Traditional manufacturing enterprises are facing severe challenges in digital transformation. With the increasing demand for personalized product production, customers are becoming more stringent about product quality. The state of production equipment affects production efficiency and product quality. Production data and equipment data are becoming the core driving forces for the digital transformation of production lines. Traditional digital upgrade solutions require combining PLCs, PCs, gateways, SCADA software, and other products from different functional areas into a single system to achieve industrial IoT solutions. This results in a complex system architecture, high costs, and significant security risks. This also increases the programming development difficulty for software engineers and raises the costs of software development, on-site maintenance, and spare parts replacement.

As the trend toward intelligent equipment accelerates, engineers need products that can integrate PLC control technology with PC information technology, incorporating functions from multiple fields such as PLC controllers, PCs, gateways, motion control, I/O data acquisition, fieldbus protocols, machine vision, and equipment networking into a single control platform.

Advantech has launched the Industrial IoT Edge Controller WISE-5000 Series, which can simultaneously achieve device motion control, machine vision, predictive maintenance, device networking, data analysis, and optimization control. Data can be directly connected to the industrial cloud platform, collaborating with remote industrial cloud platforms to realize intelligent production line control.

(Click the video below to learn more ☟☟☟☟)

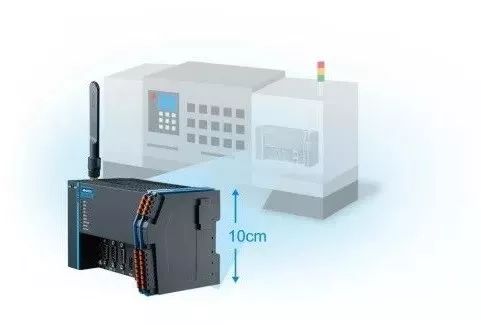

Compact size, space-saving

WISE-5000 is one of the smallest and fastest open platforms in the industry. Its compact structure is only 10 centimeters high, and the plug-in I/O modules are all installed on a standard DIN rail. When installed in the equipment control cabinet, no extra drilling or mechanical devices are needed, saving space and allowing industrial equipment to cross boundaries.

High-speed processing, improved mechanical efficiency

The WISE-5000 series is equipped with Intel’s sixth-generation Skylake Core processor. The controller features standard PCI Express high-speed interfaces and EtherCAT communication protocols on both sides, providing transmission speeds of up to 100 Mbps. This greatly enhances the real-time performance and accuracy of the WISE-5000 when transmitting and processing large data.

Flexible expansion to meet diverse needs

The WISE-5000 adopts a modular EtherCAT I/O and PCI Express interface design, providing users with various I/O and communication modules for data acquisition, control, and transmission. This maintains scalability while accurately matching actual needs, avoiding waste of additional device resources.

Highly integrated information technology and automation technology

The WISE-5000 integrates the advantages of traditional PLCs and PC platforms. It can run high-speed data acquisition, motion control, machine vision, and logic control on one platform, while also implementing information technology databases, cloud platform interactions, and third-party software integration, making it easier for equipment manufacturers to integrate IT and OT applications.

End

Previous Highlights

Three Common Issues in Servo Motor Usage

Did you know? The structure and selection of external drive linear motors

6 Key Points for Choosing a High-Quality Motor

Overview of the Permanent Magnet Motor Industry and Market Trends

Reasons and Solutions for Single-Phase Motors Making Noise but Not Turning