Formatting | Last BugThe main content shared today is derived from ADI’s SPI knowledge study. SPI is one of the most commonly used communication methods in embedded development. However, most embedded software engineers often focus more on upper-layer software development and tend to overlook some underlying signal formats. When communication issues arise, it can be quite unexpected. Therefore, this text serves as a review and reinforcement of the SPI interface.The Serial Peripheral Interface (SPI) is one of the most widely used interfaces between microcontrollers and peripheral ICs (such as sensors, ADCs, DACs, shift registers, SRAM, etc.). This article will first briefly explain the SPI interface, then introduce ADI’s analog switches and multiplexers that support SPI, and how they help reduce the number of digital GPIOs required in system circuit board design.SPI is a synchronous, full-duplex, master-slave interface. Data from the master or slave is synchronized on the rising or falling edge of the clock. The master and slave can transmit data simultaneously. The SPI interface can be either three-wire or four-wire. This article focuses on the commonly used four-wire SPI interface.

1

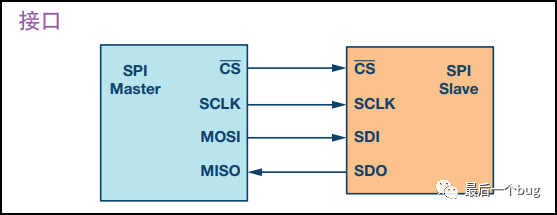

Interface

Figure 1. SPI Configuration with Master and Slave

The four-wire SPI device has four signals:

- Clock (SPI CLK, SCLK)

- Chip Select (CS)

- Master Out, Slave In (MOSI)

- Master In, Slave Out (MISO)

The device that generates the clock signal is called the master. The data transmitted between the master and slave is synchronized with the clock generated by the master. Compared to the I2C interface, SPI devices support higher clock frequencies. Users should refer to the product datasheet for the clock frequency specifications of the SPI interface.There can only be one master in an SPI interface, but there can be one or more slaves. Figure 1 shows the SPI connection between the master and slave.The chip select signal from the master is used to select the slave. This is usually a low-active signal, which disconnects the slave from the SPI bus when pulled high. When using multiple slaves, the master needs to provide a separate chip select signal for each slave. The chip select signal in this article is always a low-active signal.MOSI and MISO are the data lines. MOSI sends data from the master to the slave, while MISO sends data from the slave to the master.

2

Data Transmission

To initiate SPI communication, the master must send a clock signal and select the slave by enabling the CS signal. The chip select is typically a low-active signal.Thus, the master must send a logic 0 on this signal to select the slave. SPI is a full-duplex interface, allowing the master and slave to send data simultaneously over the MOSI and MISO lines. During SPI communication, data transmission (serially shifting out to the MOSI/SDO line) and reception (sampling or reading data on the MISO/SDI line) occur simultaneously.The serial clock edge synchronizes the shifting and sampling of data. The SPI interface allows users to flexibly choose the rising or falling edge of the clock to sample and/or shift data. To determine the number of bits transmitted using the SPI interface, refer to the device datasheet.

3

Clock Polarity and Clock Phase

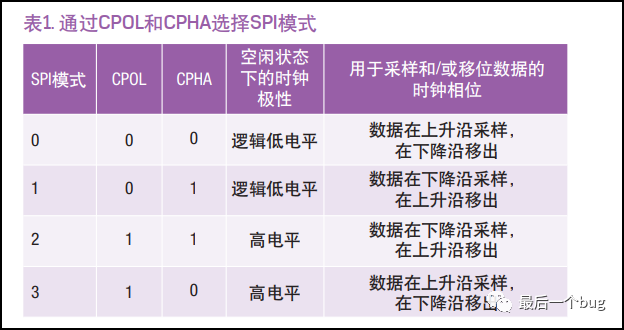

In SPI, the master can choose the clock polarity and clock phase. The CPOL bit sets the polarity of the clock signal during the idle state. The idle state refers to the period when CS is high at the start of transmission and transitions to low, as well as when CS is low at the end of transmission and transitions to high.

The CPHA bit selects the clock phase. Depending on the state of the CPHA bit, data is sampled and/or shifted using the rising or falling edge of the clock. The master must select the clock polarity and clock phase according to the requirements of the slave. Based on the selections of CPOL and CPHA bits, four SPI modes are available. Table 1 shows these four SPI modes.

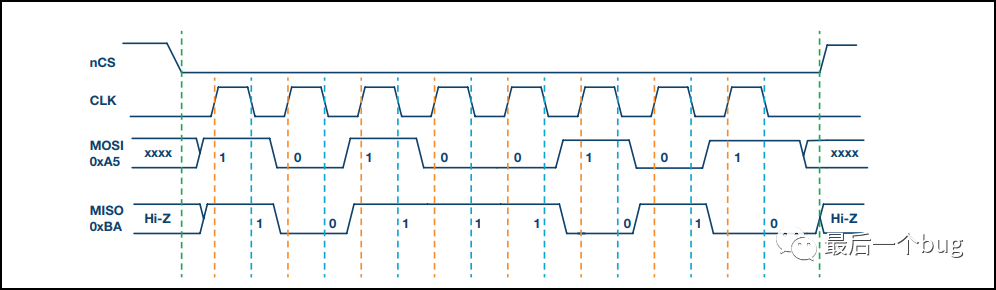

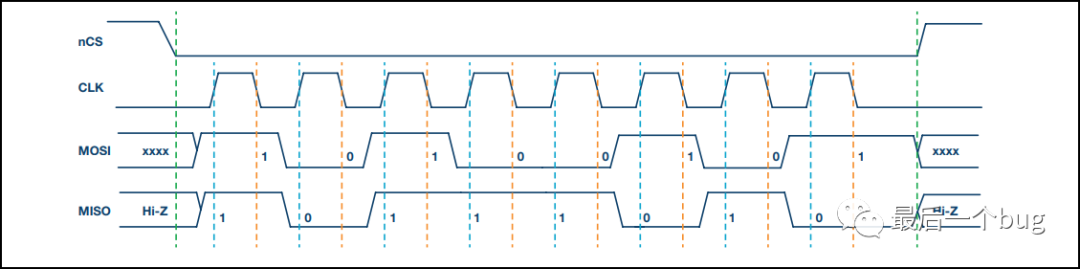

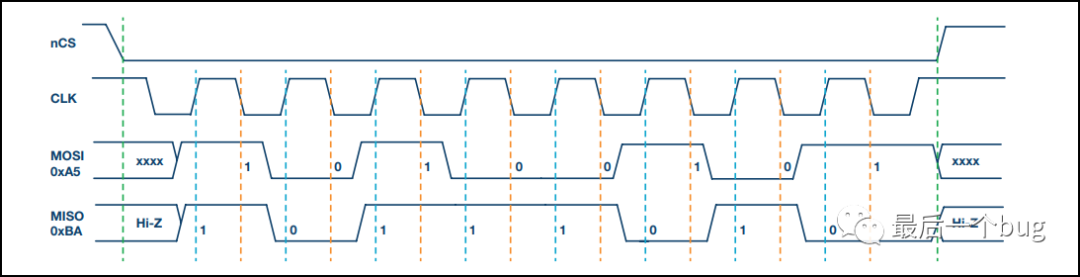

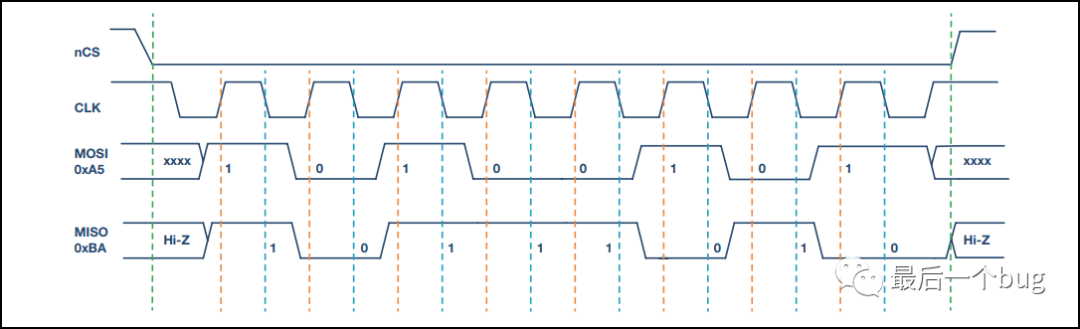

Figures 2 to 5 show communication examples under the four SPI modes. In these examples, the data is displayed on the MOSI and MISO lines. The start and end of the transmission are indicated by green dashed lines, the sampling edges by orange dashed lines, and the shifting edges by blue dashed lines. Note that these diagrams are for reference only. To successfully perform SPI communication, users must refer to the product datasheet and ensure compliance with the device’s timing specifications.

Figure 2. SPI Mode 0, CPOL = 0, CPHA = 0: CLK Idle State = Low, Data sampled on the rising edge and shifted out on the falling edge.

Figure 3 shows the timing diagram for SPI Mode 1. In this mode, the clock polarity is 0, indicating that the idle state of the clock signal is low. The clock phase in this mode is 1, indicating that data is sampled on the falling edge (shown by the orange dashed line) and shifted out on the rising edge of the clock signal (shown by the blue dashed line).

Figure 3. SPI Mode 1, CPOL = 0, CPHA = 1: CLK Idle State = Low, Data sampled on the falling edge and shifted out on the rising edge.

Figure 4 shows the timing diagram for SPI Mode 2. In this mode, the clock polarity is 1, indicating that the idle state of the clock signal is high. The clock phase in this mode is 1, indicating that data is sampled on the falling edge (shown by the orange dashed line) and shifted out on the rising edge of the clock signal (shown by the blue dashed line).

Figure 4. SPI Mode 2, CPOL = 1, CPHA = 1: CLK Idle State = High, Data sampled on the falling edge and shifted out on the rising edge.

Figure 5 shows the timing diagram for SPI Mode 3. In this mode, the clock polarity is 1, indicating that the idle state of the clock signal is high. The clock phase in this mode is 0, indicating that data is sampled on the rising edge (shown by the orange dashed line) and shifted out on the falling edge of the clock signal (shown by the blue dashed line).

Figure 5. SPI Mode 3, CPOL = 1, CPHA = 0: CLK Idle State = High, Data sampled on the rising edge and shifted out on the falling edge.

4

Multi-Slave Configuration

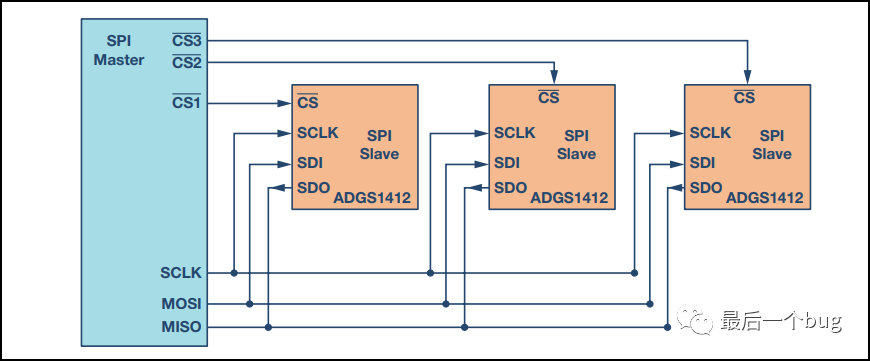

Multiple slaves can be used with a single SPI master. Slaves can be connected in either conventional mode or daisy chain mode.Conventional SPI Mode:In conventional mode, the master needs to provide a separate chip select signal for each slave. Once the master enables (pulls low) the chip select signal, the clock and data on the MOSI/MISO lines can be used for the selected slave. If multiple chip select signals are enabled, the data on the MISO line will be corrupted because the master cannot identify which slave is transmitting data.

Figure 6. Multi-Slave SPI Configuration.

As shown in Figure 6, as the number of slaves increases, the number of chip select lines from the master also increases. This quickly increases the number of inputs and outputs that the master needs to provide, limiting the number of slaves that can be used. Other techniques can be employed to increase the number of slaves in conventional mode, such as using multiplexers to generate chip select signals.

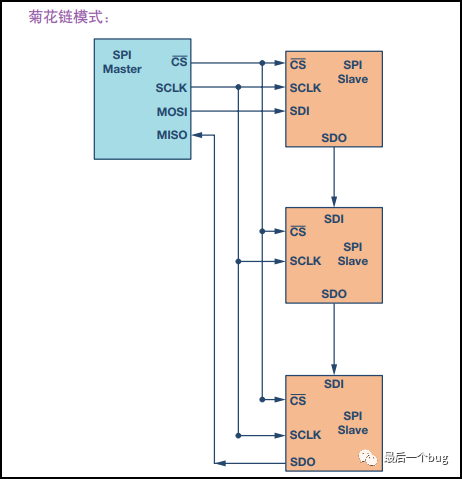

Daisy Chain Mode:

Figure 7. Multi-Slave SPI Daisy Chain Configuration.

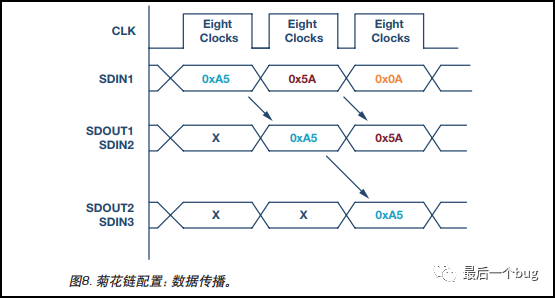

In daisy chain mode, all slave chip select signals are connected together, and data propagates from one slave to the next. In this configuration, all slaves receive the same SPI clock simultaneously. Data from the master is sent directly to the first slave, which then provides the data to the next slave, and so on.When using this method, the number of clock cycles required to transmit data is proportional to the position of the slave in the daisy chain. For example, in the 8-bit system shown in Figure 7, to enable the third slave to receive data, 24 clock pulses are needed, while only 8 clock pulses are required in conventional SPI mode. Figure 8 shows the clock cycles and data propagation through the daisy chain. Not all SPI devices support daisy chain mode. Please refer to the product datasheet to confirm the availability of daisy chain mode. ADI’s Analog Switches and Multiplexers Supporting SPIADI’s latest generation of switches supporting SPI can significantly save space without compromising precision switch performance. This part of the article will discuss a case study illustrating how SPI-supported switches or multiplexers can greatly simplify system-level design and reduce the required number of GPIOs.ADG1412 is a four-channel, single-pole single-throw (SPST) switch that requires four GPIO connections to the control inputs of each switch. Figure 9 shows the connection between a microcontroller and an ADG1412.

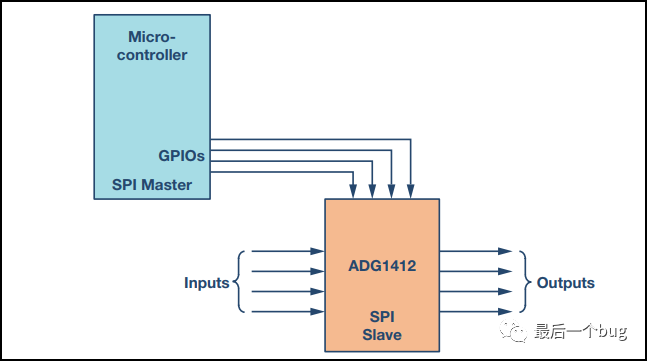

ADI’s Analog Switches and Multiplexers Supporting SPIADI’s latest generation of switches supporting SPI can significantly save space without compromising precision switch performance. This part of the article will discuss a case study illustrating how SPI-supported switches or multiplexers can greatly simplify system-level design and reduce the required number of GPIOs.ADG1412 is a four-channel, single-pole single-throw (SPST) switch that requires four GPIO connections to the control inputs of each switch. Figure 9 shows the connection between a microcontroller and an ADG1412.

Figure 9. Microcontroller GPIO Used as Control Signals for Switches

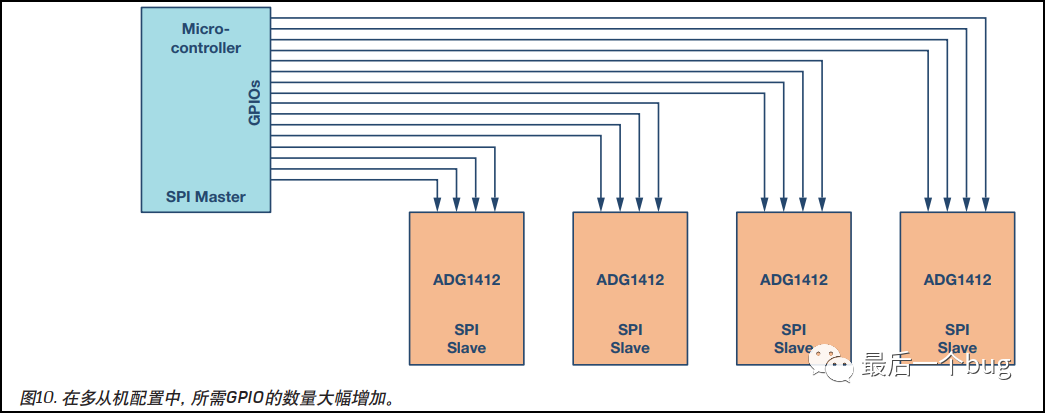

As the number of switches on the circuit board increases, the required number of GPIOs also significantly increases. For example, when designing a test instrument system, a large number of switches are used to increase the number of channels in the system. In a 4×4 crosspoint matrix configuration, four ADG1412s are used. This system requires 16 GPIOs, limiting the available GPIOs in a standard microcontroller. Figure 10 shows the connection of four ADG1412s using 16 GPIOs from a microcontroller.

Figure 10. The Required Number of GPIOs Increases Significantly in Multi-Slave Configuration

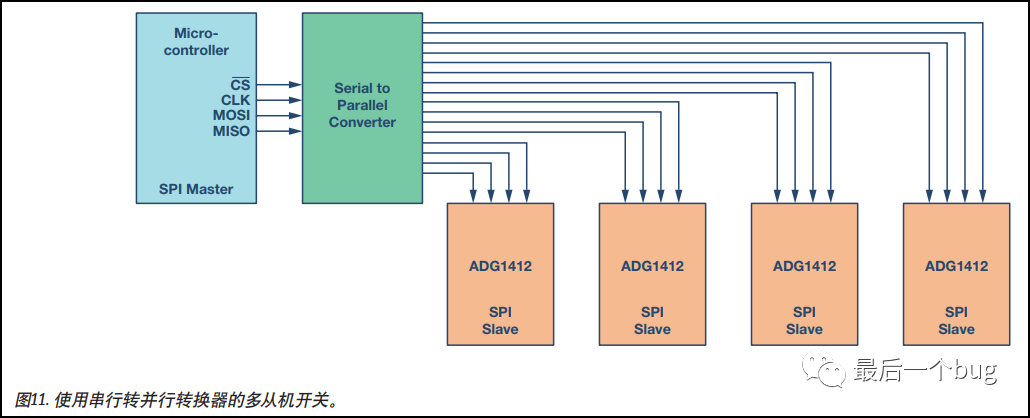

To reduce the number of GPIOs, one method is to use a serial-to-parallel converter, as shown in Figure 11. The parallel signals output by this device can be connected to the control inputs of the switches, and the device can be configured via the serial SPI interface. The downside of this method is that the additional device increases the bill of materials.

Figure 11. Multi-Slave Switch Using Serial-to-Parallel Converter

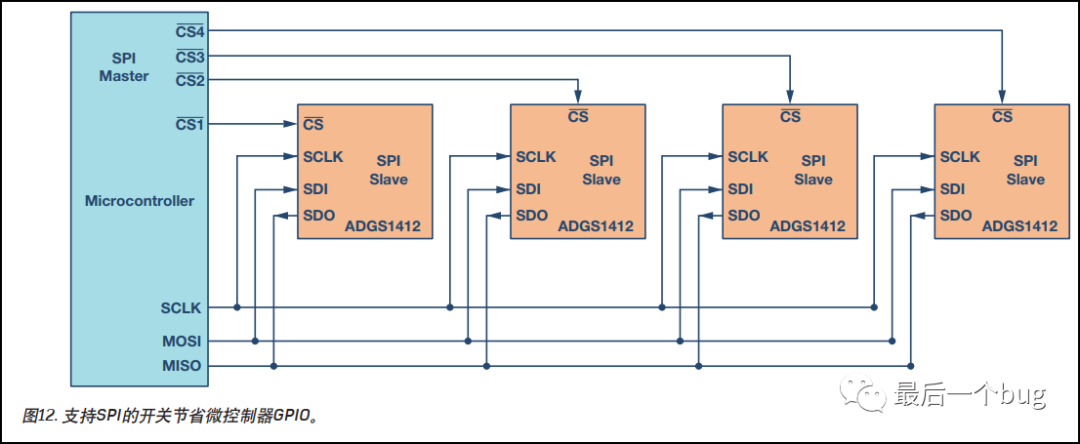

Another method is to use SPI-controlled switches. The advantage of this method is that it reduces the number of required GPIOs and eliminates the overhead of an additional serial-to-parallel converter. As shown in Figure 12, only 7 GPIOs from the microcontroller are needed to provide SPI signals to four ADGS1412s instead of 16 GPIOs.

Figure 12. SPI-Supported Switches Save Microcontroller GPIOs

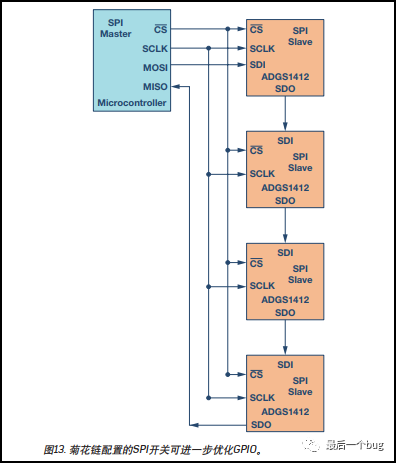

Switches can be configured in a daisy chain to further optimize the number of GPIOs. In a daisy chain configuration, regardless of how many switches the system uses, only four GPIOs from the master (microcontroller) are used.

Figure 13. Daisy Chain Configuration of SPI Switches Further Optimizes GPIO

Figure 13 is for illustration purposes. The ADGS1412 datasheet recommends using a pull-up resistor on the SDO pin. For more information on daisy chain mode, please refer to the ADGS1412 datasheet. For simplicity, this example uses four switches.As the number of switches in the system increases, the advantages of simplicity and space-saving on the circuit board become important. When placing eight four-channel SPST switches on a six-layer circuit board in a 4×8 crosspoint configuration, ADI’s SPI-supported switches can save 20% of the total circuit board space. The article “Precision SPI Switch Configuration Enhances Channel Density” details how precision SPI switch configurations can enhance channel density.Figure 13 is for illustration purposes. The ADGS1412 datasheet recommends using a pull-up resistor on the SDO pin. For more information on daisy chain mode, please refer to the ADGS1412 datasheet. For simplicity, this example uses four switches.As the number of switches in the system increases, the advantages of simplicity and space-saving on the circuit board become important. When placing eight four-channel SPST switches on a six-layer circuit board in a 4×8 crosspoint configuration, ADI’s SPI-supported switches can save 20% of the total circuit board space. The article “Precision SPI Switch Configuration Enhances Channel Density” details how precision SPI switch configurations can enhance channel density.

This article is sourced from ADI’s official website,

Author: Piyu Dhaker Reference link:

https://www.analog.com/cn/products/switches-multiplexers/analog-switches-multiplexers.html#

Copyright belongs to the original author. This is for the dissemination and discussion of technology. If there are any copyright issues, please contact me for removal.

Alright, if you found this helpful, remember to give alike~~

👉 Program comments should use /**/, not //👉A product-level MCU menu framework design👉RF routing and grounding issues👉“Driver Separation” design concept for MCU firmware

👉 Program comments should use /**/, not //👉A product-level MCU menu framework design👉RF routing and grounding issues👉“Driver Separation” design concept for MCU firmware