In today’s rapidly advancing technology, creating a toy car that can be wirelessly controlled via a smartphone not only allows us to gain a deeper understanding of electronic circuits and programming knowledge but also brings a great sense of accomplishment. Today, let’s complete this fun project using Arduino UNO and Bluetooth Module.

1. Required Materials List

| Component | Model/Parameters | Purpose |

|---|---|---|

| Arduino UNO | Standard development board | The “brain” of the project, controlling logic |

| Bluetooth Module | HC-05/HC-06 (requires pairing and debugging) | The wireless bridge between the phone and the car |

| L298N Motor Driver Board | Dual H-bridge design, supports dual motor control | Provides power and controls direction for the motors |

| DC Motor ×2 | 12V, 200-500RPM (suitable for toy cars) | Power source for front and rear wheels |

| 12V Battery Pack | 2 AA batteries or lithium battery | Power supply system |

| Toy Car Chassis | Small car base with wheels | Integrates all hardware |

| Dupont Wires | Several | Connects circuits |

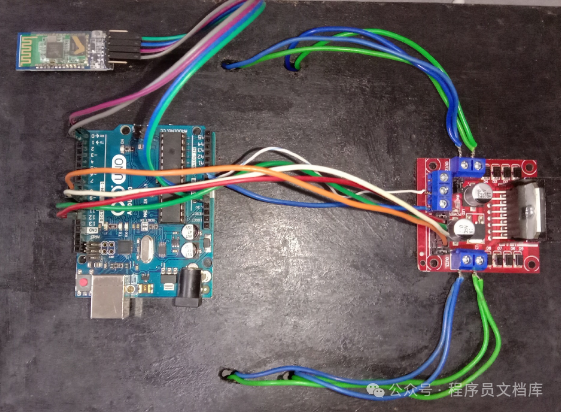

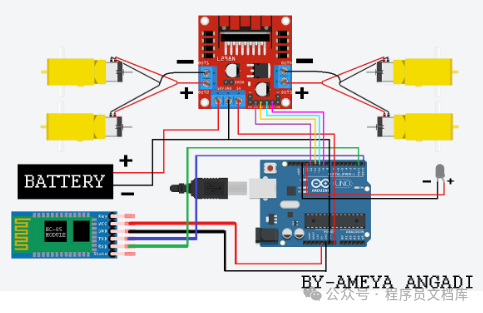

2. Hardware Connection Steps (Detailed with Images)

1. Connecting the Bluetooth Module to Arduino UNO

HC-05 Bluetooth Module → Arduino UNO:

TXD → RX (0) # Data reception

RXD → TX (1) # Data transmission

VCC → 5V # Power supply (do not use 3.3V!)

GND → GND # Common ground

HC-05 Bluetooth Module → Arduino UNO:

TXD → RX (0) # Data reception

RXD → TX (1) # Data transmission

VCC → 5V # Power supply (do not use 3.3V!)

GND → GND # Common groundKey Details:

- Use 3.3V power supply to power the Bluetooth module to avoid damaging it with excessive voltage.

- The default baud rate for HC-05 is 9600, which needs to be confirmed via AT commands (see appendix at the end).

2. Connecting the L298N Motor Driver Board to Arduino UNO

L298N → Arduino UNO:

IN1 → D2 # Control positive direction of left motor

IN2 → D3 # Control negative direction of left motor

ENA → D9 # Control speed of left motor (PWM)

IN3 → D4 # Control positive direction of right motor

IN4 → D5 # Control negative direction of right motor

ENB → D10 # Control speed of right motor (PWM)

GND → GND # Common ground

+12V → External power positive terminal # Motor power supply

L298N → Arduino UNO:

IN1 → D2 # Control positive direction of left motor

IN2 → D3 # Control negative direction of left motor

ENA → D9 # Control speed of left motor (PWM)

IN3 → D4 # Control positive direction of right motor

IN4 → D5 # Control negative direction of right motor

ENB → D10 # Control speed of right motor (PWM)

GND → GND # Common ground

+12V → External power positive terminal # Motor power supply3. Connecting the Motors to the Wheels

- Fix the two DC motors on either side of the chassis, with the driving wheels being the rear wheels (or adjust according to the chassis structure).

- Use zip ties or screws to secure the motor shafts to the wheels, ensuring smooth rotation.

3. Software Programming (Code Can Be Copied Directly)

// Define motor control pins

const int leftMotorPin1 = 2;

const int leftMotorPin2 = 3;

const int rightMotorPin1 = 4;

const int rightMotorPin2 = 5;

const int leftEnablePin = 9;

const int rightEnablePin = 10;

void setup() {

// Initialize pins as output mode

pinMode(leftMotorPin1, OUTPUT);

pinMode(leftMotorPin2, OUTPUT);

pinMode(rightMotorPin1, OUTPUT);

pinMode(rightMotorPin2, OUTPUT);

pinMode(leftEnablePin, OUTPUT);

pinMode(rightEnablePin, OUTPUT);

// Initialize serial communication (baud rate must match Bluetooth module)

Serial.begin(9600);

}

void loop() {

if (Serial.available() > 0) {

char command = Serial.read();

switch (command) {

case 'F': // Move forward

moveForward();

break;

case 'B': // Move backward

moveBackward();

break;

case 'L': // Turn left

turnLeft();

break;

case 'R': // Turn right

turnRight();

break;

case 'S': // Stop

stopMotors();

break;

}

}

}

// Function definitions

void moveForward() {

digitalWrite(leftMotorPin1, HIGH);

digitalWrite(leftMotorPin2, LOW);

digitalWrite(rightMotorPin1, HIGH);

digitalWrite(rightMotorPin2, LOW);

analogWrite(leftEnablePin, 255);

analogWrite(rightEnablePin, 255);

}

void moveBackward() {

digitalWrite(leftMotorPin1, LOW);

digitalWrite(leftMotorPin2, HIGH);

digitalWrite(rightMotorPin1, LOW);

digitalWrite(rightMotorPin2, HIGH);

analogWrite(leftEnablePin, 255);

analogWrite(rightEnablePin, 255);

}

void turnLeft() {

// Left motor backward, right motor forward → turn left

digitalWrite(leftMotorPin1, LOW);

digitalWrite(leftMotorPin2, HIGH);

analogWrite(leftEnablePin, 150);

digitalWrite(rightMotorPin1, HIGH);

digitalWrite(rightMotorPin2, LOW);

analogWrite(rightEnablePin, 255);

}

void turnRight() {

// Left motor forward, right motor backward → turn right

digitalWrite(leftMotorPin1, HIGH);

digitalWrite(leftMotorPin2, LOW);

analogWrite(leftEnablePin, 255);

digitalWrite(rightMotorPin1, LOW);

digitalWrite(rightMotorPin2, HIGH);

analogWrite(rightEnablePin, 150);

}

void stopMotors() {

digitalWrite(leftMotorPin1, LOW);

digitalWrite(leftMotorPin2, LOW);

digitalWrite(rightMotorPin1, LOW);

digitalWrite(rightMotorPin2, LOW);

analogWrite(leftEnablePin, 0);

analogWrite(rightEnablePin, 0);

}4. Smartphone Setup

1. Bluetooth Pairing

- Set the HC-05 module to slave mode (AT+ROLE=0).

- Turn on the phone’s Bluetooth, search for devices, and connect to the device named **”HC-05″**.

2. Using Bluetooth Serial Assistant

- Download **Bluetooth Serial Assistant**

- After successful connection, send commands in the input box:

F → Move forward B → Move backward L → Turn left R → Turn right S → Stop

5. Debugging Tips and Common Issues

Q1: Unable to connect Bluetooth?

- Ensure HC-05 is in pairing mode (AT+PAIRABLE=1).

- Restart the phone’s Bluetooth or test with another phone.

Q2: The car does not move?

- Check if the power is connected (L298N’s +12V pin).

- Measure if the output voltage of the motor driver board is 12V.

Q3: Steering is not responsive?

- Adjust the servo control parameters (PWM values in the code).

- Ensure there are no obstructions on the wheel shafts.

6. Advanced Modification Suggestions

1. Add Obstacle Avoidance Function

- Use HC-SR04 Ultrasonic Sensor to detect obstacles:

int readUltrasonic() {

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

return pulseIn(echoPin, HIGH) * 0.034; // Convert to centimeters

}

void avoidObstacle() {

int distance = readUltrasonic();

if (distance < 20) { // When distance < 20cm, automatically brake

stopMotors();

delay(1000);

}

}2. Implement Smartphone App Control

- Use Blynk or MIT App Inventor to design a custom control interface.

3. Install Camera and AI

- Use the phone camera to recognize lane lines, combined with OpenCV for automatic tracking.

Notes

- Disconnect the Bluetooth module before uploading code to avoid serial conflicts that prevent program uploads.

- The motor driver board and Arduino share GND, but the power supply must be independent (12V battery directly powered).

- Pair the HC-05 for the first time, AT command operations are detailed in the appendix at the end.

Conclusion

Through this project, you not only grasp the basic principles of embedded systems but also enhance your hands-on skills and logical thinking. Go ahead and give it a try! If you encounter any issues, feel free to ask in the comments section—your work might become the star of the next tutorial!

Appendix: HC-05 Bluetooth Module AT Command Configuration

AT+UART_DEF=9600,8,1,NONE # Set baud rate

AT+ROLE=0 # Set as slave device

AT+PAIRABLE=1 # Enter pairing mode

AT+NAME=MyCar # Change device name