Driveable Micro Robots have broad application prospects in non-invasive surgery, targeted delivery, detoxification, and are receiving widespread attention. However, these applications place higher demands on the performance of micro robots.

For example, in non-invasive surgery, people hope to safely manipulate micro robots to target diseased cells without contact. In targeted delivery, micro robots with strong loading capacity are essential for transporting various drugs within the body. In detoxification applications, a larger relative contact area and pollution-free mass production are key to rapidly removing toxic substances. Therefore, micro robots with features such as non-contact manipulation, strong loading capacity, and mass production are urgently needed.

Currently, various strategies have been proposed for manufacturing micro spiral robots, such as film self-rolling, laser direct writing, etc., but these methods still face issues such as complex manufacturing processes, time-consuming operations, and weak loading capacities of the processed spiral structures.

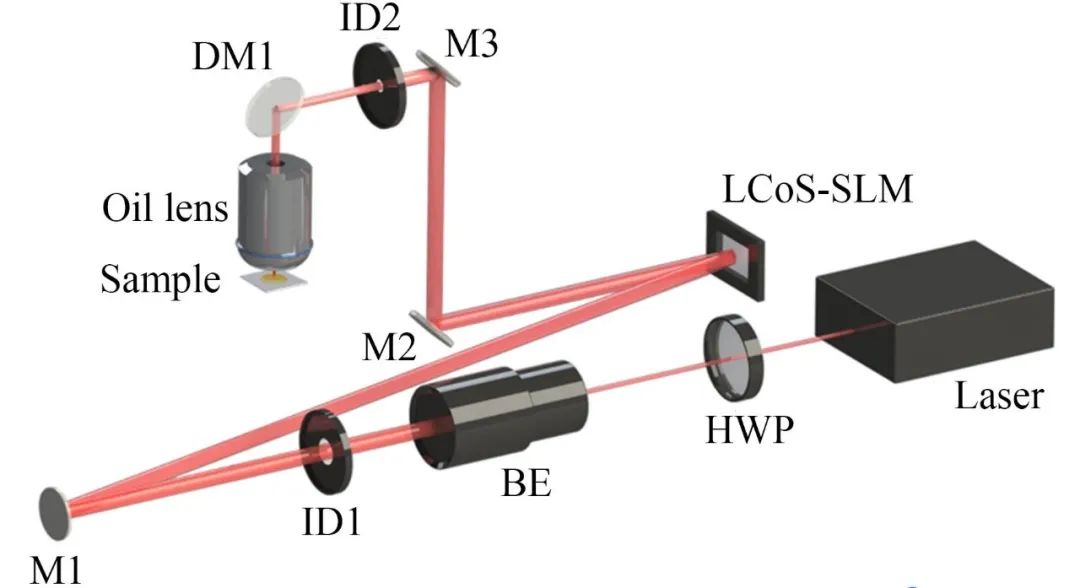

To address these issues, a team led by Associate Professor Li Jiawen from the School of Engineering Science at the University of Science and Technology of China proposed a method for generating locally enhanced annular optical fields using a femtosecond Bessel beam superposition interference approach, combined with dynamic holography, to rapidly fabricate micro hollow double-spiral robots and achieve wireless magnetic drive, providing a new avenue for the widespread application of magnetic drive micro robots with carrying capacity in the biomedical field.

This achievement, titled “Efficient Processing of Hollow Double-Spiral Micro Robots Using Femtosecond Laser Dynamic Holography,” was published in The Journal of Optical Precision Engineering and was selected as the cover article for Volume 29, Issue 9.

Paper URL

http://ope.lightpublishing.cn/thesisDetails#10.37188/OPE.20212909.2101

Reporter of this Issue: Zang Chunxiu (Scientific Editor of The Journal of Optical Precision Engineering)

A: There are several main aspects:

(2) By introducing dynamic holographic processing methods, efficient and rapid processing of micro hollow double-spiral robots was achieved, with a micro robot width of 25µm and length of 100µm.

(3) Using capillary force self-absorption, loading of microparticles with diameters of 1µm and 2.5µm was achieved.

A: To manufacture micro spiral robots with carrying capacity, there are requirements for the morphology of the micro robots to have spiral characteristics and chambers. To quickly manufacture micro robots with these two characteristics, structured light processing is a solution. Common structured lights such as Bessel light, vortex light, and Airy light cannot meet the processing requirements. The coaxial interference of vortex light to obtain annular multi-focus structured light is more suitable for processing micro cage structures, thus there is an urgent need to develop a new structured light specifically for the efficient manufacturing of micro spiral robots with carrying capacity.

Therefore, our group focused on the study of Bessel light. Since Bessel light has an annular light intensity distribution, it can achieve the processing of hollow annular chambers, but the realization of spiral characteristics still needs to be solved. Inspired by coaxial interference, our group attempted off-axis superposition interference of Bessel light, analyzing the simulated light intensity distribution of the new optical field generated by off-axis superposition interference of Bessel light, and found that the new structured light retains the annular characteristics and uniformly distributes energy enhancement points along the circle, with the number of enhancement points depending on the number of superimposed Bessels. This special light field distribution is particularly suitable for the processing of micro spiral robots with hollow chambers.

A: The adjustable range of the spiral structure width of micro robots can still be optimized. The wider the spiral structure of the micro robot, the greater the thrust given to the forward direction with each rotation, thus increasing the controllable speed range of the micro robot. Currently, our processing method mainly relies on adjusting the laser energy to regulate the spiral structure width, where larger energy enhances the nonlinear polymerization process of two photons, resulting in a larger spiral width. However, this method has limited adjustable range, thus the large-scale adjustability of the spiral structure width remains a problem in the manufacturing of micro spiral robots.

(1) In the early stages of the experiment, our group tried many methods for generating structured light, such as using local phase modulation to modulate Bessel light holograms, generating gap annular light, and successfully processing single spiral structures with dynamic holography. However, the micro spiral structures obtained using this method not only lacked chambers but also had low structural strength and were prone to deformation. Additionally, we generated petal-shaped structured light by coaxial superposition interference of vortex light, but this structured light is unsuitable for processing spiral structures.

Ultimately, we attempted the method of off-axis superposition interference of Bessel light, generating locally enhanced annular light, analyzing the effects of topological charge number, conical lens radius, and the number of superpositions on the generated structured light, and finally selecting suitable processing parameters.

Song Bowen, a master’s student in the Department of Precision Machinery and Precision Instruments at the University of Science and Technology of China, mainly engaged in research on femtosecond laser processing and light field control.

Li Jiawen, University of Science and Technology of China, PhD, Associate Professor, obtained his PhD from the University of Science and Technology of China in 2011, postdoctoral researcher from 2011 to 2013 at the University of Science and Technology of China, visiting scholar at the Department of Nanoengineering, University of California, San Diego (UCSD) from 2015 to 2016, mainly engaged in research on femtosecond laser processing, 3D bioprinting technology and applications, micro-nano functional surfaces and devices, structural color mechanisms, and processing.

Supervised by | Yuan Jingze, Zhao Yang

Edited by | Zhao Wei