interference

To address power grid interference introduced by the power supply, an isolation transformer with a 1:1 ratio and a shielding layer can be installed to reduce interference between the device and the ground. Additionally, an LC filter circuit can be connected in series at the power supply input. As shown in Figure 1.

(2) Installation and Wiring

● Power lines, control lines, and PLC power supply and I/O lines should be wired separately. The isolation transformer and PLC should be connected using double-insulated wire. The I/O lines of PLC should be separated from high-power lines, and if they must be in the same conduit, AC and DC lines should be bundled separately. If conditions allow, it is best to route them in different conduits, which not only maximizes spatial distance but also minimizes interference.

● PLCs should be kept away from strong interference sources such as welding machines, large silicon rectifiers, and large power devices, and should not be installed in the same switch cabinet as high-voltage devices. Inside the cabinet, PLCs should be distanced from power lines (the distance between them should exceed 200mm). Inductive loads with significant power, such as larger relays and contactors, should be connected in parallel with RC snubber circuits.

● It is best to separate the input and output wiring, and also to separate discrete and analog signals. The transmission of analog signals should use shielded cables, with the shielding layer grounded at one or both ends, and the ground resistance should be less than 1/10 of the shielding layer resistance.

● AC output lines and DC output lines should not use the same cable, and output lines should be kept as far away from high-voltage and power lines as possible to avoid parallel routing.

(3) Wiring at I/O Terminals

Input Wiring

● Input wiring should generally not be too long. However, if the environmental interference is low and voltage drop is minimal, input wiring can be slightly longer.

● Input/output lines should not use the same cable, and input/output lines must be separated.

● It is advisable to use normally open contact forms to connect to the input terminals, making the ladder diagram consistent with the relay schematic for easier reading.

Output Connections

● Output terminal connections can be divided into independent outputs and common outputs. Different types and voltage levels of output voltage can be used in different groups. However, outputs within the same group can only use the same type and voltage level of power supply.

● Since PLC output components are encapsulated on printed circuit boards and connected to terminal blocks, short-circuiting the load connected to output components can destroy the printed circuit board.

● When using relay outputs, the size of inductive loads can affect the lifespan of the relay; therefore, reasonable selection or the use of isolation relays is recommended when using inductive loads.

● PLC output loads may generate interference; thus, measures should be taken to control this, such as using flyback diodes for DC outputs, RC snubber circuits for AC outputs, and bypass resistors for transistor and bidirectional thyristor outputs.

(4) Proper Grounding Selection and Improvement of Grounding Systems

Good grounding is crucial for the reliable operation of PLCs, as it can prevent occasional voltage spikes from causing harm. The purposes of grounding are generally twofold: safety and interference suppression. A well-designed grounding system is one of the important measures to enhance the anti-electromagnetic interference capability of PLC control systems.

The grounding of PLC control systems includes system ground, shield ground, AC ground, and protective ground. A chaotic grounding system can interfere with PLC systems, mainly due to uneven potential distribution among grounding points, resulting in ground loop currents that affect normal operation. For example, the shielding layer of cables must be grounded at one point; if both ends A and B of the shielding layer are grounded, it creates a potential difference, causing current to flow through the shielding layer. In abnormal conditions such as lightning strikes, the ground current will be even greater.

Moreover, the shielding layer, grounding wires, and the ground can form a closed loop, where induced currents can appear under changing magnetic fields, leading to interference signal circuits through coupling between the shielding layer and core wire. If the system ground is chaotic with other grounding methods, the resulting ground loop currents can create uneven potential distributions along the ground line, affecting the normal operation of the PLC’s logical and analog circuits. PLCs have a low tolerance for logical voltage interference, and disturbances in the logical ground potential distribution can easily affect logical operations and data storage, causing data chaos, program runaway, or system crashes. Disturbances in the analog ground potential distribution can lead to measurement accuracy deterioration, causing severe distortion and misoperation in signal measurement and control.

● Safety Ground or Power Supply Ground

The grounding terminal of the power supply line and the cabinet grounding should be connected for safety grounding. If there is a power leak or the cabinet is electrified, the safety ground will direct it underground, preventing harm to personnel.

● System Ground

The PLC controller is grounded to match the potential of the controlled devices, referred to as system grounding. The grounding resistance should not exceed 4Ω, and generally, the PLC system ground should be connected to the negative terminal of the switch power supply within the control cabinet to serve as the control system ground.

● Signal and Shield Grounding

Signal lines must have a unique reference ground, and the shielding cable should be grounded at a single point in environments that may produce conducted interference. When grounding signal sources, the shielding layer should be grounded on the signal side; if not grounded, it should be grounded on the PLC side. If there are joints in the signal line, the shielding layer should be securely connected and insulated to avoid multiple grounding points. When connecting multiple measurement signal shielded twisted pairs with multi-core twisted shielded cables, the shielding layers should be well-connected and insulated, selecting appropriate single grounding points.

(5) Suppressing Interference from Frequency Converters

Interference from frequency converters can generally be addressed in the following ways:

Install isolation transformers, mainly targeting conducted interference from the power supply, which can block most of the conducted interference before reaching the isolation transformer.

Use filters, which have strong anti-interference capabilities and can prevent the device’s own interference from being conducted to the power supply. Some filters also have spike voltage absorption functions.

Use output reactors, adding AC reactors between the frequency converter and the motor mainly reduces electromagnetic radiation generated during energy transmission, affecting the normal operation of other devices.

Interference in PLC control systems is a complex issue; thus, comprehensive considerations of various factors in anti-interference design are necessary to effectively suppress interference and ensure the normal operation of PLC control systems. As the application fields of PLCs continue to expand, how to use PLCs efficiently and reliably has become an important factor in their development.

5. Conclusion

In the future, PLCs will undergo greater development, with a richer variety of products and more complete specifications. Through perfect human-machine interfaces and comprehensive communication devices, they will better meet the demands of various industrial control scenarios. As an important component of automation control networks and internationally standardized networks, PLCs will play an increasingly significant role in the industrial control field.

Hi, fellow workers,

Do you remember the last time I shared 777 Siemens cases?

Some friends mentioned that the cases were a bit old.

Also, are there any cases for S7-1200 and S7-1500?

Here I am again to share!

This time, I not only brought 777 cases

but also added 200 new cases for SMART,

S7-1200,S7-1500

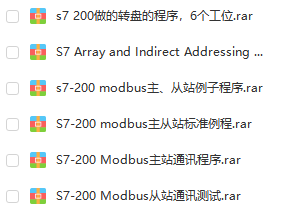

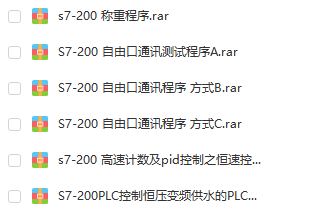

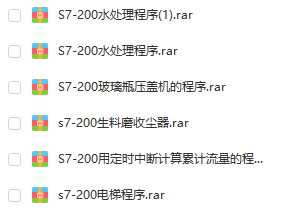

Siemens S7-200 Cases

▲ Scroll Down to View

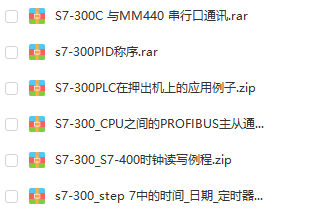

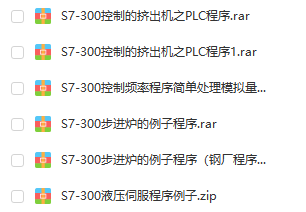

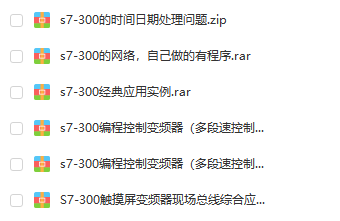

Siemens S7-300/400 Cases

▲ Scroll Down to View

Siemens S7-1200 Cases

▲ Scroll Down to View

You thought that was all?

No, I have prepared a lot of cases for everyone this time!

Colleagues in need, hurry to claim it!

[Siemens Case Programs]