According to “Hubei Daily,” on April 3, at the Dongfeng Motor Global Innovation Center, Zhang Fanwu, Chief Engineer of Intelligent Technology at Dongfeng Motor R&D Institute, stated that the DF30, the first domestically produced automotive-grade high-performance MCU chip, has completed its first tape-out (trial production) verification, and automotive-grade validation is about to begin, with plans for mass production and market launch next year, breaking the monopoly of foreign manufacturers.

As the automotive industry moves towards electrification, intelligence, and connectivity, the demand for automotive-grade chips continues to rise. In 2022, China’s automotive chip market size reached $15.8 billion, a year-on-year increase of 10.49%. Currently, traditional vehicles have 300 to 500 chips per vehicle, while electric smart vehicles exceed 1,000 chips, and high-level autonomous vehicles are even larger consumers, with over 3,000 chips per vehicle. Achieving independent and controllable chips has become the development direction of China’s chip industry.

For automotive chips, automotive-grade MCUs are crucial as they are necessary controllers for many key control links, but the R&D difficulty is relatively high. “We started by tackling a ‘hard nut’.” Zhang Fanwu remarked.

As early as May 2022, Dongfeng Motor led a joint initiative with eight organizations including China Information Technology, Wuhan Lingdian, Wuhan University of Technology, Huazhong University of Science and Technology, Xinchip Technology, and Taijing Technology to establish the “Hubei Province Automotive Grade Chip Industry Technology Innovation Consortium,” aimed at promoting the development of a localized supply chain for chips and making Hubei a national-level regional chain leader.

In July 2023, according to You Zheng, a member of the Dongfeng Company Party Committee and Deputy General Manager, the consortium achieved the first tape-out of three domestically blank automotive-grade chips, completing the first automotive-grade MCU chip based on the RISC-V instruction set architecture, breaking through core technologies in automotive chip definition, design, and process, gradually realizing key chips “from scratch” and helping the automotive industry solve the chip shortage problem, firmly promoting domestic chip substitution. The consortium has produced over 50 invention patents and integrated circuit layouts, drafted one group standard for automotive-grade chips, and received two gold awards and multiple silver awards for high-value patents in Hubei Province in 2022.

△Zhang Fanwu introduces DF30. (Photo by Dai Wenhui, Hubei Daily)

△Zhang Fanwu introduces DF30. (Photo by Dai Wenhui, Hubei Daily)

This collaborative R&D model is an exploration within the industry and was not initially smooth. During the collaboration, Dongfeng proposed using a key module in the chip, while the design company insisted on replacing it with another module. The first tape-out verification failed due to the lack of this key module, which prevented the development of a basic function for the controller using this chip. “What we are doing is a process from 0 to 1, with no templates to refer to. Everyone has their own ideas, which leads to such collisions.” Zhang Fanwu said that the tacit understanding has gradually grown through these discussions and confrontations, and now the communication mechanism within the innovation consortium is becoming smoother and more efficient.

Currently, the number of member units in the innovation consortium has grown to 44, covering the entire industry chain of automotive-grade chip standards, design, manufacturing, packaging, and application, producing over 50 invention patents and eight team standards.

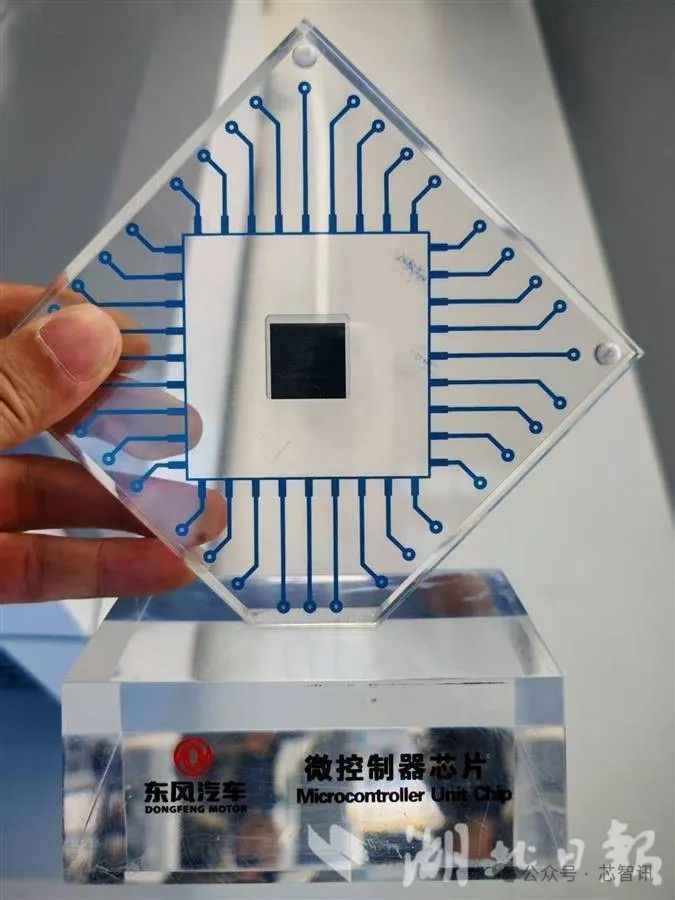

△DF30 chip. (Photo by Dai Wenhui, Hubei Daily)

△DF30 chip. (Photo by Dai Wenhui, Hubei Daily)

The DF30, which has completed tape-out, is the first fully domestically produced automotive chip. DF30 has broken through core technologies in automotive chip definition, design, and process, passing 295 strict tests including basic tests, pressure tests, and application tests in extreme cold and heat environments, featuring four major characteristics: “high performance, strong controllability, ultra safety, and extreme reliability.” The DF30 chip is also compatible with domestically developed automotive software operating systems, has a complete development environment, and can be widely used in power control, chassis, electronic information, and driving assistance fields, filling a domestic gap in this area.

The DF30 chip has a wide range of applications, suitable for fuel vehicle engines and chassis, as well as for the three electric systems of new energy vehicles, with functionality and performance comparable to similar international products. In February of this year, Dongfeng completed cold region baseline testing of the power controller developed based on DF30 in Mohe, achieving the expected goals, further strengthening the team’s determination to complete the high-quality development of this chip and its industrialization, with plans for hot region testing in Turpan this summer.

“Verification is another major difficulty in automotive chip R&D. Dongfeng is the domestic automotive enterprise with the most comprehensive variety of vehicles, which can provide the most comprehensive instance scenarios for chip verification.” Zhang Fanwu introduced that in the next step, Dongfeng will develop other models of DF30 for different application scenarios, achieving product series development while also conducting R&D on domain controller chips.

Compared to the success of a single product, Zhang Fanwu values the innovative model of the innovation consortium more. He said: “The core of self-developed chips lies in defining products based on our own needs. Dongfeng will define chips based on its unique needs and understanding of application scenarios, and streamline the entire process from chip demand, design, production to application in China, ensuring supply chain security.”

Dongfeng Motor leads the development of a series of chips in the innovation consortium. (Photo by Dai Wenhui, Hubei Daily)

Dongfeng Motor leads the development of a series of chips in the innovation consortium. (Photo by Dai Wenhui, Hubei Daily)

DF30 is just a microcosm. In recent years, around the strategic goal of “three leaps and one new direction,” Dongfeng has maintained a stable R&D investment ratio of about 8%, continuously breaking through technical barriers from developing new energy vehicles to exploring intelligent driving, upgrading efficient power systems, and applying intelligent connectivity technology, ranking first in the patent innovation index among Chinese automotive companies for three consecutive years.

Editor: Xinzhi News – Langke Jian Source: Hubei Daily

Related Articles: “Dongfeng Company Leads the Creation of Independent ‘Chinese Chip’: Three Domestic Blank Automotive Grade Chips First Tape-Out!”

“The Proportion of Domestic Automotive Chips in China Has Reached 15%”“The White List 2.0 of the China Automotive Chip Alliance Released: Over 1,800 Products, but High-End Still Short”Previous Exciting ArticlesUnder Investigation for Monopoly, DuPont China is Being Investigated!Details of the ASML Former Employee’s Espionage Case Exposed: Aiming to Help Russia Build a 28nm Wafer FactoryArm’s Ambition: To Capture 50% of the Global Data Center CPU Market by Year-End!Rumored Arm Competing with Qualcomm to Acquire SerDes Giant, Stock Price Soars 21%!Intel CEO Chen Lifeng: Divesting Non-Core Businesses, Establishing a World-Class Wafer Foundry!The World’s First! Ruisi Zhixin GESP Integrated Vision Sensor ALPIX-Pizol is Launched!2024 European Patent Application Ranking: Samsung First, Huawei Second!Infineon Executive Interview: Detailed Explanation of GaN/SiC/AI/Robotics Layout and Localization Development in China!2024Q4 Global Smartphone AP Market: Unisoc’s Share Rises to 14%, Huawei’s Share Drops to 3%!Galen Electronics Plans to Acquire Ruicheng Chip Micro, Leveraging EDA and IP SynergyNew Kailai Releases 31 Semiconductor Devices in 6 Categories (with Product Information)Following Sandisk and Yangtze Memory, Micron Also Announces Price Increases!The U.S. Lists 54 Chinese Companies Including Langhua/Ningchang/Zhongke Keke on the Entity List!The First 350nm Lithography Machine in Russia Will Be Produced in MoscowNorth Huachuang Enters the Ion Implantation Equipment Market!Chinese Academy of Sciences Successfully Develops All-Solid DUV Light Source Technology!

For industry communication and cooperation, please add WeChat: icsmart01Xinzhi News Official Communication Group: 221807116