Profibus Bus Technology

1

What is Profibus Fieldbus?

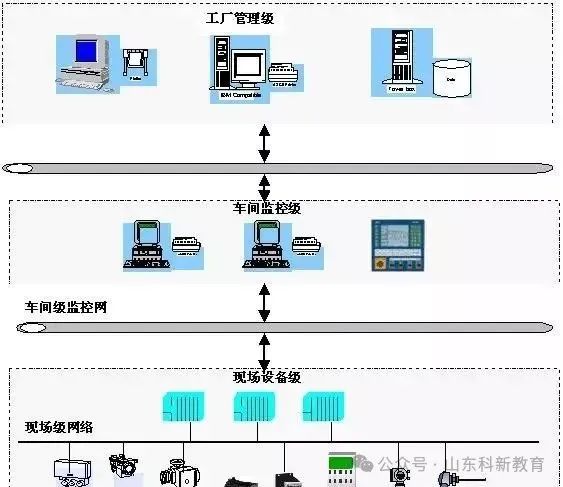

The fieldbus is a serial, digital, multipoint communication bus installed between field devices/instruments in the production process area and automatic control devices/systems in the control room. Of course, the production process includes both continuous and batch production. Profibus fieldbus is one of them.

In simple terms, Profibus connects various dispersed field devices (sensors and actuators) to controllers or control systems through a bus, while supporting both factory automation and process automation as well as drive applications.

2

Three Types of Profibus Protocols

Profibus fieldbus includes: Profibus-FMS, Profibus-DP, and Profibus-PA. The respective communication methods, application fields, and advantages are: FMS is mainly for general-purpose automation, widely applicable, and supports multiple master communications; DP is mainly for factory automation, characterized by its speed, plug-and-play capability, and efficiency; while PA is mainly used for process automation, requiring bus power and compliance with intrinsic safety standards.

Currently, the main application in the market is still the Profibus-DP network, so I will mainly introduce some knowledge about the DP network next.

3

Three Device Types Defined by Profibus-DP

1. DP Class 1 Master Device (DPM1)

The central controller that exchanges data with distributed I/O devices (DP-slaves);

Allows several DPM1s to exist simultaneously, with typical devices being PLCs, PCs, VME.

2. DP Class 2 Master Device (DPM2)

Configuration, monitoring, or engineering tools used to set network parameters, monitor DP-slave devices.

3. DP-Slave Device

Peripheral devices directly connected to I/O signals;

Typical devices include inputs, outputs, drives, valves, operator panels, etc.

4

Data Transmission Between DP Master and DP Slave

1. Parameterization Phase

The slave is parameterized by the DP master using current bus parameters, monitoring times, and specific parameters of the slave device.

2. Configuration Phase

The DP master compares the required configuration for the DP slave with the current configuration.

3. User Data Transmission Phase

After successful parameterization and configuration, the DP slave changes its state to enter the user data exchange phase.

During this phase, the parameters of the slave can be changed without interrupting data transmission.

Note: During these three phases, diagnostic data and control commands can also be transmitted.

5

Main Applications of Profibus

Profibus bus technology has now developed relatively maturely in China, and its applications are quite broad. In factory automation, it is used in vehicle manufacturing, filling plants, inventory systems, switchgear glass production, etc.; in process automation, it is used in the chemical industry, petrochemical industry, papermaking and textile industry, food and grain industry, power plants, wastewater treatment, etc.; additionally, some drive technology and safety application industries are also very widespread.

Source: This article is reproduced from the internet, and the copyright belongs to the original author. If there are copyright issues, please contact us to delete it in time. Thank you!

Scan to Follow

WeChat ID|13615417996

Follow the left QR code to get free

[Siemens Data Collection]