Many mechanical engineers have a misconception: they believe that mechanical engineers are only responsible for mechanical components, while the selection of sensors, electrical components, and control schemes is the responsibility of electrical engineers or system engineers. If you are the chief design engineer of a project, you need to consider which types of sensors to use and the action flow and control methods of the equipment during the conceptual phase.

Many mechanical engineers have a misconception: they believe that mechanical engineers are only responsible for mechanical components, while the selection of sensors, electrical components, and control schemes is the responsibility of electrical engineers or system engineers. If you are the chief design engineer of a project, you need to consider which types of sensors to use and the action flow and control methods of the equipment during the conceptual phase.

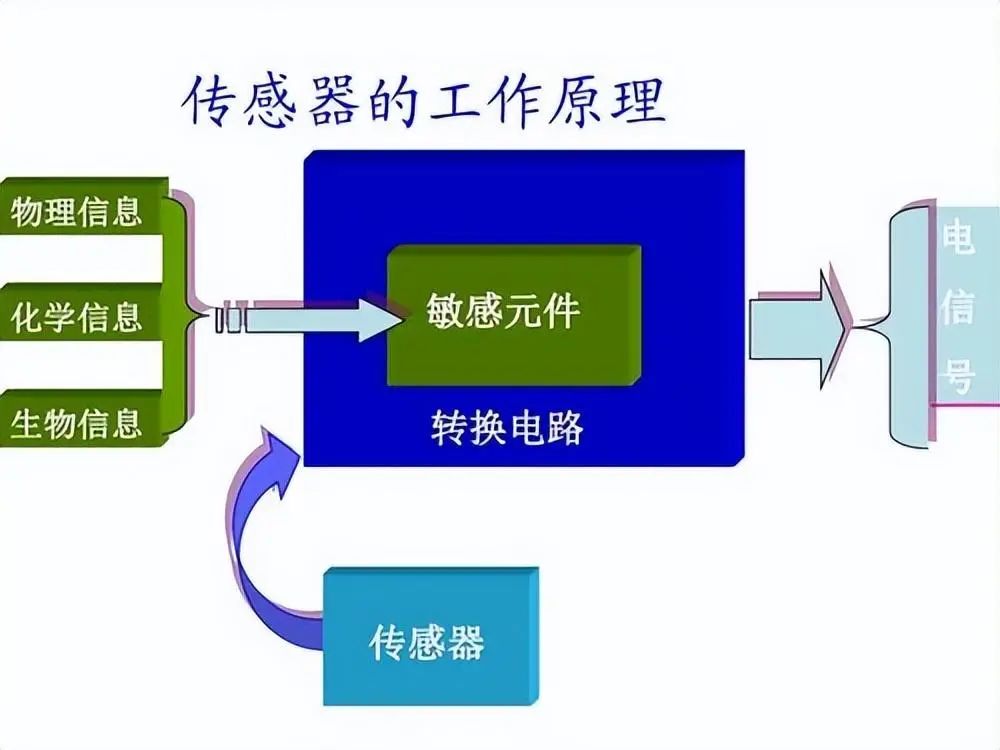

1. Definition of Sensors

2. Standards for Sensor Selection

3. Classification Standards for Sensors

Sensors can be classified according to the following standards:

The transduction principle is the basic standard that effective methods follow. Generally, the materials and technology standards are selected by the development engineering team.

According to properties, the classification is as follows:

Surface plasmon resonance and optical addressing potential from the biosensor group are new types of sensors based on optical technology. Compared to charge-coupled devices, CMOS image sensors have lower resolution but are smaller, cheaper, and consume less power, making them better replacements for charge-coupled devices. Accelerometers are grouped independently due to their important roles in future applications (such as aircraft, automobiles, etc.) and in fields like video games and toys. Magnetometers are sensors that measure magnetic flux density B (in tesla or As/m2).

Classification based on the power supply or energy supply requirements of the sensors:

· Active Sensors – Sensors that require a power supply are called active sensors. Examples: Lidar (Light Detection and Ranging), photoconductive cells.

· Passive Sensors – Sensors that do not require a power supply are called passive sensors. Examples: Radiometers, film photography.

Classification based on applications:

4. Five Common Types of Sensors

Some commonly used sensors and their principles and applications are described as follows:

(1) Temperature Sensors

This device collects information about temperature from the source and converts it into a form that can be understood by other devices or people. The best example of a temperature sensor is a glass mercury thermometer, which expands and contracts with temperature changes. The external temperature is the source of temperature measurement, and the observer reads the position of the mercury to measure temperature. There are two basic types of temperature sensors:

· Contact Sensors

This type of sensor requires direct physical contact with the object or medium being sensed. They can monitor the temperature of solids, liquids, and gases over a wide range of temperatures.

· Non-contact Sensors

This type of sensor does not require any physical contact with the object or medium being detected. They monitor non-reflective solids and liquids but are ineffective for gases due to natural transparency. These sensors use Planck’s law to measure temperature, which deals with the heat radiated from a heat source to measure temperature.

Different types of temperature sensors work based on the following principles and examples:

(i) Thermocouples – They consist of two wires (each made of different uniform alloys or metals) that form a measuring junction at one end, which is open to the measured element. The other end of the wire is connected to the measuring device, forming a reference junction. Due to the temperature difference between the two junctions, current flows through the circuit, and the measured millivolts are used to determine the temperature of the junctions. A schematic of a thermocouple is shown below.

(ii) Resistance Temperature Detectors (RTD) – This is a type of thermal resistor designed to change resistance with temperature changes, and they are more expensive than any other temperature detection device. A schematic of a resistance temperature detector is shown below.

(iii) Thermistors – They are another type of resistor, where the significant change in resistance is proportional to a small change in temperature.

(2) Infrared Sensors

This device emits or detects infrared radiation to sense specific phases in the environment. Generally, thermal radiation is emitted by all objects in the infrared spectrum, and infrared sensors detect this radiation, which is invisible to the human eye.

Advantages

Easy to connect, readily available in the market

Disadvantages

Susceptible to interference from surrounding noise, such as radiation, ambient light, etc.

Working Principle

The basic idea is to use an infrared light-emitting diode to emit infrared light towards an object. Another infrared diode of the same type will be used to detect the reflected wave from the object. A simplified working principle diagram of infrared LED sensors is shown below.

When the infrared receiver is illuminated by infrared light, a voltage difference is generated in the wire. Because the generated voltage is very small and difficult to detect, operational amplifiers (op-amps) are used to accurately detect low voltages.

Measuring the distance of an object from the receiving sensor: The electrical characteristics of the infrared sensor component can be used to measure the distance of an object. When the infrared receiver is illuminated, a potential difference is generated in the wire.

Applications

(3) Ultraviolet Sensors

These sensors measure the intensity or power of incident ultraviolet radiation. This type of electromagnetic radiation has a longer wavelength than X-rays but is still shorter than visible light. A material called polycrystalline diamond is being used for reliable ultraviolet sensing, and ultraviolet sensors can detect environments exposed to ultraviolet radiation.

Criteria for selecting ultraviolet sensors

· Wavelength range (nanometers) that can be detected by the ultraviolet sensor

· Operating temperature

· Accuracy

· Weight

· Power range

Working Principle

Ultraviolet sensors receive one type of energy signal and transmit a different type of energy signal.

To observe and record these output signals, they are directed to an ammeter. To generate graphs and reports, the output signals are transmitted to an analog-to-digital converter (ADC) and then transmitted to a computer via software.

Examples include:

· Ultraviolet phototubes are radiation-sensitive sensors used for monitoring ultraviolet air treatment, ultraviolet water treatment, and solar radiation.

· Light sensors measure the intensity of incident light.

· Ultraviolet spectral sensors are charge-coupled devices (CCD) used for scientific photography.

· Ultraviolet detectors.

· Germicidal ultraviolet detectors.

· Light stability sensors.

Applications

· Measuring parts of the ultraviolet spectrum that cause sunburn on skin

· Pharmacies

· Automobiles

· Robotics

· Solvent treatment and dyeing processes in the dyeing industry

· Chemical production, storage, and transport in the chemical industry

(4) Touch Sensors

Touch sensors act as variable resistors based on the touch position. A diagram of how touch sensors work as variable resistors.

Touch sensors consist of the following components:

· Fully conductive materials, such as copper

· Insulating spacer materials, such as foam or plastic

· Partially conductive materials

Principles and Operation

Partially conductive materials oppose the flow of current. The main principle of linear position sensors is that the longer the length of the material through which the current must flow, the more the current flow is opposed. Therefore, the resistance of the material changes by altering its contact position with the fully conductive material.

Typically, software is connected to the touch sensor. In this case, the memory is provided by the software. When the sensor is turned off, they can remember the “last touch position.” Once the sensor is activated, they can remember the “first touch position” and understand all values related to it. This action is similar to moving a mouse and positioning it at the other end of the mouse pad to move the cursor to the far end of the screen.

Applications

Touch sensors are cost-effective and durable, widely used in

· Commercial – Medical, Sales, Fitness, and Gaming

· Appliances – Ovens, Washers/Dryers, Dishwashers, Refrigerators

· Transportation – Streamlined control between cockpit manufacturing and vehicle manufacturers

· Level Sensors

· Industrial Automation – Position and level sensing, manual touch control in automation applications

· Consumer Electronics – Providing new levels of sensation and control in various consumer products

(5) Proximity Sensors

Proximity sensors detect the presence of objects with minimal contact points. Since there is no contact between the sensor and the object being measured, and lacking mechanical parts, these sensors have a long lifespan and high reliability. Different types of proximity sensors include inductive proximity sensors, capacitive proximity sensors, ultrasonic proximity sensors, photoelectric sensors, Hall effect sensors, etc.

Working Principle

Proximity sensors emit electromagnetic or electrostatic fields or beams of electromagnetic radiation (such as infrared) and wait for a return signal or changes in the field. The object being sensed is referred to as the target of the proximity sensor.

Inductive proximity sensors – They have an oscillator as input, changing the loss resistance by approaching conductive media. These sensors are preferred for metal targets.

Capacitive proximity sensors – They convert the changes in electrostatic capacitance on either side of the detection electrode and the ground electrode. This occurs by approaching nearby objects at an oscillation frequency. To detect nearby targets, the oscillation frequency is converted to a DC voltage and compared with a predetermined threshold. These sensors are preferred for plastic targets.

Applications

· Used in automation engineering to define the operational status of process engineering equipment, production systems, and automation devices

· Used in windows, where an alarm is activated when the window is opened

· Used for monitoring mechanical vibrations to compute the distance difference between the shaft and the bearing

5. Principles

Different definitions have been approved to distinguish between sensors and sensing devices. A sensor can be defined as a component that perceives one form of energy to produce a variant of the same or another form of energy. Sensors utilize transduction principles to convert the measured object into the desired output.

According to the signals obtained and produced, principles can be classified into the following categories: electrical, mechanical, thermal, chemical, radiation, and magnetic.

Taking ultrasonic sensors as an example.

Ultrasonic sensors are used to detect the presence of objects. They achieve this by emitting ultrasonic waves from the device head and then receiving the reflected ultrasonic signals from the relevant object. This helps to detect the position, presence, and movement of objects.

Since ultrasonic sensors rely on sound rather than light for detection, they are widely used in measuring water levels, medical scanning procedures, and the automotive industry. Ultrasonic sensors can detect transparent objects such as transparent films, glass bottles, plastic bottles, and flat glass.

Working

The movement of ultrasonic waves varies depending on the shape and type of medium. For example, ultrasonic waves travel in a straight line in a uniform medium and reflect and return at the boundaries between different media. The human body causes significant reflection in the air and is easily detected.

The best way to explain the propagation of ultrasonic waves is to understand the following:

1. Multiple Reflections

Multiple reflections occur when waves are reflected several times between the sensor and the detected object.

2. Limiting Zone

The minimum and maximum sensing distances can be adjusted. This is called the limit zone.

3. Undetected Zone

The undetected area is the gap between the sensor head surface and the minimum detection distance generated by the detection distance adjustment. As shown in the figure below.

The undetected area is the region close to the sensor, where detection is not possible due to the sensor head configuration and reverberation. Detection may occur in uncertain areas due to multiple reflections between the sensor and the object.

Applications

Sensors are used in various applications, such as:

· Impact detection

· Machine monitoring applications

· Vehicle dynamics

· Low-power applications

· Structural dynamics

· Medical aerospace

· Nuclear instruments

· Pressure sensors in mobile phone “touch keyboards”

· Lights that brighten or dim when contacting the lamp holder

· Touch buttons in elevators

6. Advanced Sensor Technologies

Sensor technology has a wide range of applications in the manufacturing field. Advanced technologies are as follows:

1. Barcode Recognition

Products sold in the market have a Universal Product Code (UPC), which is a 12-digit code. Five digits represent the manufacturer, and the other five represent the product. The first six digits are represented by bright and dark bars. The first digit indicates the type of numerical system, and the second indicates parity to represent reading accuracy. The remaining six digits are represented by dark and dark bars, in reverse order of the first six digits. The barcode is shown below.

Barcode readers can manage different barcode standards even without knowing the standard code. The disadvantage of barcodes is that if they are covered by grease or dirt, barcode scanners will not be able to read them.

2. Transponders

In many cases, radio frequency devices are used in the automotive sector. The transponder is hidden within the plastic head of the key, invisible to anyone. The key is inserted into the ignition lock. When you turn the key, the computer sends a radio signal to the transponder. The computer will not allow the engine to start until the transponder responds to the signal. These transponders are powered by radio signals.

3. Electromagnetic Identification of Manufactured Parts

This is similar to barcode technology, where data can be encoded on magnetic stripes. With magnetic stripe technology, data can be read even if the code is hidden under grease or dirt.

4. Surface Acoustic Waves

This process is similar to radio frequency identification. Here, component identification is triggered by radar-type signals and transmitted over long distances compared to RF systems.

5. Optical Character Recognition

This is an automatic identification technology that uses alphanumeric characters as an information source. In the United States, mail processing centers use optical character recognition. They are also used in visual systems and voice recognition systems.

More Videos

-END-

版权说明:感谢每一位作者的辛苦付出与创作,除转载众多无法溯源的文章,我们均在文章中备注了来源。如转载涉及版权等问题,请联系我们删除或支付稿费,非常感谢!

点分享

点点赞

点在看