Authors: Maurizio Di Paolo Emilio, Junko Yoshida

EDN Electronic Technology Design Original

The global market for surveillance cameras reached $20 billion in 2019, with China’s Hikvision being one of the largest suppliers.

In both China and other regions of the world, the demand for surveillance systems has rapidly increased in recent years. Many government agencies and companies have found that cameras are essential for building so-called “smart cities” to achieve ubiquitous surveillance.

The reason why Hikvision’s thermal imaging camera developed in 2016 caught the attention of System Plus Consulting analysts is mainly due to AI. Hikvision combined AI hardware and software to develop the first camera with AI capabilities. System Plus Consulting, a subsidiary of Yole Développement, conducted an in-depth study on this camera, revealing the technology behind it.

According to System Plus, the highlight of Hikvision’s cameras lies in the combination of the essence of Eastern and Western design—”micro-radiation thermometers and camera processors made in China” and “non-Chinese AI/analog/other processing components.”

Hikvision’s competitors in this specialized field include China’s Dahua and Uniview Technology, as well as Germany’s Bosch and Sweden’s Axis.

System Plus believes that Hikvision stands out because it can design and manufacture its own products. Hikvision has its own MEMS production line to complete MEMS packaging/testing, as well as multiple surface mount technology (SMT) production lines and strong assembly capabilities.

Intel, Huawei HiSilicon, and Movidius (acquired by Intel) provide three unique key components for Hikvision cameras:

Intel’s reconfigurable solution completes digital signal processing after the micro-radiation thermometer output is digitized and performs thermal management together with the Maxim Peltier controller.

HiSilicon designed a chip to perform image signal processing, video encoding, and encryption, and provides Ethernet interfaces.

The Movidius processor enables visual processing for AI applications. Let’s delve into the internals of Hikvision’s thermal imaging camera.

Thermal Imaging Camera

The thermal imaging camera can detect the heat emitted by the human body and convert it into images through complex signal analysis—these images are generated through temperature detection and analysis. In recent years, the cost of thermal imaging applications has significantly decreased due to the adoption of micro-radiation thermometers.

A micro-radiation thermometer is a sensor that detects infrared radiation, consisting of a grid of thermally sensitive points (pixels), each made up of different layers and absorption materials such as vanadium oxide or amorphous silicon (α-Si).

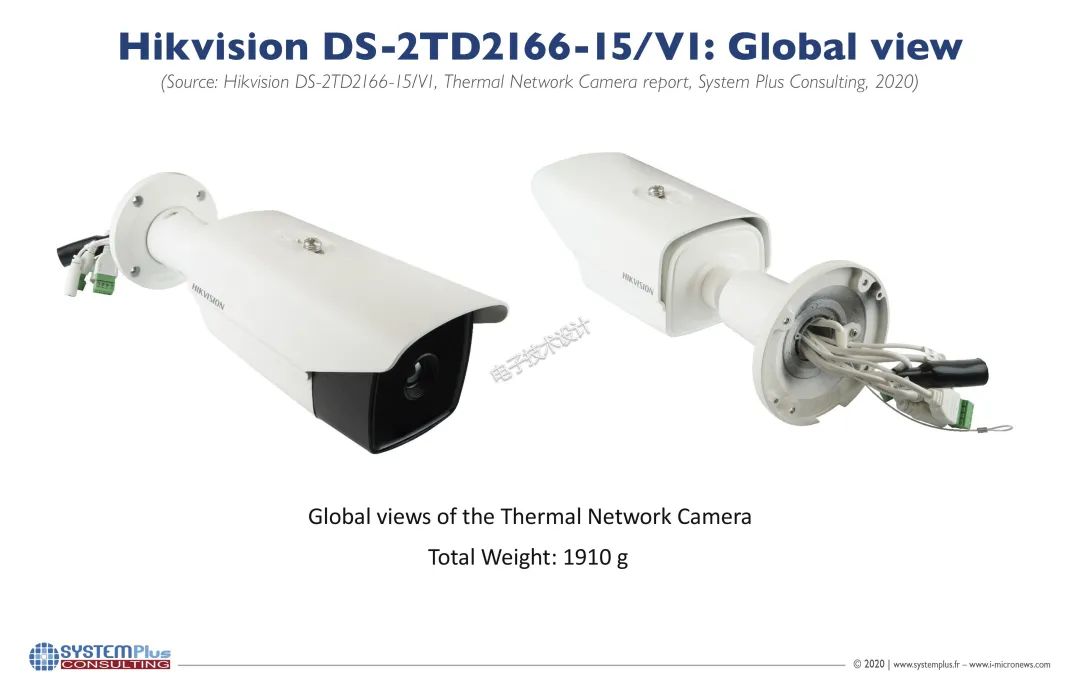

During an interview with System Plus Consulting, I inquired about the technology and structure used in Hikvision’s DS-2TD2166-15/V1 thermal imaging network camera. The technicians at System Plus Consulting explained the electronic and physical hardware structure of the system, focusing on the different components of the system.

The Hikvision DS-2TD2166-15/V1 thermal imaging network camera adopts an image sensor based on a vanadium oxide uncooled focal plane array (Figure 1), utilizing intelligent analysis algorithms to support applications in key infrastructures such as airports and railways. This thermal imaging camera contains multiple chipsets, such as a 640×512 pixel array (17μm pitch) RTD6171MR micro-radiation thermometer, FPGA Cyclone V 550MHz 224I/O (FBGA484), SDRAM 2Gb (128M×16) 800MHz 13.75ns (TFBGA96), temperature controller for Peltier modules (TQFN48), professional HD IP camera SoC, visual processing unit 2×32Bit RISC Proc. 4Gb LPDDR3 and DDR4 DRAM 8Gb (512M×16) 2400Mbps.

The technology and structure used in this thermal imaging camera enable it to timely detect overheating and temperature changes in company and industrial environments, making it an ideal choice for fire prevention.

Its VCA (Video Content Analysis) function supports two completely different processes: one is to detect events in time and space, and the other is to analyze video. It has four types of VCA rules (crossing the boundary, intrusion, entering the area, and leaving the area), supporting up to eight VCA rules.

The camera captures thermal images, allowing users to detect people, objects, and unexpected situations in completely dark environments and harsh conditions. Because it is only sensitive to the infrared radiation emitted by objects, it can view and record images regardless of the lighting conditions on-site.

Using its temperature measurement function, it can measure the actual temperature of the monitored point, and an alarm will sound when the temperature exceeds the threshold. Now let’s take a look at the structure of the camera hardware.

Figure 1: Hikvision DS-2TD2166-15/V1 thermal imaging network camera. (Image source: System Plus Consulting)

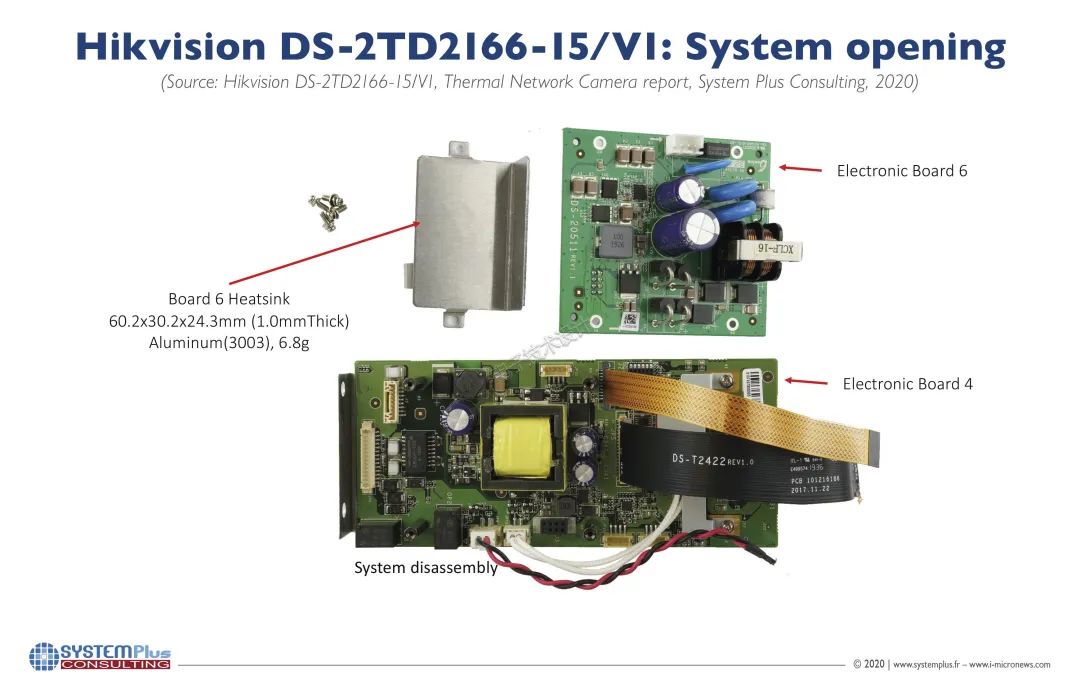

Hikvision Hardware

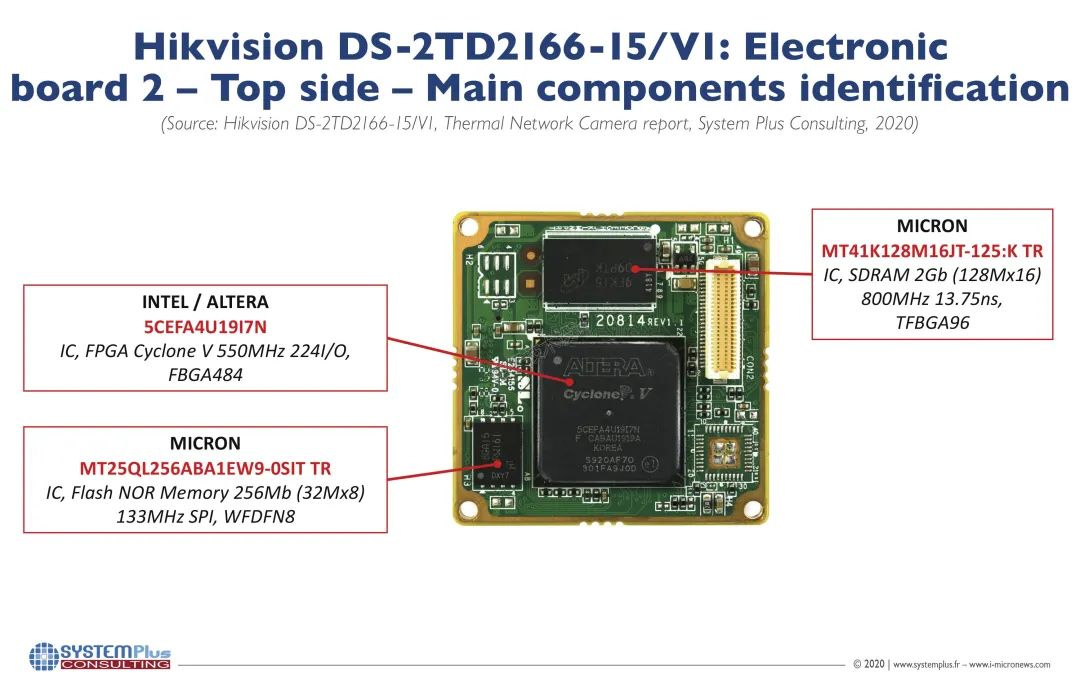

The thermal imaging camera contains six circuit boards, each with different purposes. Let’s analyze some of these circuit boards (Figures 2 and 3). The Cyclone V SoC FPGA is manufactured using TSMC’s 28nm low power (28LP) process, consisting of a dual-core ARM Cortex-A9 MPCore processor, multiple peripherals, and a shared multi-port SDRAM controller. Using this FPGA improves the consistency of integrated data between the processor and FPGA, reduces power consumption, and supports peak bandwidths exceeding 100 Gbps.

Figure 2: Several circuit boards from Hikvision. (Image source: System Plus Consulting)

Figure 3: Hikvision electronic circuit board 2. (Image source: System Plus Consulting)

The signal conditioning/amplifier devices consist of various ICs, including AD8605ARTZ-REEL general-purpose amplifiers, LT6203IMS8 dual-channel amplifiers (100MHz), and LT1994IMS8 differential amplifiers (70MHz). The AD8605ARTZ provides extremely low offset voltage, low input voltage and current noise, and wide signal bandwidth. It uses ADI’s patented DigiTrim trimming technology to adjust circuit performance by digitizing the weighted current source.

The LT6202 has a noise voltage of 1.9nV/√Hz, with each amplifier consuming only 2.5mA of supply current. This amplifier combines low noise and supply current with a 100MHz gain bandwidth product and a 25V/µs slew rate, optimized for low power signal conditioning systems like the thermal imaging camera discussed in this article. At 1MHz, the harmonic distortion is less than -80dBc, making it suitable for low-power data acquisition systems.

The LT1994 is ideal for driving differential input, single-supply ADCs and is an ideal choice for level shifting signals referenced to ground. The output common-mode voltage of the LT1994 is independent of the input common-mode voltage, which can be adjusted by applying a voltage to the VOCM pin, as described in its datasheet.

The ADS1112IDGSR 16-bit ADC and LT3042IDD, along with the FPGA, are used for the conditioning circuit. The ADS1112 is designed for high-resolution measurement applications with high spatial and power requirements. The LT3042IDD is a low-dropout linear regulator that powers noise-sensitive RF applications. On circuit board 3 and circuit board 1, there are other ICs to support the power supply of related integrated subsystems, such as linear regulators and buck converters. 80% of its cost comes from the micro-radiation thermometer (vanadium oxide), and the Peltier battery and its temperature control circuit support it.

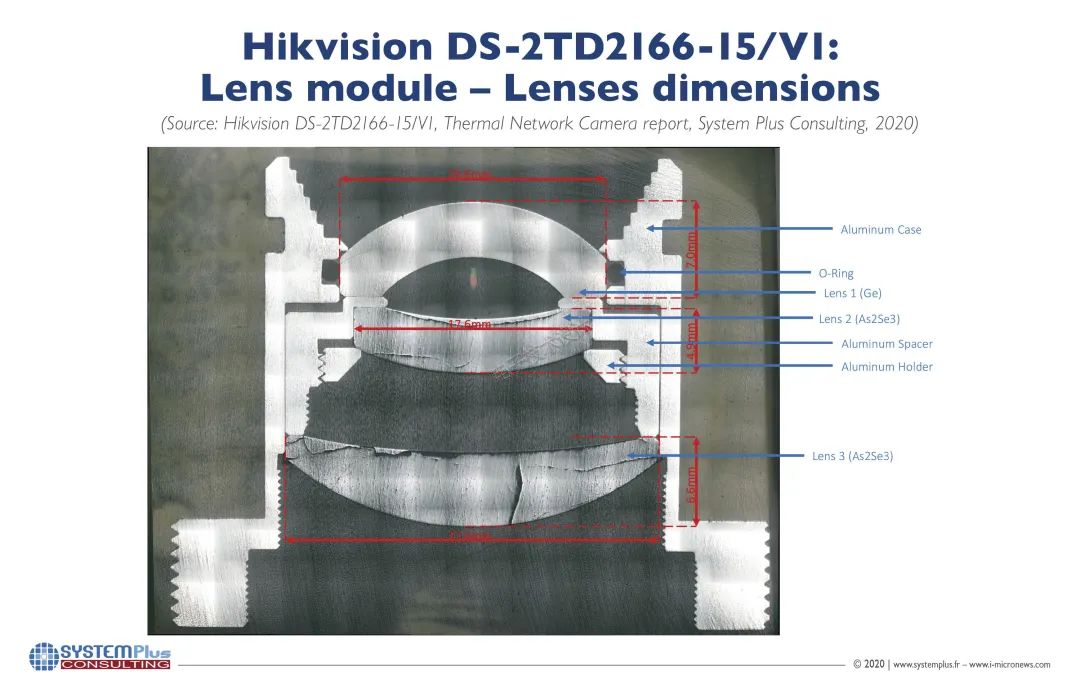

Lenses

The main module supporting the micro-radiation thermometer consists of various lenses to optimize the infrared beam on the sensor. Figures 4 and 5 show a 19.6mm diameter germanium (Ge) lens and two different diameter arsenic selenide (As2Se3) lenses, one with a diameter of 17.6mm and the other 27.6mm.

Figure 4: Camera module. (Image source: System Plus Consulting)

Figure 5: Lens module. (Image source: System Plus Consulting)

In optics, the F-number (sometimes referred to as the focal ratio or relative aperture) is a parameter of an optical system that indicates the area of light reception, i.e., the focal length divided by the aperture. Lenses with larger apertures can allow more light or infrared radiation to pass through, and a large amount of infrared radiation can improve measurement effects based on the signal-to-noise ratio. The parameter “NETD (Noise Equivalent Temperature Difference)” is usually expressed in milli-Kelvin (mK) and can be used to determine measurement quality, measuring the ability of thermal image detectors to resolve subtle differences in thermal radiation images. The typical value for non-cooled thermal imaging cameras based on micro-radiation thermometers is about 45mK.

Micro-Radiation Thermometer

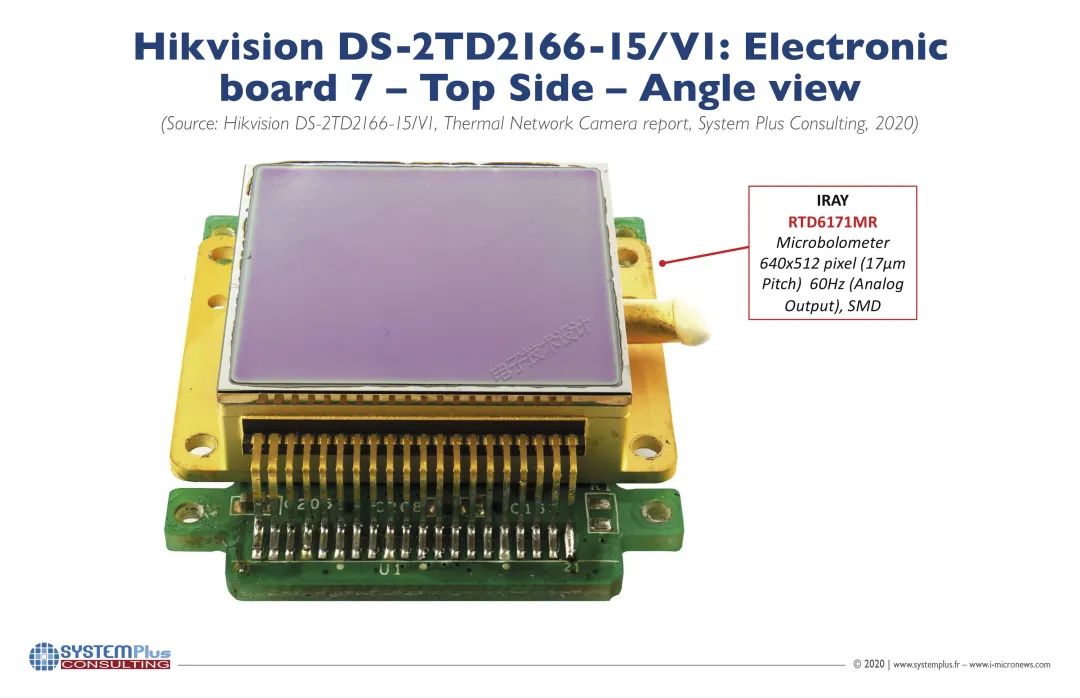

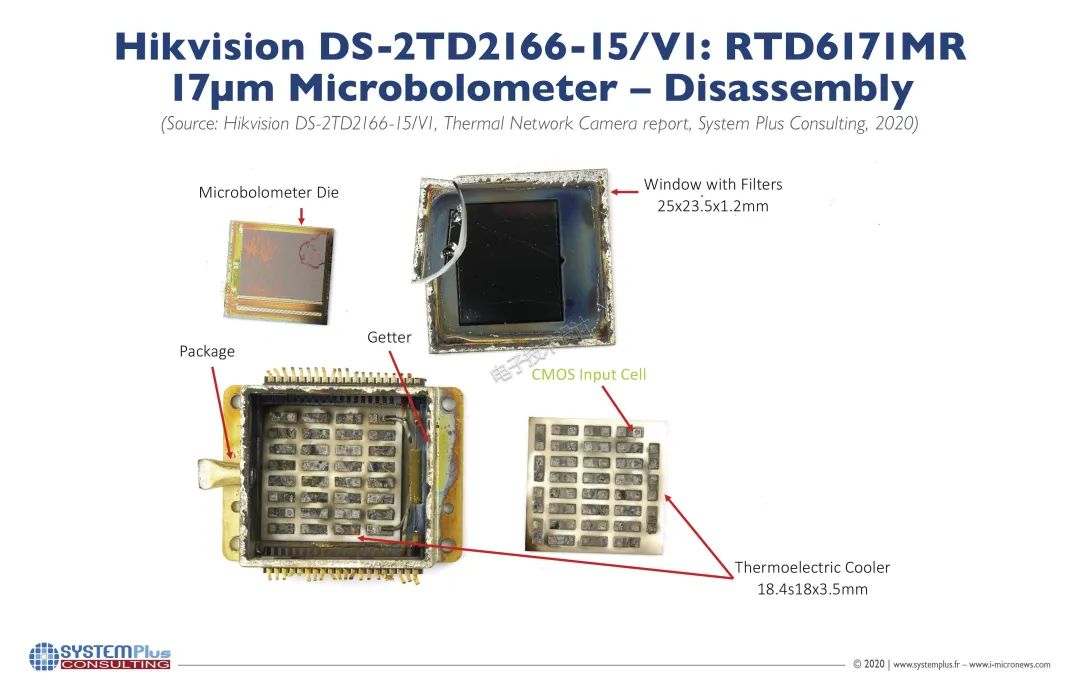

The uncooled sensor consists of a grid of resistive pixels, known as micro-radiation thermometers. Each incident radiation on the absorbing element causes its temperature to rise above the resistance temperature; the higher the absorbed power, the higher the temperature rise. The resistance value changes with the incident radiation (especially the infrared radiation that raises the surface temperature). Each pixel is represented by a CMOS input unit (Readout Integrated Circuit – ROIC), processed through the conditioning circuit to generate images on a computer or monitor via the FPGA (Figures 6 and 7). The structure of micro-radiation thermometers can typically be optimized to achieve higher sensitivity in the 8~14µm spectral band. The sensor used in Hikvision DS-2TD2166-15/V1 is IRAY RTD6171MR, with a 640×512 pixel array (17μm pitch), 60Hz analog output, and is a surface mount device.

Figure 6: Micro-radiation thermometer IRAY RTD6171MR. (Image source: System Plus Consulting)

Figure 7: Disassembled RTD6171MR 17µm micro-radiation thermometer. The sorbent significantly reduces outgassing, keeping the interior of the package at low pressure. (Image source: System Plus Consulting)

The physical characteristics of micro-radiation thermometers summarized by System Plus are as follows:

Chip Area:175.2mm² (13.6×12.8mm)

Pixel Area:96.4mm² (10.9×8.85mm)

Pixel Array:641×520

Active Pixel Array:640×512

Number of Pads:107

Wire Bonding:32 pairs of micro-radiation thermometers were analyzed, finding that there is a reflector beneath the absorbing material that contacts the substrate, which can redirect stray light, optimizing the signal. The absorbing material is “suspended” on the substrate for thermal insulation, and the vacuum-sealed pixel grid enhances durability and reliability. Most micro-radiation thermometers used in thermal imaging cameras employ vanadium oxide as the absorbing material, as it provides good thermal contrast, ensuring images are more accurate and clearer.

For typical resistors, the impedance of vanadium oxide detectors is about 100kΩ, while the impedance of α-Si detectors is usually 30MΩ. Under these conditions, the Johnson noise voltage of vanadium oxide material is lower, resulting in less noise during measurements. The Johnson noise voltage depends on three conditions: resistance value, circuit bandwidth, and temperature.

The camera contains a temperature reference element, stabilized by the AD5645RBRUZ quad-channel 14-bit DAC with an on-chip reference voltage source and the MAX1978ETM+T temperature controller for the Peltier module.

Peltier batteries are inexpensive thermoelectric components used in applications such as power generation, refrigeration, and precise temperature control, keeping the object temperature constant at a set value. The operation of Peltier batteries is based on the thermoelectric phenomenon, which generates a voltage difference at the PN junction of two different metallic materials.

MAX1978 includes on-chip power FETs and thermal control loop circuits to minimize the use of external components while maintaining high efficiency. The ultra-low drift chopper amplifier keeps temperature stability at ±0.001°C. Temperature sensors are installed on the lens module, based on NTC/PTC thermistors. There is also a digital temperature sensor TMP75AIDRG4 that monitors the system (environment) temperature directly managed by the FPGA.

Unlike other types of infrared detection devices, vanadium oxide micro-radiation thermometers do not require cooling. Vanadium oxide exhibits different characteristics at different temperatures. Coated glass can block infrared radiation (rather than visible light) at certain specific temperatures, allowing the camera’s electronic components to perform pseudo-color processing and restoration of images in the electromagnetic spectrum.

Other Modules

The thermal imaging camera supports industrial interface RS232 transmission using the SP3232EEN-L interface IC, and also supports Ethernet transmission through RTL8201FI-VC-CG. The AC/DC power system on circuit board 6 (Figure 2) includes transient voltage suppression diodes (TVS) to prevent electronic circuits from suffering from transients and overvoltage, such as EFT (Electrical Fast Transients) and ESD (Electrostatic Discharge).

The thermal imaging camera also includes a PoE (Power over Ethernet) interface, supported by TI’s TPS2378DDDAR PoE high-power PD interface and TL2845BDR-8 current mode PWM controller. The TL2845BDR-8 current mode PWM controller provides all the functions needed to implement offline or DC-DC fixed frequency current mode control schemes with a minimal number of external components.

The internal switch resistance of TPS2378DDAR is low, only 0.5Ω, and the thermal performance of the PowerPAD package is improved, allowing the PoE system to continuously handle currents of up to 0.85A. Power over Ethernet (PoE) is a technology that transmits power over twisted pairs, with the device providing power referred to as power sourcing equipment (PSE), and the powered device referred to as powered device (PD). When the PD is connected to the PSE, the PoE standard specifies the inrush current flowing into the PD to prevent large current spikes. Additionally, the PoE standard provides an analog handshake (classification) between the PSE and PD to negotiate power.

This thermal imaging camera is supported by the HI3519 V111 SoC suitable for professional HD IP cameras, using H.265 video compression encoder along with advanced low-power technology and architectural design. The Hi3519 V101 utilizes hardware and algorithms to design various models of IP cameras and audio codecs, supporting 90° or 270° rotation and lens distortion correction. This SoC is supported by two pairs of 4Gb DDR4 memory and GD5F2GQ4UB9IGR NAND flash 2Mb SPI.

On circuit board 4 (Figure 2), there is an Intel Movidius MA2450 VPU running at a frequency of 933MHz, utilizing it for fast identification of objects and people, analyzing public crowd information, inspecting manufactured products, etc. Computer vision utilizes deep learning to form neural networks, guiding the system in image processing and analysis.

Various thermal imaging cameras with cooled and uncooled detectors dominate the market. Thermal imaging cameras with cooled sensors are more expensive, as modern cooled thermal imaging cameras integrate a low-temperature cooler into their image sensors.

By adopting micro-radiation thermometers, thermal imaging cameras can provide high accuracy at low costs. The camera measures the surface temperature of heated objects and projects it as an image onto the thermal imaging display.

Highlights

Using Mobile EMMC Flash to Modify USB Drives

Taiwan Semiconductor Manufacturing Company Faces Water Shortages, World Faces Chip Shortages

Interpretation: The Design Process of High-End PCB Boards

DIY a Digitally Controlled FM Transmitter

The Hidden Beauty of Electronic Components