Skip to content

1.Definition and Uses of eMMC

eMMC stands for “Embedded MultiMediaCard”, which is an embedded storage solution that integrates storage chips, controllers, and interfaces. It is commonly used in embedded systems, mobile devices, and other applications requiring compact, integrated storage.

Here are some key features and uses of eMMC:

1.Integration: eMMC integrates storage chips, controllers, and interfaces into a single package, simplifying the design and connection process.

2.Package Form: Usually provided in BGA (Ball Grid Array) package form, with a set of spherical solder balls at the bottom for connecting the package to the printed circuit board (PCB).

3.Application Areas: Mainly used in embedded systems, smartphones, tablets, IoT devices, digital cameras, and other devices requiring compact, integrated storage solutions.

4.Capacity Range: Offers various storage options, typically ranging from a few GB to several hundred GB, to meet different application storage needs.

5.Interface Standards: Uses an interface standard similar to MMC (MultiMediaCard), but compared to traditional MMC cards, eMMC focuses more on embedded applications and typically integrates more features.Typically adopts an 8-bit parallel data interface.

6.Performance Level: eMMC performance levels depend on specific specifications and versions, typically including sequential read and write speeds as well as random read and write speeds.

7.Low Power Consumption: In embedded applications, eMMC is typically designed for low power consumption to meet the requirements of mobile and portable electronic devices.

8.Easy Integration: Due to its high integration, eMMC is relatively easy to design and integrate, making it suitable for embedded system designs.

Overall, eMMC provides a convenient, compact, and highly integrated storage solution suitable for many embedded and mobile applications.

2.Considerations When Purchasing

When purchasing eMMC (Embedded MultiMediaCard), there are several key considerations to ensure the selection of the right product for specific applications. Here are some recommendations:

1.Capacity Requirements: Determine the required storage capacity. eMMC offers various capacity options; choose the appropriate capacity to meet the application’s storage needs.

2.Performance Requirements: Consider the desired performance levels, including sequential read and write speeds as well as random read and write speeds. Performance levels may vary across different eMMC versions and specifications.

3.Application Environment: Consider eMMC the environmental conditions in which it will be used, including operating temperature range, humidity, and durability. Ensure that the selected eMMC meets the application environment’s requirements.

4.Interface Compatibility: Ensure that the interface type of the selected eMMC matches the requirements of the main controller or system. Common interface types include MMC, SPI (Serial Peripheral Interface) etc.

5.Specifications and Technical Documentation: Carefully read the specifications and technical documentation of the eMMC to understand performance parameters, features, and supported functionalities. These documents typically provide critical technical information.

6.Brand and Manufacturer Reputation: Select products from well-known brands and reputable manufacturers to ensure product quality and reliability. Checking user reviews and feedback is also a good approach.

7.Security Features: If security features are required in the application, such as hardware encryption or secure erase, ensure that the selected eMMC supports these features.

8.Cost: Consider budget constraints, but do not choose solely based on the cheapest product. Factors such as performance, reliability, and support are equally important.

9.Long-Term Supply and Support: Ensure that the selected eMMC model can be supplied long-term, and that the manufacturer provides adequate technical support.

10.Testing and Verification: After selection, perform necessary testing and verification to ensure that eMMC works correctly in practical applications.

By comprehensively considering these factors, you can better choose an eMMC storage solution suitable for specific application needs.

3.What Tests and Verifications Should Be Conducted When Purchasing

When purchasing eMMC (Embedded MultiMediaCard), conducting a series of tests and verifications is crucial to ensure that the selected product meets specific application requirements. Here are some common testing and verification steps:

1.Performance Testing: Test the sequential read and write speeds and random read and write speeds of eMMC to ensure its performance meets application needs. Use performance testing tools for these tests.

2.Operating Temperature Testing: Test eMMC performance within the specified operating temperature range. Ensure that eMMC can operate stably in actual working environments.

3.Durability Testing: Conduct durability tests to simulate prolonged read and write operations to evaluate eMMC lifespan and stability.

4.Compatibility Testing: Ensure that eMMC is compatible with the hardware and software of the main controller or system. Test its integration performance with specific motherboards, operating systems, and applications.

5.Security Feature Testing: If the application requires security features such as hardware encryption or secure erase, ensure that eMMC supports and correctly implements these features.

6.Capacity Verification: Verify whether the actual storage capacity of eMMC meets the manufacturer’s specifications and ensure that the usable capacity meets the needs in practical applications.

7.Error Handling and Reliability Testing: Test eMMC performance when facing data errors or abnormal situations, as well as its built-in error handling and reliability features.

8.Power and Power Consumption Testing: Test eMMC power requirements and power consumption under normal and maximum loads to ensure it meets power requirements in the system.

9.Long-Term Operation Testing: Conduct long-term operation tests to simulate device working conditions in practical applications to evaluate its long-term stability.

10.Supply Chain and Brand Verification: Ensure that eMMC is purchased from reliable suppliers and brands to avoid counterfeit products.

When conducting these tests and verifications, professional testing tools, performance analysis instruments, and device simulators can be used. Develop a comprehensive testing plan and validate eMMC performance and stability in actual application scenarios to ensure that the selected storage solution meets requirements.

4.What Reliability Tests Should eMMC Undergo Before Leaving the Factory:

1.Error Detection and Correction (Error Detection and Correction, EDC): Test eMMC error detection and correction mechanisms to ensure the device can detect and correct data errors occurring on the storage medium.

2.Bad Block Management: Simulate or introduce bad blocks and test eMMC bad block management mechanisms. Ensure that the device can correctly mark and handle bad blocks to prevent data corruption.

3.Write Protection and Data Retention: Test eMMC data protection mechanisms in the event of power outages or abnormal power loss to ensure data integrity and reliability.

4.Read Timeout and Error Handling: Simulate read timeouts or other read errors, and test eMMC error handling mechanisms to ensure that the device can appropriately handle these exceptions.

5.Erase/Trim Operations:Test eMMC secure erase and Trim operations to ensure that the device can securely and reliably delete unnecessary data blocks.

6.Voltage and Temperature Variation Testing: Test eMMC performance and reliability under different voltage and temperature conditions to evaluate the device’s stability in various environments.

7.Cycle Write Testing: Simulate continuous write operations to test eMMC lifespan and durability. This helps assess the device’s reliability during long-term use.

8.Fault Recovery: Test eMMC ability to recover after errors or abnormal situations to ensure the device can automatically or assistively recover from error states.

9.Data Consistency and Integrity: Test eMMC data consistency and integrity under various conditions (e.g., sudden power loss) to ensure that the device maintains data correctness under various operating conditions.

5.Main Problems with Non-Compliant eMMC Products:

1.Performance Standards Not Met: Counterfeit eMMC may not provide the claimed performance levels. For example, their read and write speeds may be significantly lower than the specified values, affecting system performance.

2.Inaccurate Capacity: Counterfeit products may claim to have a certain capacity, but the actual capacity may be less than claimed, leading to data storage issues and insufficient capacity.

3.Lack of Reliability: Counterfeit products may lack adequate error detection and correction mechanisms, or mishandle bad blocks, leading to data corruption and device unreliability.

4.Short Lifespan: Counterfeit products may use inferior flash memory chips, resulting in a shorter storage lifespan, especially under frequent write conditions.

5.Security Issues: Counterfeit products may lack necessary security features such as hardware encryption or secure erase, posing potential threats to sensitive stored data.

6.Supply Chain Risks: Counterfeit products may enter the market through informal or unreliable supply chains, making it difficult for users to trace the source and manufacturer of the product.

7.Compatibility Issues: Due to potentially poor quality control of counterfeit products, compatibility issues with devices or main controllers may arise, leading to unstable system performance.

8.After-Sales Service Issues: Due to counterfeit products typically not being supported by manufacturers, buyers may find it difficult to obtain after-sales service, technical support, or warranties.

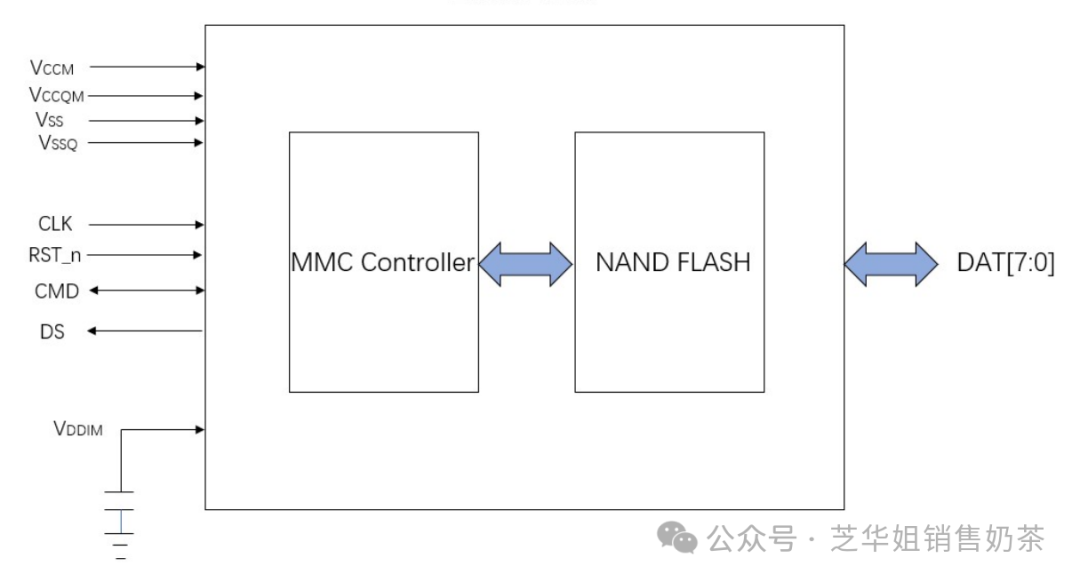

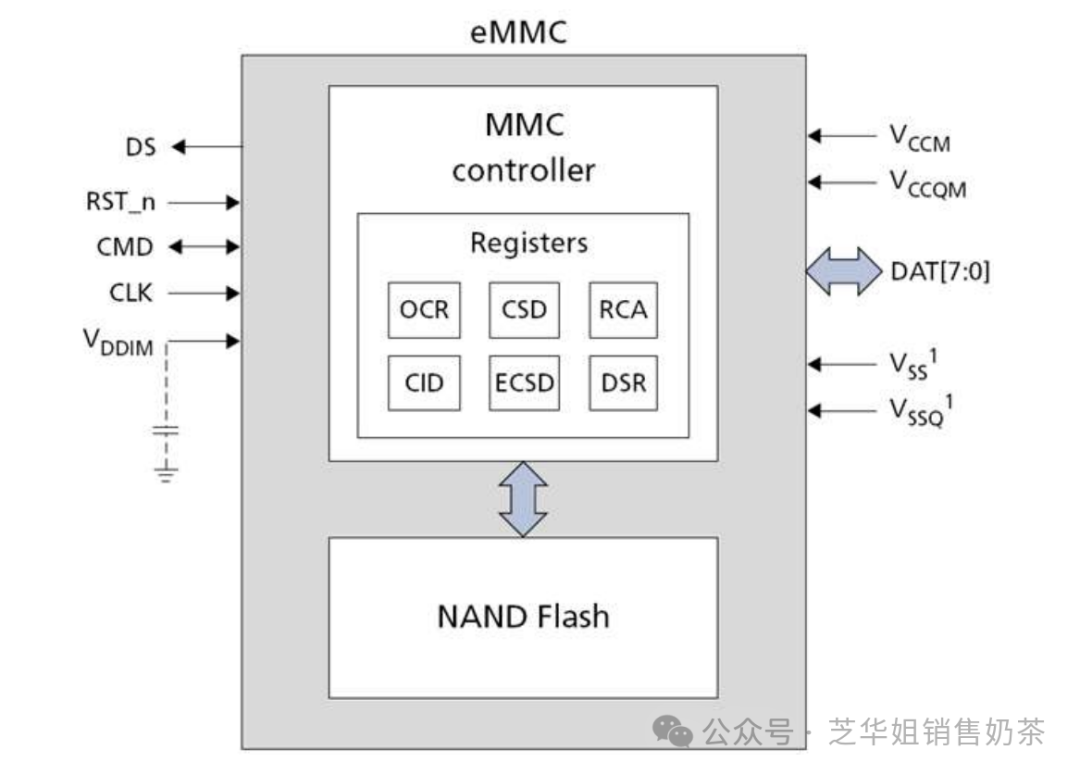

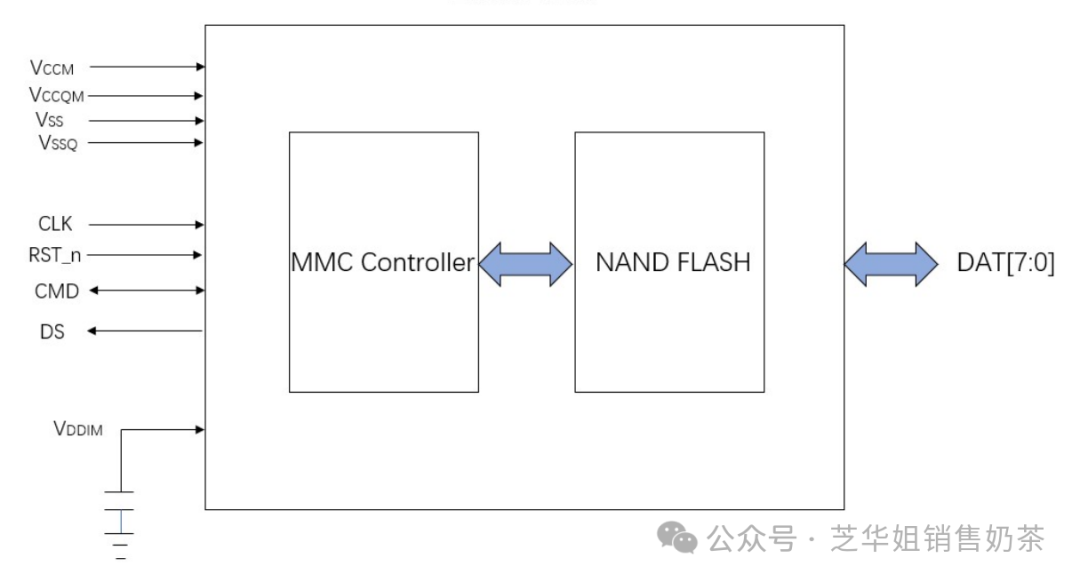

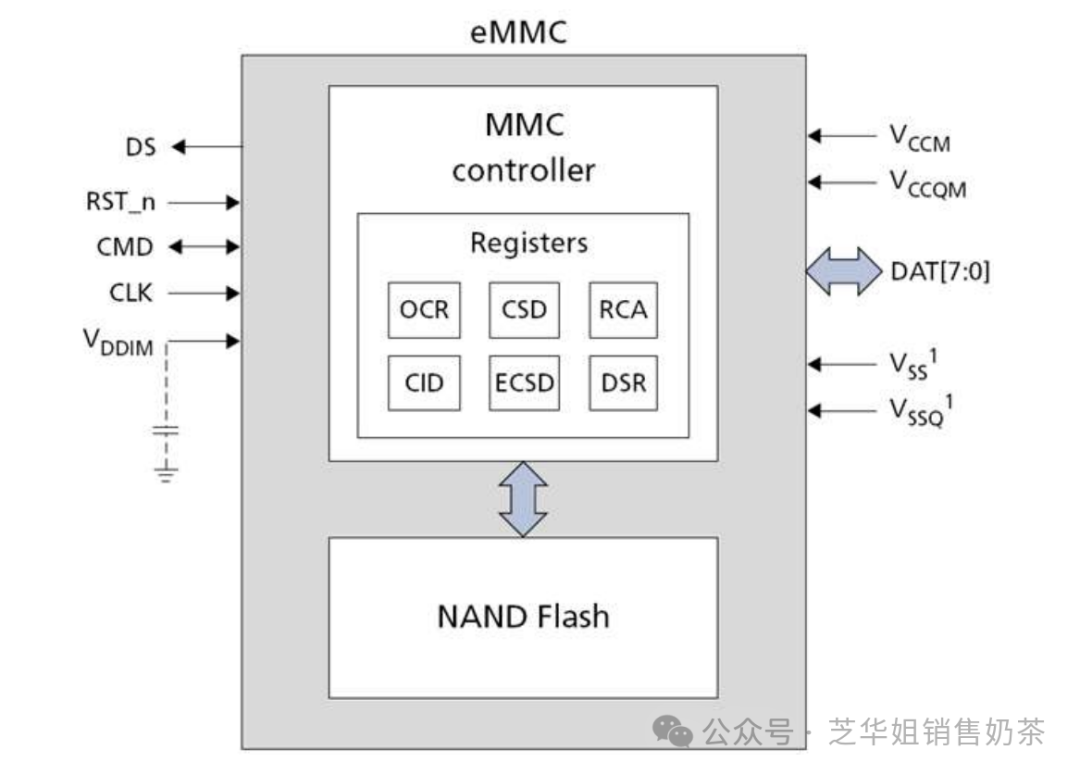

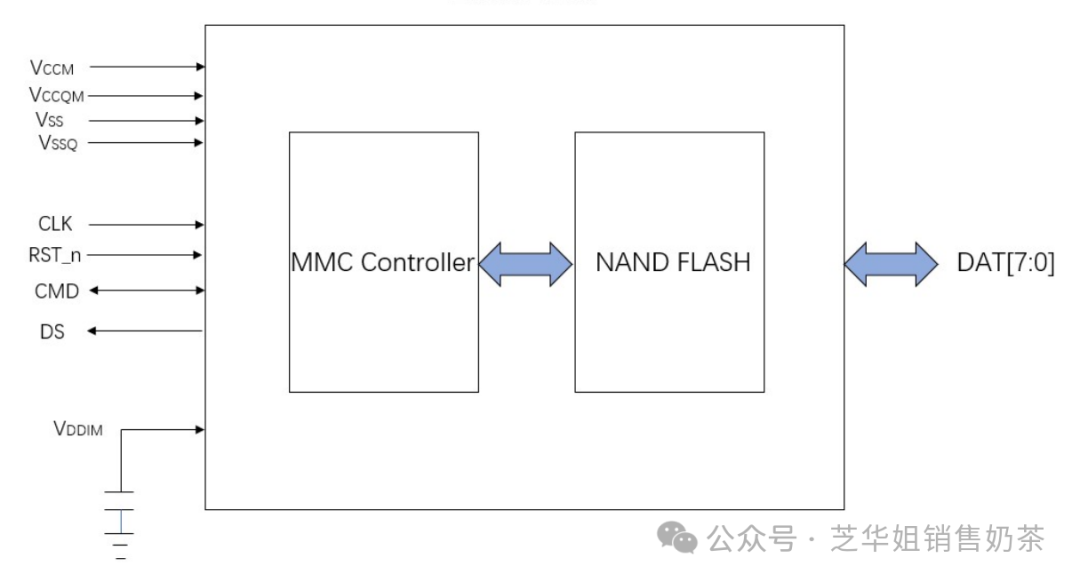

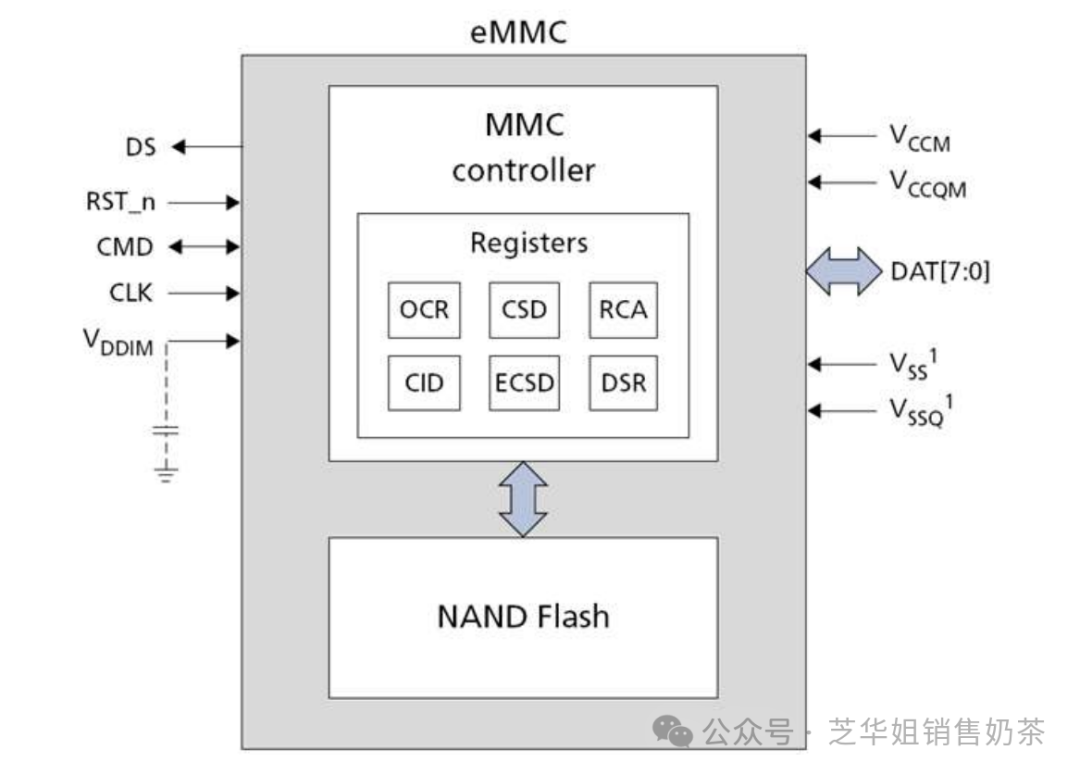

7.Interface Definition of eMMC:

2.CMD:A bidirectional channel used for device initialization and command transmission, CMD signals have 2 modes of operation:

① Open Drain—Used for initialization mode

② Push-Pull—Used for fast command transmission

3.DAT [7:0]:Bidirectional data signals, modes include 1 (DAT0), 4 (DAT0-DAT3) or 8 (DAT0-DAT7).

4.RST_n:Reset signal used by the host to reset the device, placing it into a pre-idle state.

5.DS:Data pulse generated by the device used for data output in HS400 mode and CRC status response output.

eMMC (Embedded MultiMediaCard) power supply mainly includes VCC, VCCQ (I/O power), and VSS (power ground). These power lines provide the necessary energy for eMMC to ensure its normal operation.

1.VCC (Power Positive):VCC is the main power supply for eMMC , providing operational energy for the device. It is typically connected to the system’s main power supply and provides the required operating voltage for eMMC.

2.VCCQ (I/O Power): VCCQ is the input/output (I/O) power supply, mainly used for eMMC data lines (e.g., DAT0-DAT7). It may have lower voltage levels to accommodate eMMC controller’s I/O level requirements.

3.VSS (Power Ground):VSS is the power ground, working together with VCC and VCCQ to form the power circuit. It provides the current return path for eMMC , ensuring that current can flow back to the power system completely.

Power is critical for eMMC normal operation. Proper power voltage and current levels are key factors to ensure eMMC device performance and stability. In design, it is important to ensure the stability of power lines, avoiding power noise, to prevent any impact on eMMC read and write performance and reliability.

When using eMMC, it is also important to pay attention to the timing of power on and off to avoid switching power to eMMC under inappropriate conditions, which could lead to potential data corruption or errors. eMMC typically provides detailed power specifications and recommendations in its specifications or data sheets, which designers need to follow closely.

9.Definition and Role of eMMC Registers:

1.OCR (Operating Conditions Register): OCR register is used to configure eMMC operating conditions, including voltage range, etc. This is a standard MMC register used to determine eMMC working conditions.

2.CID (Card Identification Register):CID register stores the unique identification number of the eMMC card, including manufacturer ID, product series number, production date, and other information.CID can be used to identify specific eMMC cards.

3.CSD (Card Specific Data Register): CSD register contains information related to the performance and storage capacity of eMMC cards. This includes maximum clock frequency, block length, read and write speeds, etc.

4.EXT_CSD (Extended Card Specific Data Register):EXT_CSD register is an extended register in the MMC card specification, containing more configuration and control options such as high-speed mode, data protection, and write latency.

5.RCA (Relative Card Address):RCA is used to uniquely identify eMMC with a relative address. Each chip is assigned an RCA to distinguish different chips in a multi-chip environment.

6.DSR (Device Status Register):DSR register contains information about eMMC device status. For example, DSR can be used to indicate whether eMMC is ready to accept commands.

These registers and identifiers are crucial for initializing, configuring, and monitoring eMMC device status. When using eMMC, the main controller typically interacts with these registers to correctly configure the device and obtain information about its performance and status.

10.NAND Partitioning of eMMC:

The NAND partitioning of eMMC refers to different areas divided within the eMMC storage for storing different types of data or configuration information. These partitions may include the main user data storage area, as well as special partitions for management and control. Here are some possible eMMC NAND partitions:

1.User Data Partition: This is the largest part of eMMC, used to store user applications, files, media, and other data. This partition is typically user-visible and is used for storing the main data of the device.

2.Boot Partition: The boot partition contains the bootloader and associated boot information used to start the device. This partition is typically used to store the bootloader and boot configuration.

3.Extended Partition: Sometimes eMMC may include an extended partition for storing additional user data or data for special purposes.

4.Metadata Partition: The metadata partition is used to store file system metadata such as file tables, indexes, and permissions.

5.Firmware Partition: This partition contains the firmware or operating system of the device. In certain cases, eMMC may have partitions for storing device firmware or operating systems.

6.Configuration Partition: Used to store device configurations and parameters. This may include some settings, calibration data, etc.

The specific eMMC NAND partition structure may vary by manufacturer and device model. The size, number, and use of partitions are typically detailed in the eMMC specifications or data sheets. Understanding the eMMC partition structure is crucial for system design, data management, and maintenance.

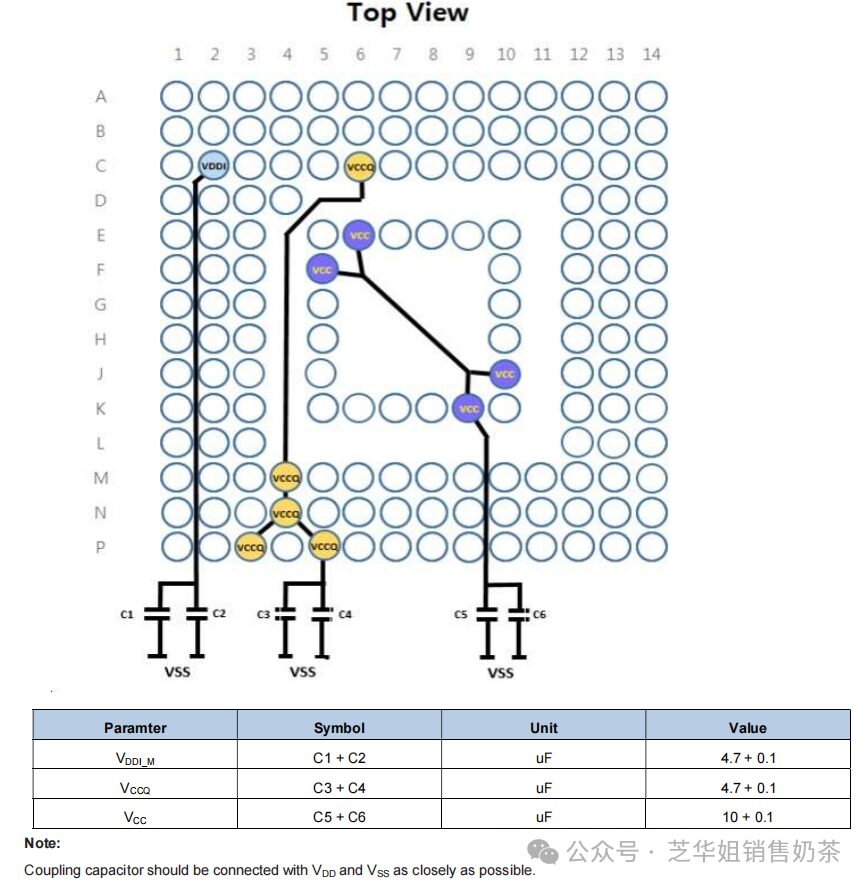

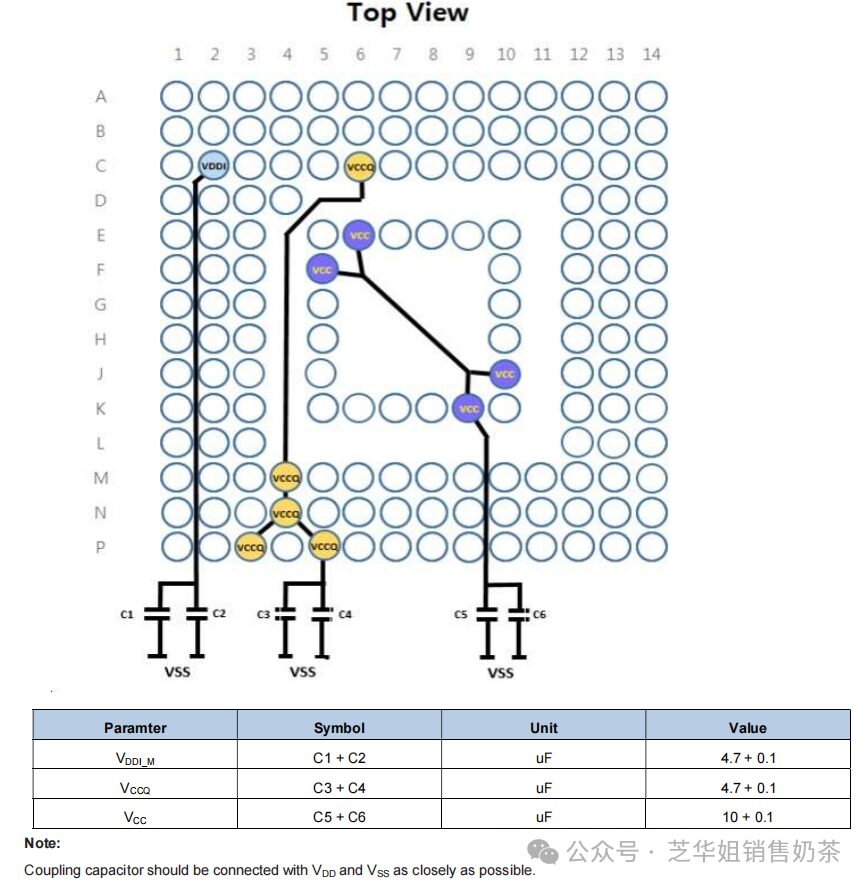

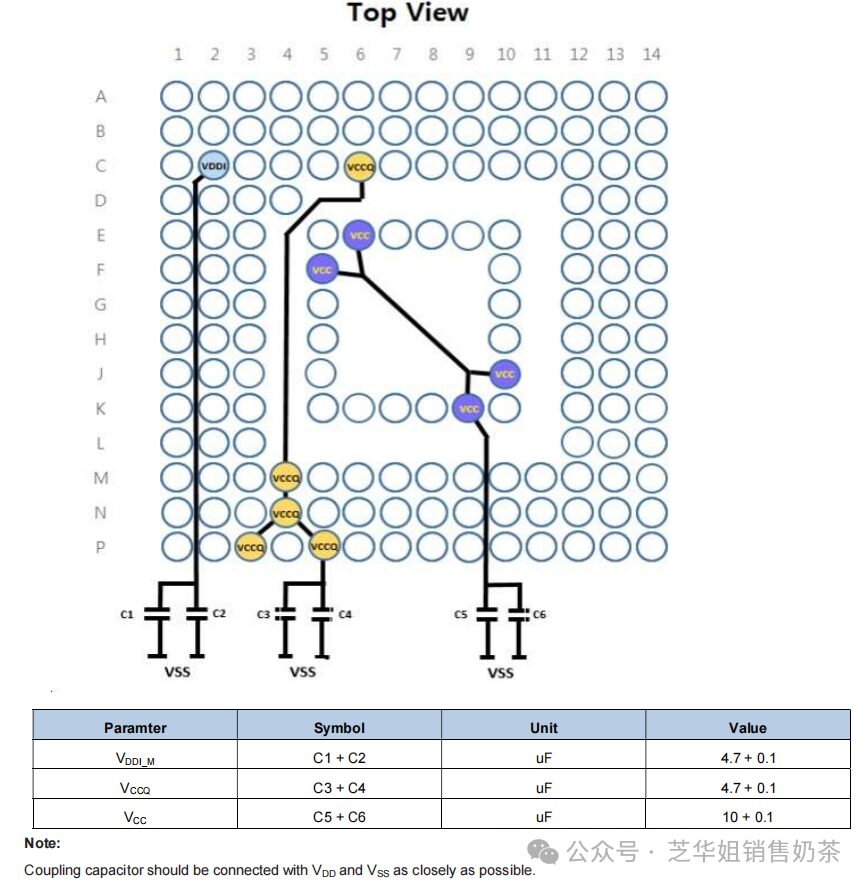

11.Hardware Design Recommendations:

When connecting eMMC on the system board, there are some key points to ensure connection reliability, performance, and stability. Here are some suggestions and considerations when connecting eMMC:

1.Correct Pin Connections: Ensure that eMMC device pins are correctly connected to the system board. Check the eMMC specifications and system board designs to ensure correct pin mapping, including power, clock, data lines, etc.

2.Signal Integrity: Ensure signal integrity, especially for high-speed data transmission. Use appropriate PCB (Printed Circuit Board) design and routing techniques to minimize signal noise and timing issues.

3.Power Supply: Provide stable, clean power to ensure compliance with eMMC specifications. Power noise can negatively affect eMMC performance and stability.

4.Impedance Matching: In PCB design, pay attention to impedance matching to ensure that the signal transmission line impedance matches the requirements in the specifications. This helps reduce signal reflections and maintain signal integrity.

5.Pin Voltage Levels: Ensure that voltage levels on the system board match those specified in eMMC specifications. In particular, check whether the eMMC device requires VCCQ (I/O power).

6.Temperature Control: Consider the operating temperature range of eMMC in design, especially in high or low-temperature environments. Proper temperature control is crucial for maintaining eMMC stability.

7.Physical Support: Provide adequate physical support to ensure that eMMC is securely fixed to the system board, preventing mechanical stress from affecting the connection.

8.Ground Design: Ground design should be reasonable to ensure good grounding. This plays a key role in reducing resistance and noise in ground return paths.

9.Electrostatic Protection: When connecting and handling eMMC devices, take appropriate electrostatic precautions to prevent static electricity from damaging the device.

10.Follow Specifications: Carefully read eMMC specifications and system board design documents to ensure that the system board design meets eMMC requirements.

12.Why is There Such a Large Difference Between Sequential Read/Write and Random Read/Write Speeds of eMMC?

The significant differences between sequential read/write and random read/write speeds in eMMC are typically related to the internal structure and characteristics of NAND Flash storage technology. Here are some factors that may contribute to this speed difference:

1.NAND Flash Structure:NAND Flash storage media is typically divided into pages and blocks. In sequential read/write, data can be stored and retrieved in page order, while in random read/write, it may require crossing multiple blocks, resulting in additional addressing and operational overhead.

2.Erase Operations: NAND Flash typically requires an erase operation before writing. In sequential read/write, adjacent data is usually located within the same block, which can avoid frequent erase operations. In random read/write, due to data potentially being spread across different blocks, the frequency of erase operations may be higher.

3.Write Amplification: In random write scenarios, due to the need to overwrite existing data, additional write amplification may occur. Write amplification refers to the phenomenon where the actual amount of data written to NAND Flash may exceed the amount requested by the host, increasing write time and lifespan degradation.

4.Addressing and Operational Overhead: Random read/write typically requires more addressing and operational overhead, as the controller must locate the correct position within NAND Flash for read/write operations. In contrast, sequential read/write can more effectively utilize the continuity of the storage medium.

5.Internal Caching and Algorithms: eMMC controllers typically include caches and algorithms to optimize sequential read/write performance. These optimizations may have a greater impact on sequential read/write than on random read/write.

Considering these factors, random read/write typically results in additional addressing and operational overhead, as well as higher write amplification, leading to relatively slower speeds.