Source: Sensor Technology

Written by | Sensor Technology (WW_CGQJS)

Proximity sensors are widely used in various automated production lines, mechatronic devices, and industries such as petroleum, chemical, military, and scientific research. So, what is a proximity sensor?

Proximity sensor refers to a general term for sensors that replace limit switches and other contact detection methods, aiming to detect objects without physical contact. It can convert the movement and presence information of the detected object into electrical signals.

In the methods of converting to electrical signals, it includes the method that generates eddy currents in the metal body of the detected object due to electromagnetic induction, the method that captures the capacitive changes in the electrical signals caused by the proximity of the detection body, and methods using stones and guide switches. It consists of inductive, capacitive, ultrasonic, photoelectric, magnetic, and other types.

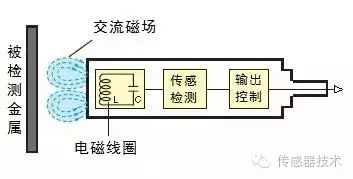

The proximity sensor utilizes an alternating magnetic field generated by a vibrator. When a metal target approaches this magnetic field and reaches the sensing distance, eddy currents occur within the metal target, causing the vibration to decay until the vibrator of the proximity sensor stops vibrating. The changes in the vibration and stop of the proximity sensor’s vibrator are processed by the subsequent amplification circuit and converted into switch signals, triggering control devices, thus achieving the goal of non-contact detection of the proximity sensor. This is the working principle of the proximity sensor.

1. Since it can detect without contact, it will not wear out or damage the detected object.

2. Due to the use of a non-contact output method, the lifespan is extended (except for magnetic types) using semiconductor output, which has no impact on the lifespan of contact points.

3. Unlike optical detection methods, it is suitable for use in environments with water and oil, and is hardly affected by stains, oil, and water on the detected object. In addition, there are products with Teflon shells and good chemical resistance.

4. Compared to contact switches, it can achieve high-speed response.

5. It can correspond to a wide temperature range.

6. It is not affected by the color of the detected object: it detects changes in the physical properties of the detected object, so it is hardly affected by surface colors.

7. Unlike contact types, it can be influenced by surrounding temperatures, surrounding objects, and similar sensors, including inductive and capacitive types, which can interfere with each other. Therefore, when setting up sensors, mutual interference needs to be considered. Additionally, in inductive types, the influence of surrounding metals must be considered, while in capacitive types, the influence of surrounding objects must be taken into account.

When a metal detection body approaches the sensing area of the sensor, the switch can issue electrical commands without contact, pressure, or sparks, quickly reflecting the position and stroke of the moving mechanism. Whether used for general stroke control, its positioning accuracy, operating frequency, lifespan, ease of installation and adjustment, and suitability for harsh environments are unmatched by general mechanical stroke switches.

Classification of Proximity Sensors

Proximity sensors are classified by working principle:

High-frequency oscillation type, capacitive type, inductive bridge type, permanent magnet type, and Hall effect type.

According to the operating principle, they can be divided into three categories:

High-frequency oscillation type utilizing electromagnetic induction, magnetic force type using magnets, and capacitive type utilizing capacitance changes.

Classified by detection methods:

General type: mainly detects ferrous metals (iron).

All-metal type: detects any metal within the same detection distance.

Non-ferrous metal type: mainly detects non-ferrous metals like aluminum.

Classified by structural type:

1. Two-wire proximity sensors:

Two-wire proximity sensors are easy to install and connect; they are widely used but have significant residual voltage and leakage current drawbacks.

DC three-wire proximity sensors have NPN and PNP output types. Most Japanese products in the 1970s were NPN output, while both NPN and PNP output types are available in Western European countries. PNP output proximity sensors are generally used in PLCs or computers as control commands, while NPN output proximity sensors are often used to control DC relays. In practical applications, the output form should be selected based on the characteristics of the control circuit.

Working Principles of Different Types of Proximity Sensors

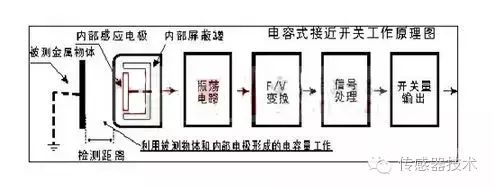

Working principle of capacitive proximity sensors: Capacitive proximity sensors consist of high-frequency oscillators and amplifiers, forming a capacitor between the sensor’s detection surface and the ground, participating in the oscillation circuit’s operation, initially in an oscillating state. When an object approaches the sensor’s detection surface, the circuit’s capacitance changes, causing the high-frequency oscillator to oscillate. The two states of oscillation and stop are converted into electrical signals and amplified into binary switch signals.

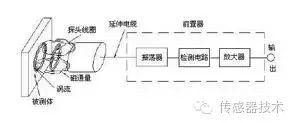

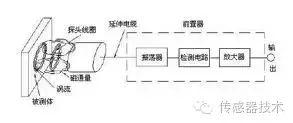

Working principle of inductive proximity sensors: Inductive proximity sensors consist of high-frequency oscillation, detection, amplification, triggering, and output circuits. The oscillator generates an alternating electromagnetic field at the sensor’s detection surface. When a metal object approaches the sensor’s detection surface, the eddy currents generated in the metal absorb energy from the oscillator, weakening the oscillation until it stops. The two states of oscillation and stop are converted into electrical signals and shaped and amplified into binary switch signals, output after power amplification.

Working principle of high-frequency oscillation type proximity sensors: It consists of an LC high-frequency oscillator and amplification processing circuit. When a metal object approaches the oscillation sensing head, eddy currents are generated, weakening the oscillation capability of the proximity sensor, and the parameters of the internal circuit change, thus identifying the presence of a metal object and controlling the switch’s on or off.

Working principle of all-metal type sensors: All-metal type sensors are essentially high-frequency oscillation types. Like ordinary types, it also has an oscillation circuit, and energy loss caused by induced currents flowing within the target affects the oscillation frequency. When the target approaches the sensor, regardless of the type of metal, the oscillation frequency increases. The sensor detects this change and outputs a detection signal.

Working principle of non-ferrous metal type sensors: Non-ferrous metal sensors are essentially high-frequency oscillation types. It has an oscillation circuit, and energy loss caused by induced currents flowing within the target affects the change in oscillation frequency. When a non-ferrous metal target like aluminum or copper approaches the sensor, the oscillation frequency increases; when a ferrous metal target like iron approaches the sensor, the oscillation frequency decreases. If the oscillation frequency exceeds the reference frequency, the sensor outputs a signal.

Working principle of general proximity sensors: A coil L in the oscillation circuit generates a high-frequency magnetic field. When the target approaches the magnetic field, induced currents (eddy currents) are generated in the target due to electromagnetic induction. As the target approaches the sensor, the induced current increases, causing the load in the oscillation circuit to increase. Then, the oscillation weakens until it stops. The sensor uses amplitude detection circuits to detect changes in the oscillation state and outputs detection signals.

Selecting and Testing Proximity Sensors

Selecting Proximity Sensors:

For different materials of detection bodies and different detection distances, different types of proximity sensors should be selected to achieve high performance-to-price ratios in the system. Therefore, the following principles should be followed in selection:

1. When the detection body is made of metal: High-frequency oscillation type proximity sensors should be selected, as this type is most sensitive to detection bodies made of iron, nickel, and A3 steel. The detection sensitivity for aluminum, brass, and stainless steel is lower.

2. When the detection body is made of non-metallic materials: Capacitive proximity sensors should be selected, such as wood, paper, plastic, glass, and water.

3. When detecting and controlling both metallic and non-metallic objects from a distance: Photoelectric proximity sensors or ultrasonic proximity sensors should be selected.

4. When the detection body is metal but the sensitivity requirement is not high: Inexpensive magnetic proximity sensors or Hall effect proximity sensors can be selected.

Factors for Selecting Proximity Sensors:

① Detection type: Built-in amplifier type, separate amplifier type; ② Shape: Round, square, groove type; ③ Detection distance: Measured in mm; ④ Detected objects: Iron, steel, copper, aluminum, plastic, water, paper, etc.; ⑤ Working power supply: DC, AC, universal AC/DC; ⑥ Output form: Normally open (NO), normally closed (NC); ⑦ Output method: Two-wire, three-wire (NPN, PNP); ⑧ Shielded, non-shielded; ⑨ Wire lead type, plug type, plug relay type; ⑩ Response frequency: How many objects can be detected per second.

Testing Proximity Sensors:

Determining the release distance: When the actuator leaves the sensing surface of the proximity sensor from the front, measure the maximum distance the actuator can leave the sensing surface when the switch transitions from actuation to release.

Determining the hysteresis H: The absolute value of the difference between the maximum actuation distance and the release distance.

Determining the actuation frequency: Using a variable speed motor to drive a rubber disk, several steel pieces are fixed on the disk. Adjust the distance between the switch sensing surface and the actuator to about 80% of the switch actuation distance. Rotate the disk sequentially to bring the actuator close to the proximity sensor. The main shaft of the disk is equipped with a speed measuring device. The switch output signal is shaped and connected to a digital frequency meter. At this time, start the motor and gradually increase the speed. Under the condition that the product of speed and actuator equals the frequency count, the switch’s actuation frequency can be directly read from the frequency meter.

Determining repeat accuracy: Fix the actuator on a measuring tool, approaching the switch’s actuation distance from more than 120% away, controlling the movement speed at 0.1mm/s. When the switch actuates, read the measurement on the tool, then exit the actuation area to turn off the switch. Repeat this 10 times, finally calculating the maximum and minimum values of the 10 measurements and their difference from the average value. The larger difference is the repeat accuracy error.

Troubleshooting Common Proximity Sensor Issues

1. Provide stable power supply to the proximity sensor independently;

2. Ensure response frequency is within rated range;

3. Objects may shake during detection, leading to exceeding the detection area;

4. Multiple probes installed closely may interfere with each other;

5. Other objects may be present in the detection area around the sensor probe;

6. There may be electrical interference from high-power devices around the proximity sensor.

Proximity sensors are widely used in machine tools, metallurgy, chemical, textile, and printing industries. In automatic control systems, they can serve as limit, counting, positioning control, and automatic protection components. Proximity sensors feature long lifespan, reliable operation, high repeat positioning accuracy, no mechanical wear, no sparks, no noise, and strong vibration resistance. Currently, the application range of proximity sensors is increasingly broad, and their development and innovation speed is also extremely rapid.

Disclaimer: This article is copyrighted by the original author. If any videos, images, or text used in this article involve copyright issues, please inform us immediately, and we will confirm the copyright based on the materials you provide and pay remuneration according to national standards or delete the content immediately! The content of this article represents the views of the original author and does not reflect the views of this public account or its authenticity.

Reprinted content only represents the author’s views

Does not represent the position of the Institute of Semiconductors, Chinese Academy of Sciences

Editor: Six Yuan Fish