Hello, everyone. Today we will take a look at the hazardous chemicals in semiconductor manufacturing—Ammonium Ferrous Sulfate.

1. Basic Information

Chemical Name in Chinese: 硫酸亚铁铵。

Chemical Name in English: FERROUS AMMONIUM SULFATE; Ammonium iron sulfate; Mohr’s salt.

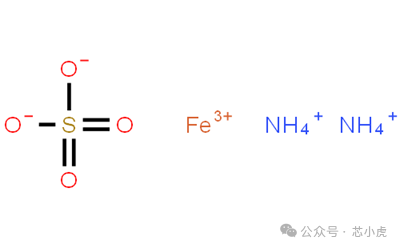

Molecular Formula: Fe2H8N2O4S; Fe2(NH4)2SO4.

Molecular Weight: 392.1308.

CAS No.: 2310045-89-3.

2. Composition/Information on Ingredients

Composed of ammonium ions, ferrous ions, sulfate ions, and crystallization water.

3. Physical and Chemical Properties

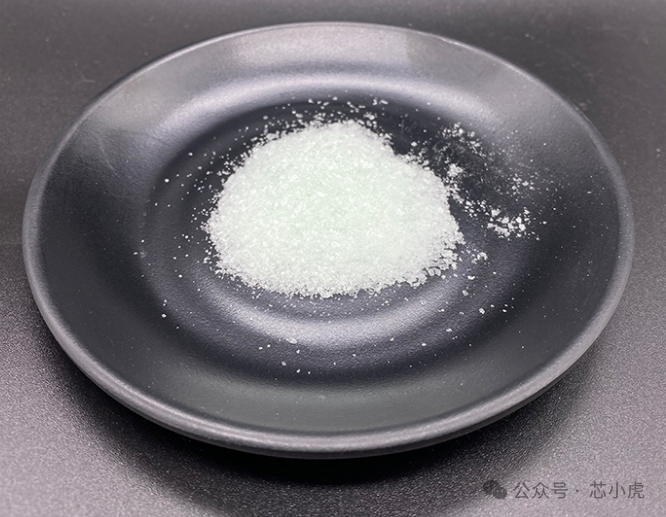

Appearance and Properties: Light green or blue-green solid (powder or crystalline form).

Purity: The purity of Ammonium Ferrous Sulfate typically comes in various specifications, commonly including analytical grade and chemical grade. Analytical grade Ammonium Ferrous Sulfate has a higher purity, generally reaching above 99.5%, suitable for precise chemical analysis and scientific experiments; chemical grade has a relatively lower purity but can still meet general chemical experiment and industrial production needs.

In semiconductors, it is mainly used as an additive in chemical plating solutions and in the composition of etching solutions.

4. Stability and Reactivity

Conditions to Avoid: Light.

5. Overview of Hazards

Routes of Exposure: Inhalation, ingestion, contact with eyes and skin.

Health Hazards: Irritation of the eyes, nasal cavity, and throat; prolonged exposure can cause brown discoloration of the eyes, significant iron accumulation in the body can lead to vomiting, stomach pain, constipation, black stools, and repeated exposure may damage the liver and irritate the lungs.

6. First Aid Measures

Skin Contact: Remove contaminated clothing and rinse the affected skin with water.

Eye Contact: Rinse with plenty of water for at least 15 minutes; seek medical attention.

7. Firefighting Measures

Extinguishing Method: Use extinguishing agents suitable for the surrounding fire source.

8. Emergency Response to Spills

Emergency Handling: Wear protective equipment to enter the site, absorb the spilled liquid with vermiculite, dry sand, soil, or similar materials, and collect the spilled powder in a closed container using the safest method.

If you have any comments or suggestions, feel free to leave a message or send a private message. The editor is also learning and growing.

*Disclaimer:This article is created by the original author.The content of the article represents their personal views, and our reposting is only for sharing and discussion, not representing our endorsement or agreement. If there are any objections or copyright issues, please contact us for removal! Source from the internet.

▌⊰Related Knowledge Navigation ⊱

Chip Manufacturing Process–LITHO【Illustrated Introduction】

Chip Manufacturing Process–CMP【Illustrated Introduction】

Chip Manufacturing Process–IMP【Illustrated Introduction】

What stages must a semiconductor chip manufacturing FAB go through to achieve full automation?

In batch operations, when does a semiconductor FAB use Lot? When does it use Batch?

▌Click on “Chip Little Tiger” below to follow me for more chip knowledge and news

▌If you like it, please “like” + “look” + “✿, thank you

▌For learning, communication, and cooperation, please scan the following to add,please note your name + position + company,thank you!