0 Introduction

Electric vehicles are efficient, clean, and sustainable transportation tools of the 21st century. They are also an important solution to the two prominent issues of the energy crisis and environmental pollution. The main power source for electric vehicles is the battery, which is also a key factor limiting the development of electric vehicles. Currently, the technology for electric vehicles has gradually matured, and a single charge can generally meet the transportation mileage requirements in urban areas. However, large-scale application and the issue of driving range are still not ideal, and there are many challenges such as long charging times, low charging efficiency, and faults in the charging control system. Therefore, developing an intelligent on-board charging device is an effective method to extend driving range and address the long charging time issue under limited battery energy.

1 Intelligent On-Board Charging System

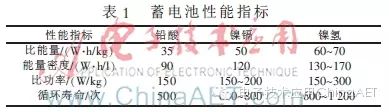

The development of the intelligent on-board charging system aims to achieve smart charging of nickel-hydrogen battery packs within a short time. Before charging, the system first uses the maximum voltage method to detect the initial state of the battery pack’s voltage, determining the initial state of charge, terminal voltage, and internal temperature of the battery pack. Based on the initial state of the battery, the charging voltage, current, and time for the charging system are set. During the charging process, real-time monitoring and sampling of battery parameters are conducted. By combining the performance indicators of the battery parameters (as shown in Table 1), the ARM processor can analyze the performance status of the current battery and its connection lines, as well as the load driving capability, displaying the analysis results on the LCD touchscreen.

The quality of the battery and charging control technology are the two main factors determining the lifespan of the battery. Over the years, continuous research and improvement have been made on charging control technology. Currently, popular charging methods include pulse charging, constant current and constant voltage charging, and positive-negative pulse charging. The charging method used in this article is positive-negative pulse charging: charging the battery with positive pulses—short time negative pulse discharge—short intermittent time. The positive-negative pulse charging method can accelerate the charging speed, absorb heat, and eliminate battery polarization.

2 Hardware Design of the Intelligent On-Board Charging System

2.1 ARM Hardware System

Embedded systems are characterized by minimal software code, high automation, and fast response speed. They are currently a popular research area and are widely used in industries such as network communication, industrial control, and automotive electronics. As shown in Figure 1, the intelligent on-board charging system uses the S3C6410 processor as the control core, consisting of a data monitoring module and a display module. The dashed box includes the JTAG, UART, Flash, and SDRAM, forming the minimum ARM system. Based on the actual needs of the intelligent on-board charging system, modules such as touchscreen display, data monitoring, and auxiliary circuits are expanded on the minimum system. The use of the LCD touchscreen better realizes human-computer interaction and intelligence.

2.2 Main Charging Circuit

The main charging circuit converts fluctuating AC mains power into stable DC power, and its design directly affects the performance of the entire charging system. As shown in Figure 2, the main charging circuit of the intelligent on-board charging system consists of two full-bridge circuits, a full-bridge inverter circuit made up of four insulated gate bipolar transistors (IGBTs), and a high-frequency transformer. The 220 V mains power first goes through a full-bridge circuit and a large capacitor for rectification and filtering to obtain DC power. However, at this point, the DC power has a large ripple and cannot be used as a charging source; it needs to be converted back into adjustable high-frequency AC power through the full-bridge inverter circuit. This is then coupled to the secondary side via the high-frequency transformer, and after full-bridge rectification and inductive-capacitive filtering, a DC voltage with very little ripple is obtained, which serves as the final charging power source.

3 Software Design of the Intelligent On-Board Charging System

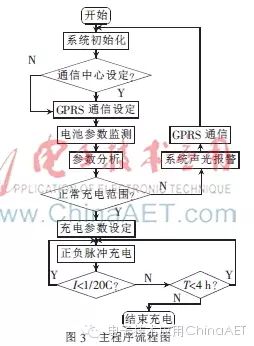

The software of the intelligent on-board charging system is mainly divided into five functional parts: battery parameter monitoring tasks (voltage data monitoring, current data monitoring, temperature data monitoring), data processing and storage tasks, UART communication tasks, abnormal alarm tasks, and GPRS communication tasks. The main program flowchart is shown in Figure 3.

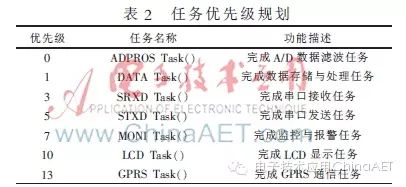

Before executing tasks in the charging system, the priority of system tasks is first planned to prevent chaos from multiple task executions. The priority of tasks is determined based on their criticality, relevance, urgency, complexity, and expediency, as shown in Table 2.

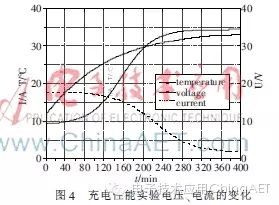

4 Experimental Results Analysis

The main charging target of the intelligent on-board charging system studied in this article is the nickel-hydrogen battery. A simulation test was conducted using 12 individual nickel-hydrogen batteries. During the charging process, the changes in charging voltage, current, and internal temperature of the battery were continuously monitored, with the monitoring results shown in Figure 4. The charging time, energy input, and charging efficiency were compared with the constant current and constant voltage charging method, with the results shown in Table 3. From the monitoring results, it can be seen that compared to the constant current and constant voltage charging method, the positive-negative pulse charging method effectively shortened the charging time and improved charging efficiency, making it very suitable for charging electric vehicles powered by nickel-hydrogen batteries.

5 Conclusion

This article constructs the software and hardware platform for the intelligent on-board charging system of electric vehicles using the Samsung S3C6410 processor as the system control core, analyzing the ARM hardware structure and the main charging circuit. The positive-negative pulse charging method has been employed to protect and extend the lifespan of nickel-hydrogen batteries. The charging termination control method combines timing control, temperature control, and maximum voltage control to effectively prevent overcharging. Based on the existing charging system, this intelligent on-board charging system performs real-time monitoring of battery parameters, enhancing the stability and safety of the charging system. Experimental results demonstrate that this intelligent on-board charging system has significant practical application value, providing favorable conditions for the popularization of electric vehicles.

Long press the fingerprint recognition QR code in the image to receive a free Xiaomi smart socket!