What Are Smart Sensors?

As tools for humans to obtain information, sensors are an important part of modern information technology. Traditionally, sensors output mostly analog signals, lacking signal processing and networking capabilities, and must be connected to specific measuring instruments to complete signal processing and transmission functions. Smart sensors can process raw data internally and exchange data with the outside world through standard interfaces, as well as change the sensor’s operation through software control based on actual needs, thus achieving intelligence and networking. Due to the use of standard bus interfaces, smart sensors have good openness and scalability, providing significant development space for system expansion.

The concept of smart sensors was first proposed by NASA during the development of spacecraft, and products were formed in 1979. Spacecraft require a large number of sensors to continuously send data such as temperature, position, speed, and attitude to the ground or processors on the spacecraft, and even with a large computer, it is difficult to process such massive data simultaneously. Moreover, the spacecraft restricts the size and weight of computers, so there was a hope that the sensors themselves would have information processing capabilities, leading to the combination of sensors with microprocessors, thus creating smart sensors.

Smart sensors are a new type of sensor that can sense and detect certain information from the measured object; they can learn, reason, and process signals; and they have communication and management functions. Smart sensors have capabilities such as automatic zero calibration, calibration, compensation, and data collection. Their capabilities determine that smart sensors also have high precision and resolution, high stability and reliability, good adaptability, and compared to traditional sensors, they have a very high cost-performance ratio.

Early smart sensors processed the output signals of sensors and sent them to microprocessors for computation after conversion. In the 1980s, smart sensors were mainly centered around microprocessors, integrating sensor signal conditioning circuits, microelectronic computer memory, and interface circuits onto a single chip, giving sensors a degree of artificial intelligence. In the 1990s, intelligent measurement technology improved further, allowing sensors to achieve miniaturization, integrated structures, array types, and digital forms, making them easy to use, simple to operate, and equipped with self-diagnosis functions, memory and information processing capabilities, data storage functions, multi-parameter measurement functions, network communication capabilities, logical thinking, and judgment functions.

Smart sensors can be roughly divided into three types: sensors with judgment capabilities; sensors with learning capabilities; and sensors with creative capabilities.

Structure of Smart Sensors

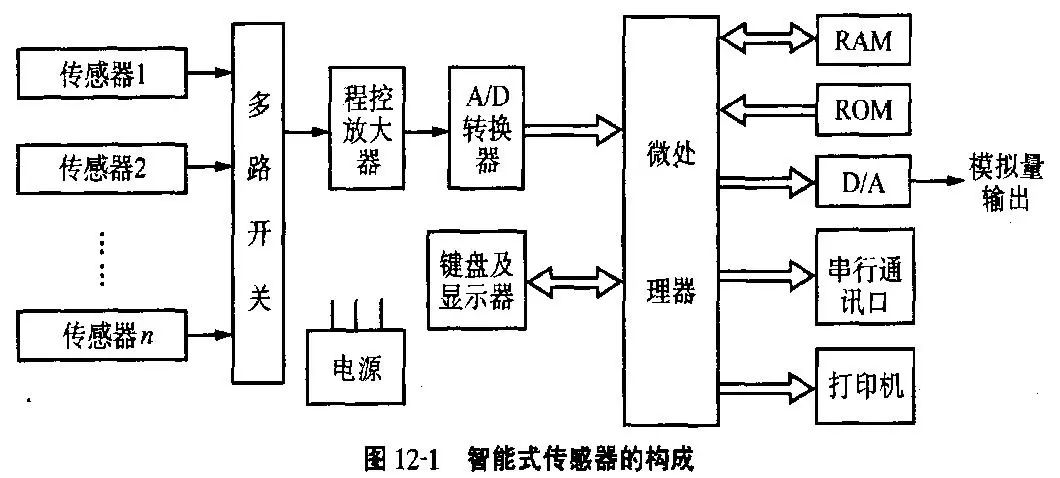

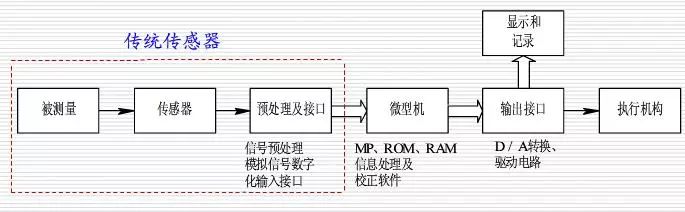

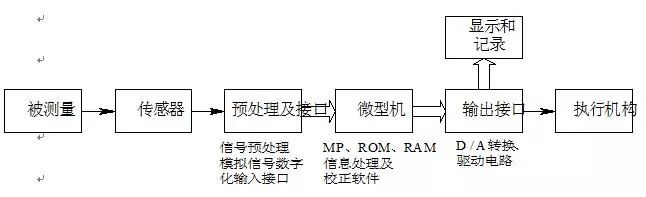

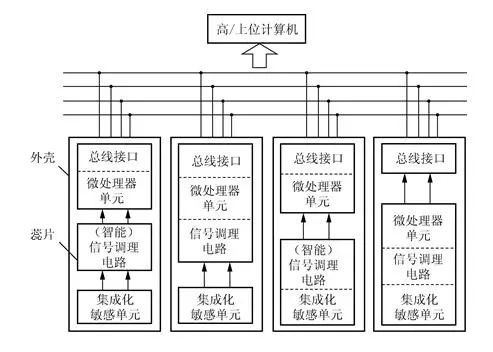

The smart sensor system mainly consists of sensors, microprocessors, and related circuits, as shown in the figure. The sensor converts the measured physical and chemical quantities into corresponding electrical signals, which are sent to the signal conditioning circuit, filtered, amplified, and converted through A/D before reaching the microprocessor. The microprocessor calculates, stores, and analyzes the received signals, adjusting the sensor and signal conditioning circuit through feedback loops to regulate and control the measurement process; on the other hand, it transmits the processed results to the output interface, which processes the results according to the output format and interface specifications to output digitized measurement results. The microprocessor is the core of the smart sensor, as it fully utilizes the functions of various software to make the sensor intelligent, significantly improving the performance of the sensor.

Characteristics of Smart Sensors

-

High Precision

Smart sensors can eliminate zero points through automatic zero calibration, perform overall system calibration in real-time by comparing with standard reference benchmarks, correct systematic errors such as non-linearity, and collect a large amount of data for analysis, eliminating the influence of random errors, thus ensuring the high precision of smart sensors.

-

High Reliability and Stability

Smart sensors can automatically compensate for system characteristic drift caused by changes in working conditions and environmental parameters, such as drift in zero points and sensitivity due to fluctuations in environmental temperature and system power supply voltage; they can automatically change the range after the measured parameters change, conduct real-time self-checks, analyze, and judge the rationality of the collected data, and automatically handle emergencies.

-

High Signal-to-Noise Ratio and High Resolution

Due to the data storage, memory, and information processing functions of smart sensors, noise can be removed from input data through digital filtering and other related analyses, automatically extracting useful data; through data fusion and neural network technology, the influence of cross-sensitivity under multi-parameter conditions can be eliminated.

-

Strong Adaptability

Smart sensors possess judgment, analysis, and processing capabilities, enabling them to decide the power supply conditions for various parts based on system operating conditions and the data transmission rate with higher-level computers, allowing the system to operate in an optimal low-power state and optimize transmission efficiency.

-

High Cost-Performance Ratio

The high performance of smart sensors is not achieved by pursuing the perfection of the sensors themselves, through meticulous design and debugging of each link like traditional sensor technology, but by combining with microprocessors/microcomputers, using inexpensive integrated circuit technology and chips, along with powerful software, thus achieving a high cost-performance ratio.

Main Functions of Smart Sensors

The functions of smart sensors are proposed through simulating the coordinated actions of human senses and brain, combined with long-term research on testing technology and practical experience. They are relatively independent intelligent units, alleviating the stringent requirements on the original hardware performance and significantly enhancing sensor performance with the help of software.

Smart sensors can typically achieve the following functions:

1. Composite Sensitivity Function

We observe natural phenomena around us; common signals include sound, light, electricity, heat, force, and chemical signals. Sensitive elements measure generally through two methods: direct and indirect measurement. Smart sensors have composite functions, capable of simultaneously measuring multiple physical and chemical quantities, providing comprehensive information reflecting the laws of material movement. For example, the composite liquid sensor developed by the University of California can simultaneously measure the medium’s temperature, flow rate, pressure, and density. The composite mechanical sensor developed by EG&GIC Sensors can measure the three-dimensional vibration acceleration, speed, and displacement at a specific point of an object simultaneously.

2. Adaptive Function

Smart sensors can automatically adapt their characteristics to changes in conditions within a certain range. By employing adaptive technology, they can compensate for parameter drift caused by aging components, thereby extending the lifespan of devices or systems. The adaptive technology also expands their operational range, as it can automatically adjust to different environmental conditions. Adaptive technology improves the repeatability and accuracy of sensors, as the calibration and compensation values are no longer averages but the true corrected values of the measurement points.

3. Self-Check, Self-Calibrate, and Self-Diagnosis Functions

Ordinary sensors require regular inspection and calibration to ensure sufficient accuracy during normal use; these tasks generally require removing the sensors from the field to the laboratory or inspection department. In contrast, the situation greatly improves with smart sensors. First, the self-diagnosis function conducts self-checks upon power-up, diagnosing to determine whether components have faults. Second, calibration can be performed online based on usage time, with the microprocessor using the metering characteristic data stored in E2PROM for comparison and calibration.

4. Information Storage Function

Information is often the key to success. Smart sensors can store a large amount of information, which users can query at any time. This information may include the device’s historical data, such as how many hours the sensor has operated, how many times power has been replaced, etc. It also includes all data and charts from the sensor, as well as configuration selection instructions, serial numbers, production dates, directory tables, and final factory test results. The content can be unlimited, constrained only by the smart sensor’s storage capacity. In addition to enhancing process data processing, self-diagnosis, configuration, and information storage functions, smart sensors also provide digital communication capabilities and adaptive capabilities.

5. Data Processing Function

Process data processing is a very important task that smart sensors provide. Smart sensors can amplify signals, digitize them, and use software for signal conditioning. Typically, basic sensors cannot provide linear signals, whereas process control takes linearity as an important goal. Smart sensors can linearize non-linear signals through lookup tables. Of course, a separate data table must be compiled for each sensor. Another example of process data processing by smart sensors is filtering digital signals through digital filters, thereby reducing noise or other related effects. Moreover, developing complex filters using software is much easier than using discrete electronic circuits. Environmental factor compensation is also an important task in data processing. Microcontrollers can help improve the accuracy of signal detection. For example, by measuring the temperature of the basic detecting element, a correct temperature compensation coefficient can be obtained, thus achieving temperature compensation for the signal. Software can also implement non-linear compensation and other more complex compensations because lookup tables can generate curves of almost any shape. Sometimes, it is necessary to measure and process several different physical quantities, which will yield their respective data. The microcontroller in smart sensors makes it easy for users to perform addition, subtraction, multiplication, and division of multiple signals. Smart sensors can truly shine in process data processing.

Furthermore, decentralizing these operations from the central control room to near the signal generation points is also highly beneficial. Firstly, because sending additional signals to the control room is costly, using smart sensors eliminates the need for additional sensors and leads. Secondly, since additional information is detected at the application point of the information, this significantly reduces the negative effects introduced by long-distance transmission (such as noise, potential difference, etc.), making the signals more accurate. Thirdly, it can simplify the software in the main controller, improving the speed of the control loop.

6. Configuration Function

Another major feature of smart sensors is the configuration function. How much should the signal be amplified? Should temperature sensors output in Celsius or Fahrenheit? For smart sensors, users can freely choose the required configuration, such as detection range, programmable on/off delay, selected counting mode, normally open/closed, 8/12 bit resolution selection, etc. These are just a few among countless configurations available in today’s smart sensors. The flexible configuration function greatly reduces the number of different types and quantities of sensors that users need to develop and replace. Utilizing the configuration function of smart sensors allows the same type of sensor to operate at optimal conditions and perform different tasks in different situations.

7. Digital Communication Function

As mentioned above, since smart sensors can generate a large amount of information and data, the single wire of ordinary sensors cannot provide the necessary input and output for the device’s data. However, it is also not feasible to use a separate wire for each piece of information, as this would complicate the system significantly. Therefore, a flexible serial communication system is needed. In process industries, point-to-point connections and series networks are commonly seen. The current trend is to develop towards series networks. Because smart sensors themselves have microcontrollers, they are inherently digital, thus naturally configured for external digital serial communication. Serial networks are much more resistant to environmental influences (such as electromagnetic interference) than ordinary analog signals. Connecting serial communication to devices can effectively manage information transmission, ensuring data is only output when needed.

Realization Paths of Smart Sensors

Currently, the realization of smart sensors is progressing along three paths of sensor technology development: a, utilizing computer synthesis, i.e., intelligent synthesis; b, utilizing special functional materials, i.e., intelligent materials; c, utilizing functional geometric structures, i.e., intelligent structures. Intelligent synthesis is manifested in the combination of sensor devices with microprocessors, which is the primary path at present.

According to the synthesis method of sensors with computers, current sensing technology implements smart sensors through the following three specific methods.

1. Non-Integrated Modular Approach

Non-integrated smart sensors are systems that combine traditional basic sensors, signal conditioning circuits, and microprocessors with digital bus interfaces into a single unit. This type of non-integrated smart sensor has rapidly developed under the trend of fieldbus control systems. The existing production process and equipment of automation instrument manufacturers remain fundamentally unchanged, with an additional microprocessor board with a digital bus interface assembled, equipped with intelligent software capable of communication, control, self-calibration, self-compensation, self-diagnosis, etc., thus realizing the functions of smart sensors. This is the most economical and fastest way to establish smart sensors.

2. Integrated Realization

This smart sensor system utilizes micro-mechanical processing technology and large-scale integrated circuit technology, using silicon as the basic material to manufacture sensitive elements, signal conditioning circuits, and microprocessor units, integrating them onto a single chip. Integrated realization allows smart sensors to achieve miniaturization and structural integration, thereby improving precision and stability. When sensitive elements are arranged in an array, combined with corresponding image processing software, it can achieve image formation and constitute multi-dimensional image sensors, thus reaching the highest form of smart sensors.

3. Hybrid Realization

Implementing smart sensor systems on a single chip involves many tricky challenges. Depending on needs and possibilities, various integrated components (such as sensitive units, signal conditioning circuits, microprocessor units, digital bus interfaces) can be integrated in different combinations on two or three chips, encased in a single housing.

Development and Trends of Smart Sensor Technology

-

Development Trends

1, Development Towards High Precision

As the level of automation in production increases, the requirements for sensors are continuously rising, necessitating the development of new sensors with high sensitivity, high precision, fast response, and good interchangeability to ensure the reliability of automated production.

2, Development Towards High Reliability and Wide Temperature Range

The reliability of sensors directly affects the anti-interference performance of electronic devices, and developing sensors with high reliability and wide temperature ranges will be a permanent direction. The development of emerging materials ( such as ceramics) for sensors will be very promising.

3, Development Towards Miniaturization

The functions of various control instruments and equipment are becoming increasingly powerful, requiring that the volume of each component be as small as possible, thus the size of sensors themselves should also be minimized, necessitating the development of new materials and processing technologies. Currently, sensors made from silicon materials are already very small. For instance, traditional acceleration sensors are made from gravity blocks and springs, which are larger, less stable, and have shorter lifespans, whereas silicon acceleration sensors made using laser and other micro-processing technologies are very small and have good interchangeability and reliability.

4, Development Towards Low Power Consumption and Passive Operation

Sensors generally convert non-electrical quantities into electrical quantities, and cannot operate without a power supply. In outdoor or remote locations away from power grids, they are often powered by batteries or solar energy, making the development of low-power sensors and passive sensors an inevitable direction, which can save energy and extend system lifespan. Currently, the development of low-power chips is progressing rapidly, such as the T12702 operational amplifier, which has a static power consumption of only 1.5 μA, and requires only 2~5V for operating voltage.

5, Development Towards Intelligent Digitalization

With modernization, the functions of sensors have surpassed traditional capabilities, and their outputs are no longer a single analog signal ( such as 0~10mV) , but rather digital signals processed by microcomputers, some even with control functions, which are referred to as digital sensors.

6, Development Towards Networking

Networking is an important direction for sensor development, as the roles and advantages of networks are gradually becoming evident. Networked sensors will undoubtedly promote the development of electronic technology.

-

Focus of Development

1, Application of Machine Intelligence for Fault Detection and Prediction. Any system must detect or predict potential problems before errors occur and lead to severe consequences. Currently, models for abnormal states have not been accurately defined, and there is a significant lack of abnormal detection technologies. There is an urgent need to combine sensing information with knowledge to improve machine intelligence.

2, Under normal conditions, the ability to perceive physical parameters of targets with high precision and sensitivity; however, there has been little progress in detecting anomalies and misoperations. Therefore, there is an urgent demand for fault detection and prediction, which should be vigorously developed and applied.

3, Currently, sensing technology can accurately sense physical or chemical quantities at single points, but it is challenging to sense multi-dimensional states. For example, environmental measurements have characteristic parameters that are widely distributed and have temporal and spatial correlations, which is an urgent problem that needs to be solved. Therefore, it is necessary to strengthen research and development in multi-dimensional state sensing.

4, Remote Sensing for Target Component Analysis. Chemical component analysis is mostly based on sampled materials, and sometimes it is difficult to sample target materials. For instance, measuring ozone content in the same temperature layer requires remote sensing, and the combination of spectral measurement with radar or laser detection technology is a potential approach. Analysis without sample components can easily be interfered with by various noise or media between the sensing system and target components, while machine intelligence in sensing systems is expected to resolve this issue.

5, Intelligent Sensors for Efficient Resource Recycling. Modern manufacturing systems have achieved efficient automated production processes from raw materials to products. When products are no longer in use or discarded, the recycling process is neither efficient nor automated. If the recycling of renewable resources can be conducted effectively and automatically, it can prevent environmental pollution and energy shortages, achieving lifecycle resource management. Utilizing machine intelligence to discern target components or certain determined components is a very important task for intelligent sensing systems.

-

Research Hotspots

1, Research on Physical Conversion Mechanisms

Digital output is one of the typical features of smart sensors; it is not merely a simple digitization achieved through analog-to-digital conversion, but rather digital output is realized from a mechanistic perspective. Among them, resonant sensors have advantages such as direct digital output, high stability, high repeatability, strong anti-interference capabilities, high resolution, and measurement accuracy. The frequency signal detection of traditional photoelectric sensors requires complex designs, limiting their widespread application and development in industrial fields. Now, it is only necessary to integrate intelligent detection circuits on the same silicon chip, allowing for rapid extraction of frequency signals, making resonant micro-mechanical sensors a research hotspot internationally.

2, Research on Multi-Data Fusion

Data fusion is a data integration and processing technology, integrating and applying many traditional disciplines and new technologies, such as communication, pattern recognition, decision theory, uncertainty theory, signal processing, estimation theory, optimization processing, computer science, artificial intelligence, and neural networks. Currently, data fusion has become an important field and research hotspot in the theory of integrated intelligent sensors. That is, comprehensive processing and evaluation of multiple sensors or multi-source information to obtain more accurate and reliable conclusions. Therefore, for arrays composed of multiple sensors, data fusion technology can fully utilize the characteristics of each sensor, leveraging their complementarity and redundancy to improve the accuracy and reliability of measurement information and extend the system’s lifespan. In recent years, data fusion has also incorporated genetic algorithms, wavelet analysis techniques, and virtual technologies.

Smart sensors represent the overall trend of sensor development, and they have received global attention and recognition, therefore, it can be said that smart sensors are a new type of sensor with very promising development prospects. In the future, with the development of silicon micro-processing technology, the functions of the next generation of smart sensors will become even more diverse. They will utilize artificial neural networks, artificial intelligence, information processing technologies, etc., to give sensors more advanced intelligent functions, while also developing towards the direction of micro-sensors, micro-actuators, and micro-processors forming a micro-system.

Examples of High-Tech Applications of Smart Sensors

-

Molecular Sensors

Although there has been technology using chemical substances in encrypted “invisible ink,” constantly improving detection methods have made it difficult to guarantee that hidden information cannot be read without authorization. In response to this, David Margulis and his research team at the Weizmann Institute of Science in Israel developed a fluorescent molecular sensor that can distinguish different chemicals by generating specific fluorescent emission spectra. Considering recent concerns about global electronic surveillance, this sensor provides a secure means of bypassing electronic communication systems.

-

Wireless Sensors

In recent years, fitness trackers have become a more popular wearable technology product. However, engineers at the University of California, Berkeley have advanced this concept further by developing extremely small wireless sensors to detect health status within the human body. Reportedly, these devices have been miniaturized to the size of a cubic millimeter, about the size of a grain of dust, and are referred to as “neural dust.” These sensors can be implanted inside a person’s body, where they will conduct real-time monitoring of tissues, muscles, and nerves.

Wireless sensors are increasingly being applied in industrial, agricultural, military, aviation, construction, medical, environmental protection, and other fields. Shenzhen Xinyi Technology has long been committed to the design and development of various types of wireless sensors and providing wireless data acquisition and transmission monitoring system solutions based on wireless sensor networks. For example, wireless temperature and humidity sensors, wireless pressure sensors, wireless temperature sensors, wireless gas sensors, and wireless level sensors. Practical applications include intelligent agricultural greenhouse environmental monitoring systems, intelligent breeding environmental monitoring systems, storage collection environmental monitoring systems, intelligent pipeline monitoring systems, major hazard source environmental monitoring systems, energy management systems, atmospheric environmental quality monitoring systems, and intelligent monitoring systems for production and manufacturing.

-

Bioluminescent Sensors

Bioluminescent sensors are actually a new type of research tool, invented by a group of scientists at Vanderbilt University in the United States by genetically modifying the enzyme luciferase. According to researchers, this new type of sensor can be used to track internal interactions of large neural networks in the brain.

-

Artificial Hair Sensors

For humans, the skin serves not only as a barrier to protect us from dust and bacterial invasion but also as a medium through which we sense changes in the external environment. As researchers delve deeper into robotics technology, they are also striving to create functions for robots that mimic real skin. Professor He Xiaodong from Harbin Institute of Technology in China and his colleagues have made innovations in this area, developing new technology that mimics the fine hairs on the human body, transmitting sensory information to robots. Researchers use 30-micron fine wires instead of hairs and embed a row of fine wires in silicone rubber, which serve to relay external information to the artificial skin. This research outcome can be used for sensory prosthetics or corresponding medical devices.

-

Composite Touch Sensors

Currently, most robotic touch sensors only have force sensing capabilities, so they can only detect the hardness and texture of objects, resulting in low precision in recognizing external objects. However, by combining with traditional force sensors, composite touch sensors can help robots identify the composition of objects. This principle was demonstrated by experts at Georgia Institute of Technology in the United States, who designed a “skin” for robots made from conductive and non-conductive fabrics and thermistors that can generate heat.

-

Air Quality Sensors

TZOA has recently launched a new air quality sensor. This sensor can collect information about air quality, including the types and quantities of particulates and whether they contain harmful chemicals. Additionally, the device can protect fetuses and children from pollutants that may affect brain development. In the future, the company plans to sell outdoor pollution devices in China and India, as well as indoor pollution devices in the United States.TZOA is also developing asthma devices that help identify triggers for asthma attacks.

-

Sleep-Promoting “Sense” Sensors

According to reports, James in London, UK, invented a sleep sensor called “Sense.” This sensor can automatically adjust lighting, control heating, and even play soothing music to promote human sleep, while also adjusting the environment to the most comfortable conditions during sleep. It can monitor sound, light, temperature, humidity, and air quality, scoring users on their sleep conditions each night.

-

Electromyography Sensors

Sensors play a crucial role in data collection in the medical and health fields. The electromyography sensor independently developed by Shanghai Chengdian is a charge sensor characterized by high sampling rate, strong anti-interference capability, and good filtering effect. This sensor has been successfully applied in rehabilitation medicine and bionic prosthetics, and in the future, it is expected to expand into emerging industries such as VR/AR, sports fitness, and exoskeletons.

-

Temperature Sensors

A startup dedicated to health monitoring for diabetes patients,SirenCare has developed an intelligent sock that uses temperature sensors to detect whether patients have inflammation, thus monitoring the health status of diabetes patients in real-time. Compared to other companies’ boots and insoles,Siren‘s sock is closer to the skin. The sensor is woven into the sock, allowing for continuous monitoring of foot inflammation, with all detected information uploaded to an app on a smartphone, enabling patients to stay informed about their foot health.

-

Skin Sensors

Recently, researchers in Japan invented a low-cost integrated sensor that is as thin as a Band-Aid. This integrated sensor can be freely attached to the body and monitor physical activity, heart rate, and UV intensity, making it applicable in health management and the Internet of Things. The patch-like skin sensor is printed using the latest printing technology on a thin plastic film, offering low cost while maintaining convenience of use, compared to traditional semiconductor sensor manufacturing technologies.

– END –

Source: Sensor Technology

Previous Articles

Notice for Submissions for the “State Monitoring Sensor Technology” Column of “Measurement and Control Technology”

Open Access | Measurement and Control Technology, 2020, Vol. 39, No. 8, Special Issue on Machine Vision Technology

Academician Tan Jiubin of the Chinese Academy of Engineering: The Core Key is to Solve the Problem of Ultra-Precision Measurement Capability

Recommended Article | FADEC Software Development for Aircraft Engines Based on SCADE

Recommended Article | Research on Large-Size Absolute Measurement Methods Based on Laser Interferometry