This article is compiled from the NVIDIA lecture “Empower Your Industrial Edge AI Applications with NVIDIA Jetson“

(This is not a complete lecture, just selected slides we believe are key)

Let’s dive into the industrial aspects. What challenges exist in cognitive environments? Industrial applications need to consider various shock factors. For example, systems may experience bumps while on a delivery truck, encountering a certain degree of impact. There are also greater vibration requirements. For instance, tractors may drive on rugged terrain, experiencing more vibrations. Since these systems often need to operate under various climatic conditions, requirements for extreme and harsh environments must also be considered, from extreme cold to heat—imagine a tractor working on a hot farm. Typically, considerations for operational lifespan and product lifecycle requirements, as well as memory error correction needs, must also be taken into account.

What are some typical industrial applications? They include many of the contents you see here. Therefore, there is industrial manufacturing, where customers need more autonomy in their applications, as well as agricultural applications such as harvesting and construction, which need machinery to withstand heavy loads, cope with rugged terrain, and maintain continuous operation, regardless of varying temperatures. Farms need to harvest thousands of acres of crops across various terrains and carry fertilizers and herbicide sprayers. Construction sites have heavy equipment that must operate in various weather conditions. Logistics, aviation, and defense applications often need to withstand significant impacts, vibrations, temperatures, and longer operational lifespans and product lifecycles. For example, space applications require systems with radiation tolerance, and more recording drones that need to withstand extreme impacts, collisions, and vibrations while flying in harsh environments. In railway applications, high-speed trains generate vibrations, and the interaction between train wheels and tracks can also lead to additional intermittent vibrations and shocks. Transport companies use jets for object detection, accident prevention, and optimizing maintenance costs. Oil, gas, inspection, and mining applications have similar requirements to those we just discussed. For instance, mining trucks need to operate in open or extreme environments. In summary, these are many critical requirements.

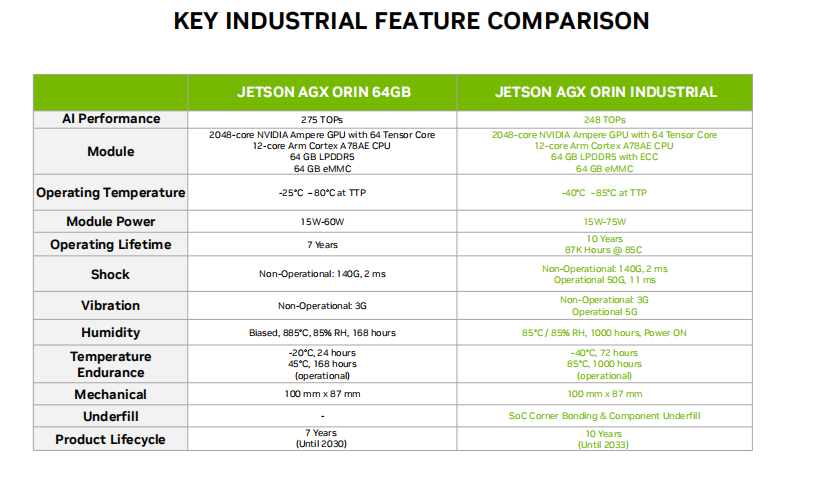

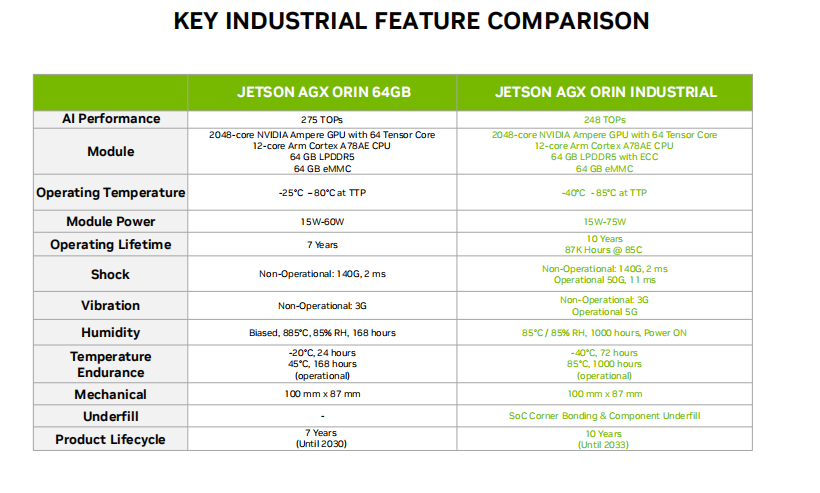

Introducing our Jetson AGX Orin industrial module. This module is now available and is designed to bring server-level performance to industrial applications. It offers up to 248 DL TOPS, thanks to the industrial module leveraging our own architecture. This brings our latest generation Ampere GPU. The industrial module is equipped with up to 2048 CUDA cores and 64 Tensor cores for sensor fusion aggregation and signal processing. In addition to the latest Ampere GPU, you will also get higher performance and more energy-efficient third-generation Tensor cores. Compared to previous architectures, we have also launched a new version of the Deep Learning Accelerator (DLA), which is higher performing and designed to accelerate your AI workloads. Besides, the industrial module also utilizes 12 Arm Cortex-A78 CPU cores, along with 64GB of memory and built-in ECC memory. The industrial module truly brings server performance to the edge. The industrial module not only leverages the Orin architecture but is also specifically designed with certain industrial features. This includes solutions to some of the challenges we just discussed. For example, mechanical shock support for operational shocks of up to 50G, operational vibrations of up to 5G, and an extended operating temperature range of -40°C to 85°C. Additionally, the industrial module has an extended operational lifespan of up to ten years and includes some component filling to ensure the module can operate in harsher environments and withstand a broader temperature range. Most importantly, the pin compatibility between the industrial and commercial modules is 100%, allowing you to design a carrier board to support both modules. The industrial module also supports all enabled security features, which are often necessary in industrial applications, including hardware trust roots, secure boot hardware, accelerated encryption, and support for encrypted storage and memory. The price for 1000 pieces is $2149 each. Most importantly, it is truly designed for industrial applications.

Above is a comparison of industrial and commercial specifications.

Above is a comparison of AGX Xavier industrial and AGX Orin industrial specifications.

Next, I will explain how to develop software on the AGX Orin industrial module.

The software stack on Jetson Orin Industrial supports various security features to protect your products deployed in the field.

Security features include secure boot to encrypt and sign the bootloader. We also introduced FTPM support information for the first time. FTPM can be used for device authentication as well as storing encryption keys and certificates. We also provide support for measured boot to ensure platform integrity. Support for secure storage also includes encrypted storage and encrypted memory. We provide opt on jetson as a trusted execution environment to ensure fully isolated execution to protect code and data. There is also a security engine to accelerate encryption operations. You can use hardware fuses to control different security aspects, such as configuring secure boot keys. We also support rollback protection that you can enable to prevent unreliable personnel from rolling your stack back to previous versions. With these security features, you can fully protect your platform and achieve security from edge to cloud.

Let’s quickly look at this year’s JetPack roadmap. JetPack 5.1 and 5.1.1 were released in January and March of this year. JetPack 5.1.2 is the final feature release of JetPack 5, which also supports the Jetson AGX Orin industrial module. After this version, JetPack 5 will not have new features or compute tracking updates. We will transition JetPack 5 to maintenance mode and will release a general version of Jet Pack 5 that only includes security fixes and critical bug fixes. Starting around October this year, we will release the first version of JetPack 6, which will be a new feature branch supporting Ubuntu 22.04. We will regularly release JetPack 6 and provide new features and compute stack updates. This is the project for the remaining time this year.

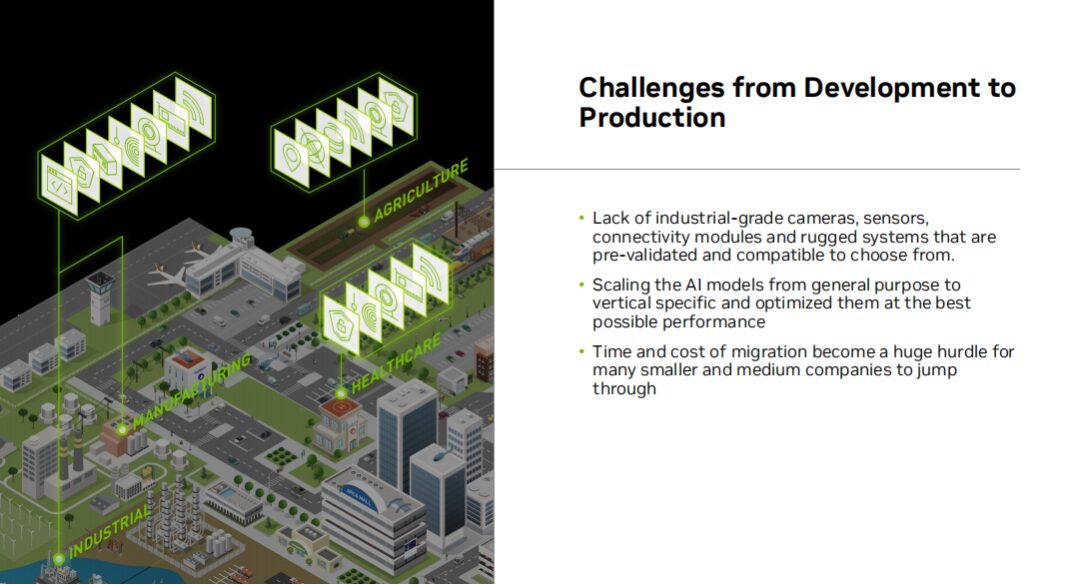

Before I delve into normal AI use cases, it is important to understand some key challenges from development to production. As often asserted, pushing production solutions to market requires a complete ecosystem. When we are in the early stages of the AI journey, one challenge faced is the lack of pre-validated and compatible industrial grid cameras, sensors, connectivity modules, and software stacks. Another challenge people often face is extending models from general to vertical-specific and truly optimizing them for best performance. Therefore, the time and cost of migration, along with the arduous design and system journey, become significant barriers that many small companies need to overcome.

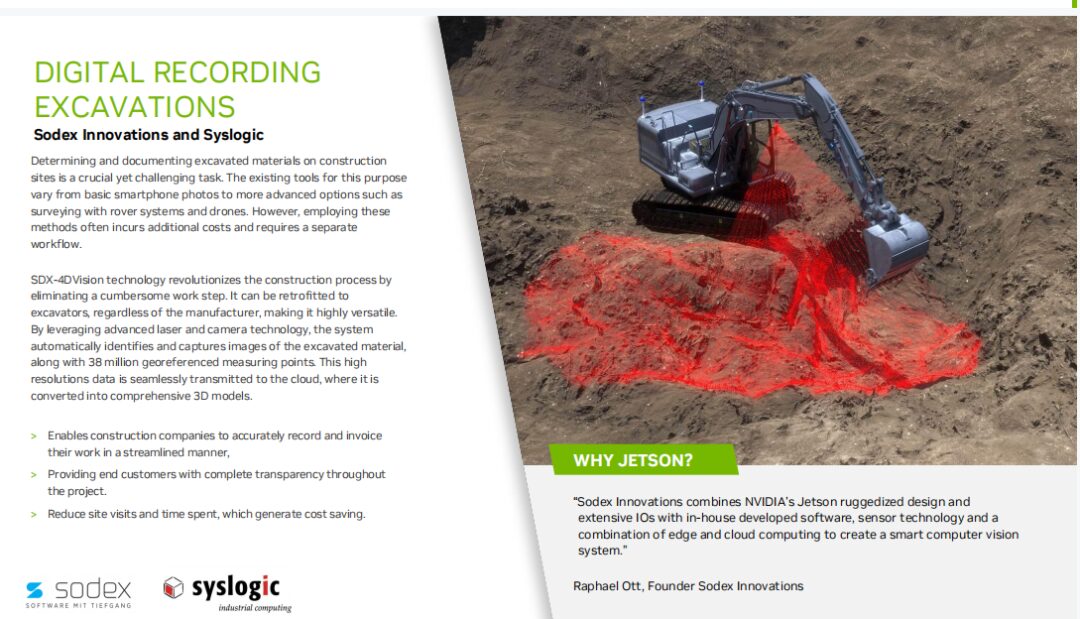

I will start with construction use cases. Sodex Innovation created a groundbreaking digital record solution for construction sites, simplifying the task of identifying and recording showcased materials. Unlike existing methods, which can be costly and require separate workflows, this technology can be retrofitted to any embodiment, making it highly versatile. It utilizes advanced laser and imaging technology to automatically identify and capture images of active materials, along with 38 million GE reference material points. The data is then transmitted to the cloud, where it is transformed into comprehensive 3D models. Benefits of this solution include accurate record-keeping and accelerated construction work, streamlining processes for construction companies, enhancing transparency for customers throughout the project, and of course, reducing site visits and saving time, thereby lowering costs. Jetsonpanter stated that sysLogic partnered with Sodex to provide reliable design and rich IO interfaces so they could focus on developing software technology and edge-to-cloud workflows.

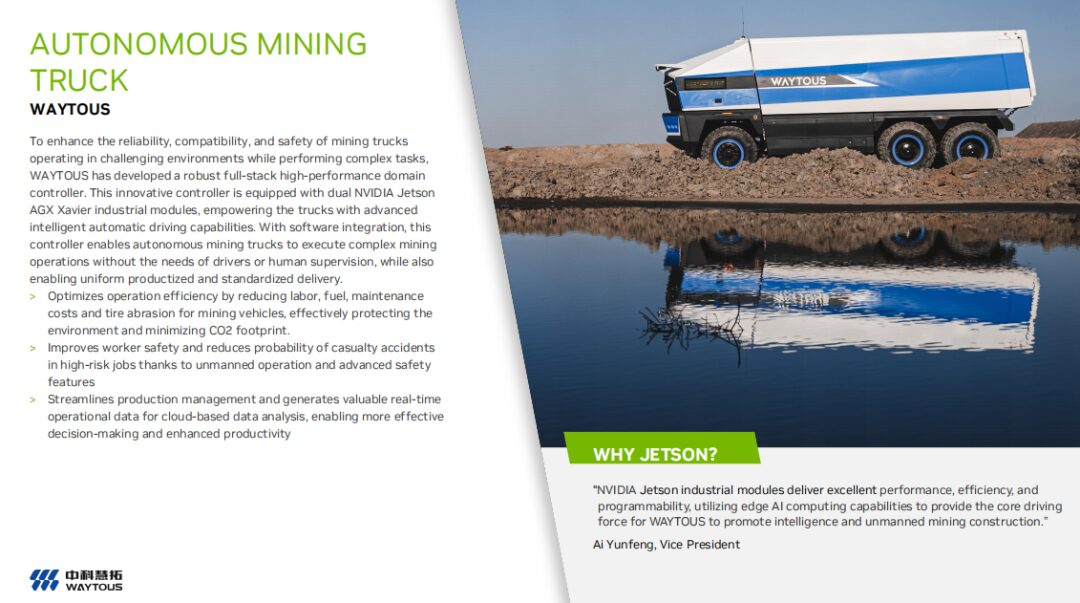

Waytous is a leading provider of autonomous solutions in the mining industry. They have developed a powerful high-performance domain controller that connects to four radars and a camera to enhance the reliability and safety of mining trucks. This controller is equipped with dual Nvidia Jetson Xavier industrial modules for autonomous driving, allowing many trucks to perform complex operations without human supervision. On the software side, the attendant deployed models for object detection and utilized 3D point clouds for obstacle detection. This solution effectively enhances worker safety and reduces the likelihood of casualties in high-risk environments. The NVDIA Jetson industrial model provides them with exceptional performance, efficiency, and programmability, while the dual Xavier design ensures they have enough AI computing power to achieve Level 4 autonomous mining capabilities.

Vulcan is the next-generation weeding tool. It was created by farmers and encapsulates cutting-edge computer vision into a lightweight, open tillage framework. Designed around NVIDIA Jetson Orin, the walking brain can process high-quality images and provide reliable weed control solutions for vegetables while moving at high speed. Thanks to high frame rate cameras, frames, and vision components designed by Jetson Partners, the walking mechanism can see each plant five to twenty times. This brings higher predictive accuracy and extremely high blade-driven precision. The end result is that farmers see labor and reduce the use of herbicides.

Now that so many use cases have been deployed on Earth, how about sending Jason to space? This is more challenging due to extreme environments, but it is certainly possible. We have only seen implementation solutions from space agencies like NASA and many commercial companies. One common feedback we hear from these customers is that it is much cheaper compared to traditional CPU solutions, reducing time-to-market from years to months. One example is Orbital Sidekick, which operates satellites with hyperspectral imaging payloads. Hyperspectral data is crucial for chemical fingerprint analysis, such as methamphetamine, soybeans, and many other hydrocarbons. By combining the AGX Xavier industrial module with specialized sensor designs, Orbital Sidekick can prepare to analyze or algorithmically process all sensor data in space, such as matching future molecular absorption models or even your network models. Detecting hydrocarbon leaks, intrusions, new mineral exploration hazards, waste monitoring, and even precision agriculture. Jetson GPU acceleration makes it a leader in democratizing aerospace application technologies.

Another outstanding space application is wildfire detection and monitoring. As we all have heard, wildfires have become the most common natural disaster in regions like California, Australia, and recently Canada, causing millions of dollars in infrastructure damage and significant carbon dioxide emissions. Orora Tech is a global intelligence service company that uses thermal intelligence to promote the sustainable development of the Earth. Their wildfire solution utilizes high-resolution thermal data from their Promory, a space sensor system trusted globally to revolutionize wildfire detection. Due to computing capabilities, this solution processes data in orbit to ensure that the data sent to Earth is optimized to include only useful images rather than returning raw information. This provides real-time alerts and insights to ensure community safety and protect our most valuable assets.