1. Industry Transformation Gives Rise to a New Species of “High-End Intelligent Control MCU”

Driven by the strong momentum of automotive intelligence and new energy trends, the electronic and electrical architecture is rapidly transforming from traditional distributed systems to a “central computing + regional control” architecture. This profound change aims to optimize wiring layouts, enhance software integration, and reduce costs while improving efficiency. Moreover, it is a pressing response to the complex functional demands, particularly in key areas such as efficient control of power systems, precise execution of intelligent driving, and overall vehicle safety protection.

In this process, the Zone Controller (ZCU) serves as a critical hub of the new architecture, placing high demands on the microcontroller (MCU) responsible for its main control tasks — it must possess high performance, high real-time capability, and high safety. Clearly, traditional single-function basic control MCUs can no longer meet the performance upgrade needs of the entire vehicle system. The industry urgently requires a new type of MCU that can handle complex algorithms, support concurrent multitasking, and provide high integration and comprehensive safety protection capabilities, leading to the emergence of the “High-End Intelligent Control MCU”.

Globally, semiconductor giants like Infineon and Renesas are accelerating their layout in the “High-End Intelligent Control MCU” arena. In China, the booming automotive market and the strong demand for supply chain security and autonomy have prompted local chip companies to catch up quickly, accelerating technological breakthroughs and product iterations.

In the domestic automotive-grade chip sector, Sintronic Technology, with its core product in intelligent vehicle control — the E3 series MCU, is innovating technology and collaborating with ecosystems to set a benchmark for the rise of local high-end intelligent control MCUs.

At this year’s Shanghai Auto Show, Sintronic Technology showcased its phased achievements in the high-end intelligent control field, including the mass production-level solutions for its flagship intelligent control MCU product E3650 and the new power domain control MCU product E3620P, attracting widespread attention from the industry.

2. Technical Requirements and Design Challenges of High-End Intelligent Control MCUs

Under the new generation of automotive electronic and electrical architecture, regional controllers and domain controllers need to gradually achieve cross-domain integration, consolidating functions originally dispersed across multiple ECUs into a single controller. This high level of integration significantly raises the technical requirements for the main control MCU, particularly in terms of processing capability, parallel task management, communication efficiency, and system safety.

1. Applications for Regional Controllers

As the main control MCU for regional controllers, its design must feature a powerful processing core, ample storage, and efficient communication capabilities. Taking the Sintronic E3650 as an example, it adopts an ARM Cortex R52+ lock-step multi-core architecture, with a clock frequency of up to 600MHz, integrating 16MB of embedded storage and over 4MB of large-capacity SRAM, achieving a 40% increase in computing power compared to similar products and a 30% expansion in storage capacity, realizing a generational upgrade in computing power and storage. This performance enhancement is not merely a simple hardware stack but a deep optimization for the multi-tasking scenarios of regional controllers:

High computing power and strong real-time R52+ multi-core + advanced storage architecture: The new generation flagship processing core R52+ provides higher real-time performance, stronger computing power, and enhanced functional safety features. Its over 4MB SRAM, through advanced storage architecture design, optimally deploys multi-core tasks, ensuring lower response latency for high real-time tasks (such as chassis signal processing) within the regional controller;

Communication acceleration engine: Integrating a dedicated communication engine for SSDPE, it achieves zero packet loss transmission even under the simultaneous operation of 16 CAN FD channels, significantly reducing CPU load;

Virtualization support: Accompanied by high real-time Hypervisor software specifically designed for domain control MCU scenarios, typical CPU usage is expected to be <1%, with interrupt latency reaching microsecond (us) levels. As regional controllers gradually integrate applications of different safety levels and iteration frequencies, the complexity of functions increases, and real-time virtualization can efficiently address issues of multi-department collaborative development, multi-system integration, and business isolation;

Integrated innovation: The E3650 achieves system-level cost reduction and miniaturization breakthroughs through key technological innovations. It integrates over 350 usable GPIOs, reducing the number of IO expansion chips, allowing a single chip to replace the MCU + numerous IO expansion chips in traditional solutions; it is equipped with a custom ASIL D level power PMIC; with a package size of 19×19mm, it is 40% smaller than similar competing products, meeting the space compression needs of new energy vehicles; multiple gigabit Ethernet ports can save peripheral switch chips under specific network topologies.

2. Applications for Power Domain Control Scenarios

Power domain control is another typical application of high-end intelligent control. The power systems of new energy vehicles have unique and stringent requirements for MCUs, such as real-time performance and precision in high-voltage and high-speed control, as well as collaborative management of multiple power sources (such as hybrid power). The configuration of the new member of the Sintronic E3 family, the E3620P, fully reflects its adaptability to power domain control scenarios:

Equipped with a 6-core R52+ cluster, with a clock frequency of up to 500MHz, over 2MB of SRAM, and various dedicated peripherals for electric drive/power scenarios, including the GTM 4.1 timer module, multiple independent high-precision DS ADCs, and built-in high-precision HRPWM. Additionally, through innovative designs such as hardware rotary decoder accelerators, mathematical algorithm accelerators, digital filters, and SDL data-specific high-speed buses, it provides serialized product solutions that fully meet the stringent requirements for high computing power, extreme real-time performance, and high-precision control in single electric control, hybrid dual electric control, distributed electric drive control, and multi-in-one power domain scenarios.

In terms of safety, the E3620P not only meets ASIL-D functional safety levels and AEC-Q100 Grade 1 automotive reliability standards but also integrates a dedicated information security engine, supporting hardware acceleration for various information security encryption and decryption algorithms, including national secret algorithms, exceeding the Evita Full standard and establishing hardware-level dual redundancy protection.

Currently, the leading electric drive company, Zhenqu Technology, has taken the lead in equipping the E3620P in its new generation products, marking a breakthrough in the import substitution of domestic MCUs in the power domain control field, providing key technical support for the autonomy of core components in new energy vehicles.

3. Applications for ADAS and Cabin-Driving Integration Scenarios

In response to the demand for upgrading intelligent driving assistance from L2+ to L4, Sintronic Technology’s E3 series, centered around the E3650 and E3620B, constructs a tiered MCU solution for advanced intelligent driving assistance and cabin-driving integration platforms. Compared to traditional MCUs, the E3 series offers stronger computing resources (600MHz clock frequency), larger storage capacity (over 4MB SRAM), and richer peripheral interfaces, supporting higher precision sensor data preprocessing, enabling the deployment of more complex regulatory algorithms on the MCU side, and achieving stronger system safety redundancy. The integrated information security modules in the E3650 and E3620B can also save board-level national secret chips, reducing system costs.

Currently, the Sintronic E3 series MCUs have shipped nearly one million units in intelligent driving scenarios (including LiDAR, front-view integration machines, etc.), achieving large-scale production in several mainstream automotive companies, continuously leading the domestic high-performance automotive-grade MCU market for auxiliary driving applications, and providing an important demonstration for the localization of domestic chips in key areas of intelligent driving assistance.

3. Ecosystem Collaboration: The “Core” Foundation of High-End Intelligent Control

The complexity of high-end intelligent control MCUs necessitates strong ecosystem support for their industrialization. From a complete software toolchain to reliable functional safety and information security services, to deep collaboration with automakers and Tier 1 suppliers, ecosystem development is key to the large-scale application of high-end intelligent control chips.

For example, in response to the trend of “one chip integrating multiple ECU functions” under centralized electronic and electrical architecture, supporting hardware virtualization and corresponding Hypervisor software is particularly important, as it can greatly enhance the efficiency of multi-system integration and address security isolation issues in cross-domain applications. At the same time, user-friendly and efficient development toolchains can significantly shorten the development cycle for automotive companies.

1. Toolchain Ecosystem: Full Empowerment from Development to Mass Production

A complete toolchain ecosystem is the foundation for accelerating chip application deployment. Taking Sintronic Technology’s E3 as an example, by collaborating with leading global embedded tool manufacturers, a comprehensive support system covering design, debugging, and safety certification has been established:

1) Development Environment: Collaborating with industry partners such as IAR, Green Hills, and HighTec, continuously improving the E3 series toolchain ecosystem, effectively enhancing development efficiency and software quality, and facilitating the implementation of high-performance, high-safety automotive-grade MCU solutions.

2) AUTOSAR: Collaborating with Vector, ETAS, and PWC to complete AUTOSAR, providing customers with high-performance hardware-software integrated solutions, improving development efficiency, and facilitating rapid mass production of vehicle models.

3) Virtualization Support: Providing high real-time, high safety, and low resource overhead Hypervisor software specifically designed for domain control scenarios and high-performance MCUs, effectively assisting in parallel development across departments, multi-system integration, and business isolation after cross-domain integration.

2. Comprehensive Safety Protection System

In terms of functional safety, Sintronic Technology has collaborated with Vector to develop the MICROSAR evaluation package for the E3650 development board designed for regional controller (ZCU) application scenarios, including comprehensive support for multi-core and memory protection AUTOSAR SC3 multi-core OS, boot code, MCAL integration, and sample projects with complete communication, diagnostics, storage, and other functions.

At the same time, IAR Embedded Workbench for Arm has fully supported the Sintronic E3650, providing one-stop development and debugging services.

In terms of information security, Sintronic has partnered with ETAS to launch an HSM network security solution based on the Sintronic E3 in March 2024, and the scope of cooperation has further expanded to include basic software, information security, and calibration tools.

During the Shanghai International Auto Show in April this year, Sintronic Technology signed a strategic cooperation agreement with Yishi Intelligent to jointly promote the application of the first domestic automotive-grade MCU in post-quantum cryptography (PQC) algorithms. The two parties are building a local solution to resist quantum attacks based on the high-performance automotive-grade MCU chip E3650 and Yishi Intelligent’s PQC hardware acceleration technology. During the auto show, Sintronic also deepened cooperation with Bosch Semiconductor, focusing on three major technical directions: IP integration innovation, system-level solutions, and software ecosystem development. This includes improving the functional safety development ecosystem through ETAS’s AutoSAR and HSM solutions, covering the entire series of Sintronic SoCs and MCUs.

3. Industry Chain Collaboration: Demand-Driven + Technology-Pushed

In terms of industry chain collaboration, domestic high-end intelligent control MCUs are accelerating their layout. During this year’s Shanghai Auto Show, Sintronic announced several major strategic collaborations:

-

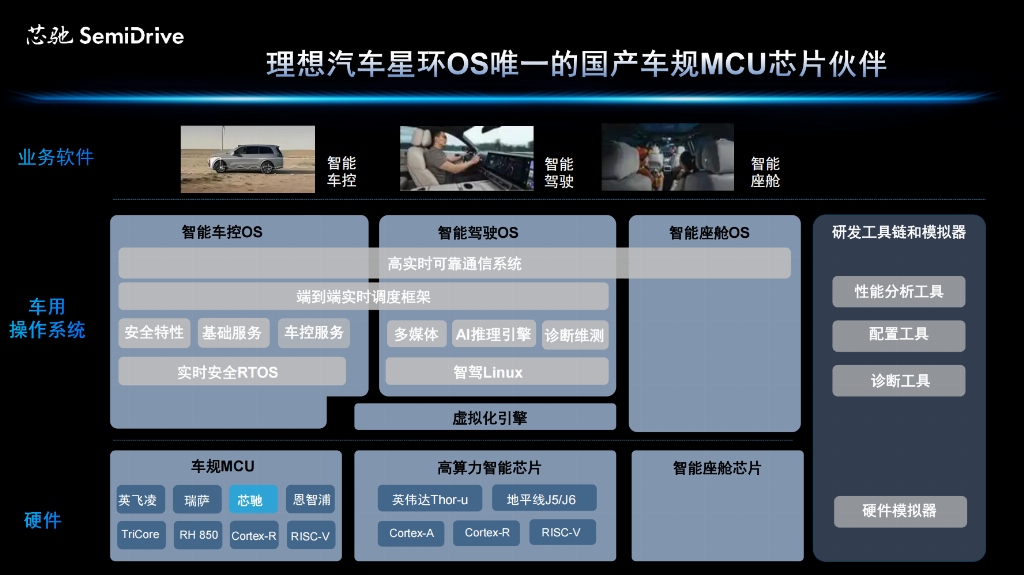

Li Auto: The Sintronic E3650 is the first domestic automotive-grade MCU to support Star Ring OS;

-

SAIC-GM Wuling, Zhenqu Technology: Sintronic Technology has reached deep cooperation with SAIC-GM Wuling and Zhenqu Technology to jointly create industry-leading electric drive solutions for new energy vehicles based on the latest released E3620P main control chip product family, covering all application scenarios from pure electric single drive to hybrid dual drive. In 2024, Zhenqu electric control equipped with Sintronic E3430 and E3640 chips has achieved large-scale production in popular models such as Wuling Xingguang and Bingguo family;

-

Sintronic has also engaged in strategic collaboration with several industry chain ecosystem companies such as Desay SV, Huayang General, Guangting Information, and Banma Intelligent in the fields of regional control and body domain control, creating vertically integrated solutions from underlying systems to upper-level applications.

As of now, Sintronic has partnered with over 200 ecosystem partners, building a complete technology stack that includes underlying operating systems, middleware platforms, development toolchains, and intelligent application algorithms, reducing the barriers to intelligent vehicle chip applications through systematic technological integration, forming a full-cycle innovation acceleration engine covering R&D, testing, and deployment, continuously driving the rapid maturation of the intelligent automotive industry innovation ecosystem.

4. The Rise of Domestic High-End Intelligent Control MCUs

1. Filling Domestic Gaps and Challenging International Giants

With continuous technological advancements and rapid market development, domestic automotive-grade chips are gradually breaking through the technological barriers of international giants, especially showing strong momentum in the high-end intelligent control MCU field.

The author has compiled a comparison of the characteristics of domestic and international high-end intelligent control MCUs based on data sheets from various manufacturers and online channels (see the table below), particularly in key indicators required for regional/domain control scenarios such as clock frequency, SRAM capacity, number of peripheral IOs, and information security capabilities, the Sintronic E3650 demonstrates high competitiveness. This indicates that in the competition for high-end intelligent control, domestic products have already achieved technical strength comparable to or even surpassing that of international giants, standing on the same starting line to jointly support the upgrade and transformation of the entire vehicle’s electronic and electrical architecture. The rise of domestic power not only helps enhance the automotive industry chain’s autonomy and controllability but also provides vehicle manufacturers with more diverse and cost-effective chip options.

2. Collaboratively Defining “Scenario-Based” Chips

As a rapidly evolving field, high-end intelligent control MCUs require deep collaboration with customers and product definition based on actual application scenarios. This helps ensure that chip performance precisely matches target scenarios, avoiding redundant designs, thereby optimizing costs while meeting functional requirements.

Sintronic Technology’s MCU product line manager, Zhang Xitong, stated in an interview: “Precise product definition requires deeper collaboration. In the early stages of product planning, we engage in very in-depth collaboration with customers (including OEMs and Tier 1 suppliers) and ecosystem partners to deeply understand their system requirements, the evolution direction of the next-generation architecture, and specific application scenarios, ensuring that product performance accurately fits and matches target scenarios, meeting the performance upgrade needs of the scenarios while avoiding redundant designs and resource waste, thereby reducing costs by improving the alignment with application needs.”

Taking the E3650 as an example, compared to most products in the same tier, its computing power has increased by nearly 40%, storage capacity has expanded by 30%, the number of available peripherals and GPIOs has increased by 30%, and low-power performance has improved by 50%, while the chip area has decreased by 40%. Additionally, through the higher integration of the E3650, significant simplification of system design and reduction of BOM costs can be achieved.

Conclusion: China’s “Chip” Paradigm Leading the Future of the Industry

The exploration and practice of domestic power in the high-end intelligent control MCU field are reflected not only in the enhancement of single-point technical performance but also in providing new solutions for the industry through technological innovation, ecosystem collaboration, and scenario-driven product definitions around the new generation of electronic and electrical architecture. This helps promote the autonomous and controllable development of the automotive industry chain in key areas and lays the foundation for the accelerated popularization of intelligent vehicles.

In the future, with continuous technological iteration and the ongoing improvement of the industry chain, domestic high-end intelligent control MCUs will play an increasingly important role in the global automotive intelligence process, leading the industry to new heights..