Today, let’s take a break from the hustle and simply write a bit.

In ECU design, the selection of power supply chips is an unavoidable topic, so let’s discuss the characteristics of PMICs and SBCs and summarize them briefly.

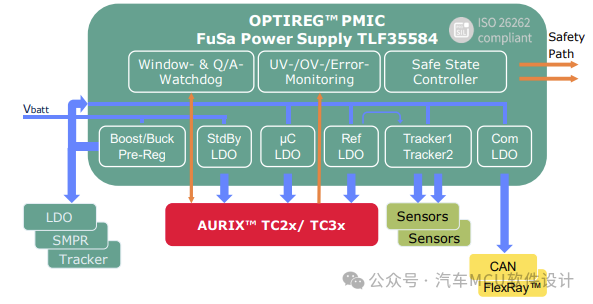

PMIC, short for Power Management Integrated Circuits, sounds very professional: power management. Its core task is to handle power conversion, distribution, and various anomaly monitoring (watchdog, voltage, etc.) for the system.

For example, the Infineon TLF35584 has multiple LDO outputs, such as StandBy-LDO (3.3V/5V @ 10mA), Communication-Supply (5V@200mA), µC-Supply (3.3V/5V@600mA), Reference-LDO (5V@ 150mA (±1%)), and 2x Tracker (5V@150mA). It also includes watchdog monitoring for the MCU, OV/UV error monitoring, and can work with chips to complete functional safety closed loops.

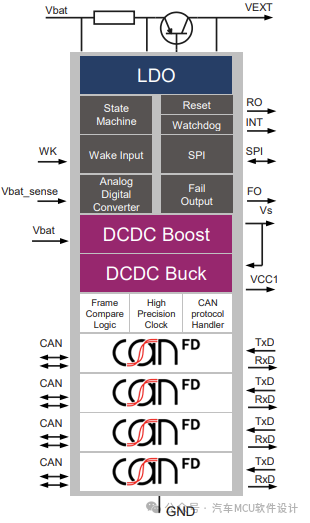

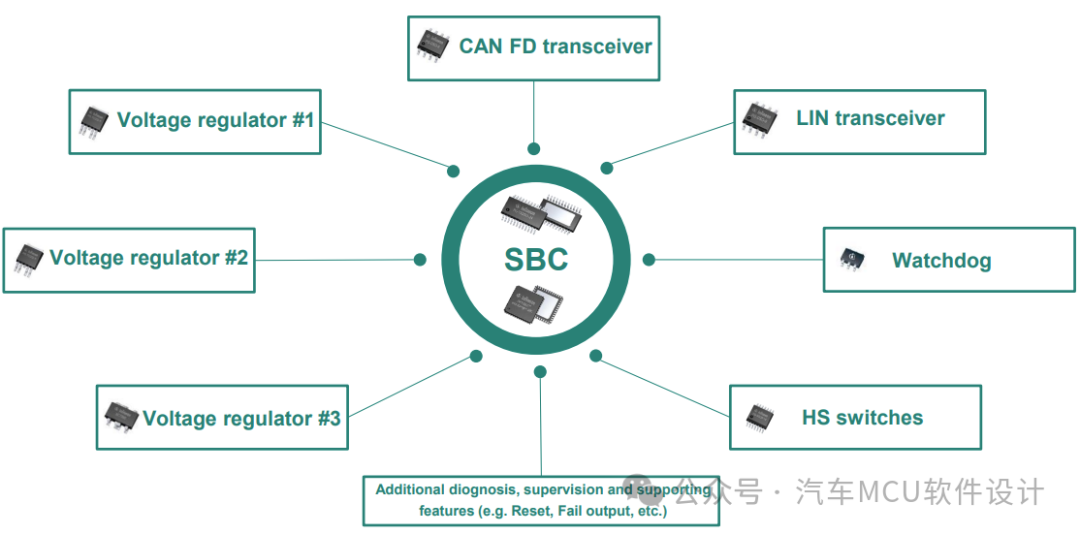

SBC, short for System Basic Chip, sounds like a mixed bag. In addition to providing power, it also integrates communication interfaces such as CAN and LIN.

For instance, the TLE9278(-3)BQX(V33) includes 4 CAN FD transceivers (capable of 5Mbps), one 5V/3.3V Buck, one Boost converter, battery voltage measurement, watchdog, etc.

From the above images, we can see that the advantage of SBCs lies in significantly increasing the integration of functional modules, reducing the number of components while decreasing PCB area usage, thus lowering system costs.

With such advantages, why not just choose SBC? Why is there still a need for PMICs?

This requires a specific analysis of the issues.

We all know that if a person has a broad knowledge base, the depth of certain knowledge cannot be too deep;

the same goes for chips. SBCs manage both power and network, which inevitably means they cannot be too broad or detailed, but PMICs focus solely on power, allowing them to provide better power supply services.

Therefore, if the system has different power supply requirements, such as needing precise management of multiple power supplies with different voltages, considering conversion efficiency, dynamic adjustments, and other complex power management functions, PMICs are more suitable;

if the system requires a single chip to integrate multiple basic functions, such as power, communication, monitoring, and diagnostics, to simplify circuit design, improve integration, and reliability; or if the system has high communication interface requirements, needing to communicate with multiple external devices and sensors with diverse communication protocols and interfaces, SBCs are the ideal choice.

Additionally, I checked the prices of these two components. On xx mall, the current price for TLF35584QVVS2XUMA2 is about 35 each, while TLE9278BQX is about 40 each. If ordered in bulk, the price will drop further, indicating a significant cost difference between the two.

Previous Reviews:

1. Selected Automotive Calibration

Automotive Calibration Technology – Detailed Explanation of Calibration ConceptsAutomotive Calibration Technology – The Past and Present of BypassLong Article: Automotive Calibration Technology – Overview of XCP

2. AUTOSAR Selected

AUTOSAR CryptoStack – What’s Included in the CSM JobAUTOSAR Diagnostic Stack Analysis (Part 1)AUTOSAR OS Overview (Part 1)

3. Automotive Cybersecurity Selected

Automotive Information Security – Common Password Algorithms for MCU StartupAutomotive Cybersecurity Solution Requirement AnalysisAutomotive Information Security – Common Automotive MCU Secure Startup SolutionsOverview of In-Vehicle Information Security Scenarios

4. Automotive Functional Safety Selected

Analysis of Functional Safety Mechanisms in TC3xx Startup

Functional Safety Closed Loop Concept of TC3xx SMU, PMIC, and Transceiver

5. Automotive Virtualization Selected

Initial Exploration of Automotive ECU Virtualization Technology (Part 1)

Automotive ECU Virtualization Technology (Part 2) – U2A Virtualization Function

6. Miscellaneous

Analysis of Flash Simulated EEPROM Principles

Long Journey: The Story of Domestic Substitution of Automotive MCU

Application Scenarios of Automotive MCUs and Progress of Domestic Substitution