This article takes the ZMC408CE motion controller with a dedicated handwheel interface from Motion Technology as an example to introduce the handwheel, its functions and principles, the wiring of the controller’s handwheel interface, and the configuration of the handwheel program.

2.Use the “Magnification Selection Knob” to choose the appropriate movement magnification (×1/×10/×100);

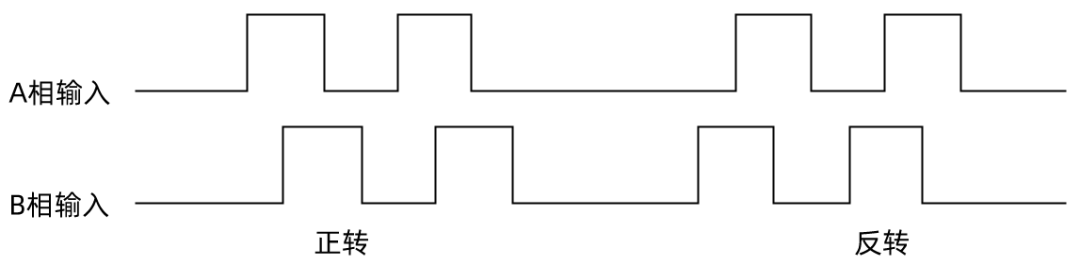

3.Rotate the “handwheel handle” to move the coordinate axis. Clockwise rotation is forward movement, counterclockwise rotation is backward movement, and the speed of rotation can control the speed of the coordinate axis;

4. The “Emergency Stop” button stops the handwheel movement immediately;

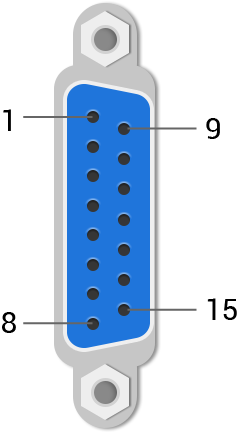

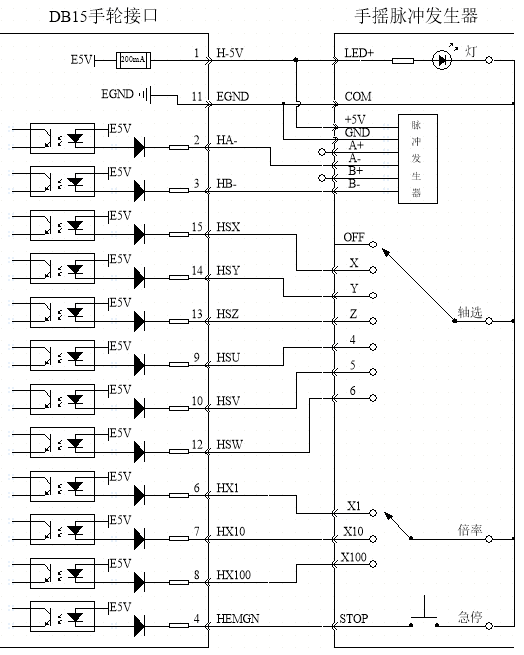

5. The controller’s handwheel interface is a dual-row standard DB15 female connector, requiring the handwheel connector to be a dual-row standard DB15 male connector.

Handwheel interface diagram

1. Hardware Introduction

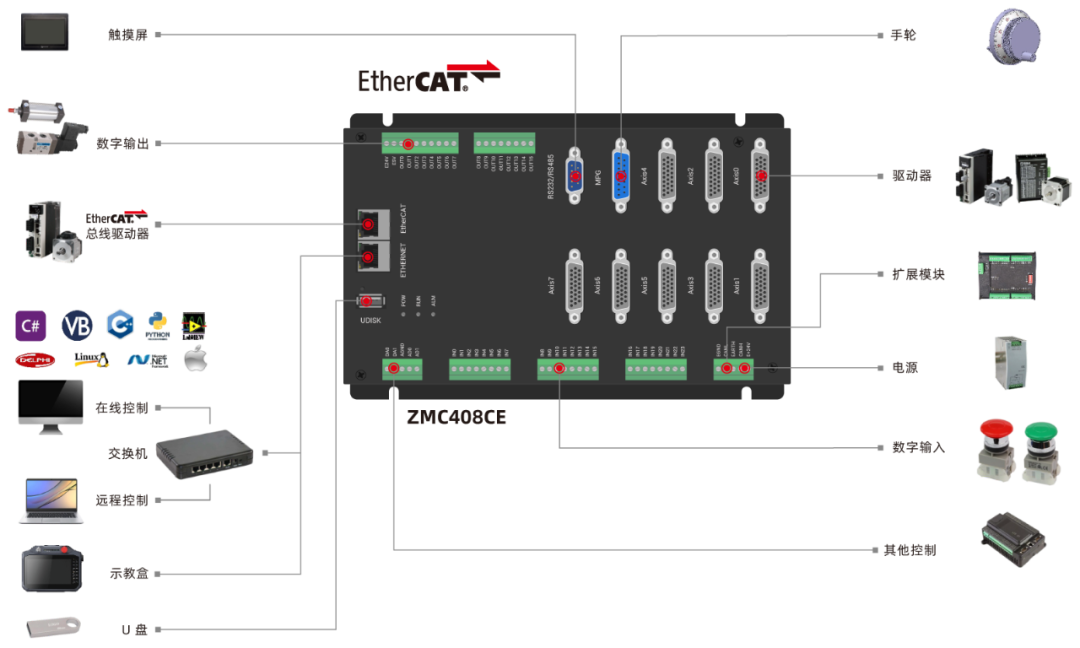

The case uses the ZMC408CE motion controller, which has a dedicated handwheel interface.

The ZMC408CE is a high-performance EtherCAT bus motion controller launched by Motion Technology, utilizing advanced FPGA technology for hardware position comparison output and precise output functions, ensuring outstanding performance and stability in continuous trajectory processing, as well as real-time dynamic data capture for more precise control and improved production efficiency and quality.

2. One-dimensional/two-dimensional/three-dimensional, multi-channel vision flying capture, high-speed and high-precision;

3. Position synchronous output PSO, precise control over glue dispensing and laser energy control during continuous trajectory processing;

4. Multi-axis synchronous control, independent control of multiple coordinate systems;

5. EtherCAT synchronous cycle as fast as 125us;

6. EtherCAT bus and pulse axis mixed interpolation;

7. Linear interpolation, arbitrary space circular interpolation, spiral interpolation, spline interpolation, etc.;

ZMC408CE Video Introduction

|

Interface |

Pin Number |

Signal |

Description |

|

|

1 |

H-5V |

5V power output positive, dedicated to powering the handwheel |

|

2 |

HA- |

Encoder A phase signal (IN40) |

|

|

3 |

HB- |

Encoder B phase signal (IN41) |

|

|

4 |

HEMGN |

Emergency stop signal (IN51) |

|

|

5 |

NC |

Unused |

|

|

6 |

HX1 |

Select X1 magnification (IN42) |

|

|

7 |

HX10 |

Select X10 magnification (IN43) |

|

|

8 |

HX100 |

Select X100 magnification (IN44) |

|

|

9 |

HSU |

Axis select 3 (IN48) |

|

|

10 |

HSV |

Axis select 4 (IN49) |

|

|

11 |

EGND |

5V power output negative, common signal |

|

|

12 |

HSW |

Axis select 5 (IN50) |

|

|

13 |

HSZ |

Axis select 2 (IN47) |

|

|

14 |

HSY |

Axis select 1 (IN46) |

|

|

15 |

HSX |

Axis select 0 (IN45) |

|

|

Note: 1. The 5V power output is only for powering the handwheel, do not use it to power other devices. 2. All signals in this interface are digital input signals, numbered IN (40-51). |

2. After powering on, please select any of the Ethernet, RS232, or RS485 interfaces to connect to ZDevelop;

BASE(目标轴号) 'Remap axis numberATYPE(目标轴号)=0 'Set axis type to 0BASE(8) 'Initial axis number of handwheel interface 8 (invalid)ATYPE(8)=0 'Set initial axis type of handwheel interface to 0AXIS_ADDRESS (目标轴号)= (-1<<16)+8 'Bind initial axis number 8 to target axis numberATYPE(目标轴号)=3 'Set handwheel axis type to orthogonal encoder typeSample program below, running the program below will enable control of the handwheel.

'Different controller models have different handwheel axis numbers, magnifications, and axis selection IN numbers, refer to the controller's user manual. This example uses the controller model ZMC408CE' Different handwheel control axes can vary; this example controls 6 axes'Axis number settingsglobal const axis_X = 0 'X axisglobal const axis_Y = 1 'Y axisglobal const axis_Z = 2 'Z axisglobal const axis_U = 3 'U axisglobal const axis_V = 4 'V axisglobal const axis_W = 5 'W axisglobal const def_R = 8 'Default axis number for handwheelglobal const axis_R = 10 'Remapped axis number for handwheel 'Magnification IN number settingsconst io_Handlow = 42 '1 magnificationconst io_Handmid = 43 '10 magnificationconst io_Handhigh = 44 '100 magnification 'Axis selection IN number settings const io_HandX = 45 'Handwheel X axisconst io_HandY = 46 'Handwheel Y axisconst io_HandZ = 47 'Handwheel Z axisconst io_HandU = 48 'Handwheel U axisconst io_HandV = 49 'Handwheel V axisconst io_HandW = 50 'Handwheel W axis 'Emergency stop signal IN number settingsconst io_HandEMGN = 51 'Emergency stopglobal dim conflag 'Handwheel connected axis flagconflag = -1ATYPE(def_R) = 0 'Restore axis 8 axis typeATYPE(axis_R) = 0 'Restore axis 10 axis typeAXIS_ADDRESS(axis_R) = (-1<<16)+ def_R 'Map MPG handwheel axis address to axis 10ATYPE(axis_R) = 3 'Set handwheel axis type to orthogonal encoder typeUNITS(axis_R) = 1 'Set handwheel axis pulse equivalent pulse to unitWhile 1 if in(io_handX) = on then if in(io_handlow) = on then connect(1, axis_R) axis(axis_X) 'Link to axis X, magnification 1 elseif in(io_handmid) = on then connect(10, axis_R) axis(axis_X) 'Link to axis X, magnification 10 elseif in(io_handhigh) = on then connect(100, axis_R) axis(axis_X) 'Link to axis X, magnification 100 endif conflag = axis_X elseif in(io_handY) = on then if in(io_handlow) = on then connect(1, axis_R) axis(axis_Y) elseif in(io_handmid) = on then connect(10, axis_R) axis(axis_Y) elseif in(io_handhigh) = on then connect(100, axis_R) axis(axis_Y) endif conflag = axis_Y elseif in(io_handZ) = on then if in(io_handlow) = on then connect(1, axis_R) axis(axis_Z) elseif in(io_handmid) = on then connect(10, axis_R) axis(axis_Z) elseif in(io_handhigh) = on then connect(100, axis_R) axis(axis_Z) end if conflag = axis_Z elseif in(io_handU) = on then if in(io_handlow) = on then connect(1, axis_R) axis(axis_U) elseif in(io_handmid) = on then connect(10, axis_R) axis(axis_U) elseif in(io_handhigh) = on then connect(100, axis_R) axis(axis_U) endif conflag = axis_U elseif in(io_handV) = on then if in(io_handlow) = on then connect(1, axis_R) axis(axis_V) elseif in(io_handmid) = on then connect(10, axis_R) axis(axis_V) elseif in(io_handhigh) = on then connect(100, axis_R) axis(axis_V) endif conflag = axis_V elseif in(io_handW) = on then if in(io_handlow) = on then connect(1, axis_R) axis(axis_W) elseif in(io_handmid) = on then connect(10, axis_R) axis(axis_W) elseif in(io_handhigh) = on then connect(100, axis_R) axis(axis_W) endif conflag = axis_W elseif conflag <> -1 then 'Cancel connection cancel(2) axis(conflag) conflag = -1 elseif in(io_HandEMGN) = off then RAPIDSTOP(2) endif WendThis time, Motion Technology shared the application of the EtherCAT motion controller in CNC handwheel tracking, here.

For more exciting content, please follow the “Motion Assistant” public account. For related development environments and example code, please consult Motion Technology sales engineers: 400-089-8936.

Review Previous Content

It’s time to announce the winners! Fans who participated in the “Motion Control System Application and Practice” book giveaway, look here

Book Giveaway! Fully Autonomous IDE of “Motion Control System Application and Practice”

Application of High Flexibility SS Acceleration and Deceleration Curve in Lithium Battery Welding

What are the differences between EtherCAT and Ethernet, and what does communication cycle mean?

In the era of Industrial Ethernet, how to choose a bus motion controller?

PSO Visual Flying Capture and Precise Output of Motion Controller C++ Development (III): Two-Dimensional/Three-Dimensional/Multi-Axis PSO Output

PSO Visual Flying Capture and Precise Output of Motion Controller C++ Development (II): Multi-Axis PSO Equidistant/Cyclic Output

PSO Visual Flying Capture and Precise Output of Motion Controller C++ Development (I): Single Axis PSO

Eight-Channel PSO of Motion Controller Visual Flying Capture and Precise Output

Windows Real-Time Motion Control Soft Core (VII): LOCAL High-Speed Interface Testing with Labview

Windows Real-Time Motion Control Soft Core (VI): LOCAL High-Speed Interface Testing with Matlab

Windows Real-Time Motion Control Soft Core (V): LOCAL High-Speed Interface Testing with VC6.0

Windows Real-Time Motion Control Soft Core (IV): LOCAL High-Speed Interface Testing with VB.NET

Windows Real-Time Motion Control Soft Core (III): LOCAL High-Speed Interface Testing with C++

Windows Real-Time Motion Control Soft Core (II): LOCAL High-Speed Interface Testing with Qt

Windows Real-Time Motion Control Soft Core (I): LOCAL High-Speed Interface Testing with C#

Open Laser Galvo Motion Controller: C++ Rapid Call Graphical Library Application

Open Laser Galvo Motion Controller: C++ Galvo Correction Methods and Implementation

Open Laser Galvo Motion Controller: C++ Rapid Development

Open Laser Galvo Motion Controller (V): ZMC408SCAN Fiber Laser Energy Control

Open Laser Galvo Motion Controller (IV): ZMC408SCAN Galvo Control for Fiber Laser Processing

Open Laser Galvo Motion Controller (III): ZMC408SCAN Axis Control for Fiber Laser Processing

Open Laser Galvo Motion Controller (II): ZMC408SCAN Laser Interface and Control

Open Laser Galvo Motion Controller (I): ZMC408SCAN Interface and Functions

PSO Position Synchronous Output of Motion Controller (III): High Precision Equidistant Two-Dimensional Three-Dimensional PSO Output

PSO Position Synchronous Output of Motion Controller (II): Detailed Explanation of PSO Mode

PSO Position Synchronous Output of Motion Controller (I): Hardware Platform and Introduction to PSO Commands

Economical EtherCAT Motion Controller (X): Quick Start Guide to EtherCAT Bus

Economical EtherCAT Motion Controller (IX): Use of Oscilloscope

Economical EtherCAT Motion Controller (VIII): Axis Parameters and Motion Commands

Economical EtherCAT Motion Controller (VII): Motion Buffering

Economical EtherCAT Motion Controller (VI): Data Storage

Economical EtherCAT Motion Controller (V): Multi-Task Operation

Economical EtherCAT Motion Controller (IV): ModbusRTU or ModbusTcp Communication with Touch Screen

Economical EtherCAT Motion Controller (III): PLC Realization of Multi-Axis Linear Interpolation and Electronic Cam

Economical EtherCAT Motion Controller (II): ZBasic Implementation of Multi-Axis Linear Interpolation Motion

Economical EtherCAT Motion Controller (I): Function Introduction and Application Scenarios

Motion Control + Machine Vision Demo Software Framework (III): Visual Correction + Continuous Interpolation Recipe Editing

Motion Control + Machine Vision Demo Software Framework (II): Mobile Calibration and Shape Matching

Motion Control + Machine Vision Demo Software Framework (I): Management of Mechanical Parameters and Recipe Files

Overview of Motion Control + Machine Vision Demo Software Framework System

Open Laser Galvo + Motion Controller (VI): Dual Galvo Motion

Open Laser Galvo + Motion Controller (V): Introduction to ZMC408SCAN Controller Hardware

Open Laser Galvo + Motion Controller (IV): Application of PSO Position Synchronous Output in Laser Galvo Processing

Open Laser Galvo + Motion Controller (III): Galvo Correction

Open Laser Galvo + Motion Controller (II): Galvo Filling

Open Laser Galvo + Motion Controller (I): Hardware Interface

Quick Start | Part Twenty-One: Introduction to ZHMI Configuration Programming of Motion Controllers

Quick Start | Part Twenty-One: Custom Communication of Motion Controllers by Motion Technology

Quick Start | Part Twenty: Modbus Communication of Motion Controllers by Motion Technology

Quick Start | Part Nineteen: Multi-Axis Synchronization and Electronic Cam Command Introduction of Motion Controllers by Motion Technology

Quick Start | Part Eighteen: Use of Pulse Type Motion Controllers by Motion Technology

Quick Start | Part Seventeen: Use of Multi-Axis Interpolation Motion Commands of Motion Controllers by Motion Technology

Quick Start | Part Sixteen: Quick Start Guide to EtherCAT Bus of Motion Controllers by Motion Technology

Quick Start | Part Fifteen: Introduction to Motion Buffering of Motion Controllers by Motion Technology

Quick Start | Part Fourteen: Basic Axis Parameters and Basic Motion Control Commands of Motion Controllers by Motion Technology

Quick Start | Part Thirteen: Use of ZDevelop Programming Software for Motion Controllers by Motion Technology

Quick Start | Part Twelve: Use of USB Interface of Motion Controllers by Motion Technology

Quick Start | Part Eleven: Application of Interrupts in Motion Controllers by Motion Technology

Quick Start | Part Ten: Features of Multi-Task Operation of Motion Controllers by Motion Technology

Quick Start | Part Nine: How to Apply Oscilloscope with Motion Controllers by Motion Technology?

Quick Start | Part Eight: How to Use EtherCAT Bus of Motion Controllers by Motion Technology?

Quick Start | Part Seven: How to Use ZCAN Bus Expansion Module of Motion Controllers by Motion Technology?

Quick Start | Part Six: How to Apply Data and Storage with Motion Controllers by Motion Technology?

Quick Start | Part Five: How to Apply Input/Output IO of Motion Controllers by Motion Technology?

Quick Start | Part Four: How to Communicate with Touch Screen using Motion Controllers by Motion Technology?

Quick Start | Part Three: How to Develop ZPLC Program using Motion Controllers by Motion Technology?

Quick Start | Part Two: How to Develop ZBasic Program using Motion Controllers by Motion Technology?

Quick Start | Part One: How to Upgrade Firmware of Motion Controllers by Motion Technology?

Configuration and Implementation of EtherCAT and RTEX Driver Axis Zeroing

Application of G-code on Motion Controllers

Custom G-code Programming Application for Motion Controllers

Offline Simulation Debugging to Accelerate Project Progress!

Use of 8-Axis EtherCAT Axis Expansion Module EIO24088

Demo of Motion Controller Pursuit Cutting Application

Application of Position Latching Function of Motion Controllers

Quick Start for ZMC Motion Controller SCARA Robot Application

Quick Start for RTEX Bus Usage of Motion Controllers

Usage of CAD Mapping Software with Controllers by Motion Technology

Advanced Application of EtherCAT Bus Motion Controllers

EtherCAT Motion Control Card Development Tutorial with Qt (Middle): Continuous Trajectory Processing, Pause and Resume

EtherCAT Motion Control Card Development Tutorial with Qt (Upper): Development Environment Configuration and Simple Motion Control Application

EtherCAT Motion Control Card Development Tutorial with Python

Application of EtherCAT Motion Control Card for SCARA and Other Robot Instructions

Synchronization of PWM and Analog Output with Motion Speed of EtherCAT Motion Control Card

Hardware Comparison Output and Encoder Latching of EtherCAT Motion Control Card

IO Actions and Motion Control Synchronization of EtherCAT Motion Control Card

Real-Time Program Operation and Read/Write Control of EtherCAT Motion Control Card

Pause, Resume, and System Safety Settings of EtherCAT Motion Control Card

Continuous Interpolation Motion of EtherCAT Motion Control Card with Small Line Segments

Multi-Axis Interpolation Motion and Handwheel Motion of EtherCAT Motion Control Card

Introduction to Auxiliary Debugging Tools and Methods of EtherCAT Motion Control Card

Axis Parameter Settings and Axis Motion of EtherCAT Motion Control Card

Hardware Wiring and C# Hardware Peripheral Read/Write and Zeroing Motion of EtherCAT Motion Control Card

Hardware Wiring and C# Single Axis Motion Control of EtherCAT Motion Control Card

Simple and Easy-to-Use Motion Control Card (XVI): Pitch Compensation and Reverse Gap Compensation

Simple and Easy-to-Use Motion Control Card (XV): Real-Time Program of PC Start-Stop Controller

Simple and Easy-to-Use Motion Control Card (XIV): Synchronization of PWM, Analog Output and Motion Control

Simple and Easy-to-Use Motion Control Card (XIII): Synchronization of IO Actions and Motion Control

Simple and Easy-to-Use Motion Control Card (XII): Safety Settings of Motion Control Systems

Simple and Easy-to-Use Motion Control Card (XI): Pause, Resume and Speed Magnification Settings of Motion

Simple and Easy-to-Use Motion Control Card (X): Continuous Interpolation and Small Line Segment Prediction

Simple and Easy-to-Use Motion Control Card (IX): Circular Interpolation and Spiral Interpolation

Simple and Easy-to-Use Motion Control Card (VIII): Linear Interpolation and Handwheel Motion

Simple and Easy-to-Use Motion Control Card (VII): One-Time Loading of Multiple Continuous Small Line Segment Data

Simple and Easy-to-Use Motion Control Card (VI): Basic File Download and Continuous Trajectory Processing

Simple and Easy-to-Use Motion Control Card (V): IO Configuration and Zeroing Motion

Simple and Easy-to-Use Motion Control Card (IV): Function Library Encapsulation

Simple and Easy-to-Use Motion Control Card (III): Axis Parameter Configuration and Single Axis Motion Control

Simple and Easy-to-Use Motion Control Card (II): Peripheral Read/Write and ZDevelop Diagnosis

Simple and Easy-to-Use Motion Control Card (I): Hardware Wiring and Upper Computer Development

Application of Motion Control Card in ROS (Lower)

Application of Motion Control Card in ROS (Upper)

EtherCAT Motion Control Card and LabVIEW Build Smart Equipment (V)

EtherCAT Motion Control Card and LabVIEW Build Smart Equipment (IV)

EtherCAT Motion Control Card and LabVIEW Build Smart Equipment (III)

EtherCAT Motion Control Card and LabVIEW Build Smart Equipment (II)

EtherCAT Motion Control Card and LabVIEW Build Smart Equipment (I)

Motion Control and Data Acquisition of EtherCAT Motion Control Card in LabVIEW

Application Development Tutorial of Motion Control Card in MATLAB

Application Development Tutorial of Motion Control Card in C++

Application Development Tutorial of Motion Control Card in Python

Application Development Tutorial of Motion Control Card in C#

Application Development Tutorial of Motion Control Card in Linux

Application Development Tutorial of Motion Control Card in VB.NET

Application Development Tutorial of Motion Control Card in VB6.0

Application Development Tutorial of Motion Control Card in VC6.0

Application Development Tutorial of Motion Control Card using Qt

Application Development Tutorial of Motion Control Card in LabVIEW

Application Development Tutorial of Motion Control Card for Laser Galvo Control

Application Development Tutorial of Motion Control Card for Hardware Comparison Output

About Motion Technology

Motion Technology focuses on research in motion control technology and the development of general motion control software and hardware products, is a national high-tech enterprise, with main products including motion controllers, motion control cards, vision motion control integrated machines, human-machine interfaces, and expansion modules.

Motion Technology brings together outstanding talents from companies such as Huawei and ZTE, actively collaborating with major universities to research the basic technologies of motion control while adhering to independent innovation, making it one of the fastest-growing companies in the domestic industrial control field, and one of the few companies in the country that fully masters core motion control technologies and real-time industrial control software platform technologies.

Motion Technology is backed by the booming manufacturing industry, keeping pace with the times, being innovative, and is committed to continuously improving the technical application and manufacturing level of intelligent manufacturing equipment suppliers and end-users. After years of application development with numerous partners, its products are widely used in various domestic and international fields such as 3C electronics, semiconductors, printing and packaging, textile and clothing, laser processing, mechanical processing, robotics, new energy, healthcare, and stage entertainment.