In the wave of digital transformation, a profound revolution in automotive electronic and electrical architecture is brewing. The automotive industry is stepping into the intelligent era, following the path once taken by the PC and mobile phone industries. Automotive electronic systems, in-vehicle entertainment, human-vehicle interaction, and vehicle networking will play increasingly important roles, focusing on service orientation for drivers and passengers. The complexity of software will rise exponentially, requiring rapid iteration of vehicle functions. To cope with this system transformation, it is necessary to detach the corresponding software systems from the dispersed controllers and reintegrate them into the corresponding domain controllers.

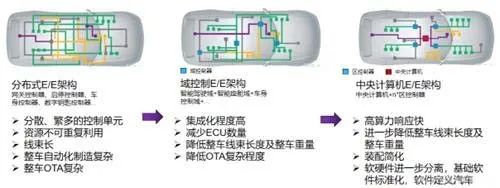

The automotive E/E architecture is gradually evolving from distributed to domain-controlled E/E architecture and central computing E/E architecture, progressively increasing integration, reducing the number of ECUs, simplifying the complexity of vehicle component assembly, and lowering the length and weight of the vehicle wiring harness; hardware and software are also gradually decoupling, and the basic software is becoming standardized to meet the architectural requirements of software-defined vehicles.

△ Automotive Domain Architecture Evolution

Following the major trend of moving from distributed to centralized systems, software and hardware must be decoupled. Tesla’s Model 3 was the first to transition from a distributed architecture to a domain-based centralized architecture, which is a key reason for its intelligent level being far ahead of many automakers.

01

Traditional Function Partitioning in Three Domain Centralized Systems

Unlike Tesla’s “location domain,” the specific division of functional domains varies among automotive manufacturers based on their design philosophies. For example, Bosch divides it into five domains: Power Train, Chassis, Body/Comfort, Cockpit/Infotainment, and ADAS (Advanced Driver Assistance Systems). This represents the classic five-domain centralized E/E architecture. Some manufacturers further integrate the original power, chassis, and body domains into a vehicle control domain, forming a three-domain centralized E/E architecture, namely: Vehicle Domain Controller (VDC), ADAS/AD Domain Controller (ADC), and Cockpit Domain Controller (CDC). Volkswagen’s E3 architecture and Huawei’s CC architecture belong to this three-domain centralized E/E architecture.

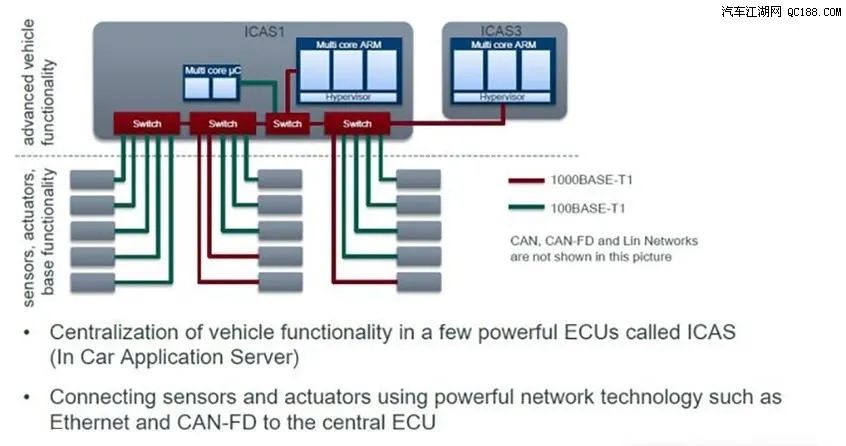

The E3 electronic architecture proposed by Volkswagen is actually a breakthrough from the previous Delphi functional domain. However, unlike Tesla, which divides by left, center, and right positions, it focuses more on simplifying and centralizing based on Delphi’s functional domain. The E3 architecture’s E/E architecture includes three intelligent domain controllers (ICAS): Vehicle Control Domain (ICAS1), Intelligent Driving Domain (ICAS2), and Intelligent Cockpit Domain (ICAS3). Currently, ICAS1 and ICAS3 have been developed and are equipped in new vehicles like ID.3 and ID.4, while ICAS2 is still under development, meaning high-level assisted driving will take some time.

△ Volkswagen E3 Body Domain Architecture

△ Volkswagen E3 Body Domain Architecture

Currently, the ICAS1 microprocessor (MPU) in the E3 architecture uses Renesas Technology’s R-CarM3 solution with a computing power of 30,000 DMIPS. The scope of ICAS1 does not differ significantly from traditional automotive functions, including high-voltage power supply, low-voltage power supply, mileage data, fatigue recognition, driving profiles, etc. Volkswagen has matured in the hardware-software integration in this field, with the challenge being to connect ICAS1 to the network and integrate these traditional functions with the intelligent cockpit, which is a completely new interaction model that Volkswagen has not previously had.

△ Huawei’s CC Architecture

Source: Gaishi Automotive

Huawei’s CC architecture proposes a structure of distributed networks plus domain controllers, dividing the vehicle into three main parts: driving, cockpit, and overall vehicle control, and launching three major platforms: MDC Intelligent Driving Platform, CDC Intelligent Cockpit Platform, and VDC Overall Vehicle Control Platform. Huawei aims to build each of these three platforms into an ecosystem by providing chips and operating systems.

In the VDC Overall Vehicle Control Platform, which is the intelligent electric platform, Huawei will develop an MCU and an overall vehicle control operating system, opening this operating system to automakers so they can differentiate their overall vehicle control based on the VDC platform.

02

Body Domain Partitioned by Location Rather than Function Achieves Software-Defined Body

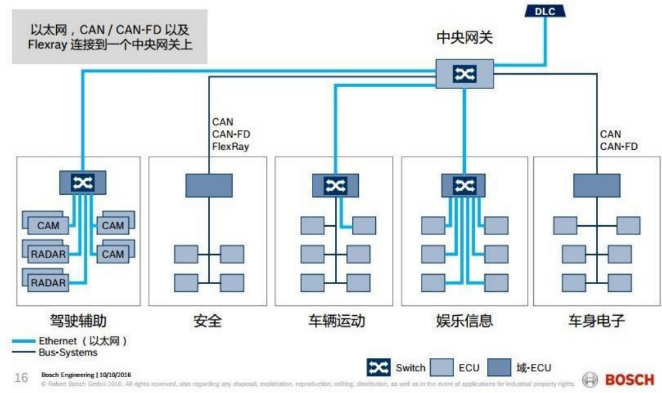

Similarly, Tesla’s approach to domain controllers is always more advanced. For example, as one of the first companies to propose domain controllers, Bosch’s approach is still influenced by traditional modular electronic architecture. In 2016, it proposed a five-domain architecture based on functional partitioning, integrating the vehicle’s ECUs into five domains: driving assistance, safety, vehicle dynamics, entertainment information, and body electronics, with connections between different domains through domain controllers and gateways.

As can be seen from the figure, although Bosch’s solution greatly reduces the number of ECUs, the internal complexity of each domain still requires relatively complex wiring connections, and the overall vehicle wiring complexity remains high. However, Tesla has redefined the concept of “domain,” breaking down the barriers between functions and traditional vehicle architecture design thinking, equipping the vehicle with a computer, and directly transitioning to a computer-based and area-oriented architecture.

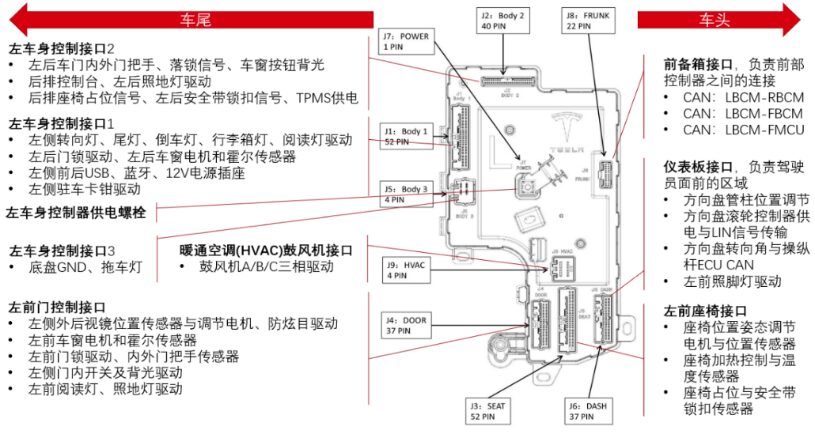

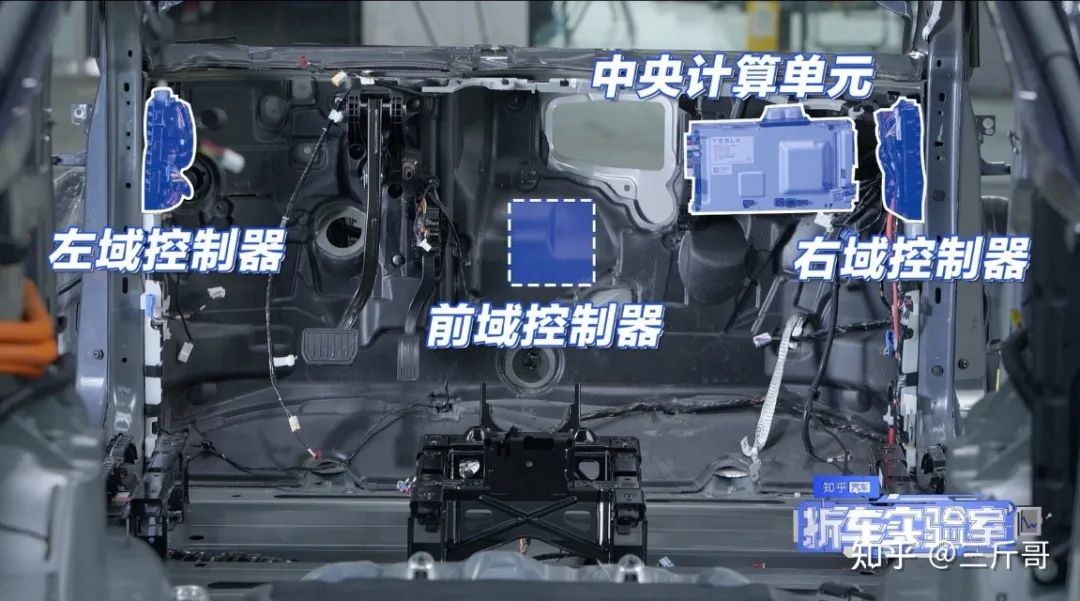

△ Tesla Model 3’s Three Body Controllers

Tesla Model 3 was released in 2016 and went into mass production in 2017, almost at the same time as Bosch’s report. From Model S to Model 3, Tesla no longer uses a functional domain electronic architecture but a location domain: namely, the central computing domain, left body control domain, and right body control domain, where the central computing domain is responsible for the infotainment system, driving assistance system, and in-vehicle communication connection. The left body control domain is responsible for body convenience systems, including steering, assistance, and braking, while the right body control domain is responsible for chassis safety systems, power systems, and thermal management. According to Tesla’s approach, each controller should be responsible for controlling its nearby components rather than all similar components in the vehicle, maximizing the reduction of body wiring complexity and fully utilizing the versatility and high performance of today’s chips. Data from Model S to Model 3 shows that the wiring harness length of Model 3 decreased from 3 kilometers to 1.5 kilometers, and the number of components dropped from 30,000 to 10,000, reflecting the advantages of low cost and ease of manufacturing.

03

Characteristics and Advantages of Tesla’s Front-Left and Right Body Domains

Firstly, the front body domain controller is located in the front compartment, which theoretically encounters a higher probability of collision, thus adopting an aluminum protective shell, while the left and right body domain controllers, being inside the passenger compartment, have a lower probability of external collisions, and their protective shells are made of plastic.

△ Model 3 Front Body Domain (FBCM)

The primary function is to serve as a power source, supplying power to the ESP body stability system, EPS power steering, and other controllers. The benefits are obvious; firstly, it allows for controllable power supply to each controller, monitoring the power consumption of each ECU, and completely cutting off power to certain ECUs during high static power consumption; secondly, it eliminates the need for traditional distributors and fuse boxes, using MOSFETs instead, which enhances the reliability of the power supply section. The second major function is logical control, which includes traditional BCM functions such as: electric window control, central locking control, remote anti-theft, lighting system control, electric mirror heating control, instrument backlight adjustment, and power distribution.

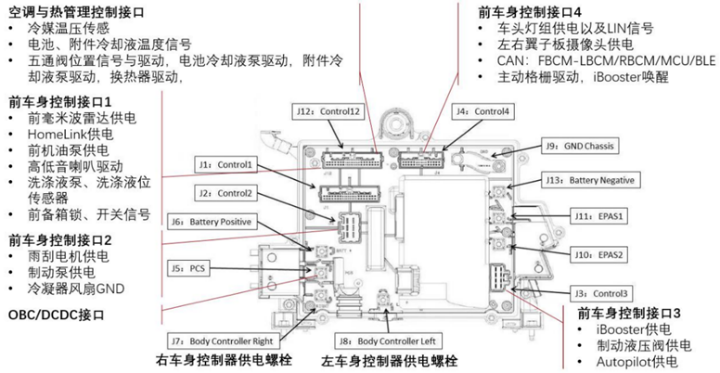

Upon opening the front body domain controller shell, one can see 13 connectors distributed on top, including control-related connectors and power distribution-related connectors. In the front body controller, we can see that Tesla has largely replaced traditional electrical components with semiconductor components.

△ Tesla Model 3 Front Body Controller (FBCM) Interface Function and Layout

△ Tesla Model 3 Left Body Domain (LBCM)

Source: Automotive Young General

The left body controller is located in front of the driver’s left calf, aligned with the vehicle’s longitudinal layout, and uses a plastic shell to save costs. The left body controller is responsible for managing the left side body components in the cockpit and rear, fully reflecting the guiding principle of minimizing wiring length to control costs. The left body controller is mainly responsible for several types of electrical distribution and control, including the left side: dashboard, steering wheel position adjustment, footwell lights, left front seat, left rear seat, front door, rear door, seat, tail lights, etc.

The left body controller has nine connectors, covering all load ranges controlled by the left body controller. However, it is worth noting that the loads here are all on the left side, while the right side loads are managed by the right body controller.

Source: Automotive Young General, Zhihu @Cold Winter Melon, CITIC Securities Research Department

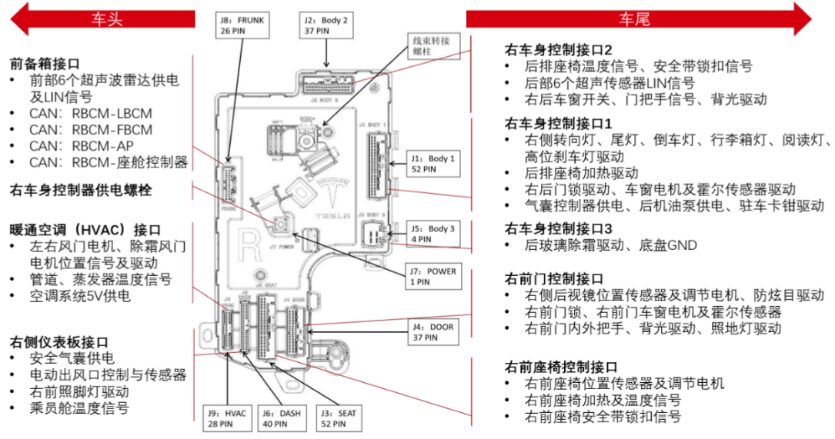

The right body controller is basically symmetrical to the left body controller, with a similar interface layout but some differences. The right body domain is responsible for ultrasonic radar and air conditioning, while the right body also undertakes more tail control functions, including the high-mounted brake light and rear oil pump control.

△ Tesla Model 3 Right Body Controller (RBCM) Interface Function and Layout

△ Tesla Model 3 Right Body Controller (RBCM) Interface Function and Layout

Source: Automotive Young General, CITIC Securities Research Department

04

Tesla’s Body Domain Concept and Future Direction

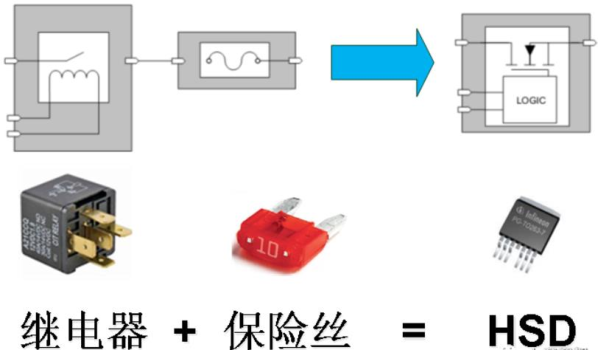

The body domain is the area where Tesla differs the most from traditional vehicles. Traditional vehicles use numerous ECUs, while Tesla achieves overall vehicle control through three domains. Although both are moving towards domain controllers, Tesla does not adopt Bosch’s functional domain approach, but rather completely partitions by area, standardizing hardware as much as possible and showcasing the idea of defining vehicles through software. In addition, Tesla also chips many electrified components, such as using a large number of HSD chips in the body domain to replace relays and fuses, improving reliability and enabling programming, which better realizes the software-defined vehicle concept.

△ HSD chips can replace relays and fuses

Source: Jiuzhang Intelligent Driving

△ Tesla Model Y Compared to Volkswagen ID.4 and Ford Mach E Electronic and Electrical Architecture

△ Tesla Model Y Compared to Volkswagen ID.4 and Ford Mach E Electronic and Electrical ArchitectureSource: Munro & Associates, 3IS, Ping An Securities Research Institute

Another development trend reflected in Tesla’s body controllers is the continuous integration and cost reduction of components. The body controller of Model Y has already differed from the first generation Model 3, with a noticeable increase in component density. For instance, the spacing of MOSFETs (the small black squares in the image) in Model Y is significantly smaller than in Model 3. Thus, under the same area, the controller can accommodate more components and integrate more functions. The increase in components further enhances the integration of the controller. The result of increased integration is a further simplification of the automotive electronic and electrical architecture and a reduction in automotive electronic costs.

△ Model Y Controller Component Spacing is Noticeably Smaller

△ Model Y Controller Component Spacing is Noticeably SmallerThe continuous integration of hardware also creates conditions for the integration and development of software. In the traditional automotive industry chain, the independence of different functions is very high, and each function’s ECU comes from different suppliers, making it difficult to work together. However, Tesla integrates a large number of ECUs, keeping only the actuators responsible for various functions on the body while unifying the main control functions in the domain controllers, using a small number of MCUs and relying more on software to achieve functional control. For example, Tesla Model 3’s left and right body domain controllers each have three MCUs, significantly reducing the number, and different control functions interact in software, allowing for greater collaborative innovation space. Moreover, Tesla can collect data from software control and continuously improve control functions, enhancing user experience.

(Originally published in “Southwest Automotive Information”, September 2022)