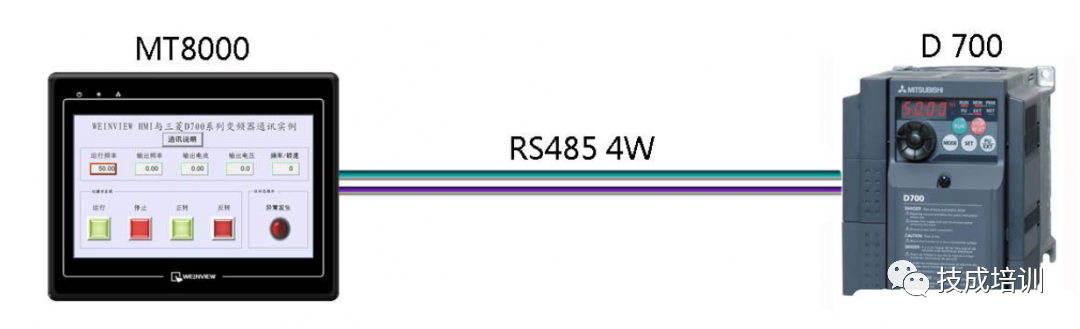

In most cases, the touchscreen is connected to a PLC, which then connects to the inverter. However, the touchscreen can also connect directly to the inverter without going through the PLC, controlling the inverter’s start, stop, frequency change, etc.

Today, we will take the Wecon touchscreen controlling the Mitsubishi D series inverter as an example to explain.

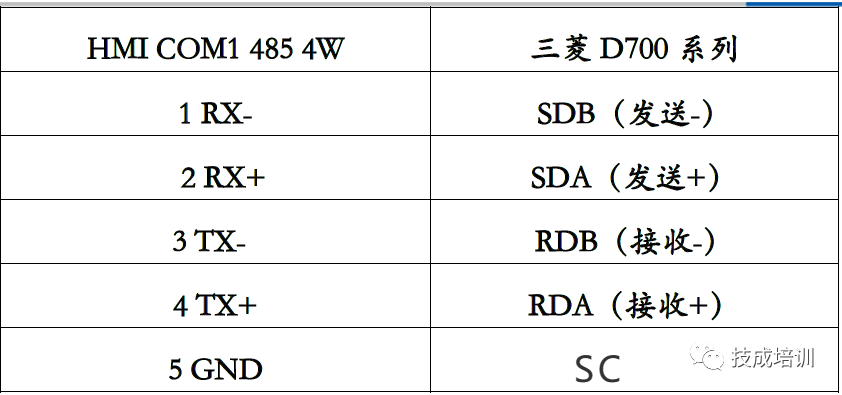

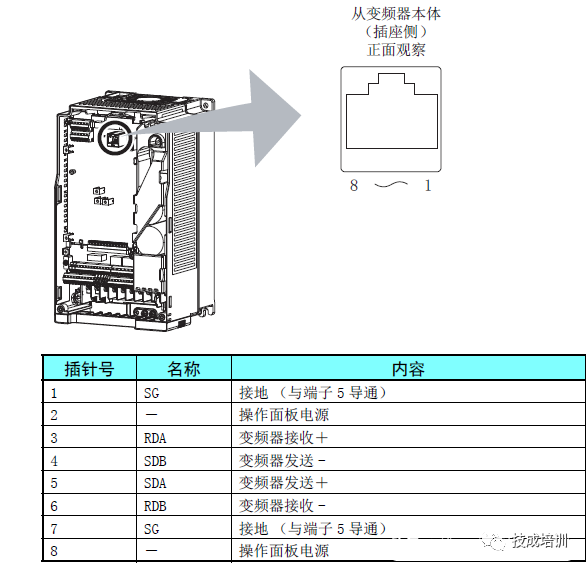

The touchscreen controls the inverter using RS485-based communication. Traditional RS485 uses two wires, but Mitsubishi’s automation products generally use a four-wire system. Therefore, when communicating between the touchscreen and the inverter, four wires are used.

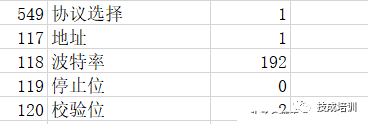

On the inverter side, relevant communication parameters need to be set, mainly baud rate, address, and parity.

It is important to note that Mitsubishi inverters do not default to the MODBUS RTU protocol and require setting parameter 549. The communication data must be consistent between the touchscreen and the inverter; otherwise, communication will fail.

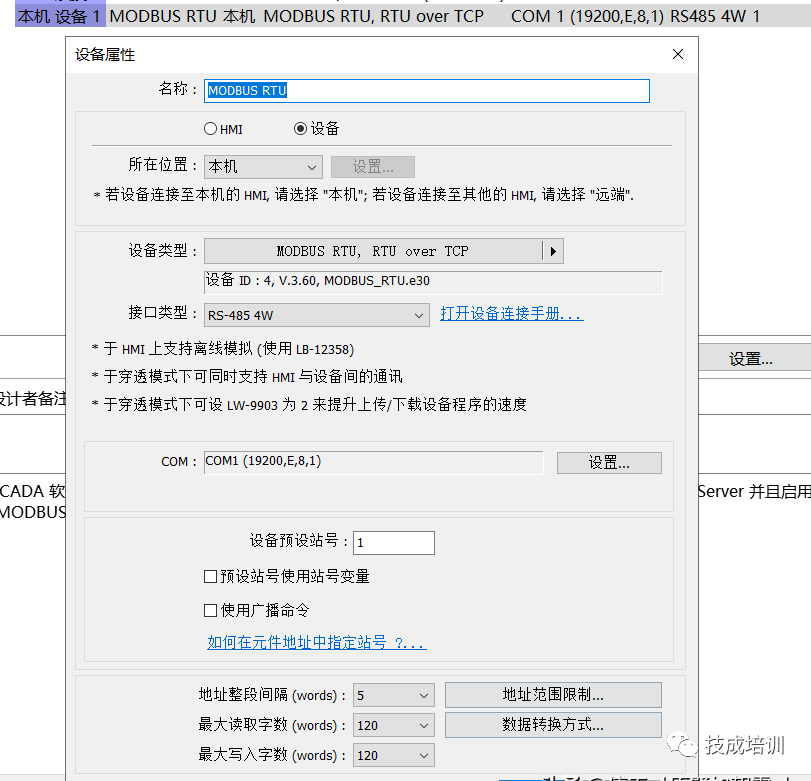

On the touchscreen side, we add a MODBUS RTU slave.

The communication parameters between the inverter and the touchscreen must be consistent; otherwise, communication will not work.

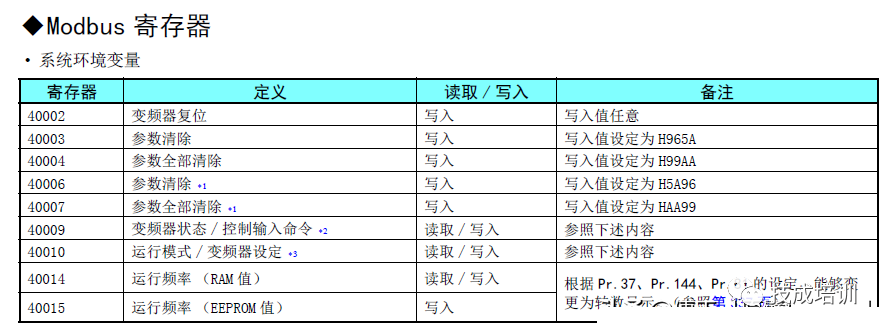

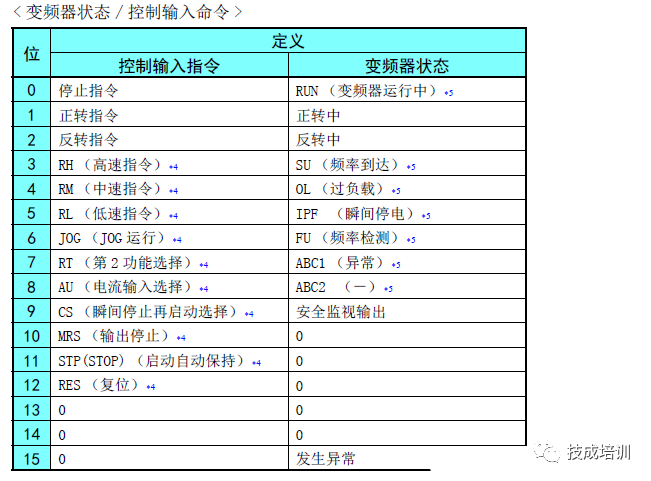

For the inverter to operate, it must receive a start signal and a speed signal. Therefore, we need to configure the screen to send the start signal and speed signal to the inverter. The addresses for the start signal and speed signal can be found in the inverter manual.

Above are the relevant address descriptions from the inverter manual. We just need to implement the corresponding start, stop, and speed settings on the screen.

1120 Copies of Inverter Manuals

16 Essential Inverter E-books

Disclaimer: This article is reproduced from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact us to delete it. Thank you!

Complete set of junior electrician exam questions for 2023 (including answers)

Three essential tools for electricians, available for one-click use on WeChat!

[Collection] The “Path” of a veteran electrician, the secret to earning over ten thousand a month!

Which of the five major electrical drawing software (CAD, Eplan, CADe_simu…) do you prefer?

The latest electrical CAD drawing software, with a super detailed installation tutorial!

The latest electrical drawing software EPLAN, with a super detailed installation tutorial!

Common problems for beginners using S7-200 SMART programming software (with download link)

Comprehensive electrical calculation EXCEL sheet, automatically generated! No need to ask for electrical calculations!

Bluetooth headphones, electrician/PLC introductory books are available? Come and get your electrical gifts!

Basic skills in PLC programming: Ladder diagrams and control circuits (with 1164 practical cases of Mitsubishi PLC)

Still can’t understand electrical diagrams? Basics of electrician diagram reading, simulation software available, rapid hands-on theory and practice!

12 free electrician video courses, 10GB of software/e-book materials, and 30 days of free live electrician courses are being given away!