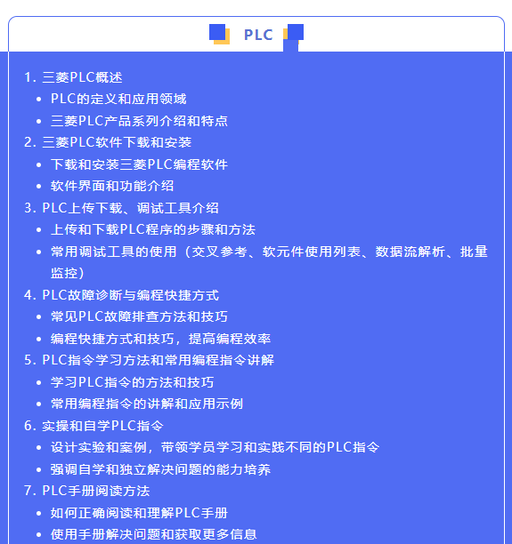

Why Experts Always Draw Process Flow Diagrams Before Writing PLC Programs: This Step Can Save You 80% of Debugging Time!

Do you remember that project that kept me awake all night? A packaging production line, with the client pushing hard for results. I thought to myself, this is just a simple conveyor control, I can jump right in and write the program. But what happened? I spent three whole days debugging, with problems popping up … Read more