With a single 3D printing process, a “living” micro-robot can achieve twisting, stretching, contracting, and rotating?

This is precisely what a new study from the University of California, Los Angeles (UCLA) has achieved. The 3D printed micro-robots can autonomously walk, perceive their environment, and navigate independently, filling the gap in the application of additive manufacturing technology in robotics and electronic devices.

(Source: Science)

The related paper titled “Design and Printing of Proprioceptive Three-Dimensional Architected Robotic Metamaterials” was recently published in Science [1]. Reviewers commented on the technology, stating: “The quality of the research conducted by this team exceeds the current state-of-the-art and represents a significant breakthrough in the fields of mechanical metamaterials and micro-robots.”

▲ Figure | Related paper (Source: Science)

▲ Figure | Related paper (Source: Science)

Realizing 3D Printed Metamaterials Integrating Multifunctional Micro-Robots

Previously, academic research and industry focused primarily on 3D printing structural materials, such as metals, plastics, ceramics, and soft materials.

These structural materials have limited functionality, with only a few soft materials applied in the biological field or electronic devices. However, soft materials are also constrained by factors such as slower speeds, lower frequency responses, and lower strength. Currently, the application of 3D printing in robotic sensors and electronic communications is just beginning, so the printable structures are also limited.

▲ Figure | Corresponding author of the paper, Associate Professor Zheng Xiaoyu from UCLA’s Department of Civil and Environmental Engineering and Department of Mechanical and Aerospace Engineering (currently at UC Berkeley’s Department of Materials Science and Engineering) (Source: Zheng Xiaoyu)

▲ Figure | Corresponding author of the paper, Associate Professor Zheng Xiaoyu from UCLA’s Department of Civil and Environmental Engineering and Department of Mechanical and Aerospace Engineering (currently at UC Berkeley’s Department of Materials Science and Engineering) (Source: Zheng Xiaoyu)

Zheng Xiaoyu’s team combines optics, mechanics, and materials science to develop new materials and additive manufacturing methods for smart materials and structures, energy, robotics, communications, and healthcare. At the beginning of this research, they aimed to use 3D printing technology to break through previous limitations, allowing hard electrical materials such as robotic sensors or electronic communication devices to be conveniently printed.

What are the challenges of 3D printing sensors? Zheng Xiaoyu pointed out that to overcome these limitations, there are stringent requirements for materials, such as high-frequency response, high signal-to-noise ratio, high precision, and the need to combine with controllers for closed-loop control; at the same time, it must be capable of precise shaping to meet the manufacturing requirements for accuracy, size, and printing speed.

The research developed manufacturing technology for directly printable piezoelectric actuators and robots, enabling the one-step printing of materials with different properties, including dielectric materials, piezoelectric materials, and conductive metals. The uniqueness of this 3D printing technology lies in its ability to directly print electronic components (such as actuators and robotic arms) with materials that also have a high-frequency response (10 MHz).

▲ Figure | The 3D printed lattice forming the basis of the micro-robot, designed for rapid bending, twisting, rotating, expanding, or contracting (Source: Zheng Xiaoyu)

▲ Figure | The 3D printed lattice forming the basis of the micro-robot, designed for rapid bending, twisting, rotating, expanding, or contracting (Source: Zheng Xiaoyu)

Zheng Xiaoyu stated, “From the perspective of additive manufacturing, 3D printing can achieve structures that traditional processing techniques cannot, thus cleverly combining electronic components and structural designs to print components that realize all robotic functions.”

Another breakthrough of this research is the significant simplification and customization of robot design. For a long time, robots and power devices have relied on different processes to be combined. For example, assembling a robot requires electronic components such as actuators, controllers, sensors, mechanical arms, and transmission devices.

Zheng Xiaoyu said, “How to convert power into force and motion requires mechanical transmission devices, which necessitates different materials, and they must be manufactured separately using different processing methods before all components can be assembled together.”

▲ Figure | Multi-material manufacturing platform (Source: Science)

▲ Figure | Multi-material manufacturing platform (Source: Science)

The team achieved the integration of all functions required by robots into a tiny 3D structure through 3D structuring, enabling autonomous walking, environmental perception, and autonomous navigation. “This simplifies the complex processes of processing and combining different materials, equivalent to completing the entire complex process of traditional methods in one-step 3D printing,” he said.

He also stated that in the future, if users wish to achieve different robotic functions, they can do so by designing and outputting the structure through 3D printing, and this structure itself will be a robot.

From the perspective of metamaterials, the breakthrough of this research lies in transforming originally immobile “dead materials” into robotic forms through 3D design and printing, allowing them to self-regulate and “move.” Zheng Xiaoyu explained, “We use piezoelectric metamaterials that can sense external environments and make decisions on their own. We refer to them as ‘robotic metamaterials.'”

Realizing the Joint Printing of Different Properties of Materials Through Structural Design

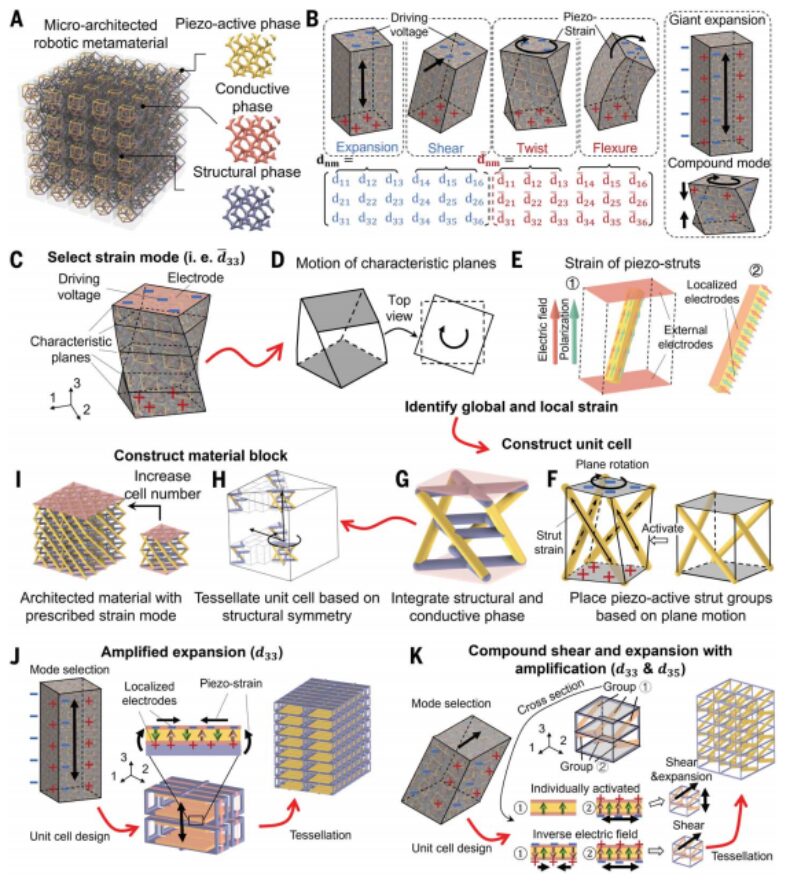

So, how were these breakthroughs achieved? First, the team tackled design challenges. Ordinary piezoelectric materials often only deform laterally when voltage is applied, and their material deformation is small, typically within the range of 0%-0.5%.

“We used electrodynamics design to enable the printed materials to convert the voltage applied at both ends into any different mechanical motion patterns. The materials can twist, stretch, contract, and rotate on their own. Moreover, the deformation and displacement of piezoelectric materials can be significantly amplified,” said Zheng Xiaoyu.

Once the deformable metamaterial structure is designed, the next step is to transform the metamaterial structure into a walking robot. The first author of the paper, Dr. Cui Huachen, explained, “The design inspiration for the robot comes from nature, mimicking the body structure of a cheetah. This design makes the micro-robot more agile and flexible and allows it to be driven and achieve rapid leaps and strides using simple principles.”

▲ Figure | Reasonable design of robotic metamaterials with arbitrary strain modes (Source: Science)

▲ Figure | Reasonable design of robotic metamaterials with arbitrary strain modes (Source: Science)

After confirming the design scheme, the next challenge for the team was to achieve multi-material 3D printing. In previous studies, the printing precision and functionality of materials often could not be achieved simultaneously. In other words, when aiming for high material functionality, the printing precision would become very low.

To address this issue, Zheng Xiaoyu’s team optimized the functional properties of materials through multi-material 3D printing combined with subsequent heat treatment. He stated, “Compared to ordinary multi-material printing, this 3D printing method can print electrical structural materials and functional materials together, achieving the combination of materials with different properties.”

Applications for Sensor Printing and Personalized Driver Design, Underwater and Oil Exploration, Precision Medical Detection, etc.

Through this technology, complex shapes can be 3D printed, leading to diverse application scenarios. First, it enables personalized design for sensor printing and drivers, allowing users to customize functional devices according to their needs.

▲ Figure | Micro-robot (Source: Zheng Xiaoyu)

▲ Figure | Micro-robot (Source: Zheng Xiaoyu)

Second, it can be applied to underwater exploration and oil detection. “By 3D printing micro-robots, they can detect underwater animals, walk between small rocks or crevices on the seabed, and autonomously detect and navigate their surroundings or conduct oil exploration,” said Zheng Xiaoyu.

Third, in the biomedical field, micro-robots can be used for internal body detection and precise drug delivery at specific locations within blood vessels.

▲ Figure | Some members of Zheng Xiaoyu’s research group, from left to right: PhD student Victor Couedel, corresponding author Professor Zheng Xiaoyu, first author Cui Huachen (currently a postdoctoral researcher in Professor Zheng’s group, soon to become an assistant professor at the Hong Kong University of Science and Technology Guangzhou Campus), PhD student Xu Zhenpeng (Source: Zheng Xiaoyu)

▲ Figure | Some members of Zheng Xiaoyu’s research group, from left to right: PhD student Victor Couedel, corresponding author Professor Zheng Xiaoyu, first author Cui Huachen (currently a postdoctoral researcher in Professor Zheng’s group, soon to become an assistant professor at the Hong Kong University of Science and Technology Guangzhou Campus), PhD student Xu Zhenpeng (Source: Zheng Xiaoyu) ▲ Figure | Some members of Zheng Xiaoyu’s research group, first author Cui Huachen (right) and Professor Zheng Xiaoyu (left) discussing metamaterial structure design (Source: Zheng Xiaoyu)

▲ Figure | Some members of Zheng Xiaoyu’s research group, first author Cui Huachen (right) and Professor Zheng Xiaoyu (left) discussing metamaterial structure design (Source: Zheng Xiaoyu)